Professional Documents

Culture Documents

Porto-Power Kit: Operating Instructions & Parts Manual

Porto-Power Kit: Operating Instructions & Parts Manual

Uploaded by

SMWilsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Porto-Power Kit: Operating Instructions & Parts Manual

Porto-Power Kit: Operating Instructions & Parts Manual

Uploaded by

SMWilsonCopyright:

Available Formats

Porto-Power Blackhawk Automotive is a licensed trademark

Porto-Power Kit

Operating Instructions & Parts Manual

U.S. PATENT 5,520,400

Model Number Capacity

B65114 4 Ton

B65115 10 Ton

SFA Companies

10939 N. Pomona Ave. Kansas City, MO 64153

816-891-6390

sales@blackhawk-automotive.com

- Before using this product, read this manual and follow all its Safety Rules and Operating Instructions

Made in China

B65114-M0 rev 11/05

Downloaded from www.Manualslib.com manuals search engine

ONE YEAR LIMITED WARRANTY

For a period of one (1) year from date of purchase, SFA Companies will repair or replace, at its option, without charge,

any of its products which fails due to a defect in material or workmanship under normal usage. This limited warranty is

a consumer's exclusive remedy.

Performance of any obligation under this warranty may be obtained by returning the warranted product, freight prepaid,

to SFA Companies Warranty Service Department, 10939 N. Pomona Ave., Kansas City, MO 64153.

Except where such limitations and exclusions are specifically prohibited by applicable law.

(1) THE CONSUMER'S SOLE AND EXCLUSIVE REMEDY SHALL BE THE REPAIR OR REPLACEMENT OF DEFEC-

TIVE PRODUCTS AS DESCRIBED ABOVE.

(2) SFA COMPANIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGE OR LOSS

WHATSOEVER.

(3) ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL BE LIMITED TO ONE YEAR, OTHERWISE

THE REPAIR, REPLACEMENT OR REFUND AS PROVIDED UNDER THIS EXPRESS LIMITED WARRANTY IS THE

EXCLUSIVE REMEDY OF THE CONSUMER, AND IS PROVIDED IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED.

(4) ANY MODIFICATION, ALTERATION, ABUSE, UNAUTHORIZED SERVICE OR ORNAMENTAL DESIGN VOIDS

THIS WARRANTY AND IS NOT COVERED BY THIS WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to

you. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

SFA Companies

10939 N. Pomona Ave. Kansas City, MO 64153

816-891-6390

sales@blackhawk-automotive.com

2

Downloaded from www.Manualslib.com manuals search engine

SAVE THESE INSTRUCTIONS

For your safety, read and understand the information contained within. The owner and operator shall have an under-

standing of this product and safe operating procedures before attempting to use this product. Instructions and Safety

information shall be conveyed in the operator's native language before use of this product is authorized. Make certain

that the operator thoroughly understands the inherent dangers associated with the use and misuse of the product. If

any doubt exists as to the safe and proper use of this product as outlined in this factory authorized manual, remove from

service immediately.

Inspect before each use. Do not use if broken, bent, cracked or otherwise damaged parts are noted. If any component

of this product has been or suspected to have been subjected to a shock load (a load dropped suddenly, unexpectedly

upon it), discontinue use until checked out by a Porto-Power Blackhawk Automotive Authorized Service Center. Owners

and operators of this equipment shall be aware that the use and subsequent repair of this equipment may require

special training and knowledge. It is recommended that an annual inspection be done by qualified personnel and that

any missing or damaged parts, decals, warning / safety labels or signs be replaced with factory authorized replacement

parts only. Any component of this Porto-Power Kit that appears to be damaged in any way, is worn or operates

abnormally shall be removed from service immediately until such time as it can be repaired/replaced. Labels and

Operator's Manuals are available from manufacturer.

PRODUCT DESCRIPTION

Porto-Power Kits are designed to be used for pushing, spreading, and pressing of vehicle body panels as well as

various component parts and assemblies. A variety of attachments are included. B65114 is rated 8,000PSI and B65115

is rated 10,000PSI, where rams are rated from 4 to 10 tons.

WARNING: when extension tubes and/or offset attachments are used, the rated capacity is always reduced

by 50% for each tube or offset attachment connected. Refer to figure 3 on page 8 for more offset illustration.

SPECIFICATIONS

Ram Number of

Model Capacity Weight

Closed Height Extended Height Attachments

B65114 4 Ton 11" 15 3/4" 14 46 lbs

B65115 10 Ton 13 5/8" 19 3/4" 13 88 lbs

Handle

Oil Filler Screw Release Valve

Ram Plunger

Hose Ram

Hose

Coupler

Ram Coupler

Dust Cover

Figure 1 - B65114 and B65115 Components

3

Downloaded from www.Manualslib.com manuals search engine

SAFETY INSTRUCTIONS

BEFORE USE (Refer to Figure 1 on page 3)

1. Study, understand, and follow all instructions provided with and on this device before use.

2. Inspect before each use. Do not use if bent, broken, leaking or damaged components are noted.

3. Ensure that product and application are compatible.

4. Check to ensure that all parts of your kit are included (see illustration and parts list on page 10 & 11).

5. Carefully remove the dust covers and plugs from hose coupler and ram coupler.

6. Connect hose coupler to ram coupler, ensure that there are no fluid leaks.

7. Locate and open release valve. Pump handle a few strokes to purge air from system. Close release valve and pump

handle until ram is fully extended, then open release valve until ram has fully retracted.

8. With ram fully retracted and release valve open, place pump in horizontal position. Locate and open oil filler screw (on

reservoir body, near the back). This will release air trapped within the reservoir. Retighten the oil filler screw.

GENERAL SAFETY INFORMATION

1. Ensure that attachments are fully engaged before applying load.

2. Ensure that load is centrally applied to attachment or ram saddle. Do not load off center.

3. Always monitor the force applied to workpiece by using a load cell and indicator or you may monitor pressure

developed in the ram by using an inline pressure gauge, then calculate the applied force using the formula:

F = P x A, where F = lbs force, P = pressure in PSI, and A = effective ram area in in².

Ram Area of B65114 is: 0.998 in²

Ram Area of B65115 is: 2.431 in²

you can refer to the Load-Pressure Correlation chart on page 12.

4. If bowing or bending of ram or any attachment occurs during use, "STOP", release pressure immediately and

reconsider application. Application may not be compatible with product, a ram kit with a higher capacity may be

needed.

! DANGER ! ! WARNING

• If oil leakage is detected, discontinue use of the ram • All WARNING statements must be carefully observed

immediately and contact your nearest Porto-Power to help prevent personal injury.

Blackhawk Automotive Authorized Service Center. • Do not exceed rated capacity.

The ram could develop excessive pressure and cause • Use only on hard, level surfaces capable of

the ram, hose or coupler to burst, which could cause sustaining rated capacity loads.

serious injury or death. • Do not open oil filler screw unless ram is fully

retracted.

• Do not wear sandals and jewelry when operating

! WARNING this equipment.

• Do not use as a vehicle lifting device or vehicle support.

To avoid crushing and • Any attachment that is not loaded centrally, as

related injuries: through the centerline of the ram, is considered to

Do not work on, under or be "offset".

around a lifted load. • When extension tubes and/or offset attachments

Always support with are used, the rated capacity is always reduced by

appropriate mechanical 50% for each tube or attachment connected.

means. • Monitor pressure and load at all times.

• Always verify load with calibrated load cell and

indicator, known good pressure gauge or equivalent

devices.

Wear protective clothing

• Do not modify this device.

and safety goggles to

• Failure to heed these markings may result in

reduce the risk of

personal injury and/or property damage.

injection.

Downloaded from www.Manualslib.com manuals search engine

! WARNING! ! WARNING

Hydraulic Hoses and Fluid Transmission Lines • Ram must be on a stable base, which is able to

• Avoid short runs of straight line tubing. Straight line support the load while pushing or lifting.

runs do not provide for expansion and contraction due • Ensure ram is fully engaged into/onto adapters,

to pressure and/or temperature changes. extension accessories.

• Reduce stress in tube lines. Long tubing runs should • To help prevent personal injury, use shims, friction

be supported by brackets or clips. Before operating material or constraints to prevent slippage of the

the pump, all hose connections must be tightened base or load.

with the proper tools. Do not overtighten. Connections • Do not off-center loads on a ram. The load can tip or

should only be tightened securely and leak-free. the ram can "kick out" and cause personal injury.

Overtightening can cause premature thread failure or • As the load is lifted, use blocking and cribbing to

high pressure fittings to burst. guard against a falling load.

• Should a hydraulic hose ever rupture, burst or need • Never allow personnel to work on, under or around a

to be disconnected, immediately shut off the pump load before it is properly supported by appropriate

and release all pressure. Never attempt to grasp a mechanical means. Never rely on hydraulic

leaking pressurized hose with your hands. The pressure alone to support load.

force of escaping hydraulic fluid can inflict injury. • All personnel must be clear before lowering.

• Do not subject the hose to potential hazard such • Never try to disassemble a hydraulic cylinder, Refer

as fire, sharp objects, extreme heat or cold, or repairs to qualified, authorized personnel.

heavy impact.

• Do not allow the hose to kink, twist, curl, crush, cut

or bend so tightly that the fluid flow within the hose is

blocked or reduced. Periodically inspect the hose for

wear, because any of these conditions can damage

the hose and possibly result in personal injury.

• Do not pull, position or move setup by the hose. Doing

so can damage the hose and possibly cause personal

injury. Center loads on ram

• Hose material and coupler seals must be compatible

with hydraulic fluid used. Hoses also must not come IMPORTANT

in contact with corrosive materials such as battery • Keep ram clean at all times.

acid, creosote-impregnated objects and wet paint. • When the ram is not is use, keep the piston(s) fully

Hose deterioration due to corrosive material can result retracted.

in personal injury. Never paint a coupler or hose. • Use an approved, high-grade pipe thread sealant to

• The user must be a qualified operator familiar with the seal all hydraulic connections. Teflon tape can be used

correct operation, maintenance, and use of rams. Lack if only one layer of tape is used and it is applied

of knowledge in any of these areas can lead to personal carefully (two threads back) to prevent the tape from

injury. being introduced into hydraulic system. A piece of tape

• Use only approved accessories and approved could travel through the system and obstruct the flow

hydraulic fluid. of fluid and adversely affect function.

• Do not exceed the rated capacity of the ram. • Never attach ANY component not authorized by

• Inspect each ram and coupler before each use to manufacturer.

prevent unsafe conditions from developing. • Never use other than factory provided and/or

• Do not use rams if they are damaged, altered or in authorized fasteners.

poor condition.

• Do not use rams with bent or damaged coupler or KNOW YOUR SYSTEM

damaged threads. Your ram, hose(s), couplings and pump all must be rated

• Under certain conditions, the use of an extension for the same maximum operating pressure, correctly

with a hydraulic ram may not be advisable and _connected and compatible with the hydraulic fluid used.

could present a dangerous condition. An improperly matched system can cause the system

• Avoid pinch points or crush points that can be to fail and possibly cause serious injury. If you are in

created by the load or parts of ram. doubt, consult your nearest Porto-Power Blackhawk

• To help prevent material fatigue if the ram is to Automotive Dealer.

be used in a continuous application, the load

should not exceed 85% of the rated capacity.

5

Downloaded from www.Manualslib.com manuals search engine

OPERATION

Note: Inspect before each use for evidence of fluid leaks, damaged

hydraulic fittings, bent or broken attachments and missing parts.

1. Locate and close release valve by turning it clockwise until firmly

closed. (Do not over tighten)

2. Operate by pumping handle. This will send fluid from the pump

reservoir into the high pressure hose assembly and into the ram

assembly.

3. Continue pumping until ram reaches desired height.

Note: Pump may be used in horizontal and vertical position as

illustrated (See figure 2).

To Release Pressure on work piece: Figure 2 - Horizontal and Vertical Position

Slowly, carefully turn the release valve counterclockwise until ram

retracts to desired position. Never turn release valve more than

1/2 full turn. The ram return system is spring loaded, allowing

controlled retraction of the ram.

MAINTENANCE

Important: Use only good grade hydraulic oil. We recommend Hein-Werner HW93291. Avoid mixing different types of

fluid and Never use brake fluid, turbine oil, transmission fluid, motor oil or glycerin. Improper fluid can cause failure of

the pump and the potential for sudden and immediate loss of load.

Adding oil

1. With ram fully lowered, set pump unit in its normal, level position. Locate and remove oil filler screw (see Figure 1).

2. Fill until oil is within 1/4" (6 mm) of the hole opening, reinstall oil filler screw.

Changing oil

For best performance and increased system life, replace the complete fluid supply at least once per year.

1. With ram fully lowered, remove the oil filler screw from the pump reservoir as above.

2. Lay the pump on its side and drain the fluid into a suitable container.

Note: Dispose of hydraulic fluid in accordance with local regulations.

3. Set pump in its level upright position.

4. Fill with good quality hydraulic oil to within 3/8" of the oil filler screw hole opening. Reinstall oil filler screw.

Lubrication

A periodic coating of light lubricating oil to pivot points and hinges will help to prevent rust and assure that pump

assemblies move freely.

Cleaning

Periodically check the pump piston and ram for signs of rust or corrosion. Clean as needed and wipe with an oily cloth.

Note: Never use sandpaper or abrasive material on these surfaces!

Storage

When not in use, store with the pump piston and ram fully retracted.

REPLACEMENT PARTS (refer to page 10 & 11)

Not all components of the porto-power kit are replacement items, but are illustrated as a convenient reference of

location and position in the assembly sequence. When ordering parts, give model number, serial number and parts

description. Call or write for current pricing: SFA Companies 10939 N. Pomona Ave. Kansas City, MO 64153, U.S.A.

Tel:(816)891-6390 Fax:(816)891-6599 E-Mail: sales@blackhawk-automotive.com

Downloaded from www.Manualslib.com manuals search engine

Basic Setup

The capacity of the Porto-Power Kit can be significantly affected by the number of attachments used and the type of

load applied. The approximate load capacity of each function setup is illustrated below. When two or more extension

tubes are used together, be sure to position the shortest tube further away from the ram.

Note: Not all accessories in the illustrations provided in the Porto-Power Kit.

A. Push & Stretch

Serrated Saddle Male

Flat Base

Connector

100% Ram

Ram

Rubber Head

Male Connector

100%

Flat Base

(i) Vertical Push (ii) Horizontal Push

Flat Base Extension Tube Male Connector Ram Combination

Head (900)

25%

(iii) Horizontal Push with Extension

Male

Extension Tube Connector Ram Extension Tube Clamp

25%

(iv) Horizontal Stretch with Extension

B. Clamp & Pull

Pull Ram Lifting Toe Plunger Base Chain

Chain Pull Plate

50% 100%

Saddle

Ram

(i) Clamp with Pull Ram (ii) Pull with Chain

C. Spread

Ram

25% 0.5 Ton

Ram Toe Hydraulic

Ram Plunger Toe

Spreader

Ram Toe

50%

Extension Tube

Flat Base

(i) Vertical Spread (ii) Horizontal Spread (iii) Hydraulic Spreader

7

Downloaded from www.Manualslib.com manuals search engine

TROUBLESHOOTING

Symptom Possible Causes Corrective Action

Ram will not extend • Release valve not tightly closed • Ensure release valve tightly closed

• Overload condition • Remedy overload condition

Ram will not lift to full extension • Fluid level low • Ensure proper fluid level

Spongy effect • Air trapped in system • Bleed air from system

Ram *bleeds off after lift • Release valve not tightly closed • Ensure release valve tightly closed

• Dirt in pump's return check valve • Flush the system

• Hydraulic unit malfunction • Replace ram/pump or, contact service

center

Handle kick-back • Dirt in return check valve • Flush the system

• Reservoir overfilled • Drain fluid to proper level

Ram will not lower after • Damage coupler • Replace coupler

unloading • Bent plunger/ ram damaged • Replace ram

• Fluid level low • Ensure proper fluid level

Poor performance • Air trapped in system • Bleed air from system

* "Bleeds off" means that ram begins to slowly retract rather than maintain position

How to remove faulty coupler

If ram does not retract, secure load by other means. Open pump release valve to depressurize pump and hose. To

avoid hydraulic oil from spilling, wraps the grasping tool with rags or similar padding. Remove the ram from

application. Disconnect and replace with new coupler.

How to bleed air from system

1. Bleed air from ram: Place pump at a higher elevation than the hose and ram (refer to figure 4). The objective is to

"float the air bubbles up hill and back to the reservoir where they belong. Close valve and extend ram as fast as

possible. Open valve fully allowing oil and air to return to reservoir. Repeat this procedure two or three times will do

the trick.

2. Bleed air from pump: With ram fully retracted, remove oil filler screw to let pressurized air escape, then reinstall oil

filler screw.

Figure 4 - Pump and ram illustration to bleed air

Downloaded from www.Manualslib.com manuals search engine

Replacement Parts for Model B65114

Item # Part # Description Qty.

1 B65161 Extension Tube (19-1/2") 1

2 B65160 Extension Tube (16-1/2") 1

3 B65159 Extension Tube (8-1/2") 1

4 B65158 Extension Tube (6-1/8") 1

5 B65157 Extension Tube (3") 1

6 B65177 Male connector 1

7 B65153 Wedge Head (offset) 1

8 B65151 Serrated Saddle 1

9 B65156 Flat Base 1

10 B65154 Plunger Toe (offset) 1

11 B65155 Ram Toe (offset) 1

12 B65178 Rubber Head 1

13 B65152 Combination Head 900 1

14 B65123 1/2 Ton Spreader 1

15 434-6-3313-101 Dust Cover - Hose 1

16 434-6-3312-109 Dust Cover - Ram 1

17 B69478 Hose Coupler, Male 1

18 B69477 Ram Coupler, Female 1

19 B65187 4 Ton Hydraulic Ram 1

20 426-3-1301-203 Release Valve Knob 1

21 431-6-1702-404 Pump Handle 1

22 B65291 Hose w/ Coupler 1

23 324-4-1900-208 Oil Filler Screw 1

24 B65186 4 Ton Hydraulic Pump 1

25 B65067 Plastic Case 1

- B65114-L0 Label (not shown) 1

- B65114-M0 Manual 1

Figure 5 - Replacement Parts Illustration for B65114

9

Downloaded from www.Manualslib.com manuals search engine

Replacement Parts for Model B65115

Item# Part# Description Qty.

1 B65162 Extension Tube (27") 1

2 B65163 Extension Tube (18") 1

3 B65164 Extension Tube (10") 1

4 B65165 Extension Tube (4") 1

5 B65179 Male Connector 1

6 B65166 Wedge Head (offset) 1

7 B65167 Serrated Saddle 1

8 B65168 Flat Base 1

9 B65172 Plunger Toe (offset) 1

10 B65169 Ram Toe (offset) 1

11 B65180 Rubber Head 1

12 B65173 Combination Head 90o 1

13 B65123 1/2 Ton Spreader 1

14 434-6-3313-101 Dust Cover - Hose 1

15 434-6-3312-109 Dust Cover - Ram 1

16 B69478 Hose Coupler, Male 1

17 B69477 Ram Coupler, Female 1

18 B65189 10 Ton Hyd. Ram 1

19 426-3-1301-203 Release Valve Knob 1

20 430-6-1702-407 Pump Handle 1

21 B65291 Hose w/ Coupler 1

22 324-4-1900-208 Oil Filler Screw 1

23 B65188 10 Ton Hyd. Pump 1

24 B65068 Mobile Case 1

- B65115-L0 Label (not shown) 1

- B65114-M0 Manual 1

Figure 6 - Replacement Parts Illustration for Model B65115

10

Downloaded from www.Manualslib.com manuals search engine

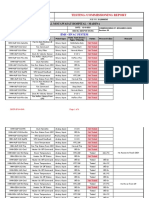

Load - Pressure Correlation For Model B65114 & B65115

Always monitor the force applied to workpiece by using a load cell and indicator or you may monitor pressure

developed in the ram by using an inline pressure gauge, then calculate the applied force using the formula:

where F = Force/ Load (lbs);

P = Hydraulic working pressure (psi) and;

F=PxA A = Ram effective area (in²)

For model B65114, A = 0.998 in² ;

For model B65115, A = 2.411 in²

Example1 Example2

Model B65114 lifting 5,000 lbs will require what Model B65115 operating at 6,000 psi will generate

presure? what force?

Pressure = 5,000 lbs y 0.998 in² = 5,010 psi Force = 6,000 psi x 2.411 in2 = 14,466 lbs

Load Pressure of 4 Ton Ram, Pressure of 10 Ton Ram,

. where A = 0.998 in2 where A = 2.411 in2

(lbs) (psi) (psi)

1,000 1002 415

2,000 2004 830

3,000 3006 1244

4,000 4008 1659

5,000 5010 2074

6,000 6012 2489

7,000 7014 2903

8,000 8016 3318

9,000 3733

10,000 4148

11,000 4562

12,000 4977

13,000 5392

14,000 5807

15,000 6221

16,000 6636

17,000 7051

18,000 7466

19,000 7881

20,000 8295

SFA Companies ©2005

10939 N. Pomona Ave. Kansas City, MO 64153

816-891-6390

sales@blackhawk-automotive.com

11

Downloaded from www.Manualslib.com manuals search engine

memo.

Downloaded from www.Manualslib.com manuals search engine

You might also like

- AVH-120BT OwnersManual081219Document96 pagesAVH-120BT OwnersManual081219Gilbert LabananNo ratings yet

- PC2150EN CD Version RemovedDocument1,416 pagesPC2150EN CD Version RemovedЛеонид БеркоNo ratings yet

- Stihl 08S ManualDocument51 pagesStihl 08S ManualSMWilsonNo ratings yet

- Aries F450 F550 ManualDocument19 pagesAries F450 F550 Manualedbodie33% (3)

- Allison Part ManualDocument16 pagesAllison Part ManualJacob AbrhamNo ratings yet

- MTX Service ManualDocument66 pagesMTX Service ManualJohn HollandNo ratings yet

- Briggs NStratton 170400Document8 pagesBriggs NStratton 170400Bob HaysNo ratings yet

- Chalmers 800Document49 pagesChalmers 800Hamilton MirandaNo ratings yet

- Kenmore 790.7050 7060 7323 7343 Range Owners GuideDocument22 pagesKenmore 790.7050 7060 7323 7343 Range Owners GuideSMWilsonNo ratings yet

- Biochemical Test of BacteriaDocument33 pagesBiochemical Test of Bacteriaaziskf100% (2)

- Driveline Components Catalog Flange & End Yoke Applications: August 2008 Supersedes Section 10 Dated March 2006Document173 pagesDriveline Components Catalog Flange & End Yoke Applications: August 2008 Supersedes Section 10 Dated March 2006mattkidoNo ratings yet

- Spring 2020Document45 pagesSpring 2020Jeff AllisonNo ratings yet

- GX630 GX690: Owner'S Manual Manuel de L'Utilisateur Manual Del PropietarioDocument45 pagesGX630 GX690: Owner'S Manual Manuel de L'Utilisateur Manual Del PropietarioOsman ElmaradnyNo ratings yet

- 2008 Nissan QuestDocument376 pages2008 Nissan Questwifv7enuybyNo ratings yet

- Equivalentes de FiltrosDocument2 pagesEquivalentes de FiltrosMariant ColmenarezNo ratings yet

- HD Wheel Hardware Interchange CatalogDocument36 pagesHD Wheel Hardware Interchange CatalogGustavo Mosquera100% (1)

- Ac Catalog Compressor Parts 2010Document19 pagesAc Catalog Compressor Parts 2010edgardo tovarNo ratings yet

- Ducati 749s Parts BookDocument179 pagesDucati 749s Parts BookAlex AleksicNo ratings yet

- Big Tractor Parts 2008 CatalogDocument43 pagesBig Tractor Parts 2008 CatalogtotcsabNo ratings yet

- Manual Comparativo de Potencia Motores Multimarcas.Document11 pagesManual Comparativo de Potencia Motores Multimarcas.Santiago Mancilla AlvarezNo ratings yet

- Wacker Neuson Light CompactionDocument13 pagesWacker Neuson Light CompactionBusiness Trade Import100% (1)

- 428 Mk19Document4 pages428 Mk19Jose Luis Atao SantiagoNo ratings yet

- Electrical System: Chassis Electrical Devices Wiring Outline StructureDocument28 pagesElectrical System: Chassis Electrical Devices Wiring Outline StructurecckasNo ratings yet

- Frd-Furukawa: F-Series Hydraulic BreakersDocument28 pagesFrd-Furukawa: F-Series Hydraulic BreakersManuel Alcedo MeleroNo ratings yet

- 2009 Commercial Truck BrochureDocument17 pages2009 Commercial Truck BrochureGateway Chevrolet Cadillac100% (1)

- 150 GY 3 - Manual PDFDocument24 pages150 GY 3 - Manual PDFMisy MihainoNo ratings yet

- Parts and Service Interval DD90HF M@SH PDFDocument2 pagesParts and Service Interval DD90HF M@SH PDFjrincon26No ratings yet

- 900A ProductGuideDocument16 pages900A ProductGuideEdson EscobedoNo ratings yet

- Airbags PDFDocument207 pagesAirbags PDFZak Carrigan0% (1)

- Chamberlain 1215e Fs2 Manual de UsuarioDocument80 pagesChamberlain 1215e Fs2 Manual de Usuariojuan camilo EscuderoNo ratings yet

- Toma Fuerza Chelsea-489-Parts-ManualDocument44 pagesToma Fuerza Chelsea-489-Parts-ManualJorge MendozaNo ratings yet

- Bonluck MCI LZ Falcon 45 Operator & Maintenance ManualDocument116 pagesBonluck MCI LZ Falcon 45 Operator & Maintenance ManualCarl Von RydingNo ratings yet

- All-Wheel Steer Loader: A220 A300 A300 A300 A300 A770Document29 pagesAll-Wheel Steer Loader: A220 A300 A300 A300 A300 A770ramon hidalgoNo ratings yet

- 863-863h 6900648 SM 10-98 PDFDocument3 pages863-863h 6900648 SM 10-98 PDFPepe AlNo ratings yet

- Diagrama FODR F150 1 PDFDocument1 pageDiagrama FODR F150 1 PDFPatricio Edgar Gualli CalagullinNo ratings yet

- 1998 Sec 4-Driveline & AxleDocument330 pages1998 Sec 4-Driveline & AxleLuis TomboNo ratings yet

- ForewordDocument2 pagesForewordInjeletro DieselNo ratings yet

- Fordson Dexta Shopmanual Sec WatDocument233 pagesFordson Dexta Shopmanual Sec WatElias JohanssonNo ratings yet

- 2010 Chevrolet Equinox Owner's ManualDocument410 pages2010 Chevrolet Equinox Owner's Manualerjenkins1100% (1)

- 6 Speed RWD (Electronic Control) 2007-: Revision 10/2009Document3 pages6 Speed RWD (Electronic Control) 2007-: Revision 10/2009krzysiek1975100% (2)

- PCM 3Document1 pagePCM 3Enrique Arevalo LeyvaNo ratings yet

- 2007 HD Difftrans 2006Document334 pages2007 HD Difftrans 2006David RosadoNo ratings yet

- Catalog-F7-05-47 Elevated Monitor PDFDocument3 pagesCatalog-F7-05-47 Elevated Monitor PDFAhmed Hassan100% (1)

- Bomag BT 60 - 4 Operating Instructions ManualDocument58 pagesBomag BT 60 - 4 Operating Instructions ManualIslam AttiaNo ratings yet

- Catalogo SircoDocument280 pagesCatalogo Sircoalix beltranNo ratings yet

- Clutch Manual 2013 PDFDocument16 pagesClutch Manual 2013 PDFArnaldo BenitezNo ratings yet

- RailKing Gen5 DiagramsDocument16 pagesRailKing Gen5 DiagramsAndy Franz100% (1)

- ELC 4-Speed Automatic Transaxle (Part 1 of 6) : Diagrams Electrical Diagrams Transmission Control SystemsDocument7 pagesELC 4-Speed Automatic Transaxle (Part 1 of 6) : Diagrams Electrical Diagrams Transmission Control SystemsVikas NarangNo ratings yet

- Each Schematic Diagram of Complete Vehicle Electrical System of C&C TrucksDocument20 pagesEach Schematic Diagram of Complete Vehicle Electrical System of C&C TrucksĐông Nguyễn100% (2)

- Manual JerdanDocument57 pagesManual Jerdanjhocet16No ratings yet

- Atap Air BagsDocument21 pagesAtap Air BagsCarlos CáceresNo ratings yet

- Component Locator - Powertrain Component ViewsDocument9 pagesComponent Locator - Powertrain Component ViewsMoises Cob100% (1)

- 2005 Service LIT 11616 18 43Document36 pages2005 Service LIT 11616 18 43Dawie HenningNo ratings yet

- Manual Taller Yamaha Grizzly 550 EFI 2009 34D-28197-E0Document458 pagesManual Taller Yamaha Grizzly 550 EFI 2009 34D-28197-E0torbelascoainNo ratings yet

- Article Beginning DefoggersDocument15 pagesArticle Beginning DefoggersSergio Marcano100% (1)

- HondaOwnersManual-GX240 GX270 GX340 GX390Document64 pagesHondaOwnersManual-GX240 GX270 GX340 GX390Ryr MonNo ratings yet

- Sistema Electrico 7400 Internatinal-1Document350 pagesSistema Electrico 7400 Internatinal-1omar suazoNo ratings yet

- R-Series: Electric Drive Compressors & UnitsDocument32 pagesR-Series: Electric Drive Compressors & UnitsAlexNo ratings yet

- Lehf0136 01Document4 pagesLehf0136 01Jose MoralesNo ratings yet

- BHK B65114 M0 - ManualDocument11 pagesBHK B65114 M0 - Manuallizardoluna04.92No ratings yet

- Carrier 424 Parts ManualDocument10 pagesCarrier 424 Parts Manualarturo100% (58)

- Pulling Post Kit: Operating Instructions & Parts ManualDocument8 pagesPulling Post Kit: Operating Instructions & Parts ManualAndreea MihailaNo ratings yet

- Devilbiss mbc510 ManualDocument8 pagesDevilbiss mbc510 ManualSMWilsonNo ratings yet

- MERC Thunderbolt Ignition 1500 1400 1350 1150Document1 pageMERC Thunderbolt Ignition 1500 1400 1350 1150SMWilsonNo ratings yet

- List of Isuzu EnginesDocument10 pagesList of Isuzu EnginesSMWilson50% (4)

- Instruction Manual PR5020 1 6: Quick-Start GuideDocument60 pagesInstruction Manual PR5020 1 6: Quick-Start GuideSMWilsonNo ratings yet

- Soleus Ac Sg-Wac-06 - 08ese-F Manual 2-24-11Document17 pagesSoleus Ac Sg-Wac-06 - 08ese-F Manual 2-24-11SMWilsonNo ratings yet

- SONY DSC w270 w275 w290 CameraDocument60 pagesSONY DSC w270 w275 w290 CameraSMWilsonNo ratings yet

- 2017 Griswold Skillet ChartDocument1 page2017 Griswold Skillet ChartSMWilsonNo ratings yet

- Makita Mac 5200Document20 pagesMakita Mac 5200wdowiuueNo ratings yet

- The Vinegar Solution PDFDocument26 pagesThe Vinegar Solution PDFSMWilson100% (2)

- Firearm Fill in Data SheetDocument1 pageFirearm Fill in Data SheetSMWilsonNo ratings yet

- Scumacher Battery Charger Manual PDFDocument36 pagesScumacher Battery Charger Manual PDFSMWilsonNo ratings yet

- South Bend Lathe TrainingDocument68 pagesSouth Bend Lathe TrainingSMWilson100% (2)

- Basic-Ignition-System - PNG (PNG Image, 700 × 895 Pixels) file:///root/Downloads/Basic-Ignition-System - PNGDocument1 pageBasic-Ignition-System - PNG (PNG Image, 700 × 895 Pixels) file:///root/Downloads/Basic-Ignition-System - PNGSMWilsonNo ratings yet

- The Parts of A Bicycle Nomenclature NamesDocument2 pagesThe Parts of A Bicycle Nomenclature NamesSMWilsonNo ratings yet

- Ithaca 37Document20 pagesIthaca 37SMWilson100% (1)

- Lecture 2 The Meanings and Dimensions of Culture NewDocument30 pagesLecture 2 The Meanings and Dimensions of Culture NewKanwal100% (1)

- Concept Questions From Marine BiologyDocument2 pagesConcept Questions From Marine BiologyJameeNo ratings yet

- 2020 Conference PaperDocument2 pages2020 Conference PaperHealthcare Pro LearningNo ratings yet

- DDCP SF 04 04aDocument6 pagesDDCP SF 04 04aMohammad FarajNo ratings yet

- Do We Know JackDocument20 pagesDo We Know JackAbdul-Ganiyu MannirNo ratings yet

- Check Your Listening Comprehension - Matching SpeakersDocument50 pagesCheck Your Listening Comprehension - Matching Speakerslindazykov43719No ratings yet

- 2020-07-16 St. Mary's County TimesDocument32 pages2020-07-16 St. Mary's County TimesSouthern Maryland OnlineNo ratings yet

- Gender Based CounsellingDocument5 pagesGender Based CounsellingUnnimaya M SNo ratings yet

- (ch3) 2so4Document6 pages(ch3) 2so4arbol100No ratings yet

- Conscientious Objector Info Pack Part 2Document194 pagesConscientious Objector Info Pack Part 2Shot_infoNo ratings yet

- 1C Cu Epr-Pvc 35KV@133% 2017Document2 pages1C Cu Epr-Pvc 35KV@133% 2017CarlosNo ratings yet

- Demolition Instructions With Heavy Duty Construction MachineryDocument2 pagesDemolition Instructions With Heavy Duty Construction Machinerymiraç burak navruzNo ratings yet

- Renewable Energy TypesDocument4 pagesRenewable Energy TypesNaufal IhsanNo ratings yet

- Education InfographicDocument1 pageEducation Infographickim angelo ulleroNo ratings yet

- Climate and Consumption Pattern - Demand and Supply of Water District ConcessionairesDocument3 pagesClimate and Consumption Pattern - Demand and Supply of Water District ConcessionairesIJAERS JOURNALNo ratings yet

- Hse FormDocument2 pagesHse FormPhilip Tcs100% (1)

- Cementitious Slurries From CeresitDocument7 pagesCementitious Slurries From CeresitMostafa Hussein AbdouNo ratings yet

- Theories of FailureDocument23 pagesTheories of FailureDheerajGunwant25% (4)

- 3 - Cardiovascular System PDFDocument54 pages3 - Cardiovascular System PDFMSKCNo ratings yet

- LD630Document1 pageLD630Luis Jonathan Bahamaca FernandezNo ratings yet

- Guide Falsework AustraliaDocument4 pagesGuide Falsework AustraliaHafizah MohdNo ratings yet

- SurgTrnds MnmalInvsve InviteDocument2 pagesSurgTrnds MnmalInvsve Inviteanand787No ratings yet

- Thesis Chapter 2 & 3Document6 pagesThesis Chapter 2 & 3Avreile100% (1)

- CIMON IXT15 Datasheet 2023.06.06Document1 pageCIMON IXT15 Datasheet 2023.06.06habacuc8891No ratings yet

- School Grievance CommitteeDocument15 pagesSchool Grievance CommitteeDeped Cavite LegalNo ratings yet

- Internal Sources of RecruitmentDocument3 pagesInternal Sources of RecruitmentakinravNo ratings yet

- Hofstead Cultural DimensionDocument29 pagesHofstead Cultural DimensionAbhishek PathodeNo ratings yet

- Foodstuff English Hindi NamesDocument16 pagesFoodstuff English Hindi NamesevilcreatureNo ratings yet

- The One Minute ManagerDocument20 pagesThe One Minute ManagerYashwant J100% (2)