Professional Documents

Culture Documents

Process Safety Incident Severity Chart

Process Safety Incident Severity Chart

Uploaded by

Wafa HabibCopyright:

Available Formats

You might also like

- COSH Module PDFDocument144 pagesCOSH Module PDFMark Allandale Dedel95% (22)

- 01 Childrenswear Safety Manual 2009 - ClothingDocument57 pages01 Childrenswear Safety Manual 2009 - Clothingmorshed_mahamud705538% (8)

- Fog Pest Control Risk AssessmentDocument5 pagesFog Pest Control Risk Assessmentطارق رضوان100% (1)

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- JSA Painting WorkDocument2 pagesJSA Painting WorkKhalid NaseemNo ratings yet

- SIL Classification Worksheets LOPADocument26 pagesSIL Classification Worksheets LOPAKamal Deshapriya75% (4)

- CFPSDocument4 pagesCFPSRajendraNo ratings yet

- Incident Management Report enDocument15 pagesIncident Management Report enS PravinthNo ratings yet

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- 3.1f2 Form JseaDocument4 pages3.1f2 Form Jseakaka347No ratings yet

- Risk Assesment MethodologyDocument7 pagesRisk Assesment MethodologyvivekanandhanNo ratings yet

- Priliminary Hazards AnalysisDocument15 pagesPriliminary Hazards AnalysisSona VermaNo ratings yet

- Jar Doc 06 Jarus Sora Annex B v1.0Document13 pagesJar Doc 06 Jarus Sora Annex B v1.0Csaba FeketeNo ratings yet

- 2safetyriskanalysis Gasplantitaly 171219103958 PDFDocument1 page2safetyriskanalysis Gasplantitaly 171219103958 PDFTatak Bay AhmedNo ratings yet

- 2safetyriskanalysis Gasplantitaly 171219103958 PDFDocument1 page2safetyriskanalysis Gasplantitaly 171219103958 PDFloopkkNo ratings yet

- 12 Hazard Risk RailDocument46 pages12 Hazard Risk Railabdelrahman.fathyNo ratings yet

- HSE Severity TableDocument1 pageHSE Severity TableMohamed HadjkacemNo ratings yet

- PIR Incident ReportDocument3 pagesPIR Incident Reportnaalifeshow143No ratings yet

- Jsa Erection Concrete Structure Cooling TowerDocument8 pagesJsa Erection Concrete Structure Cooling TowerMuhammad YusufNo ratings yet

- RA GL HAL PPS 404 (Dewatering)Document6 pagesRA GL HAL PPS 404 (Dewatering)BalasubramanianNo ratings yet

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- Contaminated Water Countermeasure - r1Document19 pagesContaminated Water Countermeasure - r1Utami RizkiNo ratings yet

- A HM 610 Risk Severity LevelsDocument2 pagesA HM 610 Risk Severity LevelsAnton Domin (Airport Manager)No ratings yet

- Science:, 1040 (2005) Evan MillsDocument6 pagesScience:, 1040 (2005) Evan MillsRamona-Elena POPESCUNo ratings yet

- Total Economic Consequences of Terrorist Attacks: Insights From 9/11Document11 pagesTotal Economic Consequences of Terrorist Attacks: Insights From 9/11Monirul IslamNo ratings yet

- CBB 40104 Bioplant Design Project 2: (Chapter 5: Process Safety)Document15 pagesCBB 40104 Bioplant Design Project 2: (Chapter 5: Process Safety)Mira Lucis CaelumNo ratings yet

- PCS-EMP-5.001 Emergency Response Contingency PlanDocument23 pagesPCS-EMP-5.001 Emergency Response Contingency PlanRFM Corporation Flour DivisionNo ratings yet

- Risk Assessment Procedure Step Wise GuideDocument6 pagesRisk Assessment Procedure Step Wise GuidemostafaNo ratings yet

- Emergency Response Plan GuideDocument11 pagesEmergency Response Plan GuideSamier MohamedNo ratings yet

- Environmental Aspect & Impact Register: Guidance NotesDocument5 pagesEnvironmental Aspect & Impact Register: Guidance NotesRASHEED YUSUFNo ratings yet

- NPP SafetyDocument11 pagesNPP SafetyWaleed TayyabNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- BID NUMBER. RW10405497/23 Bid Description: Tender For The Extension of Wastewater Treatment Works at Namahadi/Frankfort (Phase 2)Document7 pagesBID NUMBER. RW10405497/23 Bid Description: Tender For The Extension of Wastewater Treatment Works at Namahadi/Frankfort (Phase 2)david selekaNo ratings yet

- OTC Surge Protection WhitePaperDocument11 pagesOTC Surge Protection WhitePaperShakeel AhmedNo ratings yet

- SIL (LOPA) Analisys ProcedureDocument20 pagesSIL (LOPA) Analisys ProcedureCristina Mayer100% (3)

- J JLP 2010 05 009Document7 pagesJ JLP 2010 05 009AsimNo ratings yet

- Chemical, Biological, RadiologicalDocument8 pagesChemical, Biological, Radiologicalduy khanhNo ratings yet

- 5.5 Hazard and Risk Register TemplateDocument5 pages5.5 Hazard and Risk Register TemplateSebastian AlvarezNo ratings yet

- Fire Hazards and ControlDocument31 pagesFire Hazards and ControlDeva DNo ratings yet

- 16 HAZOP Basics3Document24 pages16 HAZOP Basics3BharatNo ratings yet

- Environmental Aspects Register (Iso 14001)Document11 pagesEnvironmental Aspects Register (Iso 14001)hunain zafarNo ratings yet

- Safety Form: Chemical Risk AssessmentDocument3 pagesSafety Form: Chemical Risk AssessmentMarko IvanovićNo ratings yet

- App R Failure Modes Effects AnalysisDocument24 pagesApp R Failure Modes Effects AnalysisAbass BILANo ratings yet

- RA-GL-HAL-PPS-442 (Air Pigging)Document5 pagesRA-GL-HAL-PPS-442 (Air Pigging)BalasubramanianNo ratings yet

- Emergency Response Plan GuideDocument12 pagesEmergency Response Plan GuideDave DohaNo ratings yet

- Criteria For Aspect Impact AnalysisDocument1 pageCriteria For Aspect Impact AnalysislalitNo ratings yet

- Jsa Install ScaffoldingDocument8 pagesJsa Install ScaffoldingMuhammad YusufNo ratings yet

- Environmental Aspect and Impact MatrixDocument1 pageEnvironmental Aspect and Impact Matrixมิตร อันมาNo ratings yet

- Jsa Install Distribution PipeDocument8 pagesJsa Install Distribution PipeMuhammad YusufNo ratings yet

- TRBS2152 - 02 enDocument34 pagesTRBS2152 - 02 enwhbb.obhpr74No ratings yet

- Z Fuse - c1d2 - Fusing (Phoenix Contact Theory)Document4 pagesZ Fuse - c1d2 - Fusing (Phoenix Contact Theory)theloniussherekNo ratings yet

- Emergency Preparedness and ResponseDocument4 pagesEmergency Preparedness and ResponseFernando RomeroNo ratings yet

- RA002 Transport, and Offloading The Piling RigDocument15 pagesRA002 Transport, and Offloading The Piling RigNonhleNo ratings yet

- Incident ManagementDocument38 pagesIncident ManagementricardoNo ratings yet

- Risk Assessment Guidance: Field Title Required InformationDocument14 pagesRisk Assessment Guidance: Field Title Required InformationMohd AimanNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument3 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- HIRA Boiler Pressure Part Risk AssessmentDocument15 pagesHIRA Boiler Pressure Part Risk AssessmentHARSHAL100% (2)

- Tra - Annexure A SKC TRA Consequence Impact Level SKC TRA Risk MatrixDocument1 pageTra - Annexure A SKC TRA Consequence Impact Level SKC TRA Risk MatrixMohammed AffrozeNo ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- ISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4Document1 pageISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4dnmuleNo ratings yet

- Risk Management Standard - 229874 - Julio 2020Document8 pagesRisk Management Standard - 229874 - Julio 2020Alejandro Bartolo YañezNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- Increasing Resilience to Climate Change in the Agricultural Sector of the Middle East: The Cases of Jordan and LebanonFrom EverandIncreasing Resilience to Climate Change in the Agricultural Sector of the Middle East: The Cases of Jordan and LebanonNo ratings yet

- Industrial Control Systems Vulnerabilities StatisticsDocument19 pagesIndustrial Control Systems Vulnerabilities StatisticsWafa HabibNo ratings yet

- الآثار البيئية والاقتصادية لبعض المخلفات الصناعيةDocument256 pagesالآثار البيئية والاقتصادية لبعض المخلفات الصناعيةWafa HabibNo ratings yet

- Behavior Based Safety & You!!! Part IDocument19 pagesBehavior Based Safety & You!!! Part IWafa HabibNo ratings yet

- Introduction To Process Safety PrinciplesDocument9 pagesIntroduction To Process Safety PrinciplesWafa Habib100% (1)

- Bosh QuizDocument1 pageBosh QuizNorlito VeterboNo ratings yet

- Icw0552 780Document7 pagesIcw0552 780Marcelo VieiraNo ratings yet

- Faa - Human Factors in Aviation Maintenance HF - Ops - Manual - 2014Document50 pagesFaa - Human Factors in Aviation Maintenance HF - Ops - Manual - 2014chontaduro08100% (3)

- 1100-0111 enDocument14 pages1100-0111 enMohamed HamdallahNo ratings yet

- Pre-Commissioning Checklist: ICOM Energy Association Approved Document©Document2 pagesPre-Commissioning Checklist: ICOM Energy Association Approved Document©LaurentiuNo ratings yet

- Hazard Identification TABLEDocument6 pagesHazard Identification TABLEjason a. unNo ratings yet

- Comment On Estimating Heat Release Rate For A DesignDocument5 pagesComment On Estimating Heat Release Rate For A DesigndanateoNo ratings yet

- Sika Top® - 121Document3 pagesSika Top® - 121Bogie Prastowo MahardhikaNo ratings yet

- 2014 Fuel Regulation ATP 4-43-2Document112 pages2014 Fuel Regulation ATP 4-43-2Paul Barnard100% (1)

- School Safety Checklist Revised Nov 4thDocument12 pagesSchool Safety Checklist Revised Nov 4thstefensamuelNo ratings yet

- Material Safety Data Sheet: Qingdao Sanhuan Colorchem Co., LTDDocument5 pagesMaterial Safety Data Sheet: Qingdao Sanhuan Colorchem Co., LTDwidyaNo ratings yet

- LM 75 - Partes - 1Document46 pagesLM 75 - Partes - 1Raul VergarayNo ratings yet

- Pennsville Fire Rescue 2010 SOPsDocument89 pagesPennsville Fire Rescue 2010 SOPsberoblesNo ratings yet

- FMEA and RCM Failure Mode Risk Management Fundamentals - UdemyDocument10 pagesFMEA and RCM Failure Mode Risk Management Fundamentals - UdemySantosh NathanNo ratings yet

- Accident & Incident Investigation FormDocument5 pagesAccident & Incident Investigation FormTony CampbellNo ratings yet

- 11-Highway SafetyDocument36 pages11-Highway SafetyKingNo ratings yet

- FSSAI Food Recall - PlanDocument4 pagesFSSAI Food Recall - Plannaturalpride.tinnfoodsNo ratings yet

- EF-E012 Contractors Safety RulesDocument2 pagesEF-E012 Contractors Safety RulesEZATI HANANI MURDINo ratings yet

- BARANGAY DISASTER RISK REDUCTION MANAGEMENT PLAN (p1)Document2 pagesBARANGAY DISASTER RISK REDUCTION MANAGEMENT PLAN (p1)rogelio ramiroNo ratings yet

- Girl From Nowhere Goes To Kcast ScriptDocument3 pagesGirl From Nowhere Goes To Kcast ScriptCarl ColladoNo ratings yet

- The Safe Use of The Existing Natural Gas System For Hydrogen (Overview of The Naturalhy-Project)Document7 pagesThe Safe Use of The Existing Natural Gas System For Hydrogen (Overview of The Naturalhy-Project)YvesfNo ratings yet

- ASC Audit Preparation Checklist Shrimp v1.1Document23 pagesASC Audit Preparation Checklist Shrimp v1.1Ragil Satriyo GumilangNo ratings yet

- CSA - Type X, Y & Z CertificateDocument5 pagesCSA - Type X, Y & Z CertificateTonyNo ratings yet

- Biological SafetyDocument14 pagesBiological SafetyTrường NhânNo ratings yet

- Total'S: GoldenDocument20 pagesTotal'S: GoldenBennyNo ratings yet

- Safety Data Sheet: Product Name: Mobil Polyrex emDocument10 pagesSafety Data Sheet: Product Name: Mobil Polyrex emAkmalNo ratings yet

- Terminal SafetyDocument40 pagesTerminal SafetyPort0% (1)

Process Safety Incident Severity Chart

Process Safety Incident Severity Chart

Uploaded by

Wafa HabibOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Safety Incident Severity Chart

Process Safety Incident Severity Chart

Uploaded by

Wafa HabibCopyright:

Available Formats

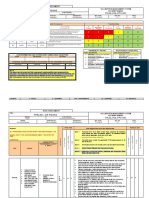

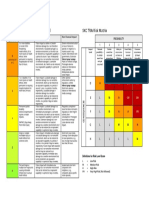

Process Safety Incident Severity Categories

A severity level will be assigned for each consequence category for each process safety incident using the

criteria shown in the following table:

Severity Level Safety/Human Health Fire or Potential Community/

(Note 4) (Note 5) Explosion chemical impact environment impact

(including (Note 3) (Note 5)

overpressure)

NA Does not meet or exceed Does not meet or Does not meet or Does not meet or exceed Level 4

Level 4 threshold exceed Level 4 exceed Level 4 threshold

threshold threshold

Injury requiring treatment Resulting in $25,000 to Chemical released Short -term remediation to

4 beyond first aid to employee $100,000 of direct within secondary address acute environmental

(1 point used in severity or contractors (or equivalent, cost containment or impact.

rate calculations for each Note 1) associated with a contained within the

of the attributes that apply process safety incident unit - see Note 2A No long term cost or company

to the incident) oversight.

(In U.S., incidents meeting the

definitions of an OSHA Examples would include spill

recordable injury). cleanup, soil and vegetation

removal.

Lost time injury to employee Resulting in $100,000 Chemical release Minor off-site impact with

3 or contractors associated with to $1 million of direct outside of containment precautionary shelter-in-place

(3 points used in severity a process safety event cost. but retained on

rate calculations for each company property OR

of the attributes that apply

to the incident). OR Environmental remediation

require with cost less than $1

flammable release million. No other regulatory

without potential for oversight required.

vapor cloud explosives

- see Note 2B OR

Local media coverage

On-site fatality - employee or Resulting in $1 million Chemical release with Shelter-in-place or community

2 contractors associated with a to $10 million of direct potential for injury off evacuation,

(9 points used in severity process safety event; multiple cost. site or flammable

rate calculations for each lost time injuries or one or release resulting in a OR

of the attributes that apply more serious offsite injuries vapor cloud entering a

to the incident). associated with a process building or potential Environmental remediation

safety event. explosion site required and cost in between $1

(congested/confined million -$ 2.5 million. State

area) with potential for government investigation and

damage or casualties if oversight of process.

ignited - see Note 2C.

OR

Regional media coverage or brief

national media coverage.

Off-site fatality or multiple on- Resulting in direct cost Chemical release with National media coverage over

1 site fatalities associated with a greater than $10 potential for significant multiple days.

(27 points used in process safety event. million. on-site or off-site

severity rate calculations injuries or fatalities - OR

for each of the attributes see Note 2D.

that apply to the incident). Environmental remediation

required and cost in excess of

$2.5 million. Federal government

investigation and oversight of

process.

OR

Other significant community

impact.

NOTE 1: for personnel located or working in process manufacturing facilities.

NOTE 2: It is the intent that the “Potential Chemical Impact” definitions shown in Table 2 to provide

sufficient definition such that plant owners or users of this metric can select from the appropriate

qualitative severity descriptors without a need for dispersion modeling or calculations. The user should

use the same type of observation and judgment typically used to determine the appropriate emergency

response actions to take when a chemical release occurs. However, CCPS does not want to preclude

the use of a “sharper pencil” (e.g. dispersion modeling) if a company so chooses. In those cases, the

following notes are being provided, as examples, to clarify the type of hazard intended with the four

qualitative categories:

A. AEGL-2/ERPG-2 concentrations (as available) or 50% of Lower Flammability Limits (LFL) does

not extend beyond process boundary (operating unit) at grade or platform levels, or small

flammable release not entering a potential explosion site (congested/confined area) due to the

limited amount of material released or location of release (e.g., flare stack discharge where pilot

failed to ignite discharged vapors).

B. AEGL-2/ERPG-2 concentrations (as available) extend beyond unit boundary but do not extend

beyond property boundary. Flammable vapors greater than 50% of LFL at grade may extend

beyond unit boundaries but did not entering a potential explosion site (congested/confined

area); therefore, very little chance of resulting in a VCE.

C. AEGL-2/ERPG-2 concentrations (as available) exceeded off-site OR flammable release

resulting in a vapor cloud entering a building or potential explosion site (congested/confined

area) with potential for VCE resulting in fewer than 5 casualties (i.e., people or occupied

buildings within the immediate vicinity) if ignited

D. AEGL-3/ERPG-3 concentrations (as available) exceeded off-site over the defined 10/30/60

minute time frame OR flammable release resulting in a vapor cloud entering a building or

potential explosion site (congested/confined area) with potential for VCE resulting in greater

than 5 casualties (i.e., people or occupied buildings within the immediate vicinity) if ignited

NOTE 3: The Potential Chemical Impact table reflects the recommended criteria. However, some

companies may object to making a relative ranking estimate on the potential impact using the terms

described. In those situations, it would be acceptable for those companies to substitute the following

criteria corporate wide: Severity Level 4: 1X to 3X the TQ for that chemical, Level 3: 3X to 9X, Level 2:

9X to 20X, and Level 1: 20X or greater the TQ for that chemical. However, if a company elects to use

this alternative approach they should be consistent and use this approach for all releases. They should

not select between the two methods on a case-by-case basis simply to get the lowest severity score.

NOTE 4: The category labels can be modified by individual companies or industry associations to align

with the severity order of other metrics. It is important is to use the same severity point assignments

shown.

NOTE 5: The severity index calculations include a category for “Community/ Environmental” impact and

a first aid (i.e., OSHA “recordable injury”) level of Safety/Human Health impact which are not include in

the PSI threshold criteria. However, the purpose of including both of these values is to achieve greater

differentiation of severity points for incidents that result in any form or injury, community, or

environmental impacts.

You might also like

- COSH Module PDFDocument144 pagesCOSH Module PDFMark Allandale Dedel95% (22)

- 01 Childrenswear Safety Manual 2009 - ClothingDocument57 pages01 Childrenswear Safety Manual 2009 - Clothingmorshed_mahamud705538% (8)

- Fog Pest Control Risk AssessmentDocument5 pagesFog Pest Control Risk Assessmentطارق رضوان100% (1)

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- JSA Painting WorkDocument2 pagesJSA Painting WorkKhalid NaseemNo ratings yet

- SIL Classification Worksheets LOPADocument26 pagesSIL Classification Worksheets LOPAKamal Deshapriya75% (4)

- CFPSDocument4 pagesCFPSRajendraNo ratings yet

- Incident Management Report enDocument15 pagesIncident Management Report enS PravinthNo ratings yet

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- 3.1f2 Form JseaDocument4 pages3.1f2 Form Jseakaka347No ratings yet

- Risk Assesment MethodologyDocument7 pagesRisk Assesment MethodologyvivekanandhanNo ratings yet

- Priliminary Hazards AnalysisDocument15 pagesPriliminary Hazards AnalysisSona VermaNo ratings yet

- Jar Doc 06 Jarus Sora Annex B v1.0Document13 pagesJar Doc 06 Jarus Sora Annex B v1.0Csaba FeketeNo ratings yet

- 2safetyriskanalysis Gasplantitaly 171219103958 PDFDocument1 page2safetyriskanalysis Gasplantitaly 171219103958 PDFTatak Bay AhmedNo ratings yet

- 2safetyriskanalysis Gasplantitaly 171219103958 PDFDocument1 page2safetyriskanalysis Gasplantitaly 171219103958 PDFloopkkNo ratings yet

- 12 Hazard Risk RailDocument46 pages12 Hazard Risk Railabdelrahman.fathyNo ratings yet

- HSE Severity TableDocument1 pageHSE Severity TableMohamed HadjkacemNo ratings yet

- PIR Incident ReportDocument3 pagesPIR Incident Reportnaalifeshow143No ratings yet

- Jsa Erection Concrete Structure Cooling TowerDocument8 pagesJsa Erection Concrete Structure Cooling TowerMuhammad YusufNo ratings yet

- RA GL HAL PPS 404 (Dewatering)Document6 pagesRA GL HAL PPS 404 (Dewatering)BalasubramanianNo ratings yet

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- Contaminated Water Countermeasure - r1Document19 pagesContaminated Water Countermeasure - r1Utami RizkiNo ratings yet

- A HM 610 Risk Severity LevelsDocument2 pagesA HM 610 Risk Severity LevelsAnton Domin (Airport Manager)No ratings yet

- Science:, 1040 (2005) Evan MillsDocument6 pagesScience:, 1040 (2005) Evan MillsRamona-Elena POPESCUNo ratings yet

- Total Economic Consequences of Terrorist Attacks: Insights From 9/11Document11 pagesTotal Economic Consequences of Terrorist Attacks: Insights From 9/11Monirul IslamNo ratings yet

- CBB 40104 Bioplant Design Project 2: (Chapter 5: Process Safety)Document15 pagesCBB 40104 Bioplant Design Project 2: (Chapter 5: Process Safety)Mira Lucis CaelumNo ratings yet

- PCS-EMP-5.001 Emergency Response Contingency PlanDocument23 pagesPCS-EMP-5.001 Emergency Response Contingency PlanRFM Corporation Flour DivisionNo ratings yet

- Risk Assessment Procedure Step Wise GuideDocument6 pagesRisk Assessment Procedure Step Wise GuidemostafaNo ratings yet

- Emergency Response Plan GuideDocument11 pagesEmergency Response Plan GuideSamier MohamedNo ratings yet

- Environmental Aspect & Impact Register: Guidance NotesDocument5 pagesEnvironmental Aspect & Impact Register: Guidance NotesRASHEED YUSUFNo ratings yet

- NPP SafetyDocument11 pagesNPP SafetyWaleed TayyabNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- BID NUMBER. RW10405497/23 Bid Description: Tender For The Extension of Wastewater Treatment Works at Namahadi/Frankfort (Phase 2)Document7 pagesBID NUMBER. RW10405497/23 Bid Description: Tender For The Extension of Wastewater Treatment Works at Namahadi/Frankfort (Phase 2)david selekaNo ratings yet

- OTC Surge Protection WhitePaperDocument11 pagesOTC Surge Protection WhitePaperShakeel AhmedNo ratings yet

- SIL (LOPA) Analisys ProcedureDocument20 pagesSIL (LOPA) Analisys ProcedureCristina Mayer100% (3)

- J JLP 2010 05 009Document7 pagesJ JLP 2010 05 009AsimNo ratings yet

- Chemical, Biological, RadiologicalDocument8 pagesChemical, Biological, Radiologicalduy khanhNo ratings yet

- 5.5 Hazard and Risk Register TemplateDocument5 pages5.5 Hazard and Risk Register TemplateSebastian AlvarezNo ratings yet

- Fire Hazards and ControlDocument31 pagesFire Hazards and ControlDeva DNo ratings yet

- 16 HAZOP Basics3Document24 pages16 HAZOP Basics3BharatNo ratings yet

- Environmental Aspects Register (Iso 14001)Document11 pagesEnvironmental Aspects Register (Iso 14001)hunain zafarNo ratings yet

- Safety Form: Chemical Risk AssessmentDocument3 pagesSafety Form: Chemical Risk AssessmentMarko IvanovićNo ratings yet

- App R Failure Modes Effects AnalysisDocument24 pagesApp R Failure Modes Effects AnalysisAbass BILANo ratings yet

- RA-GL-HAL-PPS-442 (Air Pigging)Document5 pagesRA-GL-HAL-PPS-442 (Air Pigging)BalasubramanianNo ratings yet

- Emergency Response Plan GuideDocument12 pagesEmergency Response Plan GuideDave DohaNo ratings yet

- Criteria For Aspect Impact AnalysisDocument1 pageCriteria For Aspect Impact AnalysislalitNo ratings yet

- Jsa Install ScaffoldingDocument8 pagesJsa Install ScaffoldingMuhammad YusufNo ratings yet

- Environmental Aspect and Impact MatrixDocument1 pageEnvironmental Aspect and Impact Matrixมิตร อันมาNo ratings yet

- Jsa Install Distribution PipeDocument8 pagesJsa Install Distribution PipeMuhammad YusufNo ratings yet

- TRBS2152 - 02 enDocument34 pagesTRBS2152 - 02 enwhbb.obhpr74No ratings yet

- Z Fuse - c1d2 - Fusing (Phoenix Contact Theory)Document4 pagesZ Fuse - c1d2 - Fusing (Phoenix Contact Theory)theloniussherekNo ratings yet

- Emergency Preparedness and ResponseDocument4 pagesEmergency Preparedness and ResponseFernando RomeroNo ratings yet

- RA002 Transport, and Offloading The Piling RigDocument15 pagesRA002 Transport, and Offloading The Piling RigNonhleNo ratings yet

- Incident ManagementDocument38 pagesIncident ManagementricardoNo ratings yet

- Risk Assessment Guidance: Field Title Required InformationDocument14 pagesRisk Assessment Guidance: Field Title Required InformationMohd AimanNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument3 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- HIRA Boiler Pressure Part Risk AssessmentDocument15 pagesHIRA Boiler Pressure Part Risk AssessmentHARSHAL100% (2)

- Tra - Annexure A SKC TRA Consequence Impact Level SKC TRA Risk MatrixDocument1 pageTra - Annexure A SKC TRA Consequence Impact Level SKC TRA Risk MatrixMohammed AffrozeNo ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- ISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4Document1 pageISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4dnmuleNo ratings yet

- Risk Management Standard - 229874 - Julio 2020Document8 pagesRisk Management Standard - 229874 - Julio 2020Alejandro Bartolo YañezNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- Increasing Resilience to Climate Change in the Agricultural Sector of the Middle East: The Cases of Jordan and LebanonFrom EverandIncreasing Resilience to Climate Change in the Agricultural Sector of the Middle East: The Cases of Jordan and LebanonNo ratings yet

- Industrial Control Systems Vulnerabilities StatisticsDocument19 pagesIndustrial Control Systems Vulnerabilities StatisticsWafa HabibNo ratings yet

- الآثار البيئية والاقتصادية لبعض المخلفات الصناعيةDocument256 pagesالآثار البيئية والاقتصادية لبعض المخلفات الصناعيةWafa HabibNo ratings yet

- Behavior Based Safety & You!!! Part IDocument19 pagesBehavior Based Safety & You!!! Part IWafa HabibNo ratings yet

- Introduction To Process Safety PrinciplesDocument9 pagesIntroduction To Process Safety PrinciplesWafa Habib100% (1)

- Bosh QuizDocument1 pageBosh QuizNorlito VeterboNo ratings yet

- Icw0552 780Document7 pagesIcw0552 780Marcelo VieiraNo ratings yet

- Faa - Human Factors in Aviation Maintenance HF - Ops - Manual - 2014Document50 pagesFaa - Human Factors in Aviation Maintenance HF - Ops - Manual - 2014chontaduro08100% (3)

- 1100-0111 enDocument14 pages1100-0111 enMohamed HamdallahNo ratings yet

- Pre-Commissioning Checklist: ICOM Energy Association Approved Document©Document2 pagesPre-Commissioning Checklist: ICOM Energy Association Approved Document©LaurentiuNo ratings yet

- Hazard Identification TABLEDocument6 pagesHazard Identification TABLEjason a. unNo ratings yet

- Comment On Estimating Heat Release Rate For A DesignDocument5 pagesComment On Estimating Heat Release Rate For A DesigndanateoNo ratings yet

- Sika Top® - 121Document3 pagesSika Top® - 121Bogie Prastowo MahardhikaNo ratings yet

- 2014 Fuel Regulation ATP 4-43-2Document112 pages2014 Fuel Regulation ATP 4-43-2Paul Barnard100% (1)

- School Safety Checklist Revised Nov 4thDocument12 pagesSchool Safety Checklist Revised Nov 4thstefensamuelNo ratings yet

- Material Safety Data Sheet: Qingdao Sanhuan Colorchem Co., LTDDocument5 pagesMaterial Safety Data Sheet: Qingdao Sanhuan Colorchem Co., LTDwidyaNo ratings yet

- LM 75 - Partes - 1Document46 pagesLM 75 - Partes - 1Raul VergarayNo ratings yet

- Pennsville Fire Rescue 2010 SOPsDocument89 pagesPennsville Fire Rescue 2010 SOPsberoblesNo ratings yet

- FMEA and RCM Failure Mode Risk Management Fundamentals - UdemyDocument10 pagesFMEA and RCM Failure Mode Risk Management Fundamentals - UdemySantosh NathanNo ratings yet

- Accident & Incident Investigation FormDocument5 pagesAccident & Incident Investigation FormTony CampbellNo ratings yet

- 11-Highway SafetyDocument36 pages11-Highway SafetyKingNo ratings yet

- FSSAI Food Recall - PlanDocument4 pagesFSSAI Food Recall - Plannaturalpride.tinnfoodsNo ratings yet

- EF-E012 Contractors Safety RulesDocument2 pagesEF-E012 Contractors Safety RulesEZATI HANANI MURDINo ratings yet

- BARANGAY DISASTER RISK REDUCTION MANAGEMENT PLAN (p1)Document2 pagesBARANGAY DISASTER RISK REDUCTION MANAGEMENT PLAN (p1)rogelio ramiroNo ratings yet

- Girl From Nowhere Goes To Kcast ScriptDocument3 pagesGirl From Nowhere Goes To Kcast ScriptCarl ColladoNo ratings yet

- The Safe Use of The Existing Natural Gas System For Hydrogen (Overview of The Naturalhy-Project)Document7 pagesThe Safe Use of The Existing Natural Gas System For Hydrogen (Overview of The Naturalhy-Project)YvesfNo ratings yet

- ASC Audit Preparation Checklist Shrimp v1.1Document23 pagesASC Audit Preparation Checklist Shrimp v1.1Ragil Satriyo GumilangNo ratings yet

- CSA - Type X, Y & Z CertificateDocument5 pagesCSA - Type X, Y & Z CertificateTonyNo ratings yet

- Biological SafetyDocument14 pagesBiological SafetyTrường NhânNo ratings yet

- Total'S: GoldenDocument20 pagesTotal'S: GoldenBennyNo ratings yet

- Safety Data Sheet: Product Name: Mobil Polyrex emDocument10 pagesSafety Data Sheet: Product Name: Mobil Polyrex emAkmalNo ratings yet

- Terminal SafetyDocument40 pagesTerminal SafetyPort0% (1)