Professional Documents

Culture Documents

Cuttings Slip Velocity and Net Rise Velocity

Cuttings Slip Velocity and Net Rise Velocity

Uploaded by

MohitTagotraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cuttings Slip Velocity and Net Rise Velocity

Cuttings Slip Velocity and Net Rise Velocity

Uploaded by

MohitTagotraCopyright:

Available Formats

https://www.google.com/amp/s/bensaif.wordpress.

com/2012/08/03/cutting-slip-velocity-

calculation/amp/

Cutting slip velocity is velocity of cutting that naturally falls down due to its density. Cutting movement is

counteracted by annular velocity of drilling mud and mud properties which acts in the opposite way of

cutting. In order to effectively clean the hole, effect of mud flow upward direction and mud properties

must be greater than settling tendency of cuttings. Otherwise, cutting will fall down and create cutting

bed.

Let’s take a look at Strokes’ Law for setting velocity in Newtonian fluid.

Vs is the cutting slip velocity.

K is constant.

Ρs is density of cutting.

Ρf is density of drilling fluid.

D is average diameter of cutting.

µ is mud viscosity.

Simple equation from the Strokes’ Law and I would like to point out some interesting point from this

equation.

1) What should you do if you would like to reduce the cutting slip velocity?

Answer- According to the Stroke’s Law, there are three parameters that you are able to adjust in order

to control cutting slip velocity. The following parameters are listed below:

A) Increase mud weight – the more mud weight you have, the less Vs will be because

higher mud weight has more buoyancy factor.

B) Increase mud viscosity – the cuttings tend to slow down settling effect in viscous mud.

C) Decrease average diameter of cutting – the small diameter of cutting, the less slip

velocity because force due to suspension has more effect.

Cutting slip velocity is velocity of cutting that naturally falls down due to its density. In order to

effectively clean the hole, effect of mud flow upward direction and mud properties must be greater than

cutting slip velocity (settling tendency of cuttings). Otherwise, cutting will fall down and create cutting

bed.

This calculation will show annular velocity, cutting slip velocity and net velocity so you can use as a

reference for you hole cleaning indication. There are 2 calculation methods and I will show the first

method via this topic.

2) Determine annular velocity with following equation:

Where;

AV is annular velocity in ft/min.

Q is flow rate in gpm (gallon per minute).

Dh is diameter of hole in inch.

Dp is diameter of drill pipe in inch.

3) Determine cutting slip velocity with following equation:

Where; Vs is cutting slip velocity in ft/min.

PV is plastic viscosity in centi-poise.

MW is mud weight in ppg.

Dp is diameter of cutting in inch.

DenP is cutting density in ppg.

4) Determine net rise velocity with following equation:

Net rise velocity = AV – Vs

Where; AV is annular velocity in ft/min.

Vs Cutting Velocity in ft/min.

This figure indicates that cuttings are being lifted by mud or are still falling down. If net rise velocity is

positive, it means that you have good flow rate which can carry cutting in the wellbore.

On the other hand, If net rise velocity is negative, your current flow rate is NOT enough to carry cuttings.

1) Example: Please use the following information to determine annular velocity, cutting slip

velocity, net rise velocity, and tell us if the flow rate is good for hole cleaning.

Given

Flow rate = 300 gpm, Hole Diameter = 6.3 inch, Drillpipe OD = 4 inch, PV = 15 cps, MW = 10 ppg,

Diameter of cutting = 0.20 inch, Density of cutting = 20.0 ppg

1. Determine annular velocity:

AV = 310.3 ft/min

2. Determine cutting slip velocity:

Vs = 35.4 ft/min

3. Determine net rise velocity with following equation:

Net rise velocity = AV – Vs

Net rise velocity = 310.3 – 35.4 = 274.9 ft/min

Conclusion: This flow rate is GOOD for hole cleaning practice because annular velocity is more than

cutting slip velocity.

You might also like

- Annular Velocity TheoryDocument2 pagesAnnular Velocity TheoryMohitTagotraNo ratings yet

- Fracture Pressure, Equivalent Mud WT, Leak Off TestDocument3 pagesFracture Pressure, Equivalent Mud WT, Leak Off TestMohitTagotraNo ratings yet

- ANSYS Fluid Dynamics Verification Manual 18.2Document252 pagesANSYS Fluid Dynamics Verification Manual 18.2Panda HeroNo ratings yet

- Open Hole SidetrackDocument2 pagesOpen Hole SidetrackAnilNo ratings yet

- Drilling Engineering Labratory Manual - King FahadDocument98 pagesDrilling Engineering Labratory Manual - King FahadMarshal betaNo ratings yet

- Oil - Solid Controls PDFDocument282 pagesOil - Solid Controls PDFsezaitanyolu100% (1)

- Dan 3Document14 pagesDan 3Adanenche Daniel EdohNo ratings yet

- Beng Drilling Course Tutorials CementingDocument2 pagesBeng Drilling Course Tutorials CementingTamkin TamrazliNo ratings yet

- Ansi Hi 9.6.1-1998 PDFDocument24 pagesAnsi Hi 9.6.1-1998 PDFandhucaosNo ratings yet

- Head Loss Due To Pipe FittingDocument6 pagesHead Loss Due To Pipe Fittingmhk00133% (3)

- Cavings Monitoring Notes FullDocument5 pagesCavings Monitoring Notes FulloscarhuamanNo ratings yet

- Testing of Drilling Fluids: Mud DensityDocument9 pagesTesting of Drilling Fluids: Mud DensityMohammed Amin BenharkatNo ratings yet

- Section02 Drilling ApparatusDocument31 pagesSection02 Drilling ApparatusMohamed ElshoraNo ratings yet

- Alaska Drilling and Wells Recommended Practice: Lost CirculationDocument4 pagesAlaska Drilling and Wells Recommended Practice: Lost CirculationAdel Ahmed AlkhaligyNo ratings yet

- Drilling 1 AutoRecoveredDocument52 pagesDrilling 1 AutoRecoveredKhaled AdelNo ratings yet

- Perforation SeminarDocument24 pagesPerforation SeminarSuleiman BaruniNo ratings yet

- Softdrill NL Torque & Drag - Getting StartedDocument12 pagesSoftdrill NL Torque & Drag - Getting StartedKatya Fnx100% (1)

- Wait and Weight MethodDocument2 pagesWait and Weight MethodMubin Ashraf Sheikh100% (1)

- Kick Control Methods: The Driller's MethodDocument5 pagesKick Control Methods: The Driller's MethodDavid KlinkenbergNo ratings yet

- Quiz AITDocument4 pagesQuiz AITazizsarshoghNo ratings yet

- Completion and Workover FluidsDocument2 pagesCompletion and Workover FluidsJit MukherheeNo ratings yet

- Q1: List The Features of The Ideal Drilling Bit.: 1. High Drilling Rate 2. Long LifeDocument3 pagesQ1: List The Features of The Ideal Drilling Bit.: 1. High Drilling Rate 2. Long Lifeنور الهدى احمد بشير A 50No ratings yet

- Brine Fluids PlanningDocument4 pagesBrine Fluids PlanningKolawole AdisaNo ratings yet

- Water: As A Drilling Fluid in Production Zone of Geothermal WellsDocument4 pagesWater: As A Drilling Fluid in Production Zone of Geothermal WellsSuci Nur HidayahNo ratings yet

- Types of Free PointDocument19 pagesTypes of Free Pointphucbm bmNo ratings yet

- 20 - Exercise CasingDocument10 pages20 - Exercise CasingNaufal Syafiq Mohd Isa100% (1)

- Sajad FalahDocument12 pagesSajad FalahSajad FalahNo ratings yet

- WellSharp Formula SI UnitsDocument4 pagesWellSharp Formula SI UnitstanolucascribdNo ratings yet

- OsisanyaDocument66 pagesOsisanyaSyed ShaiqNo ratings yet

- Casing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling CalculationsDocument1 pageCasing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling CalculationsAanuNo ratings yet

- Carbonate Acidizing AHDocument79 pagesCarbonate Acidizing AHMarrry Florencia100% (1)

- Kick ToleranceDocument71 pagesKick ToleranceHafiz Othman100% (1)

- Kicks IndicatorsDocument17 pagesKicks IndicatorsGhavban DavidNo ratings yet

- Deflection Tools and TechniqueDocument28 pagesDeflection Tools and TechniqueMrSebolliniNo ratings yet

- Total Flow AreaDocument2 pagesTotal Flow ArealeopumpkingNo ratings yet

- Formation Integrity TestDocument1 pageFormation Integrity Testfad003100% (1)

- Cementing: IntroductionDocument4 pagesCementing: IntroductionanuNo ratings yet

- Q1: Why Do We Use Centralizers During Casing Running Operation?Document4 pagesQ1: Why Do We Use Centralizers During Casing Running Operation?زهراء عبد المنعم يوسف 17100% (1)

- Drilling CostDocument1 pageDrilling CostAmit Kumar SinghNo ratings yet

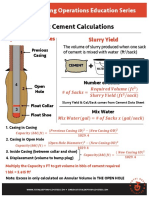

- Basic Cement CalculationsDocument1 pageBasic Cement Calculationsابوالحروف العربي ابوالحروفNo ratings yet

- Wild Well Control Technical Data BookDocument77 pagesWild Well Control Technical Data BookKaveh BahiraeeNo ratings yet

- 2-Important OperationsDocument17 pages2-Important OperationsLazharNo ratings yet

- Drilling Application: Name of Company: Well Name & Number: DateDocument1 pageDrilling Application: Name of Company: Well Name & Number: DatescrbdgharaviNo ratings yet

- Operation Related To Drilling FluidsDocument24 pagesOperation Related To Drilling FluidsPradyumnNo ratings yet

- The Fundamentals The FundamentalsDocument55 pagesThe Fundamentals The FundamentalsJose PerozoNo ratings yet

- Gas MigrationDocument39 pagesGas MigrationAli Aliiev100% (1)

- Mod 9 DRLGDocument22 pagesMod 9 DRLGMin Thant MaungNo ratings yet

- Setting & Thickening TimeDocument10 pagesSetting & Thickening TimeAlimahmood BahraniNo ratings yet

- Leak Off Test: - Procedure - Maasp - Maximum Allowable Mud WeightDocument5 pagesLeak Off Test: - Procedure - Maasp - Maximum Allowable Mud WeightSigit WiyonoNo ratings yet

- Primary Cementing and Secondary CementingDocument25 pagesPrimary Cementing and Secondary CementingAhmad RIfaiNo ratings yet

- CementingDocument9 pagesCementingakshitppe11No ratings yet

- Spe PaperDocument13 pagesSpe PaperCamilo Andrés Guerrero100% (1)

- 5 - Volumes & MaaspDocument111 pages5 - Volumes & Maaspsouthernor100% (2)

- Using Hi-Vis Sweep To Clean Hole While DrillingDocument5 pagesUsing Hi-Vis Sweep To Clean Hole While DrillingSAMIRNo ratings yet

- HPHT CementingDocument2 pagesHPHT CementingOdesya SatyaNo ratings yet

- 1D PetroMod Software Modeling of The Basrah Oil Fields Art-3A10.1007-2Fs12517-012-0640-4Document26 pages1D PetroMod Software Modeling of The Basrah Oil Fields Art-3A10.1007-2Fs12517-012-0640-4Charles PaikiNo ratings yet

- Coiled Tubing Calculation Homework HandoutDocument6 pagesCoiled Tubing Calculation Homework HandouthafsaNo ratings yet

- ENG202 ACE - 06 Liner Cementing Rev1005Document57 pagesENG202 ACE - 06 Liner Cementing Rev1005danielmcaeNo ratings yet

- Lecture2-Well CompletionDocument43 pagesLecture2-Well CompletionRamy MaamounNo ratings yet

- Artificial LiftDocument7 pagesArtificial LiftShakerMahmoodNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- ShriRam PA Cover Scooty InsuranceDocument1 pageShriRam PA Cover Scooty InsuranceMohitTagotraNo ratings yet

- Low Viscosity Drilling Fluid, LSRVDocument8 pagesLow Viscosity Drilling Fluid, LSRVMohitTagotraNo ratings yet

- API Calculations, Influx Gradient, Well Control CalculationsDocument10 pagesAPI Calculations, Influx Gradient, Well Control CalculationsMohitTagotra100% (1)

- Calcium Chloride WPSDocument1 pageCalcium Chloride WPSMohitTagotraNo ratings yet

- Initial Circulating Rate, Slow CR, ICP, FCPDocument1 pageInitial Circulating Rate, Slow CR, ICP, FCPMohitTagotraNo ratings yet

- Calcium Chloride Brine, Cacl2Document1 pageCalcium Chloride Brine, Cacl2MohitTagotraNo ratings yet

- Stuck Pipe NotesDocument2 pagesStuck Pipe NotesMohitTagotraNo ratings yet

- Concentration Sheet-Sdai, Sd#14Document5 pagesConcentration Sheet-Sdai, Sd#14MohitTagotraNo ratings yet

- BrineDocument1 pageBrineMohitTagotraNo ratings yet

- COVID-19 Vaccination Appointment Details: Center Preferred Time SlotDocument1 pageCOVID-19 Vaccination Appointment Details: Center Preferred Time SlotMohitTagotraNo ratings yet

- 457712th MCQ Test 29-1-2019Document6 pages457712th MCQ Test 29-1-2019MohitTagotraNo ratings yet

- Covaxin 1st Dose CertificateDocument1 pageCovaxin 1st Dose CertificateMohitTagotraNo ratings yet

- Balanced Cement Plug Calculation: by - , , Post Views:4,197Document7 pagesBalanced Cement Plug Calculation: by - , , Post Views:4,197MohitTagotra100% (1)

- MCQ On Rti Act PDFDocument4 pagesMCQ On Rti Act PDFMohitTagotraNo ratings yet

- Account's MCQDocument7 pagesAccount's MCQMohitTagotraNo ratings yet

- Trading and Profit Loss MCQDocument4 pagesTrading and Profit Loss MCQMohitTagotraNo ratings yet

- Design and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesDocument7 pagesDesign and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesPankaj AgarwalNo ratings yet

- Topic 4b Turbulent Flow - Major Loses 2020Document24 pagesTopic 4b Turbulent Flow - Major Loses 2020Nor SyamimiNo ratings yet

- Using DIERS Two-Phase Equations To Estimate Tube Rupture FlowratesDocument8 pagesUsing DIERS Two-Phase Equations To Estimate Tube Rupture FlowratesAugusto Jorge Lozada100% (1)

- Chapter 6: Steady Flow in PipesDocument9 pagesChapter 6: Steady Flow in PipesSyahid MuhammadNo ratings yet

- Exercise 1 Sayas Ej2Document5 pagesExercise 1 Sayas Ej2bryan50% (2)

- Research Paper For Vortex BladelessDocument7 pagesResearch Paper For Vortex BladelessasifNo ratings yet

- Plano Hidraulico 24M UENR2143UENR2143-03 - SISDocument4 pagesPlano Hidraulico 24M UENR2143UENR2143-03 - SISFredy Manrique AstoNo ratings yet

- Results and Discussion Exp 3Document2 pagesResults and Discussion Exp 3jaamartinezNo ratings yet

- Airfoil Theory IntroDocument4 pagesAirfoil Theory IntroRené Mella CidNo ratings yet

- Specifying Venturi Scrubber Throat Length For PDFDocument5 pagesSpecifying Venturi Scrubber Throat Length For PDFChristopher LloydNo ratings yet

- CFD Analysis & Experimental Model - IntakeDocument15 pagesCFD Analysis & Experimental Model - IntakeHema KumarNo ratings yet

- Hazop Study Action Response SheetDocument5 pagesHazop Study Action Response SheetborrowmanaNo ratings yet

- Two Phase FlowDocument36 pagesTwo Phase FlowAbdul Basit Ahmad100% (2)

- Orifice and Free Jet Flow: University of NebraskaDocument8 pagesOrifice and Free Jet Flow: University of NebraskaJemuel Flores100% (1)

- Aerodynamics Using LSDYNADocument22 pagesAerodynamics Using LSDYNAVanLocNo ratings yet

- Thesis On Non Newtonian FluidsDocument5 pagesThesis On Non Newtonian Fluidsrobynchampagnemanchester100% (2)

- PIPE FLOW 3-Equivalent LengthDocument4 pagesPIPE FLOW 3-Equivalent LengthBasil DubeNo ratings yet

- Ada 360979Document366 pagesAda 360979Rogerio GuahyNo ratings yet

- Choked Flow - Wikipedia, The Free EncyclopediaDocument5 pagesChoked Flow - Wikipedia, The Free EncyclopediaMichel l'AmieNo ratings yet

- Calculation of Added Mass in The Proximity of The Seabed For An Oscillating DiscDocument64 pagesCalculation of Added Mass in The Proximity of The Seabed For An Oscillating DiscTNTNo ratings yet

- Phase Field Method To Simulate Fluid FlowDocument5 pagesPhase Field Method To Simulate Fluid FlowSamNo ratings yet

- Polymer Rheology and Processing ( - ÈDocument57 pagesPolymer Rheology and Processing ( - Èabilio_j_vieiraNo ratings yet

- White - 6th Ed - 3.16Document1 pageWhite - 6th Ed - 3.16The Reviewer ChannelNo ratings yet

- Chemical Engineering 374: Fluid MechanicsDocument7 pagesChemical Engineering 374: Fluid MechanicsAnonymous 4PuFzARNo ratings yet

- Ce8302 Fluid Mechanics CivilDocument2 pagesCe8302 Fluid Mechanics CivilersnkrishnanNo ratings yet

- CBE350 2014 SyllabusDocument5 pagesCBE350 2014 Syllabusjesi5445No ratings yet

- Energy Loss in PipesDocument7 pagesEnergy Loss in PipesKarla PerezNo ratings yet