Professional Documents

Culture Documents

Read and Take Note of The Supplement To The Original Operating Manual!

Read and Take Note of The Supplement To The Original Operating Manual!

Uploaded by

joseph beckhamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Read and Take Note of The Supplement To The Original Operating Manual!

Read and Take Note of The Supplement To The Original Operating Manual!

Uploaded by

joseph beckhamCopyright:

Available Formats

Supplement to the operating manual

Using the Ruwac wet separator

Supplement to the operating manual

Read and take note of the supplement to the original operating manual!

This document only applies in combination with the original operating manual of your LaserCUSING®

machine.

The content specified in this document has been produced as a result of new findings and experiences

gained from handling the LaserCusing® machine and replaces the corresponding content from your

original operating manual.

This document contains tips which you must follow for your own personal safety and to prevent any

damage to property.

The operator is obliged to inform the personnel about the publication and the content of this

supplement to the operating manual.

To make this easier to track, the operator should have the instruction confirmed in writing in an

instruction record.

This document must be enclosed with the original operating manual and made freely accessible to all

operators.

1 General safety notices

Concept Laser GmbH constantly strives to make working on and with the LaserCusing® machines a safe

and user-friendly process.

Due to the latest findings, the following changes with a relevance to safety arise for operating and

handling your LaserCusing® machine and the peripheral equipment.

Danger of explosion from incorrect use of the Ruwac wet separator!

Swirling up of the approved reactive light-metal alloys as well as their process-related smoke and filter

residues in an atmosphere containing oxygen may produce an explosive atmosphere. There is a danger

DANGER of explosion and fire.

Before starting work, the Ruwac wet separator is to be checked to ensure it is working properly.

It may only be operated with approved accessories and if the device and the operator are earthed.

Connecting the Ruwac wet separator to the suction port of the glovebox is fundamentally

prohibited.

The operator is prohibited from sucking out the dose and build chamber shafts. These tasks may

only ever be carried out by specially trained maintenance personnel.

The sucking up of smoke residues is prohibited.

During suction work, always wear the full personal protective equipment which is appropriate for

the metal powder being used.

If possible, work in pairs when handling reactive materials. People working on their own are to be

suitably monitored, e.g. by providing suitable emergency call facilities.

Last revised: 04/05/2016 Page 1 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

Danger of explosion and fire from the formation of oxyhydrogen!

Different metals react to different degrees with water, leading to the formation of hydrogen. If water is

used as the separating medium, flammable hydrogen may be produced in the separator during

DANGER operation and when the machine is at a standstill. If the hydrogen accumulates and mixes with air

containing oxygen, this produces an explosive hydrogen/air mixture, known as oxyhydrogen.

Before starting work, the Ruwac wet separator is to be checked to ensure it is working properly.

Check the water level in the wet separator before and regularly during operation.

During suction work, always wear the full personal protective equipment which is appropriate for

the metal powder being used.

Empty and clean the wet separator and the accessories used as required, but at least once a day at

the end of the working day.

Check water level regularly before and during use!

The development of hydrogen causes the water level to fall more quickly in the wet separator.

If suction takes place when the water level is too low and hydrogen is present at the same time, this can

result in a strong explosion.

Empty and clean the wet separator and the accessories used as required, but at least once a day.

Regularly check the water level in the wet separator before each use, also after brief breaks from

suction, and during operation.

1.1 Responsibility of the operator

The operator must ensure that all persons who come into contact with the machine have read and

understood the original operating manual.

In addition, the operator must train the personnel and provide them with information about the

potential hazards at least once a year.

To make this easier to track, an instruction record should be kept.

Last revised: 04/05/2016 Page 2 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

1.2 What are reactive materials?

The metal powders which are approved for the LaserCUSING® process also include metal powders of

aluminium and titanium. These powders, and the process-related smoke of all approved metal powders,

are reactive.

This means that they react very quickly with other substances, such as with oxygen from the

atmosphere.

Reactive metal powders

Reactive metal powders are the metal powders which, as a result of their chemical properties, react

spontaneously with oxygen and nitrogen (titanium) in the presence of these elements.

The reactive metal powders include the light metal powders aluminium and titanium and all alloys of

these metals.

The reaction here is dependent on the particle size and the distribution or turbulence in the air.

Smoke

Smoke is the particulate substances which is produced during the LaserCUSING® process as a result of

the fusing and partial evaporation of the metal powders. The composition of the smoke is dependent on

the metal powder which is used. What all smoke has in common is a very low particle size and the high

level of reactivity associated with this.

All smoke is included among the reactive materials. Smoke therefore pose a risk of fire and explosion.

The ignition energy of the smoke from reactive metal powders is in fact so low that it is capable of

spontaneous ignition.

Smoke residues are identifiable by their black colouring and they occur primarily in the process chamber

and the pipe system / hose system and the filter module of the extraction and filter station.

Flammable metal dusts

A substance is deemed to be flammable if it continues to burn after catching fire even if the ignition

source is removed. After catching fire, residues of smoke, filter residues and reactive metal powders

generally tend to burn, glow or smoulder.

Dust explosion

Swirled-up dust of reactive metal powders and smoke can react in an explosive way. A dust explosion

can occur if flammable, swirled-up dust is present in a suitable concentration in a mixture with a

gaseous oxidiser (usually the oxygen in the air, "dust-air mixture") and the ignition energy is exceeded.

The ignition energy for smoke explosions is so low that with swirling up they are capable of spontaneous

ignition.

Last revised: 04/05/2016 Page 3 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

1.3 Personal protective equipment

The personal protective equipment is designed to protect people from any negative impacts on health

and safety when working.

When does the personal protective equipment have to be worn?

The personal protective equipment (PPE) which is required is dictated by the metal powders used and

the activities performed on your LaserCusing® machine.

The personal protective equipment must always be worn when the operator is working with metal

powders and their process-related smoke in an atmosphere containing oxygen.

It is possible to process two groups of metal powders, reactive and non-reactive metal powders (see

section 2.1 Classification of the approved materials (metal powders)) Depending on which group the

metal powders used are assigned to, different requirements result in terms of the personal protective

equipment that needs to be worn.

When working with reactive materials, the Extended PPE must always be worn. You can get an overview

of the protective equipment required in each case in the section Classification of the personal protective

equipment.

You will find the information you need in section 3.5 Accessories, wearing and spare parts.

Description of the personal protective equipment

Protective work clothing

Protective work clothing is close-fitting and dirt-repellent work clothing with tight sleeves and without

any protruding parts.

Protective gloves

Protective gloves are used to protect the hands from aggressive chemicals.

Respiratory mask P3

The particle-filtering half-mask prevents the user breathing in harmful dusts, mists and fumes.

Protective goggles (tight-fitting)

The protective goggles are used to protect the eyes from any powder dust, parts flying around and any

liquid splashing.

Full respiratory mask (with a particulate filter P3 )

The particle-filtering full mask prevents the user breathing in harmful dusts, mists and fumes.

The integrated face guard protects the entire area of the face from a sudden flash fire with an explosive

flame.

Last revised: 04/05/2016 Page 4 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

Antistatic protective equipment (ESD kit; ESD mat; antistatic protective clothing)

Antistatic protective equipment is used to prevent electrostatic charges.

The protective equipment comprises an ESD wrist strap with an earth lead and a push-button, and ESD

protective mats can also be laid in the hazardous areas.

Heat protection clothing

Heat protection clothing is used to provide protection from thermal risks, specifically from a sudden

flash fire with an explosive flame. The heat protection clothing is to be chosen so that the specified

protective aim is achieved. (Head and neck protection, body protection, face protection)

Heat protection gloves

Heat protection gloves are used to protect the hands from thermal risks such as heat and fire.

Classification of the personal protective equipment

Standard PPE - Protective gloves

- Protective work clothing

- Respiratory mask (half-mask)

- Protective goggles, tight-fitting

Extended PPE: - Standard PPE (protective gloves, protective work clothing)

- Antistatic protective equipment

- Heat protection gloves

- Heat protection clothing (heat protection overall with a hood or

heat protection suit and a balaclava)

- Full respiratory mask or respiratory half-mask and protective shield

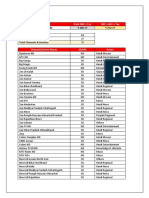

Overview of the protective equipment required depending on the metal powders used and

the activities to be performed

All activities are performed in an atmosphere containing oxygen.

Material

Activity Non-reactive metal powders Reactive metal powders

Brushing, scooping, wiping of metal

Standard PPE Extended PPE

powders

Sucking up of metal powders with the

Standard PPE Extended PPE

wet separator

Cleaning of the process chamber and

Extended PPE Extended PPE

wiping of smoke residues

Working in the closed and inertised

No PPE No PPE

glovebox

Cleaning of the extraction and filter

Extended PPE Extended PPE

module

Filter change Extended PPE Extended PPE

Last revised: 04/05/2016 Page 5 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

1.4 Avoiding electrostatic charges

Electrostatic discharge processes can have energies of less than 1 mJ up to several J. They are thus

capable of igniting dust/air mixtures and therefore belong to the effective ignition sources of reactive

materials.

An ignition source is described as effective if it can give off a sufficient amount of energy to the explosive

atmosphere that independent propagation of the burning occurs.

Appropriate protective measures should be taken to prevent electrostatic charges.

Danger areas

All areas in which there are residues of reactive metal powders or process-related smoke are classified

as danger areas.

These include the following areas in particular:

– In front of the LaserCusing® machine

– In front of the extraction and filter system

– In front of the automatic screening station

– Storage location of the reactive metal powders and the smoke residues (e.g. filter residues)

2 Technical data

2.1 Classification of the approved materials (metal powders)

The following metal powders can be procured through Concept Laser GmbH and are approved for the

LaserCUSING® process.

Non-reactive metal powders

Alloy type Name

Stainless steel CL 20ES (1.4404)

Hot-work steel CL 50WS (1.2709)

CL 80CU (only before Mlab)

CL 91RW

Nickel-base alloy CL 100NB (Inconel 718)

CoCr dental alloy remanium® Star CL

Reactive metal powders

Alloy type Name

Aluminium CL 30AL (AlSi12)

CL 31AL (AlSi10Mg)

Titanium CL 41TI (TiAl6V4 ELI)

CL 42TI pure titanium

rematitan® CL

The use of metal powders other than those listed above is only permitted with the prior, explicit consent

of Concept Laser GmbH.

Last revised: 04/05/2016 Page 6 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

3 Use of the Ruwac wet separator

The Ruwac wet separator is designed specifically for separating reactive metal powders in water.

To ensure safe operation of the Ruwac wet separator in conjunction with a LaserCusing® machine and

reactive metal powders, it is essential to observe and apply the following notices and instructions.

You should also note the operating manual for the Ruwac wet separator.

3.1 Approved accessories

The Ruwac wet separator may only be operated with the approved accessories. The use of other

attachments or accessories is prohibited.

Only attachment nozzles and accessory adapters made from stainless steel are approved for use on

the suction hose of the Ruwac wet separator.

The use of attachment nozzles made from plastic or rubber materials or brushes, even if they are

labelled as conductive, is prohibited with immediate effect.

Approved accessories

Curved stainless steel crevice nozzle Art. No.: 91767

Stainless steel accessory adapter (connecting element between hose and nozzle) Art. No.: 91766

3.2 Before use

To ensure safe operation, the checks described below are to be carried out on the Ruwac wet separator

before commencing work.

The precise operational instructions can be gleaned from the operating manual for the Ruwac wet

separator.

Before starting work, the Ruwac wet separator is to be checked to ensure it is working properly.

Check whether all gas release valves are working properly.

Check the water level in the water container of the wet separator.

Check the water container for any deposits.

Check the earthing connection and the earthing cable for any signs of damage.

Check that the suction hose is fitted correctly.

Last revised: 04/05/2016 Page 7 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

3.3 Safety-relevant notices for operation

Put on personal protective equipment

Put on your personal protective equipment before switching on the Ruwac wet separator.

If reactive metal powders are being used, the Extended PPE is to be worn.

Use of the Ruwac wet separator

Only use the Ruwac wet separator for separating small quantities of reactive metal powders in

water.

Check the water level in the container regularly during operation.

Check whether material is being sucked through the water bath.

The Ruwac wet separator must not be used in areas in which experience shows that smoke

residues are to be expected. These are:

the process chamber, and the areas directly adjacent to it

the piping system / hose system of the extraction and filter system to the process chamber

the filter module, the filter cartridge and filter residues of the extraction and filter system

If smoke residues are identified, e.g. on the build module, suction is to be stopped immediately. Pick

up smoke residues using a cloth made slightly damp with water.

Sucking up reactive metal powders

Transfer reactive metal powder residues as completely as possible, with the glovebox inertised, into

the powder overflow and thus avoid exposing metal powder to an atmosphere containing oxygen.

Wipe up non-reusable reactive metal powder residues using a cloth made slightly damp with water

if possible.

Only suck up very small residual amounts with the Ruwac wet separator.

The sucking up of metal powders from small, closed volumes is prohibited. This includes the

following activities in particular:

Connection of the wet separator to the glovebox and sucking with the glovebox closed

Sucking the powder containers

The sucking up of metal powders from filters is prohibited. This includes the following in particular:

Gloveboxfilter

Filter of the sieving station

Filter on over pressure valve vacuum unit

Filter of vacuum unit

Cyclone filter

Last revised: 04/05/2016 Page 8 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

3.4 Maintenance work

Cleaning

Calculate the cleaning intervals based on what is required. They are dictated by the length of

suction, the frequency of suction, the amount and material being sucked up.

The wet separator must be emptied and cleaned at least once a day at the end of the working day.

Check the level of contamination of the suction hose and the accessories used at least once a day.

Replace a contaminated suction hose. Cleaning with water is not recommended as residual water

in the hose can clump together with metal powder to form hard deposits.

Empty and clean the wet separator.

Top the wet separator up to the maximum fill mark. It is not permitted to store the wet separator

without water.

Topping up the wet separator with water via the suction hose is not recommended as residual

water in the hose can clump together with metal powder to form hard deposits.

Last revised: 04/05/2016 Page 9 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

3.5 Accessories, wearing and spare parts

Name Description Article No.

Standard PPE* (personal Respirator mask P2 or P3 90128

protective equipment) Protective goggles, tight-fitting

Gloves, chemical-resistant and powder-tight

ESD wrist strap* Element of ESD kit, plastic wrist strap with push- 90586

button, 3 mm

ESD discharge cable* Element of ESD kit, spiral discharge cable 90653

ESD distributor* Element of ESD kit, push-button distributor 90654

ESD protective mat M2* Electrostatically conductive floor mat to be used in 91437

front of the LaserCusing® machine

1200 x 900mm

ESD protective mat blower* Electrostatically conductive floor mat to be used in 91434

front of the extraction and filter system

1200 x 900mm

Heat protection gloves* Category III; contact heat up to 100°C with pulse 90585

protection

Heat protection clothing* Flame-retardant, antistatic type 5 and 6 overall 91771

which is certified to provide protection against

radioactive particles

Category III

Full respiratory mask* Full mask, Class 2, checked and approved in line with 91772

EN 136: 1998 CL2

Particle filter for full Protection level P3, reusable 90061

respiratory mask*

Antistatic dust bag Made from electrostatically conductive material. 90360

* Sold only in Germany

Last revised: 04/05/2016 Page 10 of 11

safety@concept-laser.de

Supplement to the operating manual

Using the Ruwac wet separator

4 Service and customer service

If you have any questions or require technical information, please contact the service department of

Concept Laser GmbH:

Address CONCEPT Laser GmbH

Department Service

An der Zeil 8

Address

96215 Lichtenfels

Telephone +49 (0) 9571 1679 444

Fax +49 (0) 9571 1679 499

E-mail service@concept-laser.de

Internet www.concept-laser.de

5 Checklists

For the prescribed use of the Ruwac wet separator on a LaserCusing® machine from Concept Laser

GmbH, we recommend completing a checklist of the activities which need to be carried out.

You will find example checklists for regular or occasional use attached to this document.

The checklists should be hung up in a highly visible way at the place where the Ruwac wet separator is

stored.

Last revised: 04/05/2016 Page 11 of 11

safety@concept-laser.de

Ruwac wet separator

Checklist for weekly use

Weekly schedule Serial number: CW: Year:

Ruwac wet separator

Day Activity Date / time Signature

Monday Check level of contamination of suction hose and

accessories

Empty and clean wet separator

Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Tuesday Check level of contamination of suction hose and

accessories

Empty and clean wet separator

Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Wednesday Check level of contamination of suction hose and

accessories

Empty and clean wet separator

Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Thursday Check level of contamination of suction hose and

accessories

Empty and clean wet separator

Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Last revised: 04/05/2016 Page 1 of 2

safety@concept-laser.de

Ruwac wet separator

Checklist for weekly use

Day Activity Date / time Signature

Friday Check level of contamination of suction hose and

accessories

Empty and clean wet separator

Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Saturday Check level of contamination of suction hose and

accessories

Empty and clean wet separator

Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Sunday Check level of contamination of suction hose and

accessories

Empty and clean wet separator

Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Last revised: 04/05/2016 Page 2 of 2

safety@concept-laser.de

Ruwac wet separator

Checklist for daily use

Daily use

Serial number: Day:

Ruwac wet separator

Activity Time Check OK Not Rectified Signature

OK

Preparation for use of the Water level

wet separator Degassing valves

Blistering in a water bath

during operation

Details

Material

Training completed

Second person is within

hailing distance

Protective clothing Put on (tick off)

Gloves

Dirt-repellent and tight-

fitting clothing

Breathing protection

Protective clothing against

heat and flames

Required only with reactive materials (e.g. Al/ Ti)

Breathing protection

ESD kit

Protective helmet with a

face shield

Heat-resistant

gloves

Empty / clean the wet Check level of contamination of the suction hose and

separator accessories

Empty and clean the wet separator

Required with reactive

materials (e.g. Al/Ti) after Check the inner hose for cracks

every use of the wet

separator Pour in water / check fill level

Check that degassing valves are working properly

Visual inspection of earthing connections

Check following use of the Check OK Not Rectified Signature

wet separator OK

Inner hose checked for

cracks

Water level

Degassing valves

Confirm material

Last revised: 04/05/2016 Page 1 of 1

safety@concept-laser.de

You might also like

- Acls Topic Wise McqsDocument40 pagesAcls Topic Wise McqsRuh ullah71% (7)

- Grading Systems and The Grading System of The Department of EducationDocument5 pagesGrading Systems and The Grading System of The Department of EducationAngela Quezada Rulete67% (3)

- Safety and Handling: Technical Data SheetDocument15 pagesSafety and Handling: Technical Data SheetRonak MotaNo ratings yet

- 16 - Inert Entry in Confined SpaceDocument2 pages16 - Inert Entry in Confined SpaceAfshadNo ratings yet

- Sulfuric Acid Material Safety Data Sheet: Section 1. Product and Company IdentificationDocument5 pagesSulfuric Acid Material Safety Data Sheet: Section 1. Product and Company IdentificationDipen DoshiNo ratings yet

- Ppis 15Document4 pagesPpis 15droidNo ratings yet

- Makalah OxidizingDocument12 pagesMakalah OxidizingCCCNo ratings yet

- Guideline For Safe Use & Handling of Mercury & Mercury CompoundsDocument15 pagesGuideline For Safe Use & Handling of Mercury & Mercury CompoundsAlfred E. NewmanNo ratings yet

- 2018 05 UNSW Carbon Fibre Safety Information SheetDocument4 pages2018 05 UNSW Carbon Fibre Safety Information SheetashchuwenxuNo ratings yet

- Spray Gun Maintenance and Troubleshooting Guide (JGA) : WarningDocument1 pageSpray Gun Maintenance and Troubleshooting Guide (JGA) : WarningpopNo ratings yet

- Purging Venting & DrainingDocument11 pagesPurging Venting & DrainingDongjie SongNo ratings yet

- Reduce Hazards-Vaccum SystemDocument7 pagesReduce Hazards-Vaccum SystemChem.EnggNo ratings yet

- Lead Exposure Fire Assay Labs2016Document19 pagesLead Exposure Fire Assay Labs2016Nikola RanđelovićNo ratings yet

- BMED LCFS Series Instruction Manual NFPA ENDocument31 pagesBMED LCFS Series Instruction Manual NFPA ENBoke BelayNo ratings yet

- Sulfuric Acid Material Safety Data Sheet: Section 1. Product and Company IdentificationDocument5 pagesSulfuric Acid Material Safety Data Sheet: Section 1. Product and Company IdentificationDipen DoshiNo ratings yet

- Sug 001Document2 pagesSug 001Dracoco GamerNo ratings yet

- ELECTRONICS MANUFACTURE-Common Processes-Polymer Health and Safety IssuesDocument2 pagesELECTRONICS MANUFACTURE-Common Processes-Polymer Health and Safety IssuesGerard PabloNo ratings yet

- Gas Cilinder SafetyDocument46 pagesGas Cilinder SafetyJoshua Kirby100% (1)

- Compressed Gas Design and Safety Handbook2006Document46 pagesCompressed Gas Design and Safety Handbook2006basura12345100% (3)

- Control Measure2Document39 pagesControl Measure2precious maningasNo ratings yet

- Organic SolventsSOPDocument6 pagesOrganic SolventsSOPNikhilesh KumarNo ratings yet

- Design of Inert Gas SystemsDocument4 pagesDesign of Inert Gas SystemsMafe SalazarNo ratings yet

- Hazardous Materials Section 4.8 Hydrogen Safety: Environment, Safety and Health Manual - ANL-EDocument11 pagesHazardous Materials Section 4.8 Hydrogen Safety: Environment, Safety and Health Manual - ANL-Ehk168No ratings yet

- Ehs UvDocument3 pagesEhs UvAdesh GurjarNo ratings yet

- Oxygen Use in The Workplace: Fire and Explosion HazardsDocument8 pagesOxygen Use in The Workplace: Fire and Explosion HazardsSebastiao DuarteNo ratings yet

- Sodium Amide Sarpong FinalDocument11 pagesSodium Amide Sarpong FinalGeorgeNo ratings yet

- Basic Guide To Explosives.Document8 pagesBasic Guide To Explosives.Seng BoucherNo ratings yet

- Cut 65 CNCDocument13 pagesCut 65 CNCSinval Santana SantosNo ratings yet

- Clemco Hollo Blast Internal Pipe Blast Tool Operator Manual 06158Document16 pagesClemco Hollo Blast Internal Pipe Blast Tool Operator Manual 06158JANETNo ratings yet

- Chemical_Handling_3Document38 pagesChemical_Handling_3zeeshanNo ratings yet

- Mothballing Using VCI (Newest, Claimed To Be The Most Efficient) NitrogenDocument3 pagesMothballing Using VCI (Newest, Claimed To Be The Most Efficient) NitrogenEriska Wahyu Kusuma100% (1)

- Definition of Oxidizing: Rust Iron (III) OxideDocument4 pagesDefinition of Oxidizing: Rust Iron (III) OxideVeroNikaNo ratings yet

- 7.4.7 Duramax Gun ManaulDocument52 pages7.4.7 Duramax Gun ManaulomarNo ratings yet

- Experiment 1: Safety Measures During Use and Preparation of Chemical SubstancesDocument6 pagesExperiment 1: Safety Measures During Use and Preparation of Chemical SubstancesAliah AzizNo ratings yet

- MSDS Luperox 11M75 (T-Butilpivalato)Document7 pagesMSDS Luperox 11M75 (T-Butilpivalato)Isabel MonroyNo ratings yet

- Potential Health & Safety Hazards: 1. 1.1. To Provide Safe Work Procedures and Guidelines On Brazing OperationsDocument8 pagesPotential Health & Safety Hazards: 1. 1.1. To Provide Safe Work Procedures and Guidelines On Brazing OperationssbjamdadeNo ratings yet

- Lista de Componentes ExC3Document9 pagesLista de Componentes ExC3pressisoNo ratings yet

- MaterialHazardsinPenetrantTesting PDFDocument3 pagesMaterialHazardsinPenetrantTesting PDFsagar mahantNo ratings yet

- Assignment of Control TechniquesDocument15 pagesAssignment of Control TechniquesAnanda NairNo ratings yet

- Msds Stainless SteelDocument11 pagesMsds Stainless Steelrakesh marwahNo ratings yet

- ProRox SDS PDFDocument7 pagesProRox SDS PDFr afriantoNo ratings yet

- Primacs TOC Analyser: Chapter 1: IntroductionDocument12 pagesPrimacs TOC Analyser: Chapter 1: IntroductionAnonymous 2LYCWDPuiuNo ratings yet

- SYSMEDOCSeries Oxygen Concentrator User ManualDocument24 pagesSYSMEDOCSeries Oxygen Concentrator User ManualHakimNo ratings yet

- HM 106 108Document8 pagesHM 106 108albaraha albarahaNo ratings yet

- 10 TBT 04 Respiratory SystemDocument3 pages10 TBT 04 Respiratory SystemZemran AsherNo ratings yet

- Labconco Acid Mechanical SystemsDocument11 pagesLabconco Acid Mechanical SystemsDiego RomeroNo ratings yet

- Shimadzu IRAffinity-1 UserGuide - Georgia Institute of TechnologyDocument23 pagesShimadzu IRAffinity-1 UserGuide - Georgia Institute of TechnologyRoger ManzanarezNo ratings yet

- Raycus C6600SDocument52 pagesRaycus C6600SLeandro PotrinoNo ratings yet

- The Importance of Acid Fume Scrubbers - SensorexDocument12 pagesThe Importance of Acid Fume Scrubbers - SensorexCarlos BarrazaNo ratings yet

- Amberlyst 15wetDocument0 pagesAmberlyst 15wetAdilaAnbreenNo ratings yet

- Cms-2 Detector de MonoxidoDocument17 pagesCms-2 Detector de MonoxidoJORGEALEXERNo ratings yet

- MC55UVM6Document28 pagesMC55UVM6Ujianto Timotius NugrohoNo ratings yet

- H2O2 Hydrogen Peroxide Passivation ProcedureDocument7 pagesH2O2 Hydrogen Peroxide Passivation ProcedureLion TigerNo ratings yet

- RFL-P30MX - (MOPA Pulsed Laser) (User Manual) 1.0Document20 pagesRFL-P30MX - (MOPA Pulsed Laser) (User Manual) 1.0Raghu VutukuruNo ratings yet

- Home Work HseDocument5 pagesHome Work Hsemimoking027No ratings yet

- MX-A430MDocument7 pagesMX-A430MMr.HYCONo ratings yet

- Standard Operating ProcedureDocument4 pagesStandard Operating ProcedureAustin LaneNo ratings yet

- Interview Questions O&G-1Document10 pagesInterview Questions O&G-1Ahmed IsahNo ratings yet

- M Terex RL4000 Partes ENGDocument64 pagesM Terex RL4000 Partes ENGHayber FerrerNo ratings yet

- Sodium Azide SopDocument13 pagesSodium Azide SopIndu BarwalNo ratings yet

- Sulfur Dioxide Handling ManualDocument16 pagesSulfur Dioxide Handling ManualManfred VonNo ratings yet

- Management of Depleted Uranium Used as Shielding in Disused Radiation DevicesFrom EverandManagement of Depleted Uranium Used as Shielding in Disused Radiation DevicesNo ratings yet

- Isx Overhaul Kits: Engine Certification Overhaul Kit Tier Part# Liner Size CplsDocument2 pagesIsx Overhaul Kits: Engine Certification Overhaul Kit Tier Part# Liner Size CplsblueseatxNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Dhaval UndaviyaNo ratings yet

- Tableau Day 14 1590099978Document4 pagesTableau Day 14 1590099978Ritvik BansalNo ratings yet

- AkuntansiDocument15 pagesAkuntansiMUHAMMAD RIZKYNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)RMNo ratings yet

- Strama Quiz 4Document5 pagesStrama Quiz 4Norhel FangedNo ratings yet

- Initio 2009 RoadmapDocument9 pagesInitio 2009 RoadmapStefan DimitrovNo ratings yet

- ElastomerDocument3 pagesElastomersiswoutNo ratings yet

- SAR Reduction With Antenna Cluster TechniqueDocument6 pagesSAR Reduction With Antenna Cluster Techniqueyoussef.amraoui2No ratings yet

- Nortel PBX Cheat SheetDocument13 pagesNortel PBX Cheat SheetRahul Saini100% (1)

- Housing and Meal Plans at Fiu: BusinessDocument2 pagesHousing and Meal Plans at Fiu: BusinessJose CamposNo ratings yet

- Company Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact PersonDocument18 pagesCompany Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact Personmurugesh18100% (1)

- Alternator AKSA AK6480Document8 pagesAlternator AKSA AK6480Cris_eu09No ratings yet

- Alcohol Module SpecificationDocument2 pagesAlcohol Module SpecificationJuan KardNo ratings yet

- KU Topup - Interim Report Template (AutoRecovered)Document23 pagesKU Topup - Interim Report Template (AutoRecovered)Chathuna SamodyaNo ratings yet

- Effectiveness of Tokyoguidelines 2018 in The Management of Acute Cholangitis and Acute CholecystitisDocument13 pagesEffectiveness of Tokyoguidelines 2018 in The Management of Acute Cholangitis and Acute CholecystitisIJAR JOURNALNo ratings yet

- 5 Enjoyable Corporate Fun 8798018Document9 pages5 Enjoyable Corporate Fun 8798018Omer MohaideenNo ratings yet

- Technology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingDocument22 pagesTechnology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingLIEZEL SERONDO75% (4)

- Lesson 4a. Officer-Violator RelationshipDocument3 pagesLesson 4a. Officer-Violator RelationshipalliahnahNo ratings yet

- Virgin America Brand GuidelinesDocument32 pagesVirgin America Brand Guidelinesnicoagudelo82No ratings yet

- Lab Report 1Document11 pagesLab Report 1Mohamed SaeedNo ratings yet

- Proposed Blended Learning Model For Don Mariano Marcos Memorial State University - South La Union Campus (Dmmmsu-Sluc)Document8 pagesProposed Blended Learning Model For Don Mariano Marcos Memorial State University - South La Union Campus (Dmmmsu-Sluc)Jose JarlathNo ratings yet

- 21st Century Literature From The Philippines and The World 1.1Document4 pages21st Century Literature From The Philippines and The World 1.1Kiefer SebastianNo ratings yet

- Hindi Basic HD 296.77 472.77 SD Channels & Services HD Channels & Services Total Channels & ServicesDocument2 pagesHindi Basic HD 296.77 472.77 SD Channels & Services HD Channels & Services Total Channels & ServicesRitesh JhaNo ratings yet

- Iot Project ProposalDocument7 pagesIot Project ProposalJames MondeloNo ratings yet

- ISE II Sample Paper 4 (With Answers)Document13 pagesISE II Sample Paper 4 (With Answers)Marta Navarro LópezNo ratings yet

- Cold in Place RecyclingDocument10 pagesCold in Place RecyclingRajesh ChoudharyNo ratings yet

- Diy Sls 3d PrinterDocument32 pagesDiy Sls 3d PrinterTF Escritório MGNo ratings yet