Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 viewsMaintenance: #E-Docket: QA105156

Maintenance: #E-Docket: QA105156

Uploaded by

Chaima Ben AliThe document is a maintenance report for four lifts (L7, L8, L9, L10) at a building in Doha, Qatar. It details the scheduled preventative maintenance tasks completed on each lift, which included checking indicators, buttons, doors, electrical equipment and replacing specific parts like the UPS unit. The technician notes that the maintenance was performed and the replaced UPS units are now working properly. The client did not provide any comments.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- M.manut. Casagrande B125Document283 pagesM.manut. Casagrande B125Augusto Oliveira100% (9)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Loop Check Sheet TransmitterDocument2 pagesLoop Check Sheet Transmittershanks263100% (2)

- DC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELDocument32 pagesDC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELBRAIYAM ALEXANDER MORENO VARGAS100% (1)

- Drift Test ProcedureDocument15 pagesDrift Test ProcedureNaPo ServiceNo ratings yet

- Annexure 4 - TransformerDocument36 pagesAnnexure 4 - TransformerBala MNo ratings yet

- 1 ShutoffDocument4 pages1 ShutoffAnonymous b5JnNafNo ratings yet

- Bus, Truck Manufacturing ProcessDocument11 pagesBus, Truck Manufacturing ProcessRavesh KaulNo ratings yet

- QA113263Document2 pagesQA113263Chaima Ben AliNo ratings yet

- QA111417Document3 pagesQA111417Chaima Ben AliNo ratings yet

- MD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFDocument11 pagesMD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFKarthikNo ratings yet

- At22 MaintenanceDocument37 pagesAt22 MaintenancefabuleukalengaNo ratings yet

- N17759-L-0146 (IB-127) Material Submittal-Pilot Operated Control Valve R..Document4 pagesN17759-L-0146 (IB-127) Material Submittal-Pilot Operated Control Valve R..unnicyriacNo ratings yet

- TL - 07 - 07-12 Microlink 3 Service BullitinDocument8 pagesTL - 07 - 07-12 Microlink 3 Service BullitinCristobal MartinezNo ratings yet

- Remote FunctionDocument7 pagesRemote FunctionlomejorNo ratings yet

- Callout: #E-Docket: QA126956Document2 pagesCallout: #E-Docket: QA126956Chaima Ben AliNo ratings yet

- ES-1019659182-0010 New International Airport Rwanda - WTCC10 PANEL TEST REPORT - R0Document15 pagesES-1019659182-0010 New International Airport Rwanda - WTCC10 PANEL TEST REPORT - R0Del KeefNo ratings yet

- Form No. 102A - Shutdown Valve 38Document2 pagesForm No. 102A - Shutdown Valve 38Victor NairNo ratings yet

- Loop Check Sheet Sol ValveDocument2 pagesLoop Check Sheet Sol Valveshanks263100% (1)

- VR Ink GR 000406492949 Pna117511 20231116Document5 pagesVR Ink GR 000406492949 Pna117511 20231116Rahul Kumar PaulNo ratings yet

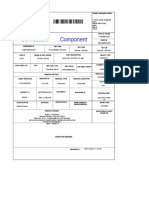

- Serviceable: ComponentDocument1 pageServiceable: ComponentFemi AgbanaNo ratings yet

- Elation Fuze Par z120 Ip - User ManualDocument30 pagesElation Fuze Par z120 Ip - User ManualkhaledNo ratings yet

- Greenheck DOAS Start-Up Report June2019Document19 pagesGreenheck DOAS Start-Up Report June2019DurgaNo ratings yet

- Mr-333272dailycheck - 1 100Document34 pagesMr-333272dailycheck - 1 100Tia MaiaNo ratings yet

- Ffianra: Existing ModificationDocument31 pagesFfianra: Existing ModificationGary ChanNo ratings yet

- Enodest ProtocoloDocument13 pagesEnodest Protocolonatalia rodriguezNo ratings yet

- Bus Coupler D130 Function Test: 1. General Data and InformationDocument7 pagesBus Coupler D130 Function Test: 1. General Data and InformationMushtaque Ahmed SoomroNo ratings yet

- Frontload Bill Validator Operation and Service Manual Testing and RepairDocument171 pagesFrontload Bill Validator Operation and Service Manual Testing and Repairpablo bulzomiNo ratings yet

- Near Miss 02-02-2022Document15 pagesNear Miss 02-02-2022Zeeshan AbbasiNo ratings yet

- P-28 Cargo Pumping System (1-4)Document281 pagesP-28 Cargo Pumping System (1-4)Raúl Oscar Ledesma100% (7)

- CL GL Hal Ni 208Document4 pagesCL GL Hal Ni 208LismiantoNo ratings yet

- D04Document7 pagesD04Ahmed SoomroNo ratings yet

- Spec Upt Page 41Document58 pagesSpec Upt Page 41midhunvarNo ratings yet

- CashCodeone QuickReference GuideDocument30 pagesCashCodeone QuickReference GuideDiego Alejandro GomezNo ratings yet

- Loop Test SheetDocument2 pagesLoop Test Sheetfadhlan hidayatNo ratings yet

- VAG-TED-F180-Iss02 Rev 00 Work Order FormDocument1 pageVAG-TED-F180-Iss02 Rev 00 Work Order FormPhạm Hà TiếnNo ratings yet

- Fw-Pump TbeDocument43 pagesFw-Pump TbeTeguh Setiono100% (1)

- A320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsDocument32 pagesA320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsnobertadilNo ratings yet

- CNM Cca - 76J006 G FinDocument409 pagesCNM Cca - 76J006 G FinvrajakisoriDasiNo ratings yet

- Spp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic CableDocument14 pagesSpp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic Cablechandrahai hrangkhawlNo ratings yet

- 5n-Lee - Serviceable TagDocument1 page5n-Lee - Serviceable TagFemi AgbanaNo ratings yet

- CHL-0714 60181509Document1 pageCHL-0714 60181509Femi AgbanaNo ratings yet

- Ceo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFDocument2 pagesCeo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFLE THAI HONG VINHNo ratings yet

- Yoke 2016Document12 pagesYoke 2016WalterNo ratings yet

- 1016-Itp 103Document3 pages1016-Itp 103yasser elhousseiniNo ratings yet

- 5117 CM 15052024Document2 pages5117 CM 15052024intikomrajaNo ratings yet

- Annex - of Manlift-Td106010 (Haulotte-230kg) - Amir Construction & Co, LTD (07!10!2022)Document4 pagesAnnex - of Manlift-Td106010 (Haulotte-230kg) - Amir Construction & Co, LTD (07!10!2022)sumit singhNo ratings yet

- QC-109 R0 End of Job ChecklistDocument1 pageQC-109 R0 End of Job ChecklistCamilo JorqueraNo ratings yet

- A0705260-Taa00001ne - 200512 Re17 Re17sDocument3 pagesA0705260-Taa00001ne - 200512 Re17 Re17saelbaroudy390No ratings yet

- MC 10209675 0001Document13 pagesMC 10209675 0001Олег ПетровскийNo ratings yet

- Ex8201 - Sos - Final Drive Pos 1 & 2Document2 pagesEx8201 - Sos - Final Drive Pos 1 & 2Reyner ChristianNo ratings yet

- CNM Cca676j001 G FinDocument669 pagesCNM Cca676j001 G FinvrajakisoriDasiNo ratings yet

- 0-WD210-ER630-00553 - Rev.2 - Steam Turbine Erection ProcedureDocument50 pages0-WD210-ER630-00553 - Rev.2 - Steam Turbine Erection ProcedureGustavo Andres Olivares Cerda100% (4)

- Approval - Ceiling Closure Witnessing FormDocument3 pagesApproval - Ceiling Closure Witnessing FormMAGDY SHOUSHANo ratings yet

- Ron ChecklistDocument10 pagesRon Checklistjesus angel miguel molinaNo ratings yet

- CNM Cca76j006 F Fin - FinDocument393 pagesCNM Cca76j006 F Fin - FinvrajakisoriDasiNo ratings yet

- SOP Stage-1 UPS FailureDocument4 pagesSOP Stage-1 UPS FailureNikhilNo ratings yet

- CSD100Document65 pagesCSD100HarshNo ratings yet

- Proton Onsite H Series 4 Generator Commissioning Report 1 of 6 Tsf1001 Rev ADocument6 pagesProton Onsite H Series 4 Generator Commissioning Report 1 of 6 Tsf1001 Rev Aanwar sadatNo ratings yet

- Elec. & Hydraulic Lift ChecklistDocument2 pagesElec. & Hydraulic Lift Checklistjillianix100% (1)

- Ferrovia Valvulas Solenoides-ParkerDocument20 pagesFerrovia Valvulas Solenoides-ParkerdcrispinNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Callout: #E-Docket: QA126956Document2 pagesCallout: #E-Docket: QA126956Chaima Ben AliNo ratings yet

- ZAS-056009 Packing List 231003Document2 pagesZAS-056009 Packing List 231003Chaima Ben AliNo ratings yet

- QA113263Document2 pagesQA113263Chaima Ben AliNo ratings yet

- QA111417Document3 pagesQA111417Chaima Ben AliNo ratings yet

- MOS For Machine Motor Bearing RepalcementDocument2 pagesMOS For Machine Motor Bearing RepalcementChaima Ben AliNo ratings yet

- M.S UPS InstallationDocument6 pagesM.S UPS InstallationChaima Ben AliNo ratings yet

- Method Statement Ver 2Document2 pagesMethod Statement Ver 2Chaima Ben AliNo ratings yet

- Loher Dynavert L03-04Document137 pagesLoher Dynavert L03-04Chaima Ben AliNo ratings yet

- Loher Dynalift - Eh AcvvDocument34 pagesLoher Dynalift - Eh AcvvChaima Ben AliNo ratings yet

- SWMS Worn Gear DriveDocument5 pagesSWMS Worn Gear DriveChaima Ben AliNo ratings yet

- Product Data Sheet: Standard Auxiliary Contact, Circuit Breaker Status OF/SD/SDE/SDV, 1 Changeover Contact TypeDocument2 pagesProduct Data Sheet: Standard Auxiliary Contact, Circuit Breaker Status OF/SD/SDE/SDV, 1 Changeover Contact TypeChaima Ben AliNo ratings yet

- Call Report: Thyssenkrupp Elevator QatarDocument6 pagesCall Report: Thyssenkrupp Elevator QatarChaima Ben AliNo ratings yet

- SCHNEIDER DAT - TeSysD Schuetze EN PDFDocument55 pagesSCHNEIDER DAT - TeSysD Schuetze EN PDFChaima Ben AliNo ratings yet

- Topics - Clutches, Belts and Ropes: Part - ADocument3 pagesTopics - Clutches, Belts and Ropes: Part - AramNo ratings yet

- Carb Disassembly 1988 Mazda B2600 PDFDocument2 pagesCarb Disassembly 1988 Mazda B2600 PDFdertyNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 407777-0128-E1Document35 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 407777-0128-E1JanisNo ratings yet

- Grinding Wheel Safety POSTER-BondedDocument2 pagesGrinding Wheel Safety POSTER-Bondedcha100% (1)

- 1971 Plymouth Body Service ManualDocument302 pages1971 Plymouth Body Service ManualСергей ФилипповNo ratings yet

- KNN 57 1506 2 - InstDocument2 pagesKNN 57 1506 2 - InsthavvkxjNo ratings yet

- 45 Series E Frame 100cc, 130cc, 147cc Parts Manual (520L0584)Document48 pages45 Series E Frame 100cc, 130cc, 147cc Parts Manual (520L0584)Sasko Dimitrov100% (4)

- Es WD Mea BD 1110Document1 pageEs WD Mea BD 1110sharoopNo ratings yet

- Anding Ollars: The Landing Collar (LC) Acts AsDocument1 pageAnding Ollars: The Landing Collar (LC) Acts AsGhinet Teodor-ioanNo ratings yet

- Cargo: C3E 100R C3E 130R C3E 150RDocument224 pagesCargo: C3E 100R C3E 130R C3E 150RalexsandrNo ratings yet

- Screw Jack Literature ReviewDocument8 pagesScrew Jack Literature Reviewc5q8g5tz100% (1)

- Pistons and Connecting Rods - Install: Cerrar SISDocument5 pagesPistons and Connecting Rods - Install: Cerrar SISHector VillegasNo ratings yet

- Bendix TABS-6 Standard and Premium Trailer ABS Controller ChecklistDocument4 pagesBendix TABS-6 Standard and Premium Trailer ABS Controller ChecklistErick CabezasNo ratings yet

- FenderDocument9 pagesFenderLaukik FegdeNo ratings yet

- Power+Take-Off+ (PTO) Eng 13 1858382Document22 pagesPower+Take-Off+ (PTO) Eng 13 1858382james100% (1)

- MitoDocument280 pagesMitoWoody FosterNo ratings yet

- Yanmar Mini Excavator SV15VT Service Manual MMB73ENMA00100Document376 pagesYanmar Mini Excavator SV15VT Service Manual MMB73ENMA00100gmpmorisNo ratings yet

- Instructions To Set Mechanical Governor (Static Governor Adjustment)Document4 pagesInstructions To Set Mechanical Governor (Static Governor Adjustment)Mar NicNo ratings yet

- Karta Katalogowa Rexroth KFADocument20 pagesKarta Katalogowa Rexroth KFASebastianNo ratings yet

- Superliner Specsheet NZ 2022Document4 pagesSuperliner Specsheet NZ 2022SanBre ChannelNo ratings yet

- PRAMAC - Service and Parts Online CenterDocument20 pagesPRAMAC - Service and Parts Online CenterChasiwat aksornpreechanonNo ratings yet

- RS X Part CatalogueDocument112 pagesRS X Part CatalogueEd RahmanNo ratings yet

- Body Repair: SectionDocument425 pagesBody Repair: SectionnyanhtunlimNo ratings yet

- A40F Hydraulic Pump Max Working Pressure Checking and AdjustingDocument5 pagesA40F Hydraulic Pump Max Working Pressure Checking and AdjustingErick Botha100% (1)

- Daftar Inventaris Materials Training EngineDocument20 pagesDaftar Inventaris Materials Training EngineLucyana PratamawatiNo ratings yet

- SAG - Automotive Servicing NC IDocument3 pagesSAG - Automotive Servicing NC IROJANE F. BERNAS, PhD.No ratings yet

- Assignment 4 Weatherproofing - 2021Document4 pagesAssignment 4 Weatherproofing - 2021Nisha PrakashNo ratings yet

- GM Customer Specific RequirementsDocument11 pagesGM Customer Specific Requirementscong daNo ratings yet

Maintenance: #E-Docket: QA105156

Maintenance: #E-Docket: QA105156

Uploaded by

Chaima Ben Ali0 ratings0% found this document useful (0 votes)

16 views3 pagesThe document is a maintenance report for four lifts (L7, L8, L9, L10) at a building in Doha, Qatar. It details the scheduled preventative maintenance tasks completed on each lift, which included checking indicators, buttons, doors, electrical equipment and replacing specific parts like the UPS unit. The technician notes that the maintenance was performed and the replaced UPS units are now working properly. The client did not provide any comments.

Original Description:

Original Title

QA105156 (3)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a maintenance report for four lifts (L7, L8, L9, L10) at a building in Doha, Qatar. It details the scheduled preventative maintenance tasks completed on each lift, which included checking indicators, buttons, doors, electrical equipment and replacing specific parts like the UPS unit. The technician notes that the maintenance was performed and the replaced UPS units are now working properly. The client did not provide any comments.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

16 views3 pagesMaintenance: #E-Docket: QA105156

Maintenance: #E-Docket: QA105156

Uploaded by

Chaima Ben AliThe document is a maintenance report for four lifts (L7, L8, L9, L10) at a building in Doha, Qatar. It details the scheduled preventative maintenance tasks completed on each lift, which included checking indicators, buttons, doors, electrical equipment and replacing specific parts like the UPS unit. The technician notes that the maintenance was performed and the replaced UPS units are now working properly. The client did not provide any comments.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

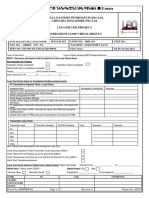

E-DOCKET

ﺍﻋﻤﺎﻝ ﺻﻴﺎﻧﺔ

N° e-docket : QA105156 page 1

Unit Gov ID EL 1775 Customer Name EMCO QATAR

Lift Number L7 Supervisor Name SUBHASH EDAKLAVAN KOYYATH

Unit Type Geared Branch Name DOH

Contract Number 10144/2304 Building Address DOHA

DOHA

ﺍﺳﻢ ﺍﻟﻤﺸﺮﻭﻉ QF NEW HQ

MAINTENANCE

Type of Visit SP2 + S

Operating Upon Departure the technician ﻧﻌﻢ

Task Set ﻣﺠﻤﻮﻋﺔ ﺍﻟﻤﻬﺎﻡ SP2 + S SP2 + S SP2 + S SP2 + S

Building/Block ﺑﻨﺎء/ﻣﺒﻨﻰ L7 L8 L9 L10

Unit ﺍﻟﻮﺣﺪﺓ EL 1775 EL 1776 EL 1777 EL 1778

AR - Arrival

Meet and advise site contact of arrival

and units to be serviced. Complete any

site log detail noting your arrival

Post "Lift Under Maintenance"

notification and safety barriers as

required

CL - Car and Landing Indicators and

Pushbuttons

Verify cabin interior, decor items, lighting

and TKE sticker status

Opening, closing and re-opening car

doors (photocells, safety edge, light

curtain, etc.)

Check control operation panel (COP)

push buttons, display indicator.

Check starting, stopping and levelling.

Observe simultaneous operation of

exterior doors on each floor

Observe clearances cabin with side

bearings and guides (cabin Play) at each

floor level.

Check Intercom and Emergency Lights

are working.

Check earth grounding

CT - Car Top and Shaft

Check cabin roof and accessories

(inspection box, guide shoes/rollers, door

operator cabin frame, Overload system,

electric/electronic devices etc.) /working

Check top final limit switches, top slow

down switches/working

Check the state, cleaning and

adjustments of the landing door

mechanisms and locks. Check interlocks

electrical / mechanical.

ME - Motor Room Equipment

Check safety gear function in Inspection

Speed

Observe operation of control panel and

tighten their power connections. Check

fuses status.

E-DOCKET

ﺍﻋﻤﺎﻝ ﺻﻴﺎﻧﺔ

N° e-docket : QA105156 page 2

Rest the cabin and counterweight on the

buffer to check the machine slippage.

PI - Pit

Verify general condition, cleanliness,

humidity, water leaks, etc. Trash

removal.

Inspect overspeed tension pulley state,

switch contact and lubrication.

Check stop switch and lighting switch pit.

Check final limit and slow down switches.

Check traction cable elongation. Check

state of buffers and counterweight

screen.

Check the lower guide shoe/rollers,

travelling cable and compensation chain

fixing. Manually actuate the safety gear

mechanism below the cabin

DE - Departure

Record landing doors checked

Ensure all safety jumpers are removed

and return unit to service

Remove all notifications and safety

barriers

Fully complete Service Docket with all

appropriate detail and required action

Meet site contact to overview detail of

Service Docket. Upon obtaining

signature, leave "customer" copy

Material Used ﺍﻟﻤﻮﺍﺩ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ L7 EL 1775-Geared: Replaced the UPS unit,

/Spare Parts Used ﻗﻄﻊ ﺍﻟﻐﻴﺎﺭ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ L8 EL 1776-Geared: Replaced UPS UNIT,

L9 EL 1777-Geared: Replaced OSG rope, replaced UPS,

L10 EL 1778-Geared: OSG rope, UPS

> Technician's comments and recommendations :

PPM is done, and replaced the UPS and testing the UPS is working good.

< ﺍﻟﻤﻮﺍﺩ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ

:

Replaced the UPS unit,

E-DOCKET

ﺍﻋﻤﺎﻝ ﺻﻴﺎﻧﺔ

N° e-docket : QA105156 page 3

CLIENT COMMENTS

N/A

TECHNICIAN SIGNATURE CLIENT SIGNATURE

ﻓﻨﻲ FELIMON BELVIS Time In ﻭﻗﺖ ﺍﻻﻧﺘﻬﺎﺀ ﻣﻦ ﺍﻟﻌﻤﻞ For the client

PATANO

ﺍﻟﺘﺎﺭﻳﺦ 12-12-2020

12-12-2020 08:01 12-12-2020 17:01

12-12-2020 17:01 12-12-2020 19:05

ﻻ ﻳﻮﺟﺪ ﺗﻮﻗﻴﻊ

Powered by TCPDF (www.tcpdf.org)

You might also like

- M.manut. Casagrande B125Document283 pagesM.manut. Casagrande B125Augusto Oliveira100% (9)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Loop Check Sheet TransmitterDocument2 pagesLoop Check Sheet Transmittershanks263100% (2)

- DC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELDocument32 pagesDC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELBRAIYAM ALEXANDER MORENO VARGAS100% (1)

- Drift Test ProcedureDocument15 pagesDrift Test ProcedureNaPo ServiceNo ratings yet

- Annexure 4 - TransformerDocument36 pagesAnnexure 4 - TransformerBala MNo ratings yet

- 1 ShutoffDocument4 pages1 ShutoffAnonymous b5JnNafNo ratings yet

- Bus, Truck Manufacturing ProcessDocument11 pagesBus, Truck Manufacturing ProcessRavesh KaulNo ratings yet

- QA113263Document2 pagesQA113263Chaima Ben AliNo ratings yet

- QA111417Document3 pagesQA111417Chaima Ben AliNo ratings yet

- MD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFDocument11 pagesMD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFKarthikNo ratings yet

- At22 MaintenanceDocument37 pagesAt22 MaintenancefabuleukalengaNo ratings yet

- N17759-L-0146 (IB-127) Material Submittal-Pilot Operated Control Valve R..Document4 pagesN17759-L-0146 (IB-127) Material Submittal-Pilot Operated Control Valve R..unnicyriacNo ratings yet

- TL - 07 - 07-12 Microlink 3 Service BullitinDocument8 pagesTL - 07 - 07-12 Microlink 3 Service BullitinCristobal MartinezNo ratings yet

- Remote FunctionDocument7 pagesRemote FunctionlomejorNo ratings yet

- Callout: #E-Docket: QA126956Document2 pagesCallout: #E-Docket: QA126956Chaima Ben AliNo ratings yet

- ES-1019659182-0010 New International Airport Rwanda - WTCC10 PANEL TEST REPORT - R0Document15 pagesES-1019659182-0010 New International Airport Rwanda - WTCC10 PANEL TEST REPORT - R0Del KeefNo ratings yet

- Form No. 102A - Shutdown Valve 38Document2 pagesForm No. 102A - Shutdown Valve 38Victor NairNo ratings yet

- Loop Check Sheet Sol ValveDocument2 pagesLoop Check Sheet Sol Valveshanks263100% (1)

- VR Ink GR 000406492949 Pna117511 20231116Document5 pagesVR Ink GR 000406492949 Pna117511 20231116Rahul Kumar PaulNo ratings yet

- Serviceable: ComponentDocument1 pageServiceable: ComponentFemi AgbanaNo ratings yet

- Elation Fuze Par z120 Ip - User ManualDocument30 pagesElation Fuze Par z120 Ip - User ManualkhaledNo ratings yet

- Greenheck DOAS Start-Up Report June2019Document19 pagesGreenheck DOAS Start-Up Report June2019DurgaNo ratings yet

- Mr-333272dailycheck - 1 100Document34 pagesMr-333272dailycheck - 1 100Tia MaiaNo ratings yet

- Ffianra: Existing ModificationDocument31 pagesFfianra: Existing ModificationGary ChanNo ratings yet

- Enodest ProtocoloDocument13 pagesEnodest Protocolonatalia rodriguezNo ratings yet

- Bus Coupler D130 Function Test: 1. General Data and InformationDocument7 pagesBus Coupler D130 Function Test: 1. General Data and InformationMushtaque Ahmed SoomroNo ratings yet

- Frontload Bill Validator Operation and Service Manual Testing and RepairDocument171 pagesFrontload Bill Validator Operation and Service Manual Testing and Repairpablo bulzomiNo ratings yet

- Near Miss 02-02-2022Document15 pagesNear Miss 02-02-2022Zeeshan AbbasiNo ratings yet

- P-28 Cargo Pumping System (1-4)Document281 pagesP-28 Cargo Pumping System (1-4)Raúl Oscar Ledesma100% (7)

- CL GL Hal Ni 208Document4 pagesCL GL Hal Ni 208LismiantoNo ratings yet

- D04Document7 pagesD04Ahmed SoomroNo ratings yet

- Spec Upt Page 41Document58 pagesSpec Upt Page 41midhunvarNo ratings yet

- CashCodeone QuickReference GuideDocument30 pagesCashCodeone QuickReference GuideDiego Alejandro GomezNo ratings yet

- Loop Test SheetDocument2 pagesLoop Test Sheetfadhlan hidayatNo ratings yet

- VAG-TED-F180-Iss02 Rev 00 Work Order FormDocument1 pageVAG-TED-F180-Iss02 Rev 00 Work Order FormPhạm Hà TiếnNo ratings yet

- Fw-Pump TbeDocument43 pagesFw-Pump TbeTeguh Setiono100% (1)

- A320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsDocument32 pagesA320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsnobertadilNo ratings yet

- CNM Cca - 76J006 G FinDocument409 pagesCNM Cca - 76J006 G FinvrajakisoriDasiNo ratings yet

- Spp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic CableDocument14 pagesSpp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic Cablechandrahai hrangkhawlNo ratings yet

- 5n-Lee - Serviceable TagDocument1 page5n-Lee - Serviceable TagFemi AgbanaNo ratings yet

- CHL-0714 60181509Document1 pageCHL-0714 60181509Femi AgbanaNo ratings yet

- Ceo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFDocument2 pagesCeo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFLE THAI HONG VINHNo ratings yet

- Yoke 2016Document12 pagesYoke 2016WalterNo ratings yet

- 1016-Itp 103Document3 pages1016-Itp 103yasser elhousseiniNo ratings yet

- 5117 CM 15052024Document2 pages5117 CM 15052024intikomrajaNo ratings yet

- Annex - of Manlift-Td106010 (Haulotte-230kg) - Amir Construction & Co, LTD (07!10!2022)Document4 pagesAnnex - of Manlift-Td106010 (Haulotte-230kg) - Amir Construction & Co, LTD (07!10!2022)sumit singhNo ratings yet

- QC-109 R0 End of Job ChecklistDocument1 pageQC-109 R0 End of Job ChecklistCamilo JorqueraNo ratings yet

- A0705260-Taa00001ne - 200512 Re17 Re17sDocument3 pagesA0705260-Taa00001ne - 200512 Re17 Re17saelbaroudy390No ratings yet

- MC 10209675 0001Document13 pagesMC 10209675 0001Олег ПетровскийNo ratings yet

- Ex8201 - Sos - Final Drive Pos 1 & 2Document2 pagesEx8201 - Sos - Final Drive Pos 1 & 2Reyner ChristianNo ratings yet

- CNM Cca676j001 G FinDocument669 pagesCNM Cca676j001 G FinvrajakisoriDasiNo ratings yet

- 0-WD210-ER630-00553 - Rev.2 - Steam Turbine Erection ProcedureDocument50 pages0-WD210-ER630-00553 - Rev.2 - Steam Turbine Erection ProcedureGustavo Andres Olivares Cerda100% (4)

- Approval - Ceiling Closure Witnessing FormDocument3 pagesApproval - Ceiling Closure Witnessing FormMAGDY SHOUSHANo ratings yet

- Ron ChecklistDocument10 pagesRon Checklistjesus angel miguel molinaNo ratings yet

- CNM Cca76j006 F Fin - FinDocument393 pagesCNM Cca76j006 F Fin - FinvrajakisoriDasiNo ratings yet

- SOP Stage-1 UPS FailureDocument4 pagesSOP Stage-1 UPS FailureNikhilNo ratings yet

- CSD100Document65 pagesCSD100HarshNo ratings yet

- Proton Onsite H Series 4 Generator Commissioning Report 1 of 6 Tsf1001 Rev ADocument6 pagesProton Onsite H Series 4 Generator Commissioning Report 1 of 6 Tsf1001 Rev Aanwar sadatNo ratings yet

- Elec. & Hydraulic Lift ChecklistDocument2 pagesElec. & Hydraulic Lift Checklistjillianix100% (1)

- Ferrovia Valvulas Solenoides-ParkerDocument20 pagesFerrovia Valvulas Solenoides-ParkerdcrispinNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Callout: #E-Docket: QA126956Document2 pagesCallout: #E-Docket: QA126956Chaima Ben AliNo ratings yet

- ZAS-056009 Packing List 231003Document2 pagesZAS-056009 Packing List 231003Chaima Ben AliNo ratings yet

- QA113263Document2 pagesQA113263Chaima Ben AliNo ratings yet

- QA111417Document3 pagesQA111417Chaima Ben AliNo ratings yet

- MOS For Machine Motor Bearing RepalcementDocument2 pagesMOS For Machine Motor Bearing RepalcementChaima Ben AliNo ratings yet

- M.S UPS InstallationDocument6 pagesM.S UPS InstallationChaima Ben AliNo ratings yet

- Method Statement Ver 2Document2 pagesMethod Statement Ver 2Chaima Ben AliNo ratings yet

- Loher Dynavert L03-04Document137 pagesLoher Dynavert L03-04Chaima Ben AliNo ratings yet

- Loher Dynalift - Eh AcvvDocument34 pagesLoher Dynalift - Eh AcvvChaima Ben AliNo ratings yet

- SWMS Worn Gear DriveDocument5 pagesSWMS Worn Gear DriveChaima Ben AliNo ratings yet

- Product Data Sheet: Standard Auxiliary Contact, Circuit Breaker Status OF/SD/SDE/SDV, 1 Changeover Contact TypeDocument2 pagesProduct Data Sheet: Standard Auxiliary Contact, Circuit Breaker Status OF/SD/SDE/SDV, 1 Changeover Contact TypeChaima Ben AliNo ratings yet

- Call Report: Thyssenkrupp Elevator QatarDocument6 pagesCall Report: Thyssenkrupp Elevator QatarChaima Ben AliNo ratings yet

- SCHNEIDER DAT - TeSysD Schuetze EN PDFDocument55 pagesSCHNEIDER DAT - TeSysD Schuetze EN PDFChaima Ben AliNo ratings yet

- Topics - Clutches, Belts and Ropes: Part - ADocument3 pagesTopics - Clutches, Belts and Ropes: Part - AramNo ratings yet

- Carb Disassembly 1988 Mazda B2600 PDFDocument2 pagesCarb Disassembly 1988 Mazda B2600 PDFdertyNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 407777-0128-E1Document35 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 407777-0128-E1JanisNo ratings yet

- Grinding Wheel Safety POSTER-BondedDocument2 pagesGrinding Wheel Safety POSTER-Bondedcha100% (1)

- 1971 Plymouth Body Service ManualDocument302 pages1971 Plymouth Body Service ManualСергей ФилипповNo ratings yet

- KNN 57 1506 2 - InstDocument2 pagesKNN 57 1506 2 - InsthavvkxjNo ratings yet

- 45 Series E Frame 100cc, 130cc, 147cc Parts Manual (520L0584)Document48 pages45 Series E Frame 100cc, 130cc, 147cc Parts Manual (520L0584)Sasko Dimitrov100% (4)

- Es WD Mea BD 1110Document1 pageEs WD Mea BD 1110sharoopNo ratings yet

- Anding Ollars: The Landing Collar (LC) Acts AsDocument1 pageAnding Ollars: The Landing Collar (LC) Acts AsGhinet Teodor-ioanNo ratings yet

- Cargo: C3E 100R C3E 130R C3E 150RDocument224 pagesCargo: C3E 100R C3E 130R C3E 150RalexsandrNo ratings yet

- Screw Jack Literature ReviewDocument8 pagesScrew Jack Literature Reviewc5q8g5tz100% (1)

- Pistons and Connecting Rods - Install: Cerrar SISDocument5 pagesPistons and Connecting Rods - Install: Cerrar SISHector VillegasNo ratings yet

- Bendix TABS-6 Standard and Premium Trailer ABS Controller ChecklistDocument4 pagesBendix TABS-6 Standard and Premium Trailer ABS Controller ChecklistErick CabezasNo ratings yet

- FenderDocument9 pagesFenderLaukik FegdeNo ratings yet

- Power+Take-Off+ (PTO) Eng 13 1858382Document22 pagesPower+Take-Off+ (PTO) Eng 13 1858382james100% (1)

- MitoDocument280 pagesMitoWoody FosterNo ratings yet

- Yanmar Mini Excavator SV15VT Service Manual MMB73ENMA00100Document376 pagesYanmar Mini Excavator SV15VT Service Manual MMB73ENMA00100gmpmorisNo ratings yet

- Instructions To Set Mechanical Governor (Static Governor Adjustment)Document4 pagesInstructions To Set Mechanical Governor (Static Governor Adjustment)Mar NicNo ratings yet

- Karta Katalogowa Rexroth KFADocument20 pagesKarta Katalogowa Rexroth KFASebastianNo ratings yet

- Superliner Specsheet NZ 2022Document4 pagesSuperliner Specsheet NZ 2022SanBre ChannelNo ratings yet

- PRAMAC - Service and Parts Online CenterDocument20 pagesPRAMAC - Service and Parts Online CenterChasiwat aksornpreechanonNo ratings yet

- RS X Part CatalogueDocument112 pagesRS X Part CatalogueEd RahmanNo ratings yet

- Body Repair: SectionDocument425 pagesBody Repair: SectionnyanhtunlimNo ratings yet

- A40F Hydraulic Pump Max Working Pressure Checking and AdjustingDocument5 pagesA40F Hydraulic Pump Max Working Pressure Checking and AdjustingErick Botha100% (1)

- Daftar Inventaris Materials Training EngineDocument20 pagesDaftar Inventaris Materials Training EngineLucyana PratamawatiNo ratings yet

- SAG - Automotive Servicing NC IDocument3 pagesSAG - Automotive Servicing NC IROJANE F. BERNAS, PhD.No ratings yet

- Assignment 4 Weatherproofing - 2021Document4 pagesAssignment 4 Weatherproofing - 2021Nisha PrakashNo ratings yet

- GM Customer Specific RequirementsDocument11 pagesGM Customer Specific Requirementscong daNo ratings yet