Professional Documents

Culture Documents

Screwguard: Rotair Altair

Screwguard: Rotair Altair

Uploaded by

AristideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screwguard: Rotair Altair

Screwguard: Rotair Altair

Uploaded by

AristideCopyright:

Available Formats

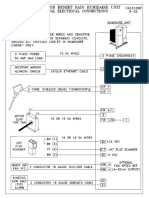

Technical specifications SCREWGUARD

SCREW COMPRESSOR LUBRICANTS

ROTAIR

ALTAIR

SCREWGUARD SCREWGUARD SCREWGUARD SCREWGUARD

ROTAIR ROTAIR Plus ROTAIR Xtra ROTAIR FoodGrade

Engineered mineral oil Engineered mineral oil Synthetic oil

Type Synthetic oil

with selected additives with special additive package with additives

2,000 hours 4,000 hours 8,000 hours 4000 hours

Drain interval

or 1 year (*) or 1 year (*) or 2 years (*) or 1 year (*)

High demand, Food and

Application Standard industry Low to high duty operation

severe conditions pharmaceutical industry

High temperature

Normal conditions Normal conditions Risk of occasional contact

and humidity

Operating conditions

Normal drain interval Long drain interval Extended drain interval Long drain interval

Order number 5 L

6215714000 6215714400 6215714800 1630082100

(1.32 gal)

Order number 20 L

6215714100 6215714500 6215714900 1630060500

(5.28 gal)

Order number 209 L

6215714200 6215714600 6215715000 1630082101

(55.21 gal)

(*) Whichever comes first in normal conditions.

PISTON COMPRESSOR LUBRICANTS

2946700175 © October 2012 - Subject to alteration without prior notice

ALTAIR PRO ALTAIR ALTAIR 150 ALTAIR PLUS

Engineered mineral oil Engineered mineral oil

Type Mineral oil Synthetic oil with additives

with selected additives with selected additives

Litre Gallon Order number Litre Gallon Order number Litre Gallon Order number Litre Gallon Order number

1L 0,26 1630020700 1L 0,26 6215716300

20*1L 20*0,26 2230006190 2L 0,53 6215715600 5L 1,32 1630047900 5L 1,32 6215715800

209L 55,21 1630020701 5L 1,32 6215715700

Application DIY, professional, home applications

Industrial environment, continu- Industrial environment, Industrial, fully synthetic, Genuine engineered oil for compressors

ous operation, general industry continuous operation, cast iron heavy load

Your compressed air specialist:

www.alup.com

Alup_lubricants_leaflet.indd 1-2 2/11/12 16:29

ENGINEERED TO PERFORM,

DESIGNED TO PROTECT

Effective lubrication is vital to numerous parts of the

compression process. To protect your investment, only high-

quality, genuine lubricants offer the reliability and efficiency

you need. Both the ScrewGuard ROTAIR and ALTAIR

engineered lubricants have passed rigorous testing and meet

your needs for any compressor set-up, in any operating

conditions.

Approved for use on our complete compressor range, they The ScrewGuard ROTAIR and ALTAIR bases have been

allow you to reduce maintenance costs, extend your enriched with carefully selected additives to meet our strict

compressor’s lifetime, and maximize its efficiency. test criteria and to match our tested components.

The end result is increased profitability.

RISKS YOU CAN AVOID

SCREWGUARD ROTAIR & ALTAIR: LUBRICANTS YOU CAN TRUST The use of poorly performing lubricants can cause irreversible damage to your equipment and

substantially increase maintenance and repair costs.

The consequences of poorly performing lubricants can be:

1T HE ASSURANCE YOU NEED

ScrewGuard ROTAIR and ALTAIR are the only lubricants that

4M AXIMUM PERFORMANCE

Designed to match your compressor’s operating conditions,

● Wear of components, increased friction, cavitation. ● Varnish layer on internal parts (coolers, piping…).

● Reduced critical clearance. ● Low performance, higher energy consumption,

are approved and tested to meet the specific quality the ScrewGuard ROTAIR and ALTAIR lubricants with high higher costs.

requirements of your compressor element. thermal conductivity maximize performance. ● Limited operation range.

Our lubricants have been thoroughly tested to allow you to As the excellent air release reduces foaming, recompression ● Reduced cooling and overheated bearings, ● Deposits.

obtain the highest level of protection, extending the of compressed air is avoided. You can rest assured that Rotair compression elements and/or components. ● High, unpredictable maintenance cost.

compressor components’ lifetime and keeping your cost of and Altair will keep the heart of your machine beating at

ownership to an absolute minimum. The use of our lubricants peak performance. ● Corrosion. ● Clogging of oil filter, separator and downstream air

ensures reliable operation and will not limit any warranty on ● Wrong pH, damage to parts, seals and internal filters.

your investment.

elements.

2A FIRM GRIP ON COSTS 5R ELIABLE PROTECTION

We don’t compromise on quality. ScrewGuard ROTAIR and

Clean internal elements and long-lasting components provide

increased efficiency and lower the cost of operation. Our ALTAIR act as structural materials and protect surfaces.

lubricants keep your compressor’s internal elements clean, by They ensure efficient lubrication and correct viscosity across

avoiding the formation of deposits and controlling external the whole operating range of temperatures and humidity.

contaminations. In addition, they reduce oil carry-over and Even after long standstill periods of the compressor, the

prevent the filters from getting clogged, which extends the lubricants allow for a smooth start. Their anti-foam

lifetime of your oil separator, oil filter and compressed air characteristics eliminate the risk of cavitation.

filters. The ScrewGuard ROTAIR and ALTAIR lubricants are fully

compatible with our complete range of compressors.

3A NTI-CORROSION CAPABILITIES

To prevent corrosion, our lubricants form a chemical bound

with metal surfaces, which not only eliminates the risk of

rusting – even during compressor standstill – but also enables

the compressor to resist water contamination.

Alup_lubricants_leaflet.indd 3-4 2/11/12 16:29

You might also like

- Building Costs Per Square Metre in The PhilippinesDocument59 pagesBuilding Costs Per Square Metre in The PhilippinesAl Patrick Dela Calzada100% (1)

- Parts Manual: Generator SetDocument76 pagesParts Manual: Generator SetAristide100% (2)

- Financial Analysis Homework Week 8Document15 pagesFinancial Analysis Homework Week 8effulgentflameNo ratings yet

- Supplement Chapter 5 DT AnswersDocument11 pagesSupplement Chapter 5 DT AnswersJea BalagtasNo ratings yet

- Hardship COVIDTenant AttestationDocument1 pageHardship COVIDTenant AttestationFormatNo ratings yet

- 8000SRM2001 (10 2016) Uk en PDFDocument20 pages8000SRM2001 (10 2016) Uk en PDFTerex Manual100% (2)

- C12 Engine and PumpsDocument2 pagesC12 Engine and PumpsSankar SNo ratings yet

- Chapter 05 Solution Manual Quantitative Methods For BusinessDocument18 pagesChapter 05 Solution Manual Quantitative Methods For BusinessJuan Francisco Pando BalandraNo ratings yet

- CP18 Lubricants Brochure 02 18 2018Document4 pagesCP18 Lubricants Brochure 02 18 2018Csaba SándorNo ratings yet

- CAPACITIES AND SPECIFICATIONSDocument12 pagesCAPACITIES AND SPECIFICATIONSWashington Loayza AlvaradoNo ratings yet

- Capacities and Specifications: MaintenanceDocument12 pagesCapacities and Specifications: MaintenanceZoltán RozinkaNo ratings yet

- Industrial Diesel Engine: TNV IDI SeriesDocument2 pagesIndustrial Diesel Engine: TNV IDI SeriesJohn GarnetNo ratings yet

- 3m 6000 Series Reusable Full Face Mask Respirator Technical DatasheetDocument5 pages3m 6000 Series Reusable Full Face Mask Respirator Technical DatasheetOviedo RocíoNo ratings yet

- Chemical Quick Guide PDFDocument1 pageChemical Quick Guide PDFAndrejs ZundaNo ratings yet

- CAPACITIESDocument18 pagesCAPACITIESJahir Frutos100% (1)

- Case Service Parts Guide Magnum TractorsDocument2 pagesCase Service Parts Guide Magnum TractorsjerryNo ratings yet

- Air Compressor Lubricants 2Document1 pageAir Compressor Lubricants 2Rifki AndriyanNo ratings yet

- TOKICO - Presentation of Fuel DispenserDocument45 pagesTOKICO - Presentation of Fuel DispenserbangladetNo ratings yet

- 7206X00000_AW-Hydraulic-Oil-ISO-32-TDSDocument2 pages7206X00000_AW-Hydraulic-Oil-ISO-32-TDSNima FakherNo ratings yet

- D6N Track Type Tractor Parts Reference GuideDocument11 pagesD6N Track Type Tractor Parts Reference GuideWilliams Araya100% (1)

- Ultra EL: Formulated To Last Up To 16,000 HoursDocument4 pagesUltra EL: Formulated To Last Up To 16,000 Hourselperrote3No ratings yet

- Servo PrimeDocument1 pageServo PrimeRakeshKumarNo ratings yet

- GreaseDocument2 pagesGreasebondholzNo ratings yet

- Process PumpsDocument10 pagesProcess PumpsJohn WatsonNo ratings yet

- Proposal For World Lubricants ProductsDocument1 pageProposal For World Lubricants ProductsAung Myat ThuNo ratings yet

- Surtac 2000Document1 pageSurtac 2000Bibhudutta JethyNo ratings yet

- H Series Small Wheel Loader Parts Reference GuideDocument8 pagesH Series Small Wheel Loader Parts Reference GuideKari MohamedNo ratings yet

- IR Megaroyal Brochure 6102020 EN WebDocument8 pagesIR Megaroyal Brochure 6102020 EN WebLuisAngelCordovadeSanchezNo ratings yet

- Machine Maintenance: From WM No. 5044 OnwardsDocument64 pagesMachine Maintenance: From WM No. 5044 OnwardsMohammedasifNo ratings yet

- Eni Turbine Oil BrochureDocument25 pagesEni Turbine Oil BrochureranjanguptNo ratings yet

- Hitachi ConstructionDocument2 pagesHitachi Constructioncatalin0303100% (1)

- Renolin Ac Compressor Oils: Product InformationDocument2 pagesRenolin Ac Compressor Oils: Product InformationSoporte Técnico RyRNo ratings yet

- D8T Dozer Parts Reference Guide: Covering Aw4, Mb8, Jj5, J8B, KPZ, MLN, FCT, FMCDocument15 pagesD8T Dozer Parts Reference Guide: Covering Aw4, Mb8, Jj5, J8B, KPZ, MLN, FCT, FMCEka AnwarNo ratings yet

- Axooil - Italian TechnologyDocument1 pageAxooil - Italian TechnologyMohammed AlZubaidiNo ratings yet

- Filters and CapacitiesDocument3 pagesFilters and CapacitiesbrunofernandesdacostNo ratings yet

- FTI brochure_cp_gpDocument4 pagesFTI brochure_cp_gpJOKO WIKARNANo ratings yet

- Grease ConvertorsDocument12 pagesGrease ConvertorsRoyce AgabasNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- Prestone COMMAND HEAVY DUTY - (FICHA TECNICA)Document2 pagesPrestone COMMAND HEAVY DUTY - (FICHA TECNICA)Denizon Guevara cubaNo ratings yet

- Datasheet B 439Document3 pagesDatasheet B 439CarlaMarquesNo ratings yet

- Datasheet 6200 SeriesDocument2 pagesDatasheet 6200 SeriesaramihzNo ratings yet

- SutorbiltLegendBrochure 16Document12 pagesSutorbiltLegendBrochure 16Wil TimpoNo ratings yet

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- MOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFDocument2 pagesMOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFFajar EkoNo ratings yet

- D8R Dozer Parts Reference Guide: Covering 9em, T5X, RJM, Mej, Jr8, DWJDocument9 pagesD8R Dozer Parts Reference Guide: Covering 9em, T5X, RJM, Mej, Jr8, DWJArifNo ratings yet

- 950H & 962H Wheel Loader Parts Reference GuideDocument7 pages950H & 962H Wheel Loader Parts Reference Guidetaba ahmedNo ratings yet

- TDS Sinopec EP Golden GreaseDocument2 pagesTDS Sinopec EP Golden Greasehuuphuc.chemlubeNo ratings yet

- Jet-O-Mizer: Size Reduction SystemsDocument4 pagesJet-O-Mizer: Size Reduction SystemsLiwen WeiNo ratings yet

- 3m 6000 Series Half Mask Data SheetDocument4 pages3m 6000 Series Half Mask Data SheetgkmlalNo ratings yet

- Naturelle S2 - копияDocument2 pagesNaturelle S2 - копияГеоргий ДогаруNo ratings yet

- Tds - Power Hydrolube Aw 68Document1 pageTds - Power Hydrolube Aw 68Daniel .alphadrives0% (1)

- Technical Data Sheet: High Performance Rail LubricantDocument1 pageTechnical Data Sheet: High Performance Rail LubricantvarunchNo ratings yet

- 320D/320D L Medium Hydraulic Excavators Parts Reference GuideDocument9 pages320D/320D L Medium Hydraulic Excavators Parts Reference GuideNilton VengoaNo ratings yet

- Product Information Sheet: Description: ApplicationDocument2 pagesProduct Information Sheet: Description: ApplicationgalaxiprinceNo ratings yet

- 2915 8275 00 - Fluids and Lubricants - 2017Document20 pages2915 8275 00 - Fluids and Lubricants - 2017GuptaNo ratings yet

- 12-20T MAINTENANCE MANUAL ZoomlionDocument23 pages12-20T MAINTENANCE MANUAL ZoomlionAbas AbasariNo ratings yet

- Data Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enDocument2 pagesData Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enMohamed Abd-alfattah100% (1)

- Summary Master List of Whole Lubricant in TerminalDocument7 pagesSummary Master List of Whole Lubricant in TerminalncthanhckNo ratings yet

- L-HG Slideway Hydraulic OilDocument2 pagesL-HG Slideway Hydraulic OilYoong TanNo ratings yet

- T Oil Presentation - Technical - 07.06.14 PDFDocument61 pagesT Oil Presentation - Technical - 07.06.14 PDFDeiva Balan Vembadi Muthu100% (2)

- KERN DSheet SODHIPO Eng2Document2 pagesKERN DSheet SODHIPO Eng2Dorina CotoarăNo ratings yet

- 9 Sinopec Hydraulic Transmission Multifunctional Fluid 10W 30 UTTO三用 1Document2 pages9 Sinopec Hydraulic Transmission Multifunctional Fluid 10W 30 UTTO三用 1Damaka LoderNo ratings yet

- Roots 400-600 RCS Blower Dimensions 861893021-861891021Document2 pagesRoots 400-600 RCS Blower Dimensions 861893021-861891021AristideNo ratings yet

- Rexroth CatDocument127 pagesRexroth CatAristideNo ratings yet

- Accessories Verins ShefferDocument20 pagesAccessories Verins ShefferAristideNo ratings yet

- Ca90010f Ca90011gDocument2 pagesCa90010f Ca90011gAristideNo ratings yet

- Sahara Storm Rev 13Document3 pagesSahara Storm Rev 13AristideNo ratings yet

- GUIDE Check and Replacement of PFC CapacitorsDocument4 pagesGUIDE Check and Replacement of PFC CapacitorsAristideNo ratings yet

- BW SCH80 SAE Flange CatalogueDocument1 pageBW SCH80 SAE Flange CatalogueAristideNo ratings yet

- Axial Piston Units A10FZO, A10VZO and A10FZG, A10VZG Series 10 For Variable-Speed DrivesDocument108 pagesAxial Piston Units A10FZO, A10VZO and A10FZG, A10VZG Series 10 For Variable-Speed DrivesAristideNo ratings yet

- Service Manual: PVR15-30B-Flanged Series PumpDocument8 pagesService Manual: PVR15-30B-Flanged Series PumpAristideNo ratings yet

- Mobile Fi Ltration Unit 34 L/min FL Ow RateDocument13 pagesMobile Fi Ltration Unit 34 L/min FL Ow RateAristideNo ratings yet

- Pompe FiltranteDocument64 pagesPompe FiltranteAristideNo ratings yet

- Screwguard Rotair Altair: People. Passion. PerformanceDocument4 pagesScrewguard Rotair Altair: People. Passion. PerformanceAristideNo ratings yet

- Rotair Food Grade SafetyDocument7 pagesRotair Food Grade SafetyAristideNo ratings yet

- Operating Instructions Accessories Component Parts DC Pro Demag Chain HoistsDocument144 pagesOperating Instructions Accessories Component Parts DC Pro Demag Chain HoistsAristideNo ratings yet

- Morse Taper DimensionsDocument1 pageMorse Taper DimensionsGordNo ratings yet

- Economic Analysis For BusinessDocument2 pagesEconomic Analysis For BusinessMohan BaralNo ratings yet

- Cost Accounting 3Document3 pagesCost Accounting 3sharu SKNo ratings yet

- Session 3 CBA in Secondary MarketDocument10 pagesSession 3 CBA in Secondary MarketShabahul ArafiNo ratings yet

- CHAPTER 3pdf - 211118 - 130431Document21 pagesCHAPTER 3pdf - 211118 - 130431Amalin IlyanaNo ratings yet

- HousekeepingDocument29 pagesHousekeepingMenchie Rose D. MendezNo ratings yet

- Analysis of Indian GDP.Document8 pagesAnalysis of Indian GDP.Navdeep TiwariNo ratings yet

- Fileupload 1381940945Document8 pagesFileupload 1381940945Cim HanoiNo ratings yet

- Chapter 5 Microeconomics by David Besanko Ronald Braeutigam Test BankDocument26 pagesChapter 5 Microeconomics by David Besanko Ronald Braeutigam Test BankNupur KasliwalNo ratings yet

- Module 2 - 3 Cost Benefit Evaluation TechniquesDocument15 pagesModule 2 - 3 Cost Benefit Evaluation TechniquesKarthik GoudNo ratings yet

- TPMO New Price (Price Escalation)Document221 pagesTPMO New Price (Price Escalation)Tadele Dandena GudetaNo ratings yet

- Sales Quiz 1Document3 pagesSales Quiz 1Roldan Cejuela CañadaNo ratings yet

- Get PDFDocument10 pagesGet PDFSantoshNo ratings yet

- Apollo Medicine InvoiceMay 19 2022 15 11Document1 pageApollo Medicine InvoiceMay 19 2022 15 11CA Sumit GargNo ratings yet

- Supply Chain Management ReportsDocument19 pagesSupply Chain Management ReportsSazeeth SinghNo ratings yet

- Richard Wyckoff Method RTTPDFDocument40 pagesRichard Wyckoff Method RTTPDFHardeep SinghNo ratings yet

- Quiz - Chapter 4 - Partnership Liquidation - 2021 EditionDocument7 pagesQuiz - Chapter 4 - Partnership Liquidation - 2021 EditionYam SondayNo ratings yet

- Critical SolvingDocument76 pagesCritical SolvingAdner CabaloNo ratings yet

- Micro Economics Consumer EquilibriumDocument34 pagesMicro Economics Consumer EquilibriumSurajNo ratings yet

- Dividend Zakat & Tax Deduction ReportsDocument4 pagesDividend Zakat & Tax Deduction ReportsfahadullahNo ratings yet

- Jim Rickard SDocument49 pagesJim Rickard SCaio RossiNo ratings yet

- Nin/Pmjay Id Name of The Vaccination Site Category Type District BlockDocument2 pagesNin/Pmjay Id Name of The Vaccination Site Category Type District BlockNikunja PadhanNo ratings yet

- Chapter 003 Fundamentals of Cost-Volume-Profit Analysis: True / False QuestionsDocument39 pagesChapter 003 Fundamentals of Cost-Volume-Profit Analysis: True / False QuestionsNaddieNo ratings yet

- College of Physicians & Surgeons Pakistan: Online Application Form (FCPS-I) ExaminationDocument2 pagesCollege of Physicians & Surgeons Pakistan: Online Application Form (FCPS-I) ExaminationUsama BilalNo ratings yet

- The Fraternal Order of Eagles Tarlac Golden Eagles Club Treasurer'S Report Date Particular Debit Credit BalanceDocument3 pagesThe Fraternal Order of Eagles Tarlac Golden Eagles Club Treasurer'S Report Date Particular Debit Credit Balancerufaida haila managil100% (1)