Professional Documents

Culture Documents

WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel

WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel

Uploaded by

Ahmed GomaaCopyright:

Available Formats

You might also like

- JSA - Mechanical-Excavation PDFDocument1 pageJSA - Mechanical-Excavation PDFAhmed GomaaNo ratings yet

- DVS 2203 - 01 Testing of Welded Joints of Thermoplastic Sheets and PipesDocument2 pagesDVS 2203 - 01 Testing of Welded Joints of Thermoplastic Sheets and PipesAhmed GomaaNo ratings yet

- Cajon-001 WPSDocument2 pagesCajon-001 WPSDanem HalasNo ratings yet

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNo ratings yet

- BX-3001 - BOX - Rev 00-Model PDFDocument1 pageBX-3001 - BOX - Rev 00-Model PDFomar mahmoudNo ratings yet

- Welding NotesDocument5 pagesWelding NotesRakesh RanjanNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- WPS - 004Document12 pagesWPS - 004MAT-LIONNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaNo ratings yet

- A Comparison of ISO 15614 Part 1 and ASME IXDocument2 pagesA Comparison of ISO 15614 Part 1 and ASME IXtuanNo ratings yet

- En 15085-2020-What Has ChangedDocument2 pagesEn 15085-2020-What Has ChangedBoran YelkenciogluNo ratings yet

- WPQ CS SmawDocument1 pageWPQ CS Smawniket0No ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- P No QaDocument11 pagesP No QadhasdjNo ratings yet

- CIGWELDDocument244 pagesCIGWELDrodastrid5653100% (1)

- WPS & Materials Applicable MatrixDocument5 pagesWPS & Materials Applicable Matrixundeath123100% (1)

- Revised Wps For Gtaw - Xls Dated 25.01.2017Document2 pagesRevised Wps For Gtaw - Xls Dated 25.01.2017GopinathNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- Filler Wires PDFDocument7 pagesFiller Wires PDFJayaram MVNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WQTR 004-2Document2 pagesWQTR 004-2walitedisonNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- DRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Document18 pagesDRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Osu AmpawanonNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- WPS - 016Document11 pagesWPS - 016MAT-LIONNo ratings yet

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- CV Painting InsulationDocument3 pagesCV Painting Insulationhamza brahmiNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- WPQR Sample FormDocument1 pageWPQR Sample FormshwayeNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- Procedure Qualification Record (PQR) Form: JointsDocument12 pagesProcedure Qualification Record (PQR) Form: JointsAl Fatih Darussalam YasfiNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- ELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermDocument15 pagesELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermAhmed GomaaNo ratings yet

- Erection Welding and Lamination of Plastic Pipelines UN 9253-07Document8 pagesErection Welding and Lamination of Plastic Pipelines UN 9253-07Ahmed GomaaNo ratings yet

- DVS 2203 - 05 Testing of Welded Joints of Thermoplastics Plates and Tubes Technological Bend TestDocument3 pagesDVS 2203 - 05 Testing of Welded Joints of Thermoplastics Plates and Tubes Technological Bend TestAhmed GomaaNo ratings yet

- Hirarc - Hazard Identification, Risk Assessment & Risk Control PDFDocument21 pagesHirarc - Hazard Identification, Risk Assessment & Risk Control PDFAhmed GomaaNo ratings yet

- 04-Project Integration Management-2019!06!13 13-20-09Document113 pages04-Project Integration Management-2019!06!13 13-20-09Ahmed GomaaNo ratings yet

- 125 Useful English PhrasesDocument11 pages125 Useful English PhrasesMohan PereraNo ratings yet

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- How To Use MPI Yokes PDFDocument12 pagesHow To Use MPI Yokes PDFAhmed Gomaa100% (1)

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- Numero 35 Art 25 PDFDocument10 pagesNumero 35 Art 25 PDFAhmed GomaaNo ratings yet

- Fulltext PDFDocument151 pagesFulltext PDFAhmed GomaaNo ratings yet

- Modeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysDocument26 pagesModeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysAhmed GomaaNo ratings yet

- Processing of Titanium & Aluminium AlloysDocument61 pagesProcessing of Titanium & Aluminium AlloysAhmed GomaaNo ratings yet

- WJ 2007 12 PDFDocument124 pagesWJ 2007 12 PDFAhmed GomaaNo ratings yet

- Characterization of Refractory Titanium Alloys Welded by TIG and Laser ProcessesDocument5 pagesCharacterization of Refractory Titanium Alloys Welded by TIG and Laser ProcessesAhmed GomaaNo ratings yet

- Quantitative Metallography of Two-Phase Titanium AlloysDocument6 pagesQuantitative Metallography of Two-Phase Titanium AlloysAhmed GomaaNo ratings yet

- Welding of An Advanced High Strength Titanium AlloyDocument8 pagesWelding of An Advanced High Strength Titanium AlloyAhmed GomaaNo ratings yet

- Ruthenium Enhanced: TitaniumDocument8 pagesRuthenium Enhanced: TitaniumAhmed GomaaNo ratings yet

- Irndt Central Certification Program For NDT PersonnelDocument31 pagesIrndt Central Certification Program For NDT PersonnelAhmed GomaaNo ratings yet

- WTCDocument57 pagesWTCSarah FrazierNo ratings yet

- WPQRDocument1 pageWPQRJBStringerNo ratings yet

- Heaters Sizing and SelectionDocument6 pagesHeaters Sizing and SelectionRajinikanth RenganathanNo ratings yet

- Seminar Report On Gas WeldingDocument17 pagesSeminar Report On Gas WeldingMohd Sohail AliNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Welding Defect in GTAWDocument19 pagesWelding Defect in GTAWMuhammad Ghiyats100% (1)

- Weld AbilityDocument34 pagesWeld AbilityGauthamSarangNo ratings yet

- Welding Application in ShipbuildingDocument9 pagesWelding Application in ShipbuildingUnaJuricNo ratings yet

- D10 11M-D10 11-2007PVDocument6 pagesD10 11M-D10 11-2007PVFiroj KhanNo ratings yet

- Approved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFDocument3 pagesApproved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFBhavani PrasadNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad BilalNo ratings yet

- Friction WeldingDocument20 pagesFriction WeldingNallappan Rajj ANo ratings yet

- AWS B2 1 1 004 2013 SWPS GMAW ShortDocument22 pagesAWS B2 1 1 004 2013 SWPS GMAW Shortreza acbariNo ratings yet

- Various Welding ProcessesDocument24 pagesVarious Welding ProcessesLalit YadavNo ratings yet

- Ducted Split Air Conditioner: Service ManualDocument19 pagesDucted Split Air Conditioner: Service ManualLuis Ernesto Cabrera MartinezNo ratings yet

- ASME IX Interpretations No. 14Document10 pagesASME IX Interpretations No. 14Justin MorseNo ratings yet

- M 3 D1.1 2015 FormDocument1 pageM 3 D1.1 2015 FormRameshBaskaranNo ratings yet

- Ealps QCDocument14 pagesEalps QCnathan2002mechNo ratings yet

- South Yoloten Gas Field Development Turkmenistan: Daily Welding ReportDocument2 pagesSouth Yoloten Gas Field Development Turkmenistan: Daily Welding ReportOctavian PanteaNo ratings yet

- Welding Qualifications GDSS.505-1: Subj CTDocument25 pagesWelding Qualifications GDSS.505-1: Subj CTOPAZOSCNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- Manufacturing ProcessesDocument6 pagesManufacturing ProcessesSudalai MadanNo ratings yet

- ASME B31.1 2018 (Inspection-Academy)Document31 pagesASME B31.1 2018 (Inspection-Academy)royal0% (1)

- Mmaw / Smaw: Carbon Steel ElectrodesDocument10 pagesMmaw / Smaw: Carbon Steel Electrodessn200709No ratings yet

- Module 4 - Welding Procedure Specification As Per AWS D1.1Document24 pagesModule 4 - Welding Procedure Specification As Per AWS D1.1strucmeNo ratings yet

- Blue Box - Geyser 2Document90 pagesBlue Box - Geyser 2tzisis100% (1)

- 7-Welding Consumable Handling and Storage - WC007Document11 pages7-Welding Consumable Handling and Storage - WC007mohd as shahiddin jafriNo ratings yet

- Edison Welding Institute Hot Tap WeldingDocument19 pagesEdison Welding Institute Hot Tap WeldingShikhar JainNo ratings yet

WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel

WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel

Uploaded by

Ahmed GomaaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel

WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel

Uploaded by

Ahmed GomaaCopyright:

Available Formats

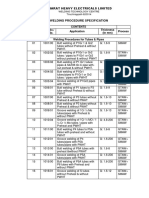

THANH LONG INDUSTRIAL CO.

, LTD

Nguyen Khanh Toan St, Cau Giay Dist, Hanoi, Viet Nam WELDING PROCEDURE SPECIFICATION (WPS)

Tel: 84 4 62813676 - Fax: 84 4 62811544 (AWS D1.6/D1.6M-2007: Structural Welding Code - Stainless Steel)

Email: thanhlongind@gmail.com

WPS No. THANHLONG-WPS-02 Date: 22th Mar, 2014 ELECTRICAL CHARACTERISTICS

Revisions 0 Current Polarity DCEP (DC+)

Welding Process(es) SMAW Amperes (Range) SEE TABLE BELOW

Type(s) Manual Volts (Range) SEE TABLE BELOW

Procedure Qualification Metal Transfer Mode N/A

THANHLONG-PQR-02

PQR No.(s)

JOINTS GAS

Joint design Groove & Fillet welds Shielding Gas(es) N/A

Backing Yes No x Percent Composition N/A

Backing Material (Type) N/A Flow Rate N/A

Other N/A Backing Gas N/A

Trailing Gas N/A

BASE METALS TECHNIQUE

P/G-No. A to P/G-No. I String or Weave Bead String and/or Weave

ASTM A240 SUS304 to JIS G3101 SS400 or

Material Spec. Orifice or Gas Cup Size N/A

Equivalent

Thickness Range (t mm) 2.0mm to 12mm Interpass Cleaning

Brushing and/or Grinding

Pipe Diameter Range: (Brushing, Grinding, etc.)

Groove N/A Method of Back Gouging Grinding

Fillet N/A Oscillation N/A

FILLER METALS Contact Tube -

F No. 5 to Work Distance

A No. 8 Multiple or Single

SINGLE or MULTIPLE

SFA No. 5.4 Pass (per Side)

AWS Class E309L-16 / E309-16 Multiple or Single

SINGLE

Elect/Filler Dia. Ø 2.6mm / Ø 3.2 mm Electrodes

Elect/ Filler Trade Name KISWEL KST-309L / KST-309 Travel Speed (Range) SEE TABLE BELOW

Other N/A

Electrode-Flux (Class) N/A

Flux Trade Name N/A

Non-Consumable Elect N/A JOINT SKETCH

POSITION

Position of Groove Flat and Horizontal

Position of Fillet Flat and Horizontal

Welding Progression: N/A

Other N/A

PREHEAT

Preheat Temperature Ambient (10ºC)

Interpass Temperature Max. 175ºC

Preheat Maintenance N/A

Method of Checking Thermometer / Tempil stick

POST WELD HEAT TREATMENT

Temperature N/A

Time Range N/A

Other N/A

WELDING PARAMETERS

Weld Elect/Filler Current Voltage Travel speed Heat Input

Process Remarks

Layers(s) AWS Class Dia. (mm) Polarity A V mm/min kJ/mm

Root SMAW E309L-16 Φ2.6 DCEP 60-75 20-30 100-150 -

Hot/Fill/Cap SMAW E309-16 Φ3.2 DCEP 80-110 20-30 150-220 -

Backweld SMAW E309-16 Φ3.2 DCEP 80-100 20-30 150-200 -

PREPARED BY: REVIEWED BY: APPROVED BY:

Name: Name:

Name:

Signature: Signature:

Signature:

Date: Date: Date:

You might also like

- JSA - Mechanical-Excavation PDFDocument1 pageJSA - Mechanical-Excavation PDFAhmed GomaaNo ratings yet

- DVS 2203 - 01 Testing of Welded Joints of Thermoplastic Sheets and PipesDocument2 pagesDVS 2203 - 01 Testing of Welded Joints of Thermoplastic Sheets and PipesAhmed GomaaNo ratings yet

- Cajon-001 WPSDocument2 pagesCajon-001 WPSDanem HalasNo ratings yet

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNo ratings yet

- BX-3001 - BOX - Rev 00-Model PDFDocument1 pageBX-3001 - BOX - Rev 00-Model PDFomar mahmoudNo ratings yet

- Welding NotesDocument5 pagesWelding NotesRakesh RanjanNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- WPS - 004Document12 pagesWPS - 004MAT-LIONNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaNo ratings yet

- A Comparison of ISO 15614 Part 1 and ASME IXDocument2 pagesA Comparison of ISO 15614 Part 1 and ASME IXtuanNo ratings yet

- En 15085-2020-What Has ChangedDocument2 pagesEn 15085-2020-What Has ChangedBoran YelkenciogluNo ratings yet

- WPQ CS SmawDocument1 pageWPQ CS Smawniket0No ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- P No QaDocument11 pagesP No QadhasdjNo ratings yet

- CIGWELDDocument244 pagesCIGWELDrodastrid5653100% (1)

- WPS & Materials Applicable MatrixDocument5 pagesWPS & Materials Applicable Matrixundeath123100% (1)

- Revised Wps For Gtaw - Xls Dated 25.01.2017Document2 pagesRevised Wps For Gtaw - Xls Dated 25.01.2017GopinathNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- Filler Wires PDFDocument7 pagesFiller Wires PDFJayaram MVNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WQTR 004-2Document2 pagesWQTR 004-2walitedisonNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- DRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Document18 pagesDRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Osu AmpawanonNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- WPS - 016Document11 pagesWPS - 016MAT-LIONNo ratings yet

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- CV Painting InsulationDocument3 pagesCV Painting Insulationhamza brahmiNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- WPQR Sample FormDocument1 pageWPQR Sample FormshwayeNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- Procedure Qualification Record (PQR) Form: JointsDocument12 pagesProcedure Qualification Record (PQR) Form: JointsAl Fatih Darussalam YasfiNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- ELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermDocument15 pagesELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermAhmed GomaaNo ratings yet

- Erection Welding and Lamination of Plastic Pipelines UN 9253-07Document8 pagesErection Welding and Lamination of Plastic Pipelines UN 9253-07Ahmed GomaaNo ratings yet

- DVS 2203 - 05 Testing of Welded Joints of Thermoplastics Plates and Tubes Technological Bend TestDocument3 pagesDVS 2203 - 05 Testing of Welded Joints of Thermoplastics Plates and Tubes Technological Bend TestAhmed GomaaNo ratings yet

- Hirarc - Hazard Identification, Risk Assessment & Risk Control PDFDocument21 pagesHirarc - Hazard Identification, Risk Assessment & Risk Control PDFAhmed GomaaNo ratings yet

- 04-Project Integration Management-2019!06!13 13-20-09Document113 pages04-Project Integration Management-2019!06!13 13-20-09Ahmed GomaaNo ratings yet

- 125 Useful English PhrasesDocument11 pages125 Useful English PhrasesMohan PereraNo ratings yet

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- How To Use MPI Yokes PDFDocument12 pagesHow To Use MPI Yokes PDFAhmed Gomaa100% (1)

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- Numero 35 Art 25 PDFDocument10 pagesNumero 35 Art 25 PDFAhmed GomaaNo ratings yet

- Fulltext PDFDocument151 pagesFulltext PDFAhmed GomaaNo ratings yet

- Modeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysDocument26 pagesModeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysAhmed GomaaNo ratings yet

- Processing of Titanium & Aluminium AlloysDocument61 pagesProcessing of Titanium & Aluminium AlloysAhmed GomaaNo ratings yet

- WJ 2007 12 PDFDocument124 pagesWJ 2007 12 PDFAhmed GomaaNo ratings yet

- Characterization of Refractory Titanium Alloys Welded by TIG and Laser ProcessesDocument5 pagesCharacterization of Refractory Titanium Alloys Welded by TIG and Laser ProcessesAhmed GomaaNo ratings yet

- Quantitative Metallography of Two-Phase Titanium AlloysDocument6 pagesQuantitative Metallography of Two-Phase Titanium AlloysAhmed GomaaNo ratings yet

- Welding of An Advanced High Strength Titanium AlloyDocument8 pagesWelding of An Advanced High Strength Titanium AlloyAhmed GomaaNo ratings yet

- Ruthenium Enhanced: TitaniumDocument8 pagesRuthenium Enhanced: TitaniumAhmed GomaaNo ratings yet

- Irndt Central Certification Program For NDT PersonnelDocument31 pagesIrndt Central Certification Program For NDT PersonnelAhmed GomaaNo ratings yet

- WTCDocument57 pagesWTCSarah FrazierNo ratings yet

- WPQRDocument1 pageWPQRJBStringerNo ratings yet

- Heaters Sizing and SelectionDocument6 pagesHeaters Sizing and SelectionRajinikanth RenganathanNo ratings yet

- Seminar Report On Gas WeldingDocument17 pagesSeminar Report On Gas WeldingMohd Sohail AliNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Welding Defect in GTAWDocument19 pagesWelding Defect in GTAWMuhammad Ghiyats100% (1)

- Weld AbilityDocument34 pagesWeld AbilityGauthamSarangNo ratings yet

- Welding Application in ShipbuildingDocument9 pagesWelding Application in ShipbuildingUnaJuricNo ratings yet

- D10 11M-D10 11-2007PVDocument6 pagesD10 11M-D10 11-2007PVFiroj KhanNo ratings yet

- Approved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFDocument3 pagesApproved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFBhavani PrasadNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad BilalNo ratings yet

- Friction WeldingDocument20 pagesFriction WeldingNallappan Rajj ANo ratings yet

- AWS B2 1 1 004 2013 SWPS GMAW ShortDocument22 pagesAWS B2 1 1 004 2013 SWPS GMAW Shortreza acbariNo ratings yet

- Various Welding ProcessesDocument24 pagesVarious Welding ProcessesLalit YadavNo ratings yet

- Ducted Split Air Conditioner: Service ManualDocument19 pagesDucted Split Air Conditioner: Service ManualLuis Ernesto Cabrera MartinezNo ratings yet

- ASME IX Interpretations No. 14Document10 pagesASME IX Interpretations No. 14Justin MorseNo ratings yet

- M 3 D1.1 2015 FormDocument1 pageM 3 D1.1 2015 FormRameshBaskaranNo ratings yet

- Ealps QCDocument14 pagesEalps QCnathan2002mechNo ratings yet

- South Yoloten Gas Field Development Turkmenistan: Daily Welding ReportDocument2 pagesSouth Yoloten Gas Field Development Turkmenistan: Daily Welding ReportOctavian PanteaNo ratings yet

- Welding Qualifications GDSS.505-1: Subj CTDocument25 pagesWelding Qualifications GDSS.505-1: Subj CTOPAZOSCNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- Manufacturing ProcessesDocument6 pagesManufacturing ProcessesSudalai MadanNo ratings yet

- ASME B31.1 2018 (Inspection-Academy)Document31 pagesASME B31.1 2018 (Inspection-Academy)royal0% (1)

- Mmaw / Smaw: Carbon Steel ElectrodesDocument10 pagesMmaw / Smaw: Carbon Steel Electrodessn200709No ratings yet

- Module 4 - Welding Procedure Specification As Per AWS D1.1Document24 pagesModule 4 - Welding Procedure Specification As Per AWS D1.1strucmeNo ratings yet

- Blue Box - Geyser 2Document90 pagesBlue Box - Geyser 2tzisis100% (1)

- 7-Welding Consumable Handling and Storage - WC007Document11 pages7-Welding Consumable Handling and Storage - WC007mohd as shahiddin jafriNo ratings yet

- Edison Welding Institute Hot Tap WeldingDocument19 pagesEdison Welding Institute Hot Tap WeldingShikhar JainNo ratings yet