Professional Documents

Culture Documents

8948 Rev1 Milton WSG001 Eng SH2 1

8948 Rev1 Milton WSG001 Eng SH2 1

Uploaded by

tshepo hlakudiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8948 Rev1 Milton WSG001 Eng SH2 1

8948 Rev1 Milton WSG001 Eng SH2 1

Uploaded by

tshepo hlakudiCopyright:

Available Formats

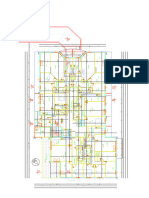

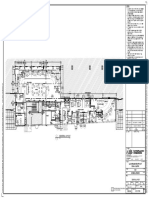

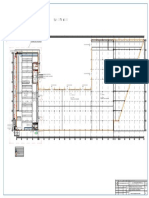

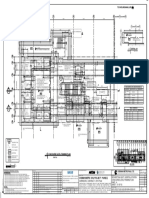

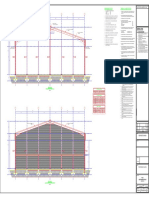

ALL AND LEVELS ARE TO BE VERIFIED ON SITE BY THE

CONTRACTOR BEFORE COMMENCING ANY WORK.

1 2 3 4 5 6 7 1 2 3 4 5 6 7 1 2 3 4 5 6 7

27160

27160 27160

13580 13580

13580 13580 13580 13580

4527 4527 4527 4527 4527 4527

4527 4527 4527 4527 4527 4527 4527 4527 4527 4527 4527 4527

FT001 FT001 FT001 FT001 FT001 FT001 FT001 1509 1509 1509 1509 1509 1509 1509 1509 1429 80 80 1429 1509 1509 1509 1509 1509 1509 1509 1509

C001 C002 C003 C004 C003 C002 C001

C001 C002 C003 C004 C003 C002 C001 C001 C002 C003 C004 RT001 C003 C002 C001

A A IJ IJ IJ IJ IJ IJ

A

BC001

BC001

BC001

BC001

BC001

BC001

IJ

IJ

IJ

IJ

WSG-100 WSG-100 WSG-100 WSG-100 WSG-100 WSG-100

SCJ

SCJ

SCJ

SCJ

1 1 1 1 1 1

5343

5343

5343

IJ IJ

FT001 FT001

C001 C001 C001

IJ IJ IJ

C001 C001 RT001 C001 GENERAL NOTES

B B B

IJ IJ 1.0 SETTING OUT AND GENERAL

IJ IJ 1.1 ALL WORK TO BE DONE IN ACCORDANCE WITH

4230

SCJ

SCJ

SCJ

SCJ

SCJ

NATIONAL BUILDING REGULATIONS AND

IJ

MUNICIPAL BYLAWS.

150 x 75 x 20 x 2,0

5343

5343

5343

IJ

1.1 ALL DIMENSIONS TO BE CHECKED ON SITE PRIOR

C-CHANNEL

TO CONSTRUCTION.

SCJ SCJ SCJ SCJ PURLINS

1.2 ALL MATERIAL TO MANUFACTURER'S

SPECIFICATIONS

4488 4488 4488 4488 4488 4488 EXTERNAL WALLS = 220MM WIDE &

FT001 FT001

C001 C001 C001 C005 C005 C001 C001 RT001 C001 INTERNAL WALLS = 110MM WIDE UNLESS

IJ

C C C

4230

OTHERWISE STATED.

SCJ

1.3 THE DEVELOPER RESERVES THE RIGHT TO

SCJ

ADAPT ALL LEVELS AND VARY POSITIONING OF

BC001

BC001

BC001

BC001

BC001

BC001

UNITS TO SUIT SITE CONDITIONS.

SCJ SCJ SCJ SCJ

1.4 ALL CONSTRUCTION WORK SHOULD COMPLY

WITH STANDARD SPECIFICATION.

5343

5343

5343

1.5 PLAN TO BE CHECKED BY DEVELOPER PRIOR TO

IJ

COUNCIL SUBMISSION AND CONSTRUCTION.

1.6 STRENGTH & STABILITY OF WALLS ACC. SABS

IJ

4230

SCJ

SCJ

SCJ

SCJ

SCJ

FT001 FT001

C001 C001 C001 C005 C005 C001 C001 RT001 C001

D D D

SCJ SCJ SCJ SCJ

RT002

5343

5343

5343

4230

SCJ

SCJ

SCJ

SCJ

IJ

FT001 FT001

C001 C001 C001 C005 C001 C001 RT001 C001

42746

42746

42746

E E SCJ SCJ SCJ SCJ E

4230

SCJ

SCJ

SCJ

SCJ

5343

5343

5343

IJ

SCJ SCJ SCJ SCJ

FT001 FT001

C001 C001 C001 C005 C001 C001 RT001 C001

F F F

4230

SCJ

BC001

BC001

BC001

BC001

BC001

BC001

IJ

5343

5343

5343

SCJ SCJ SCJ SCJ

FT001 FT001

C001 C001 C001 C001 C001 RT001 C001

SCJ

IJ

4230

SCJ

SCJ

G G G

IJ IJ

SCJ SCJ SCJ

IJ IJ

5343

5343

5343

150 x 75 x 20 x 2,0

C-CHANNEL

PURLINS

IJ

IJ

IJ

IJ

IJ

IJ

4230

SCJ

FT001 FT001

C001 C001 C001 C001 C001 RT001 C001

H H H

IJ IJ

SCJ SCJ

IJ IJ

BC001

BC001

BC001

BC001

BC001

BC001

IJ

IJ

5343

5343

5343

IJ

IJ

IJ

IJ

4230

IJ

IJ

IJ

FT001 FT001

C001 C001 C001 IJ IJ IJ IJ C001 C001 RT001 C001

I I I

C002 C003 C004 C003 C002 C002 C003 C004 C003 C002

FT001 FT001 FT001 FT001 FT001

C002 C003 C004 C003 C002

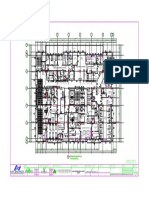

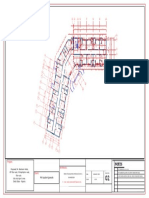

ROOF LAYOUT

SURFACE BED LAYOUT SCALE 1:100

SCALE 1:100 ISSUED FOR

0 - PM PM

CONSTRUCTION

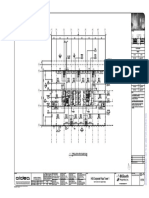

FOUNDATION LAYOUT

SCALE 1:100 COLUMN LEGEND ROOF LEGEND No Date Details Chd Appd

NUMBER COLUMN SIZE HEIGHT (mm) No. OFF NUMBER SIZE LENGTH (mm) No.OFF Revisions

FOOTING LEGEND C001 203 x 133 x 30 UC 7280 18 RT001 305 x 102 x 25 UB 13700 18

Client

C002 203 x 133 x 30 UC 7835 4 HAUNCH 305 x 102 x 25 UB (CUT)

NUMBER BASE SIZE STUB COLUMN SIZE No. OFF

FT001 1000 x 1000 x 300 Dp 350 x 350 x 700 Dp 20 C003 203 x 133 x 30 UC 8710 4 BC001 60 x 60 x 8 L METHODIST CHURCH

C004 203 x 133 x 30 UC 9254 2

C005 203 x 133 x 30 UC 2635 6 GENERAL CONCRETE NOTES

COLUMN LEGEND

NUMBER COLUMN SIZE HEIGHT (mm) No. OFF

1. GENERALLY ALL CONCRETE WORK IS TO BE IN ACCORDANCE WITH THE

FOLLOWING - CONTRACT SPECIFICATION, SANS 1200, SANS 10100 AND

STRUCTURAL STEELWORK: Engineer

C001 203 x 133 x 30 UC 7280 18 SANS 10161

S1) MATERIAL SPECIFICATION:

C002 203 x 133 x 30 UC 7835 4

a. HOT ROLLED SECTIONS SABS 1431 GRADE 350W

C003 203 x 133 x 30 UC 8710 4 2. READ THIS DRAWING IN CONJUNCTION WITH THE RELEVANT

b. COLD FORMED SECTIONS SABS 1431 GRADE 350W

SPECIFICATIONS; ARCHITECTS DRAWINGS;AND SERVICES DRAWINGS

C004 203 x 133 x 30 UC 9254 2 c. PLATES, FLATS AND ROUNDS SABS 1431 GRADE 350W

203 x 133 x 30 UC d. BOLTS AND NUTS (BEARING) SABS 1700 GRADE 8.8

C005 2635 6 3. DIMENSIONS MUST NOT BE SCALED OR ASSUMED e. HSFG BOLTS SABS 1700 GRADE 8.8S

S2) MINIMUM STANDARD WELD SIZE TO BE 6mm. ALL WELDED PARTS TO BE

4. CONCRETE MIXES: MASS CONCRETE SEAL WELDED.

MASS CONCRETE (USED AS BACKFILL TO OVERBREAK) 10/19 S3) ALL WELDING TO BE DONE BY QUALIFIED WELDERS.

FOUNDATIONS(LOAD BEARING WALLS) 25/19 S4) FLOOR BRACES SHALL BE CONNECTED TO ALL FLOOR BEAMS AT POINTS

SLABS 25/19 OF CONTACT.

BEAMS/COLUMNS

SURFACE BEDS

25/19

25MPa

REINFORCING NOTES: S5) WHERE NO FORCES OR MOMENTS ARE INDICATED ON THE DRAWING,

THE FABRICATOR WILL BE REQUIRED TO DETAIL THE CONNECTION TO

RESIST:

1. MIN. CONCRETE COVER TO REINFORCEMENT: a. TRUSSES AND BRACING - 40% OF THE LARGER MEMBERS TENSILE

5. ALL REINFORCEMENT FIXING AND PLACING MUST BE INSPECTED AND STRENGTH

- FOUNDATIONS = 50mm

APPROVED BY THE ENGINEER PRIOR TO POURING CONCRETE b. ROOF AND FLOOR BEAMS - 50% OF THE LARGER MEMBERS SHEAR ADDRESS

- SLABS = 30mm

STRENGTH

- BEAMS/COLUMNS = 30mm

6. COVER TO REINFORCING: S6) A MINIMUM OF TWO BOLTS SHALL BE USED IN ALL BOLTED CONNECTIONS.

FOUNDATIONS = 50 (EARTHFACE = 40mm) CROSS BRACES SHALL BE CONNECTED AT THE INTERSECTION WITH A

2. REINFORCEMENT TO BE SECURELY WIRED AT ALL INTERSECTIONS MINIMUM OF ONE M20 BOLT.

BEAMS/COLUMNS = 30 (EARTHFACE = 40mm) CONTACTS

S7) HSFG BOLTS SHALL BE INSTALLED IN ACCORDANCE WITH SABS 094 USING

3. REINFORCEMENT MUST BE FORMED AROUND, AND AS CLOSE AS THE TURN OF NUT METHOD.

7. CONCRETE FINISHES: TOP OF SLABS TO BE POWER FLOATED

ALLOWED TO HOLES, AND MUST NOT BE CUT. (SEE NOTE 1) S8) BOLTS, NUTS AND WASHERS SHALL BE CADMIUM OR ZINC PLATED.

S9) MILD STEEL GRATING SHALL BE OPEN GRID, NON-SLIP TYPE, WITH 100 X 40

8. COLD/WET WEATHER CONCRETING AS PER SPECIFICATION OPENINGS AND 30 X 4.5 BEARER BARS. (<--->) INDICATES DIRECTION OF

Project

4. BARS INDICATED THUS Y10, Y12 ETC. ARE HIGH TENSILE STEEL

SPAN. THE GRATING SHALL BE HOT DIP GALVANISED TO SABS 763.

9. ALL LOADBEARING BRICKWORK TO BE OF BRICKS WITH A CHARACTERISTIC S10) ALL MOMENT CONNECTIONS SHALL BE FULL STRENGTH.

5. ALL LAPS TO BE STAGGERED

COMPRESSIVE STRENGTH OF 14 MPA & LAID IN CLASS II MORTAR S11) VASTRAP PLATE SHALL BE SECURED TO SUPPORTING BEAMS WITH

COUNTERSUNK BOLTS.

6. MILD STEEL TO COMPLY WITH SABS 920 TYPE A - GRADE 3 S12) STAIR TREADS SHALL BE OPEN GRID TYPE 750mm SPAN, WITH NON-SLIP

10. BRICKFORCE IN EVERY FOURTH COURSE TO LOADBEARING BRICKWORK

NOSING.

7. HIGH TENSILE STEEL TO COMPLY SABS 920 TYPE C - GRADE 1 S13) HANDRAILING STANDARDS TO BE 1000mm ABOVE FINISH FLOOR LEVEL.

11. STRIPPING OF FORMWORK AS PER SPECIFICATION.(WITH ENGINEERS

S14) KICK FLATS TO BE 6mm THICK EXTENDING 130mm ABOVE FINISH FLOOR

APPROVAL)

8. BENDING DIMENSIONS IN ACCORDANCE WITH SABS 82 LEVEL.

S15) HANDRAIL TO BE FIXED TO FLOOR SUPPORTING STEELWORK AND NOT TO

12. DPC FORMED BRICKWORK OF 2 LAYERS OF 3 PLY MALTOID LAID ON KICK FLAT. Description

9. STIRRUP DIMENSIONS GIVEN AS OVERALL

SMOOTH MORTAR BED ON TOP OF BRICKWORK. VERTICAL SURFACES OF S16) THE FABRICATOR SHALL SUPPLY ALL BOLTS, NUTS AND WASHERS

CONCRETE TO BE SEPARATED FROM BRICKWORK BY 10 MM

POLYETHELENE FILLER BOARD

10. DIMENSION D MUST ALLWAYS BE GREATER THAN 2 x BAR DIAMETER

S17)

NECESSARY FOR ASSEMBLY AND ERECTION.

ITEM NUMBER, DRAWING NUMBER, ORDER NUMBER AND RING NUMBER TO

PLAN:

11. RADII OF ALL BENDS ARE STANDARD UNLESS r IS GIVEN IN THE

BE CLEARLY HARD MARKED AND PAINTED ON ALL ITEMS AND PARTS

THEREOF.

FOUNDATION, COLUMNS, ROOF

13. NO HOLES OR CHASES SHALL BE CUT OR FORMED IN CONCRETE UNLESS SCHEDULE

SHOWN ON DRAWINGS, DETAILED IN SPECIFICATION OR APPROVED BY S18) SHOP PREPARATION AND PAINTING TO BE IN ACCORDANCE WITH THE

PROJECT SPECIFICATION.

TRUSS LAYOUT AND DETAILS

ENGINEER 12. DIMENSIONS ARE ALL OUTSIDE DIMENSIONS S19) THE FABRICATOR SHALL SUPPLY ALL BOLTS FOR CONNECTING

MECHANICAL ITEMS TO STRUCTURAL STEEL AS INDICATED ON THE

(SHEET 02)

14. LOADING DURING CONSTRUCTION - MAXIMUM LOAD ON FLOOR DURING 13. MINIMUM LAP LENGTH - 50 x DIAMETER DRAWINGS.

CONSTRUCTION TO BE 500 kg/m² S20) BOLTS THAT ARE CADMIUN PLATED SHALL BE DEBRITTLED IN Scale Date

14. MINIMUM ANCHORAGE - 50 x DIAMETER ACCORDANCE WITH BS 1706 CLASS A. CERTIFICATION OF COMPLIANCE IS AS SHOWN JUL 2020

15. ANY DISCREPANCIES MUST BE BROUGHT TO THE ATTENTION OF THE REQUIRED.

ENGINEER AS SOON AS POSSIBLE. IF THERE IS ANY DISCREPANCY 15. REINFORCEMENT MUST BE STORED ON SITE IN CLEAN DRY AREA TO

S21) CONTACT SURFACES AT FRICTION GRIP CONNECTIONS SHALL BE Project No Drg. No Rev

BETWEEN THE DRAWINGS AND THE SPECIFICATION, THE ENGINEER MUST SANDBLASTED AND PRIMED.

AVOID RUST FORMING.

BE INFORMED S22) ALL FLAME-CUT EDGES, BURRS AND SHARP EDGES TO BE GROUND

SMOOTH. PF005/19 WSG028-ENG 03

You might also like

- TST1501 MINOR Test OneDocument3 pagesTST1501 MINOR Test Onetshepo hlakudiNo ratings yet

- Information Sheet 3.1.2 Computer Specifications: 1.2 Obtain Correct Specifications From Relevant ResourcesDocument5 pagesInformation Sheet 3.1.2 Computer Specifications: 1.2 Obtain Correct Specifications From Relevant Resourcesapi-196541959100% (2)

- 2023-12-22 Ductos Pasantes Cubierta Club La UnionDocument1 page2023-12-22 Ductos Pasantes Cubierta Club La UnionJavier ChuquitarcoNo ratings yet

- Str.01-Design of SlabDocument1 pageStr.01-Design of SlabKhoi DuongNo ratings yet

- Cardio/Pulmonary Station Dietary & Canteen: D17 D17 D22 D22Document1 pageCardio/Pulmonary Station Dietary & Canteen: D17 D17 D22 D22Berlin Andrew SionNo ratings yet

- Ground Floor Plan First Floor Plan: Department of Architecture, Guru Nanak Dev University, AmritsarDocument1 pageGround Floor Plan First Floor Plan: Department of Architecture, Guru Nanak Dev University, AmritsarRiddhi AggarwalNo ratings yet

- QTX Qa1000Document1 pageQTX Qa1000Joao Raffagnato CaldasNo ratings yet

- B1 Structure-018Document1 pageB1 Structure-018ponesakkiNo ratings yet

- AR RSK Layout2Document1 pageAR RSK Layout2Neil Brian CasemNo ratings yet

- Matchline N 8152.400 See DWG 3420-65H-003Document1 pageMatchline N 8152.400 See DWG 3420-65H-003JonathanSaucedoNo ratings yet

- Ground Floor Plan: Sheet TitleDocument1 pageGround Floor Plan: Sheet TitleEmrys MhaykuceNo ratings yet

- 1Document1 page1ahmadhelat1987No ratings yet

- Terrace Plan Second Floor Plan: Department of Architecture, Guru Nanak Dev University, AmritsarDocument1 pageTerrace Plan Second Floor Plan: Department of Architecture, Guru Nanak Dev University, AmritsarRiddhi AggarwalNo ratings yet

- RLC RDCDocument1 pageRLC RDCAntar Ben ChededNo ratings yet

- HSS Corporate Plaza Tower 1: Typical 8Th-18Th Floor PlanDocument1 pageHSS Corporate Plaza Tower 1: Typical 8Th-18Th Floor PlanPatbauNo ratings yet

- Number SeriesDocument6 pagesNumber SeriesNaveenkumar NeelamNo ratings yet

- I-A1-0150-Ground Floor General LayoutDocument1 pageI-A1-0150-Ground Floor General Layoutlinga2014No ratings yet

- Matchline N 8234.400 See DWG 3420-65H-001Document1 pageMatchline N 8234.400 See DWG 3420-65H-001JonathanSaucedoNo ratings yet

- Third Floor Plan: Schedule of EquipmentDocument1 pageThird Floor Plan: Schedule of EquipmentDominador Ladot Heraña Jr.No ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- Qur 1Document1 pageQur 1selvakumar sNo ratings yet

- Metallica OneDocument10 pagesMetallica OnejackNo ratings yet

- A A A AaaaaaaaaaaaaaaaaaaaaaaaaaDocument1 pageA A A AaaaaaaaaaaaaaaaaaaaaaaaaaCarolina RamirezNo ratings yet

- PUJ-ESM-DT-EST-10-03 (Estructural Losa Piso 2 N+6.30 y Piso 3 N+10.85)Document1 pagePUJ-ESM-DT-EST-10-03 (Estructural Losa Piso 2 N+6.30 y Piso 3 N+10.85)Welding Testing Services SASNo ratings yet

- PUJ-ESM-DT-EST-11-03 (Estructural Losa Piso 4 N+15.40 y Piso 5 N+19.95)Document1 pagePUJ-ESM-DT-EST-11-03 (Estructural Losa Piso 4 N+15.40 y Piso 5 N+19.95)Welding Testing Services SASNo ratings yet

- S01 Parter SanitareDocument1 pageS01 Parter SanitareSergiu AlupoaeNo ratings yet

- C2227 DWG DD ST 122 0002Document1 pageC2227 DWG DD ST 122 0002Mohammed AbuazzamNo ratings yet

- .E.250 - PV Wiring Plan and DetailsDocument1 page.E.250 - PV Wiring Plan and Detailsharold de guzmanNo ratings yet

- DR-CST-800-0001 - Rev ADocument1 pageDR-CST-800-0001 - Rev APinak ProjectsNo ratings yet

- Mapa Geologico LocalDocument1 pageMapa Geologico LocalLizbeth Bravo TintaNo ratings yet

- Medical Records: Ground Level Floor PlanDocument1 pageMedical Records: Ground Level Floor PlanBerlin Andrew SionNo ratings yet

- Mapa Geologico RegionalDocument1 pageMapa Geologico RegionalLizbeth Bravo TintaNo ratings yet

- Avenged Sevenfold - NobodyDocument4 pagesAvenged Sevenfold - NobodyNarayan ThapaNo ratings yet

- Matchline N 8278.770 See DWG 3420-65H-007Document1 pageMatchline N 8278.770 See DWG 3420-65H-007JonathanSaucedoNo ratings yet

- Rezistenta Final Layout-R.07 - 841x900Document1 pageRezistenta Final Layout-R.07 - 841x900Alexandru PandeleaNo ratings yet

- Cell 2Document1 pageCell 2Khoirul RezqiNo ratings yet

- X026 - Detail Drawings Package-1-2Document2 pagesX026 - Detail Drawings Package-1-2ahmet gurNo ratings yet

- Randwick For TenderDocument1 pageRandwick For Tenderrao_vinay8296No ratings yet

- 28Th Floor Plan: Contractor Architect / Engineer Project Title Owner Sheet Content Sheet NoDocument1 page28Th Floor Plan: Contractor Architect / Engineer Project Title Owner Sheet Content Sheet NoSKYLERNo ratings yet

- 0036 - O19035-C-Hp-16-Rc-0036-Rc Detail of Beams at First Floor Level (Sheet 6 of 6)Document1 page0036 - O19035-C-Hp-16-Rc-0036-Rc Detail of Beams at First Floor Level (Sheet 6 of 6)Hunny VermaNo ratings yet

- Mapa de DrenajesDocument1 pageMapa de DrenajesLizbeth Bravo TintaNo ratings yet

- OSC - Column and Wall Layout-1Document1 pageOSC - Column and Wall Layout-1AmanuelGirmaNo ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- SGCF Site PlanDocument1 pageSGCF Site PlanHoda ElebrashyNo ratings yet

- Piese Desenate PT Cornu LunciiDocument54 pagesPiese Desenate PT Cornu LunciitebreanlNo ratings yet

- Walking Bass GuitarDocument3 pagesWalking Bass GuitarJazz72No ratings yet

- Floor Plan Mezzanine (AT R.L 3.578m - TOP OF THE Structure) : Mezzanine - Office #29 Mustang Road - JandakotDocument1 pageFloor Plan Mezzanine (AT R.L 3.578m - TOP OF THE Structure) : Mezzanine - Office #29 Mustang Road - JandakotviniciuslrNo ratings yet

- SXCDVFBG NDocument1 pageSXCDVFBG NSachin AgarwalNo ratings yet

- DD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewwDocument1 pageDD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewwDavid Adi KaruniaNo ratings yet

- Rre Ry Ry1 A2a MP014 Pe CH STR B02 DWG 00101Document1 pageRre Ry Ry1 A2a MP014 Pe CH STR B02 DWG 00101md_rehan_2No ratings yet

- Beam LayoutDocument1 pageBeam Layoutshadrackmakanga1998No ratings yet

- Executive Suite 1: W 2 W 1 D 3 W 2 W 3 W 1 W 1 D 4 D 3Document1 pageExecutive Suite 1: W 2 W 1 D 3 W 2 W 3 W 1 W 1 D 4 D 3Adrian PachecoNo ratings yet

- The Misfits - Dont Open Till Doomsday Bass 2Document1 pageThe Misfits - Dont Open Till Doomsday Bass 2neotaogeoNo ratings yet

- P20c30tu02rpt Aecg Civstrdwg 30202 01 (C)Document1 pageP20c30tu02rpt Aecg Civstrdwg 30202 01 (C)subhash kumarNo ratings yet

- Lifting Eye Placement Forces On Pit: Reference Specification Technical SpecificationDocument1 pageLifting Eye Placement Forces On Pit: Reference Specification Technical Specificationsumant giriNo ratings yet

- PUJ-ESM-DT-EST-12-03 (Estructural Losa Piso 6 N+24.50 y Piso 7 N+29.05)Document1 pagePUJ-ESM-DT-EST-12-03 (Estructural Losa Piso 6 N+24.50 y Piso 7 N+29.05)Welding Testing Services SASNo ratings yet

- CRT TV - Chassis GBJL7.820.064Document1 pageCRT TV - Chassis GBJL7.820.064dra6an100% (1)

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Valhalla EdVNDocument1 pageValhalla EdVNtshepo hlakudiNo ratings yet

- 160.5.4 2D V M and F Diag ExampleDocument24 pages160.5.4 2D V M and F Diag Exampletshepo hlakudiNo ratings yet

- Silverton3 EdISDocument1 pageSilverton3 EdIStshepo hlakudiNo ratings yet

- TUT Flyer 2024Document1 pageTUT Flyer 2024tshepo hlakudiNo ratings yet

- ROUTE 4 Olievenhoutbos To Centurion Via Highveld Ecopark Southdowns EdVNDocument1 pageROUTE 4 Olievenhoutbos To Centurion Via Highveld Ecopark Southdowns EdVNtshepo hlakudiNo ratings yet

- The Rustenburg Layered Suite Formed As A Stack of Mush With Transient Magma ChambersDocument13 pagesThe Rustenburg Layered Suite Formed As A Stack of Mush With Transient Magma Chamberstshepo hlakudiNo ratings yet

- ROUTE 7 Olievenhoutbos To Wierdapark Eldoraine Clubview A EdVNDocument2 pagesROUTE 7 Olievenhoutbos To Wierdapark Eldoraine Clubview A EdVNtshepo hlakudiNo ratings yet

- Week 6Document4 pagesWeek 6tshepo hlakudiNo ratings yet

- Carbon Steel Fact SheetDocument2 pagesCarbon Steel Fact Sheettshepo hlakudiNo ratings yet

- PWD Papers 49Document8 pagesPWD Papers 49tshepo hlakudiNo ratings yet

- ROUTE 9 Olievenhoutbos To Centurion Via Irene Lyttleton StationDocument1 pageROUTE 9 Olievenhoutbos To Centurion Via Irene Lyttleton Stationtshepo hlakudiNo ratings yet

- To Be ReorderedDocument16 pagesTo Be Reorderedtshepo hlakudiNo ratings yet

- WTE1501 Major Test 01 2022Document8 pagesWTE1501 Major Test 01 2022tshepo hlakudiNo ratings yet

- Graph PaperDocument1 pageGraph Papertshepo hlakudiNo ratings yet

- 2023 EPN2601 Assessment Plan and ScopeDocument3 pages2023 EPN2601 Assessment Plan and Scopetshepo hlakudiNo ratings yet

- GS B0182fDocument11 pagesGS B0182ftshepo hlakudiNo ratings yet

- Tshepo Hlakudi MAT ExamDocument11 pagesTshepo Hlakudi MAT Examtshepo hlakudiNo ratings yet

- Week 8Document14 pagesWeek 8tshepo hlakudiNo ratings yet

- SUR1501Document5 pagesSUR1501tshepo hlakudiNo ratings yet

- Wte SuppDocument6 pagesWte Supptshepo hlakudiNo ratings yet

- Master of Applied Sciences: RemarksDocument2 pagesMaster of Applied Sciences: Remarkstshepo hlakudiNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh3 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh3 1tshepo hlakudiNo ratings yet

- ACC2601 Assignment 2Document6 pagesACC2601 Assignment 2tshepo hlakudiNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh5 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh5 1tshepo hlakudiNo ratings yet

- The Great Unknown 127Document9 pagesThe Great Unknown 127tshepo hlakudiNo ratings yet

- GO16 - PP - CH01 - GRADER - 1G - HW - Northern Lights 1.5 - InstructionsDocument2 pagesGO16 - PP - CH01 - GRADER - 1G - HW - Northern Lights 1.5 - Instructionstshepo hlakudiNo ratings yet

- Design of Compression MembersDocument56 pagesDesign of Compression Memberstshepo hlakudiNo ratings yet

- General Consideration of Structural Steel Design.Document16 pagesGeneral Consideration of Structural Steel Design.tshepo hlakudiNo ratings yet

- Comprssibility of Soil - CH2 - Part7Document3 pagesComprssibility of Soil - CH2 - Part7tshepo hlakudiNo ratings yet

- COA Chapter 1 NotesDocument14 pagesCOA Chapter 1 NotesAmitesh ki class For engineeringNo ratings yet

- MCQ PGTDocument17 pagesMCQ PGTmahajanpb2012No ratings yet

- Rapid Smith DocumentationDocument63 pagesRapid Smith DocumentationEvgeni StavinovNo ratings yet

- TLWG 2marksDocument10 pagesTLWG 2marksElakya PrabhuNo ratings yet

- Seismic Design and Steel Connection DetailingDocument16 pagesSeismic Design and Steel Connection Detailingjose felix100% (1)

- Electrical Installation StandardsDocument119 pagesElectrical Installation StandardsGeorge O'Donnell100% (2)

- Ultrasonic FlowmetersDocument30 pagesUltrasonic Flowmetersvcharles0% (1)

- Archprogramming Exhibit ADocument2 pagesArchprogramming Exhibit AshipwreckwaveNo ratings yet

- VTR 61 PDFDocument2 pagesVTR 61 PDFdmansoorNo ratings yet

- Wall Mounted PDFDocument5 pagesWall Mounted PDFAhmed AzadNo ratings yet

- Tomasulo's Algorithm and ScoreboardingDocument17 pagesTomasulo's Algorithm and ScoreboardingParth KaleNo ratings yet

- Scanning Tunneling MicroscopeDocument7 pagesScanning Tunneling MicroscopeAnonymous KGETwqYWNo ratings yet

- Type 1: Paramount Parts List Weed Eater Parts List Poulan Parts List R Parts ListDocument5 pagesType 1: Paramount Parts List Weed Eater Parts List Poulan Parts List R Parts ListchiliwillyNo ratings yet

- Amiga Machine Language 1991 AbacusDocument276 pagesAmiga Machine Language 1991 AbacusTeeNo ratings yet

- PCN V19-001-484754120aDocument6 pagesPCN V19-001-484754120ajonatas Cassiano da silvaNo ratings yet

- DESMI Self-Priming Centrifugal Pump: Modular S-NDocument20 pagesDESMI Self-Priming Centrifugal Pump: Modular S-NIlyas Rangga RamadhanNo ratings yet

- References STP Aviation EnglishDocument9 pagesReferences STP Aviation Englishexemplo55509No ratings yet

- Customer Relationship Management From: Dr. Harjit Singh 1Document23 pagesCustomer Relationship Management From: Dr. Harjit Singh 1chakshudeep15No ratings yet

- FC 822 PCB PDFDocument1 pageFC 822 PCB PDFKellyNo ratings yet

- Rock Mass ClassificationDocument8 pagesRock Mass ClassificationM JaffaNo ratings yet

- Refrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerDocument9 pagesRefrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerIshwarjit SinghNo ratings yet

- Lecture 03Document21 pagesLecture 03Riju ChatterjeeNo ratings yet

- Maintenance Procedures: Mfr. Description Date Issued: Revision DateDocument8 pagesMaintenance Procedures: Mfr. Description Date Issued: Revision DateCarolina Diaz MurillasNo ratings yet

- Standard ADA Locations and Information of Door Hardware DiagramDocument1 pageStandard ADA Locations and Information of Door Hardware DiagramEmily Jamieson BoydNo ratings yet

- Water Vapour Transmission Rate Test Report ASTM E96Document9 pagesWater Vapour Transmission Rate Test Report ASTM E96Raj BalakrisNo ratings yet

- 3G 2G Selection Reselection HandoverDocument50 pages3G 2G Selection Reselection HandoverMohammed Nazim100% (1)

- Product Sheet - MasterBox MB500 TUF EditionDocument2 pagesProduct Sheet - MasterBox MB500 TUF EditionOmar LópezNo ratings yet

- El Mundo de ScaniaDocument20 pagesEl Mundo de ScaniaElvis Eberth Huanca Machaca100% (1)

- Sartorius Balance Cable Pinouts - TALtechDocument2 pagesSartorius Balance Cable Pinouts - TALtechWill CariasNo ratings yet