Professional Documents

Culture Documents

Distillation Rectification: Basic Knowledge Basic Knowledge

Distillation Rectification: Basic Knowledge Basic Knowledge

Uploaded by

Rohan lallCopyright:

Available Formats

You might also like

- MICEI Annual Report 2023Document40 pagesMICEI Annual Report 2023Hermes MATHEUSNo ratings yet

- Differentiated Reading for Comprehension, Grade 6From EverandDifferentiated Reading for Comprehension, Grade 6Rating: 5 out of 5 stars5/5 (2)

- 51 Parex ProcessDocument2 pages51 Parex Processbengris100% (2)

- Pte Prep Tips-Compiled From Expat ForumDocument12 pagesPte Prep Tips-Compiled From Expat ForumRaja TouseefNo ratings yet

- Simple and Fractional Distillation Repaired)Document4 pagesSimple and Fractional Distillation Repaired)Janine LauretaNo ratings yet

- Chapter 2 DistillationDocument77 pagesChapter 2 DistillationAhmad DanialNo ratings yet

- 00 - Separation TechnologyDocument19 pages00 - Separation TechnologyVicente RegulezNo ratings yet

- Program Studi Teknik Kimia Fakultas Teknologi Industri Universitas Pertamina Jakarta 2019Document5 pagesProgram Studi Teknik Kimia Fakultas Teknologi Industri Universitas Pertamina Jakarta 2019Andrian PratamaNo ratings yet

- AMSOIL Synthetic Stationary Natural Gas Engine Oil ANGSDocument2 pagesAMSOIL Synthetic Stationary Natural Gas Engine Oil ANGSamsoildealerNo ratings yet

- Lab Report 4 Group 4Document19 pagesLab Report 4 Group 42023389329No ratings yet

- Destilation Column InfoDocument33 pagesDestilation Column InfokumarNo ratings yet

- Technip Separations PDFDocument60 pagesTechnip Separations PDFProcess EngineerNo ratings yet

- Lab Report Experiment 6 (g13)Document13 pagesLab Report Experiment 6 (g13)Ahmad Mu'azNo ratings yet

- Technological Institute of The Philippines - Manila (CHEP 510L1, 2 Semester, SY 2015-2016)Document4 pagesTechnological Institute of The Philippines - Manila (CHEP 510L1, 2 Semester, SY 2015-2016)Sharmaine RoseNo ratings yet

- Pentavitin Brochure The Smart Moisturizer From Head To Toe 2022 03Document6 pagesPentavitin Brochure The Smart Moisturizer From Head To Toe 2022 03Dermofarm FarmaciaNo ratings yet

- Lab Exercise No. 10 Urinary SystemDocument2 pagesLab Exercise No. 10 Urinary SystemNATALIE NICOLE GABASNo ratings yet

- Cap 9 InglesDocument54 pagesCap 9 InglesPedroTiconaNo ratings yet

- F125-5708 T685WS-D Hydraulic DiagramDocument3 pagesF125-5708 T685WS-D Hydraulic DiagramDaniel M. SandovalNo ratings yet

- Rectificacion TequilaDocument8 pagesRectificacion TequilaAldo UrielNo ratings yet

- Hydrate Formation Countering in An NGL Recovery UnitDocument6 pagesHydrate Formation Countering in An NGL Recovery UnitRicardo BecNo ratings yet

- PG 4&5-StudentsDocument2 pagesPG 4&5-StudentsShavonne LaiNo ratings yet

- PG 4&5-StudentsDocument2 pagesPG 4&5-StudentsShavonne LaiNo ratings yet

- Yechun ZhangDocument20 pagesYechun ZhangJorge Andres RiveraNo ratings yet

- Your Single Source Worldwide: Isolated Phase Bus SystemsDocument15 pagesYour Single Source Worldwide: Isolated Phase Bus Systemssameerray12100% (1)

- BAC Evaporative CondensersDocument12 pagesBAC Evaporative CondensersKONARASKI1982No ratings yet

- SyedmujahedalirizwanDocument6 pagesSyedmujahedalirizwanVictor VazquezNo ratings yet

- IFPEXOLDocument10 pagesIFPEXOLMicaela Flores LanzaNo ratings yet

- Distillation Basics: Dharmsinh Desai UniversityDocument20 pagesDistillation Basics: Dharmsinh Desai UniversityGilles DakouriNo ratings yet

- WLP Science q1 w7 LandscapeDocument17 pagesWLP Science q1 w7 LandscapeJayral PradesNo ratings yet

- Cagnini Front-Mulcher-En-Cat24Document1 pageCagnini Front-Mulcher-En-Cat24Kft. Progép-TechnikaNo ratings yet

- Mto-2 Oep (30,31,32)Document1 pageMto-2 Oep (30,31,32)Nayan ParmarNo ratings yet

- CH04PDocument35 pagesCH04Pkiran367No ratings yet

- Distillation Handbook 10004 01-08-2008 USDocument52 pagesDistillation Handbook 10004 01-08-2008 USSumit SinghNo ratings yet

- PT 4 - CatangalaDocument1 pagePT 4 - Catangalafeliciano soaresNo ratings yet

- Desenho MTDocument1 pageDesenho MTfeliciano soaresNo ratings yet

- WLP Science q1 w7w8 LandscapeDocument13 pagesWLP Science q1 w7w8 LandscapeJayral PradesNo ratings yet

- Distillation Is Defined As:: How Does Distillation Work?Document35 pagesDistillation Is Defined As:: How Does Distillation Work?sankalpnambiarNo ratings yet

- Article 1652173631Document7 pagesArticle 1652173631Shiena AscueNo ratings yet

- Sheet 6 PDFDocument1 pageSheet 6 PDFudhav cNo ratings yet

- Wilo 352996Document21 pagesWilo 352996John Rodolfo BultronNo ratings yet

- Neat CellDocument2 pagesNeat CellAngel David Bohórquez LópezNo ratings yet

- Soluble Fraction Analysis in Polypropylene For QCDocument2 pagesSoluble Fraction Analysis in Polypropylene For QCParom WaikasikarnNo ratings yet

- CEV452 Lab 2 Distillation ColumnDocument22 pagesCEV452 Lab 2 Distillation ColumnAjlaa Rahim100% (1)

- Deh-Sweet GasDocument25 pagesDeh-Sweet Gasamr ezzat100% (1)

- 1 s2.0 S0016236121022651 MainDocument7 pages1 s2.0 S0016236121022651 MainSummer NightNo ratings yet

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDocument1 pagePoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswNo ratings yet

- L-Series: The New Standard For Helium Liquefiers and RefrigeratorsDocument6 pagesL-Series: The New Standard For Helium Liquefiers and Refrigeratorsait oubella marouaneNo ratings yet

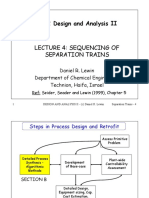

- Design and Analysis II: Lecture 4: Sequencing of Separation TrainsDocument35 pagesDesign and Analysis II: Lecture 4: Sequencing of Separation TrainsKHUSHBU BHALODIYANo ratings yet

- Distillation TypesDocument30 pagesDistillation Typesrmksna0% (1)

- Past Simple - CrosswordsDocument2 pagesPast Simple - CrosswordsPaula Sapo33% (3)

- Sequencing of Separation TrainsDocument35 pagesSequencing of Separation TrainsMohamed AliNo ratings yet

- Ode-BrewGrinder QuickStartGuideDocument5 pagesOde-BrewGrinder QuickStartGuideAlpNo ratings yet

- Low Pressure Valve PDFDocument285 pagesLow Pressure Valve PDFThái Mai ĐìnhNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Adverb English PresentationDocument17 pagesAdverb English PresentationRohan lallNo ratings yet

- Unit 10 EquilibriaDocument23 pagesUnit 10 EquilibriaRohan lallNo ratings yet

- Woolford Avenue Non-Pariel Park Georgetown GuyanaDocument1 pageWoolford Avenue Non-Pariel Park Georgetown GuyanaRohan lallNo ratings yet

- Subject RegisteredDocument3 pagesSubject RegisteredRohan lallNo ratings yet

- 2023 Sterling Application PDFDocument2 pages2023 Sterling Application PDFRohan lallNo ratings yet

- Steam TurbineDocument3 pagesSteam TurbineRohan lallNo ratings yet

- Refrigeration & Air Conditioning: The Craft ofDocument2 pagesRefrigeration & Air Conditioning: The Craft ofRohan lallNo ratings yet

- Abb Ultrasonic Level lst300 lst400 BrochureDocument8 pagesAbb Ultrasonic Level lst300 lst400 BrochureRohan lallNo ratings yet

- 0 0 121131122212131RAdditionalAttachmentsDocument31 pages0 0 121131122212131RAdditionalAttachmentsRohan lallNo ratings yet

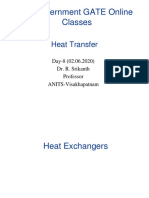

- AP Government GATE Online Classes: Heat TransferDocument88 pagesAP Government GATE Online Classes: Heat TransferRohan lallNo ratings yet

- Control,: OptimizationDocument5 pagesControl,: OptimizationRohan lallNo ratings yet

- Novel Batch Distillation Processes For The Separation of Systems With and Without Chemical ReactionDocument109 pagesNovel Batch Distillation Processes For The Separation of Systems With and Without Chemical ReactionRohan lallNo ratings yet

- Mathematics Actual SBaDocument8 pagesMathematics Actual SBaRohan lall100% (1)

- Mathematics Actual SBaDocument2 pagesMathematics Actual SBaRohan lall78% (9)

- Economics NotesDocument80 pagesEconomics NotesRohan lallNo ratings yet

- DLL - Mapeh 3 - Q1 - W7Document5 pagesDLL - Mapeh 3 - Q1 - W7ADONNIS PESCASIONo ratings yet

- Art 1Document6 pagesArt 1Cristina VladutaNo ratings yet

- LC GCDocument23 pagesLC GCEsra'A Subhi Sabri QasemNo ratings yet

- 1998 Seadoo GSX Op GuideDocument11 pages1998 Seadoo GSX Op GuideJosé HernándezNo ratings yet

- Honeywell 5800CO Data SheetDocument4 pagesHoneywell 5800CO Data SheetAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- RENOLD (Worm Gear - Models PH)Document60 pagesRENOLD (Worm Gear - Models PH)Rodrigo Leal GuzmanNo ratings yet

- Peritoneal DialysisDocument3 pagesPeritoneal DialysisGoh Kek BoonNo ratings yet

- Autoclave - Kaizen ImperialDocument3 pagesAutoclave - Kaizen ImperialAnaThomasNo ratings yet

- CL312: Computer Aided Process Equipment DesignDocument11 pagesCL312: Computer Aided Process Equipment DesignWilliam AdamsNo ratings yet

- Kingfisher BeerDocument41 pagesKingfisher BeersatyashilsNo ratings yet

- Guidance and Testing Office Individual Inventory: To The StudentsDocument4 pagesGuidance and Testing Office Individual Inventory: To The StudentsJenna FriasNo ratings yet

- Discussion Q1Document7 pagesDiscussion Q1TASHANo ratings yet

- Finefocus 800: Instruction ManualDocument64 pagesFinefocus 800: Instruction ManualMURAT ORMANNo ratings yet

- (Cbse Main Iit) I PCMC N Ipl Cbse Super Chaina 22.04.2024Document10 pages(Cbse Main Iit) I PCMC N Ipl Cbse Super Chaina 22.04.2024r.selvakumaran2007No ratings yet

- Sample Clinical Pharmacy CaseDocument41 pagesSample Clinical Pharmacy CaseLouie Fernand LegaspiNo ratings yet

- A Literature Study On Agricultural Production System Using Iot As Inclusive TechnologyDocument5 pagesA Literature Study On Agricultural Production System Using Iot As Inclusive Technologyabcd efghNo ratings yet

- 2.TECHNICAL PROPOSAL For Scope Study of Compensation For Survivors of Sexual and GBVDocument32 pages2.TECHNICAL PROPOSAL For Scope Study of Compensation For Survivors of Sexual and GBVTaufiq Us Samad TonmoyNo ratings yet

- Unit 7 - Assignment - Fictional CharactersDocument6 pagesUnit 7 - Assignment - Fictional Charactersapi-493788043No ratings yet

- Lect2 Anes Drugs PDFDocument109 pagesLect2 Anes Drugs PDFJidapa SEELADEENo ratings yet

- Remdesivir Injection's Distributor List of CiplaDocument20 pagesRemdesivir Injection's Distributor List of CiplaRahulSahujiNo ratings yet

- Notice of Non Consent LiabilityDocument3 pagesNotice of Non Consent LiabilityandrewmmwilmotNo ratings yet

- Delayed-Action AcceleratorDocument3 pagesDelayed-Action AcceleratorMOHD FIRDAUSNo ratings yet

- Exhibition Calendar 20-21Document2 pagesExhibition Calendar 20-21AwaisNo ratings yet

- Calamities in PhilippinesDocument44 pagesCalamities in PhilippinesMic BaldevaronaNo ratings yet

- Manejo de Suelos Salinos y SodicoDocument189 pagesManejo de Suelos Salinos y SodicoJean Marco Gozme AcostaNo ratings yet

- CPG - Management of AcneDocument97 pagesCPG - Management of Acneumiraihana1No ratings yet

- An Analysis On Maternity Benefit Laws of BangladeshDocument33 pagesAn Analysis On Maternity Benefit Laws of Bangladeshayesha.siddika.241No ratings yet

Distillation Rectification: Basic Knowledge Basic Knowledge

Distillation Rectification: Basic Knowledge Basic Knowledge

Uploaded by

Rohan lallOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distillation Rectification: Basic Knowledge Basic Knowledge

Distillation Rectification: Basic Knowledge Basic Knowledge

Uploaded by

Rohan lallCopyright:

Available Formats

4 Thermal process engineering

Distillation/Rectification

gunt

Basic knowledge Basic knowledge

Distillation Rectification

Distillation is a unit operation that can be used to separate into the gas phase. Examples of volatile liquids include acetone, Rectification is an application of distillation. It is used for sub- In practice, this multi-stage distillation process is carried out

homogeneous liquid mixtures. It utilises the different volatility of alcohol and petrol. stances that are required in high purity and/or large quantities, in the form of countercurrent distillation (rectification) in a

the components of the mixture to be separated. Volatility refers for example to fractionate crude oil. column.

to the tendency of a substance to pass from the liquid phase

If the distillate obtained during distillation is distilled again, a

new distillate is obtained with an even higher concentration of

volatile components. As the procedure is repeated, the concen-

tration of volatile components in the distillate increases on each

occasion.

Principle of distillation Simplified illustration of a rectification column

7

6

3

10 9

8

2

11

1 4

The liquid mixture to be separated (feed) is fed to the col-

umn and partially evaporates on its way to the bottom of the

column where it is heated to boiling. The vapour produced

1 moves upwards inside the column, exits it at the top and is

condensed. Part of the condensate is carried away as top

product. The remainder flows back into the column and moves

5 downwards as liquid phase.

Due to column internals, such as bubble cap trays or ran-

dom packings, the downward-moving liquid phase is sub-

jected to an intensive exchange of heat and material with the

upward-moving vapour phase. The less volatile components

1 boiling liquid mixture, 2 upward-moving vapour phase, of the vapour phase condense and increase in concentration

3 condenser, 4 distillate in the liquid phase. At the same time, the condensation heat

released evaporates the more volatile components of the liq-

uid phase. These processes in the column increase the vapour

To achieve separation, the liquid mixture is brought to boil- The separating principle is based on the fact that the content phase concentration of volatile components moving from the

ing point. The resulting vapour phase is made up of several of volatile components is greater in the vapour phase than in bottom to the top of the column. The liquid phase concen-

components, mainly the more volatile components of the mix- the liquid phase. 3 tration of less volatile components increases in the opposite

ture. The vapour phase is separated from the liquid phase and direction, from the top of the column to the bottom.

condensed (distillate). The less volatile components predomi- 2

4

nantly remain in the liquid phase.

Distillation does not result in complete separation of the liq-

uid mixture, but rather its division into two mixtures with 1 feed, 2 bottom of column, 3 bottom heating, 4 bottom product, 5 upward-moving vapour phase, 6 top of column, 7 condenser,

different contents of volatile and less volatile components. 8 top product, 9 reflux, 10 downward-moving liquid phase, 11 tray (here: bubble cap tray)

294 295

You might also like

- MICEI Annual Report 2023Document40 pagesMICEI Annual Report 2023Hermes MATHEUSNo ratings yet

- Differentiated Reading for Comprehension, Grade 6From EverandDifferentiated Reading for Comprehension, Grade 6Rating: 5 out of 5 stars5/5 (2)

- 51 Parex ProcessDocument2 pages51 Parex Processbengris100% (2)

- Pte Prep Tips-Compiled From Expat ForumDocument12 pagesPte Prep Tips-Compiled From Expat ForumRaja TouseefNo ratings yet

- Simple and Fractional Distillation Repaired)Document4 pagesSimple and Fractional Distillation Repaired)Janine LauretaNo ratings yet

- Chapter 2 DistillationDocument77 pagesChapter 2 DistillationAhmad DanialNo ratings yet

- 00 - Separation TechnologyDocument19 pages00 - Separation TechnologyVicente RegulezNo ratings yet

- Program Studi Teknik Kimia Fakultas Teknologi Industri Universitas Pertamina Jakarta 2019Document5 pagesProgram Studi Teknik Kimia Fakultas Teknologi Industri Universitas Pertamina Jakarta 2019Andrian PratamaNo ratings yet

- AMSOIL Synthetic Stationary Natural Gas Engine Oil ANGSDocument2 pagesAMSOIL Synthetic Stationary Natural Gas Engine Oil ANGSamsoildealerNo ratings yet

- Lab Report 4 Group 4Document19 pagesLab Report 4 Group 42023389329No ratings yet

- Destilation Column InfoDocument33 pagesDestilation Column InfokumarNo ratings yet

- Technip Separations PDFDocument60 pagesTechnip Separations PDFProcess EngineerNo ratings yet

- Lab Report Experiment 6 (g13)Document13 pagesLab Report Experiment 6 (g13)Ahmad Mu'azNo ratings yet

- Technological Institute of The Philippines - Manila (CHEP 510L1, 2 Semester, SY 2015-2016)Document4 pagesTechnological Institute of The Philippines - Manila (CHEP 510L1, 2 Semester, SY 2015-2016)Sharmaine RoseNo ratings yet

- Pentavitin Brochure The Smart Moisturizer From Head To Toe 2022 03Document6 pagesPentavitin Brochure The Smart Moisturizer From Head To Toe 2022 03Dermofarm FarmaciaNo ratings yet

- Lab Exercise No. 10 Urinary SystemDocument2 pagesLab Exercise No. 10 Urinary SystemNATALIE NICOLE GABASNo ratings yet

- Cap 9 InglesDocument54 pagesCap 9 InglesPedroTiconaNo ratings yet

- F125-5708 T685WS-D Hydraulic DiagramDocument3 pagesF125-5708 T685WS-D Hydraulic DiagramDaniel M. SandovalNo ratings yet

- Rectificacion TequilaDocument8 pagesRectificacion TequilaAldo UrielNo ratings yet

- Hydrate Formation Countering in An NGL Recovery UnitDocument6 pagesHydrate Formation Countering in An NGL Recovery UnitRicardo BecNo ratings yet

- PG 4&5-StudentsDocument2 pagesPG 4&5-StudentsShavonne LaiNo ratings yet

- PG 4&5-StudentsDocument2 pagesPG 4&5-StudentsShavonne LaiNo ratings yet

- Yechun ZhangDocument20 pagesYechun ZhangJorge Andres RiveraNo ratings yet

- Your Single Source Worldwide: Isolated Phase Bus SystemsDocument15 pagesYour Single Source Worldwide: Isolated Phase Bus Systemssameerray12100% (1)

- BAC Evaporative CondensersDocument12 pagesBAC Evaporative CondensersKONARASKI1982No ratings yet

- SyedmujahedalirizwanDocument6 pagesSyedmujahedalirizwanVictor VazquezNo ratings yet

- IFPEXOLDocument10 pagesIFPEXOLMicaela Flores LanzaNo ratings yet

- Distillation Basics: Dharmsinh Desai UniversityDocument20 pagesDistillation Basics: Dharmsinh Desai UniversityGilles DakouriNo ratings yet

- WLP Science q1 w7 LandscapeDocument17 pagesWLP Science q1 w7 LandscapeJayral PradesNo ratings yet

- Cagnini Front-Mulcher-En-Cat24Document1 pageCagnini Front-Mulcher-En-Cat24Kft. Progép-TechnikaNo ratings yet

- Mto-2 Oep (30,31,32)Document1 pageMto-2 Oep (30,31,32)Nayan ParmarNo ratings yet

- CH04PDocument35 pagesCH04Pkiran367No ratings yet

- Distillation Handbook 10004 01-08-2008 USDocument52 pagesDistillation Handbook 10004 01-08-2008 USSumit SinghNo ratings yet

- PT 4 - CatangalaDocument1 pagePT 4 - Catangalafeliciano soaresNo ratings yet

- Desenho MTDocument1 pageDesenho MTfeliciano soaresNo ratings yet

- WLP Science q1 w7w8 LandscapeDocument13 pagesWLP Science q1 w7w8 LandscapeJayral PradesNo ratings yet

- Distillation Is Defined As:: How Does Distillation Work?Document35 pagesDistillation Is Defined As:: How Does Distillation Work?sankalpnambiarNo ratings yet

- Article 1652173631Document7 pagesArticle 1652173631Shiena AscueNo ratings yet

- Sheet 6 PDFDocument1 pageSheet 6 PDFudhav cNo ratings yet

- Wilo 352996Document21 pagesWilo 352996John Rodolfo BultronNo ratings yet

- Neat CellDocument2 pagesNeat CellAngel David Bohórquez LópezNo ratings yet

- Soluble Fraction Analysis in Polypropylene For QCDocument2 pagesSoluble Fraction Analysis in Polypropylene For QCParom WaikasikarnNo ratings yet

- CEV452 Lab 2 Distillation ColumnDocument22 pagesCEV452 Lab 2 Distillation ColumnAjlaa Rahim100% (1)

- Deh-Sweet GasDocument25 pagesDeh-Sweet Gasamr ezzat100% (1)

- 1 s2.0 S0016236121022651 MainDocument7 pages1 s2.0 S0016236121022651 MainSummer NightNo ratings yet

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDocument1 pagePoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswNo ratings yet

- L-Series: The New Standard For Helium Liquefiers and RefrigeratorsDocument6 pagesL-Series: The New Standard For Helium Liquefiers and Refrigeratorsait oubella marouaneNo ratings yet

- Design and Analysis II: Lecture 4: Sequencing of Separation TrainsDocument35 pagesDesign and Analysis II: Lecture 4: Sequencing of Separation TrainsKHUSHBU BHALODIYANo ratings yet

- Distillation TypesDocument30 pagesDistillation Typesrmksna0% (1)

- Past Simple - CrosswordsDocument2 pagesPast Simple - CrosswordsPaula Sapo33% (3)

- Sequencing of Separation TrainsDocument35 pagesSequencing of Separation TrainsMohamed AliNo ratings yet

- Ode-BrewGrinder QuickStartGuideDocument5 pagesOde-BrewGrinder QuickStartGuideAlpNo ratings yet

- Low Pressure Valve PDFDocument285 pagesLow Pressure Valve PDFThái Mai ĐìnhNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Adverb English PresentationDocument17 pagesAdverb English PresentationRohan lallNo ratings yet

- Unit 10 EquilibriaDocument23 pagesUnit 10 EquilibriaRohan lallNo ratings yet

- Woolford Avenue Non-Pariel Park Georgetown GuyanaDocument1 pageWoolford Avenue Non-Pariel Park Georgetown GuyanaRohan lallNo ratings yet

- Subject RegisteredDocument3 pagesSubject RegisteredRohan lallNo ratings yet

- 2023 Sterling Application PDFDocument2 pages2023 Sterling Application PDFRohan lallNo ratings yet

- Steam TurbineDocument3 pagesSteam TurbineRohan lallNo ratings yet

- Refrigeration & Air Conditioning: The Craft ofDocument2 pagesRefrigeration & Air Conditioning: The Craft ofRohan lallNo ratings yet

- Abb Ultrasonic Level lst300 lst400 BrochureDocument8 pagesAbb Ultrasonic Level lst300 lst400 BrochureRohan lallNo ratings yet

- 0 0 121131122212131RAdditionalAttachmentsDocument31 pages0 0 121131122212131RAdditionalAttachmentsRohan lallNo ratings yet

- AP Government GATE Online Classes: Heat TransferDocument88 pagesAP Government GATE Online Classes: Heat TransferRohan lallNo ratings yet

- Control,: OptimizationDocument5 pagesControl,: OptimizationRohan lallNo ratings yet

- Novel Batch Distillation Processes For The Separation of Systems With and Without Chemical ReactionDocument109 pagesNovel Batch Distillation Processes For The Separation of Systems With and Without Chemical ReactionRohan lallNo ratings yet

- Mathematics Actual SBaDocument8 pagesMathematics Actual SBaRohan lall100% (1)

- Mathematics Actual SBaDocument2 pagesMathematics Actual SBaRohan lall78% (9)

- Economics NotesDocument80 pagesEconomics NotesRohan lallNo ratings yet

- DLL - Mapeh 3 - Q1 - W7Document5 pagesDLL - Mapeh 3 - Q1 - W7ADONNIS PESCASIONo ratings yet

- Art 1Document6 pagesArt 1Cristina VladutaNo ratings yet

- LC GCDocument23 pagesLC GCEsra'A Subhi Sabri QasemNo ratings yet

- 1998 Seadoo GSX Op GuideDocument11 pages1998 Seadoo GSX Op GuideJosé HernándezNo ratings yet

- Honeywell 5800CO Data SheetDocument4 pagesHoneywell 5800CO Data SheetAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- RENOLD (Worm Gear - Models PH)Document60 pagesRENOLD (Worm Gear - Models PH)Rodrigo Leal GuzmanNo ratings yet

- Peritoneal DialysisDocument3 pagesPeritoneal DialysisGoh Kek BoonNo ratings yet

- Autoclave - Kaizen ImperialDocument3 pagesAutoclave - Kaizen ImperialAnaThomasNo ratings yet

- CL312: Computer Aided Process Equipment DesignDocument11 pagesCL312: Computer Aided Process Equipment DesignWilliam AdamsNo ratings yet

- Kingfisher BeerDocument41 pagesKingfisher BeersatyashilsNo ratings yet

- Guidance and Testing Office Individual Inventory: To The StudentsDocument4 pagesGuidance and Testing Office Individual Inventory: To The StudentsJenna FriasNo ratings yet

- Discussion Q1Document7 pagesDiscussion Q1TASHANo ratings yet

- Finefocus 800: Instruction ManualDocument64 pagesFinefocus 800: Instruction ManualMURAT ORMANNo ratings yet

- (Cbse Main Iit) I PCMC N Ipl Cbse Super Chaina 22.04.2024Document10 pages(Cbse Main Iit) I PCMC N Ipl Cbse Super Chaina 22.04.2024r.selvakumaran2007No ratings yet

- Sample Clinical Pharmacy CaseDocument41 pagesSample Clinical Pharmacy CaseLouie Fernand LegaspiNo ratings yet

- A Literature Study On Agricultural Production System Using Iot As Inclusive TechnologyDocument5 pagesA Literature Study On Agricultural Production System Using Iot As Inclusive Technologyabcd efghNo ratings yet

- 2.TECHNICAL PROPOSAL For Scope Study of Compensation For Survivors of Sexual and GBVDocument32 pages2.TECHNICAL PROPOSAL For Scope Study of Compensation For Survivors of Sexual and GBVTaufiq Us Samad TonmoyNo ratings yet

- Unit 7 - Assignment - Fictional CharactersDocument6 pagesUnit 7 - Assignment - Fictional Charactersapi-493788043No ratings yet

- Lect2 Anes Drugs PDFDocument109 pagesLect2 Anes Drugs PDFJidapa SEELADEENo ratings yet

- Remdesivir Injection's Distributor List of CiplaDocument20 pagesRemdesivir Injection's Distributor List of CiplaRahulSahujiNo ratings yet

- Notice of Non Consent LiabilityDocument3 pagesNotice of Non Consent LiabilityandrewmmwilmotNo ratings yet

- Delayed-Action AcceleratorDocument3 pagesDelayed-Action AcceleratorMOHD FIRDAUSNo ratings yet

- Exhibition Calendar 20-21Document2 pagesExhibition Calendar 20-21AwaisNo ratings yet

- Calamities in PhilippinesDocument44 pagesCalamities in PhilippinesMic BaldevaronaNo ratings yet

- Manejo de Suelos Salinos y SodicoDocument189 pagesManejo de Suelos Salinos y SodicoJean Marco Gozme AcostaNo ratings yet

- CPG - Management of AcneDocument97 pagesCPG - Management of Acneumiraihana1No ratings yet

- An Analysis On Maternity Benefit Laws of BangladeshDocument33 pagesAn Analysis On Maternity Benefit Laws of Bangladeshayesha.siddika.241No ratings yet