Professional Documents

Culture Documents

Guide Word Process Variables Causes Consequences Action

Guide Word Process Variables Causes Consequences Action

Uploaded by

Saba waseemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide Word Process Variables Causes Consequences Action

Guide Word Process Variables Causes Consequences Action

Uploaded by

Saba waseemCopyright:

Available Formats

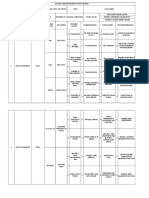

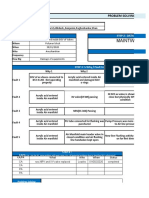

Guide word Process Causes Consequences Action

variables

None No flow Flow control Damage to the Use supporting

valve failure (v- pump. valve and check

1) either it work or

Failed closed. not.

Pressure Periodic

Valve (V-2) increases in line . inspection of

Malfunctions. valve(V-2) should

be done and

installed (FI-1)

controller.

Some exit and Stand by pump

Failure of entrance should present.

pump(P-1). temperature. Maintenance of

valve (V-1) and

instrumentation.

Pressure in line Proper inspection

Ruptured broken increases and

pipe. maintenances of

line should be

implemented.

More of More flow Valve Pressure in lines Regularly

malfunction(v-2), increases checking of

results in fully valves and

open valve. installed FI-1

indicator.

Valve(V-3) High Air pressure Use pressure

Malfunction in the line. indicator (PI-1).

Valve (v-4) Flocculated Inspection of

malfunction particles are in valve.

line.

Less of Less flow Inlet valve Flow rate Use flow

malfunctions. effected. indicator

Blockage of line Less amount of Use by pass

feed entered. system.

Use supporting

valve.

Scaling and Pipe line damage. Corrosion

corrosion in line. allowance of

2mm should be

considered in

line.

TABLE: NODE 01 (HAZOP STUDY OF SEA INTAKE TO DAF UNIT)

other Maintenance Accumulation Resulting in Regular

corrosion inspection

should be done.

You might also like

- Probability of GodDocument10 pagesProbability of Godzahoor80No ratings yet

- Hazop PPT FINALDocument13 pagesHazop PPT FINALSaba waseemNo ratings yet

- Hazop PPT FINALDocument13 pagesHazop PPT FINALSaba waseemNo ratings yet

- 02 Medium Pressure Accel Valves Celeris - (MKT 0277)Document6 pages02 Medium Pressure Accel Valves Celeris - (MKT 0277)VICTOR MANUEL SALAZAR GARCIANo ratings yet

- N-Butyl Acetate Column (Refining Column) : Presenter: Rashide Abd Rahman 2008289232Document6 pagesN-Butyl Acetate Column (Refining Column) : Presenter: Rashide Abd Rahman 2008289232ewan8607No ratings yet

- Appendix 1 HAZOPWorksheets 1 PDFDocument37 pagesAppendix 1 HAZOPWorksheets 1 PDFSDP02No ratings yet

- HAZOP FinalDocument2 pagesHAZOP Finalchiang95100% (3)

- Mixing Point STREAM 1, 2 and 34Document42 pagesMixing Point STREAM 1, 2 and 34Cheah Zong YouNo ratings yet

- Process Control A2 - Tutorial 8Document2 pagesProcess Control A2 - Tutorial 8Thabo ThaboNo ratings yet

- HAZOP Study Part IIDocument18 pagesHAZOP Study Part IIBoy farhanNo ratings yet

- HAZOP For Scrub ColumnDocument5 pagesHAZOP For Scrub ColumnCiXian Teoh100% (1)

- HAZOP Worksheet: Node: 11 Type: Drawing: Design Conditions/parametersDocument3 pagesHAZOP Worksheet: Node: 11 Type: Drawing: Design Conditions/parametersAminNo ratings yet

- Check List for BWTSDocument3 pagesCheck List for BWTSAngelo TubongbanuaNo ratings yet

- FDV-R-RN2 Ds 01Document4 pagesFDV-R-RN2 Ds 01Lucas Procópio SouzaNo ratings yet

- 1way Flow Control ValveDocument36 pages1way Flow Control ValvePyae PhyoaungNo ratings yet

- Q (Jta: AssemblylineDocument10 pagesQ (Jta: AssemblylineAryaman MahajanNo ratings yet

- Pwps Service Bulletin 96B03 Attachment A-1: Recommended Periodic Inspections For Ft8 UnitsDocument2 pagesPwps Service Bulletin 96B03 Attachment A-1: Recommended Periodic Inspections For Ft8 UnitsKarim KadriNo ratings yet

- ME Trouble Shooting - V70320-0005Document9 pagesME Trouble Shooting - V70320-0005bkans crerercNo ratings yet

- MSG11 3500UK OfflineDocument854 pagesMSG11 3500UK Offlinemanuel sebastian avendanoNo ratings yet

- General Control Valves.: Engineering Centre of Excellence Ecoe - Doha, Qatar Instrument Training - 16 July 2011Document42 pagesGeneral Control Valves.: Engineering Centre of Excellence Ecoe - Doha, Qatar Instrument Training - 16 July 2011ahmed messallamNo ratings yet

- ITEM No.: Bay No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument7 pagesITEM No.: Bay No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NosaiNo ratings yet

- CM 05002Document17 pagesCM 05002Hyury VeríssimoNo ratings yet

- Maintwiz Work Order (Recuerring Problem) : Step 1: Define Step 2: Data Measurement, Information & Evidence)Document4 pagesMaintwiz Work Order (Recuerring Problem) : Step 1: Define Step 2: Data Measurement, Information & Evidence)praveena m rNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: SPAU 341 C3 AVR RELAYDocument2 pagesCommissioning Service Department Commissioning Standard Test Formats Description: SPAU 341 C3 AVR RELAYm khNo ratings yet

- Parker HY11 3500UK Hydraulic Valves Industrial Standard PDFDocument862 pagesParker HY11 3500UK Hydraulic Valves Industrial Standard PDFWalter Victorio ValleNo ratings yet

- 486A-4861-10A-P2 - UpdateDocument28 pages486A-4861-10A-P2 - UpdatesamaluftanNo ratings yet

- Operation Manual Valve Checker GDocument20 pagesOperation Manual Valve Checker GSalim DoumbiaNo ratings yet

- Moog-Valve Checker G040-123-Application-Notes-enDocument20 pagesMoog-Valve Checker G040-123-Application-Notes-enralish12No ratings yet

- Part 4 Hydraulic Control Principle and ParametersDocument22 pagesPart 4 Hydraulic Control Principle and ParametersrohanNo ratings yet

- Rain+Birdt: DAS-ASVF Series Valve Installation and OperationDocument3 pagesRain+Birdt: DAS-ASVF Series Valve Installation and OperationcobasajamasNo ratings yet

- Pressure Test InterpretationDocument3 pagesPressure Test InterpretationCristian Ruiz Roman Ing. de ServicioNo ratings yet

- V-Ball Valve Vs Globe ValveDocument3 pagesV-Ball Valve Vs Globe ValveHector MendesNo ratings yet

- Httpsdocs - Rs Online - Comba350900766b81544c72 PDFDocument28 pagesHttpsdocs - Rs Online - Comba350900766b81544c72 PDFblackdevil967666No ratings yet

- Model DV-5 Deluge Valve - Wet Pilot Actuation: Next ReturnDocument15 pagesModel DV-5 Deluge Valve - Wet Pilot Actuation: Next ReturnNethajiNo ratings yet

- Centerfiugl Pump FMEADocument3 pagesCenterfiugl Pump FMEAAbdelaziz RagabNo ratings yet

- Hazop Worksheet Hazard Identification Study WorkDocument2 pagesHazop Worksheet Hazard Identification Study Workssat111No ratings yet

- Hazop Worksheet Hazard Identification Study WorkDocument1 pageHazop Worksheet Hazard Identification Study Workssat111No ratings yet

- Ruelco CatalogDocument264 pagesRuelco CatalogJosé Uriel Javier TorresNo ratings yet

- GAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Document15 pagesGAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Dipayan DasNo ratings yet

- GMX Complete KnowledgeDocument36 pagesGMX Complete KnowledgeSoumen PandaNo ratings yet

- Basic Control Valve Sizing and SelectionDocument53 pagesBasic Control Valve Sizing and SelectionAtul TripathiNo ratings yet

- Chapter 6 Voltage RegulatorsDocument68 pagesChapter 6 Voltage RegulatorsNabil FikriNo ratings yet

- Troubleshooting Guide V70320-0001Document7 pagesTroubleshooting Guide V70320-0001Valeriy Domashenko100% (1)

- RMU Inspection Check SheetDocument1 pageRMU Inspection Check Sheetisaacwabbi100% (2)

- Pressure: High Pressure Bulk StorageDocument2 pagesPressure: High Pressure Bulk StorageshubhamNo ratings yet

- Automation Process ControlDocument39 pagesAutomation Process ControlAbdurabu AL-MontaserNo ratings yet

- Missioning Report - WLD SystemDocument1 pageMissioning Report - WLD SystemRaj KamalNo ratings yet

- Safety and Hazard Analysis ProjectDocument16 pagesSafety and Hazard Analysis ProjectGautham Krishna KbNo ratings yet

- Missioning Report - Sprinkler SystemDocument1 pageMissioning Report - Sprinkler SystemRaj KamalNo ratings yet

- Argon Flows PMP UV-Pro From SN 48P0163 & 56Q0001Document3 pagesArgon Flows PMP UV-Pro From SN 48P0163 & 56Q0001NAdreaNo ratings yet

- 3 Port Solenoid Valve/: VP/VGDocument28 pages3 Port Solenoid Valve/: VP/VGFelipe Savieto AcorsiNo ratings yet

- MSG11-3500UK Offline 12-2019 PDFDocument814 pagesMSG11-3500UK Offline 12-2019 PDFАлександър Пухлев100% (1)

- Series 100 ValvesDocument36 pagesSeries 100 ValvesCarlos Rovello GandoNo ratings yet

- General Control Valves TrainingDocument37 pagesGeneral Control Valves TrainingMohd Amani100% (2)

- Reguladores Cooper Power (EATON)Document8 pagesReguladores Cooper Power (EATON)arthur9mozoNo ratings yet

- Mirani Water Recycling Facility (WRF) Daily Site Checklist: Name: Time: DateDocument20 pagesMirani Water Recycling Facility (WRF) Daily Site Checklist: Name: Time: Dateyinka omojesuNo ratings yet

- Horizontal Multi-Stage Jet Pumps "HMS-1FL" Series: ModelsDocument8 pagesHorizontal Multi-Stage Jet Pumps "HMS-1FL" Series: ModelsjuliusttNo ratings yet

- Proportional Pressure Regulators VPPXDocument22 pagesProportional Pressure Regulators VPPXyashwanthNo ratings yet

- C1000 Touch 2ndserviceDocument1 pageC1000 Touch 2ndserviceSidnei SantosNo ratings yet

- Flow Dtect - LevelDocument12 pagesFlow Dtect - LevelHamza ISSAOUINo ratings yet

- Petroleum Refinery Engg Presentations 2021Document3 pagesPetroleum Refinery Engg Presentations 2021Saba waseemNo ratings yet

- Water Sampling Ce-622Document6 pagesWater Sampling Ce-622Saba waseemNo ratings yet

- Air PollutionDocument22 pagesAir PollutionSaba waseemNo ratings yet

- Password Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Document4 pagesPassword Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Pratiksha SankapalNo ratings yet

- Warranty Data and AnalysisDocument11 pagesWarranty Data and AnalysisGaryNo ratings yet

- 12V DC Linear Actuator Instructions Manual 12V DC Linear Actuator Instructions ManualDocument4 pages12V DC Linear Actuator Instructions Manual 12V DC Linear Actuator Instructions Manualdc190400841 MIAN AQIL GHAFFARNo ratings yet

- اخطاء انكسار 4Document4 pagesاخطاء انكسار 4Hassan AljaberiNo ratings yet

- Networking - Xmind - Mind Mapping AppDocument2 pagesNetworking - Xmind - Mind Mapping AppLuis ValleNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- EBB 424E Semiconductor Devices and Optoelectronics: Part II - Optoelectronics DR Zainovia LockmanDocument50 pagesEBB 424E Semiconductor Devices and Optoelectronics: Part II - Optoelectronics DR Zainovia LockmanSudhanshu VermaNo ratings yet

- Animal Environment & Heat FlowDocument71 pagesAnimal Environment & Heat FlowSivakumar SadasivamNo ratings yet

- JSS2 Basic Tech 1ST Term Question Bank 1Document2 pagesJSS2 Basic Tech 1ST Term Question Bank 1Holuwa DijexNo ratings yet

- Xii - CHEM AKASH - Project - 2023 - 24Document3 pagesXii - CHEM AKASH - Project - 2023 - 24Priyaranjan PattanayakNo ratings yet

- Mar1020 Datasheet PDFDocument3 pagesMar1020 Datasheet PDFjaysonlkhNo ratings yet

- Model 401025 Digital Light Meter: User's ManualDocument5 pagesModel 401025 Digital Light Meter: User's ManualPubcrawlNo ratings yet

- Muzon Pabahay Elementary SchoolDocument3 pagesMuzon Pabahay Elementary SchoolCristeta ToqueroNo ratings yet

- Rinnai Malaysia RO E6208TA EM User ManualDocument16 pagesRinnai Malaysia RO E6208TA EM User ManualthaiNo ratings yet

- EC6703 ERTS QB 16 MarkDocument2 pagesEC6703 ERTS QB 16 MarkSuresh Kumar100% (1)

- Spe 169552 MSDocument25 pagesSpe 169552 MSJessica KingNo ratings yet

- ES 5 06 0019 - Flange Bolting GuidelinesDocument12 pagesES 5 06 0019 - Flange Bolting Guidelinessam.trags100% (1)

- Iso 2896 - 2001 eDocument16 pagesIso 2896 - 2001 ehappyhandslearningcenter2023No ratings yet

- Mitigating Congestion in Wireless Sensor NetworksDocument14 pagesMitigating Congestion in Wireless Sensor NetworksIglesia RestauracionNo ratings yet

- ASR903 Chassis SWDocument180 pagesASR903 Chassis SWLuis S TorresNo ratings yet

- Performance Analysis of Locally Design Plastic Crushing Machine For Domestic and Industrial Use in NigeriaDocument6 pagesPerformance Analysis of Locally Design Plastic Crushing Machine For Domestic and Industrial Use in NigeriaRishokNo ratings yet

- Section 5Document5 pagesSection 5Ancuta DanielaNo ratings yet

- Quantitative Chapter 1 - Simple EquationDocument10 pagesQuantitative Chapter 1 - Simple EquationSWAGATAM BAZNo ratings yet

- MongoDB ManualDocument25 pagesMongoDB ManualScreen AgersNo ratings yet

- System CommandsDocument796 pagesSystem CommandsYazz BMNo ratings yet

- Practice Problems 14: Influence LineDocument8 pagesPractice Problems 14: Influence LineMikhael Wakin RodriguezNo ratings yet

- El Husseinys Essentials of Microbiology and ImmunologyDocument387 pagesEl Husseinys Essentials of Microbiology and ImmunologyÁýáFáŕőúg100% (4)

- CH 4. Data Transfers, Addressing, and ArithmeticDocument58 pagesCH 4. Data Transfers, Addressing, and ArithmeticAlex MartinNo ratings yet

- Nonparametric Methods: Analysis of Ordinal DataDocument38 pagesNonparametric Methods: Analysis of Ordinal DataRadityaNo ratings yet