Professional Documents

Culture Documents

NX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing System

NX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing System

Uploaded by

Bartek HajaCopyright:

Available Formats

You might also like

- CP System Deep Well Anode Groundbed For PipelineDocument5 pagesCP System Deep Well Anode Groundbed For PipelineMastram HatheshNo ratings yet

- VW TL 217 2016Document8 pagesVW TL 217 2016Bartek HajaNo ratings yet

- 2012 Remington Defense CatalogDocument18 pages2012 Remington Defense CatalogMario Lopez100% (1)

- Technical Specification: B Em9henjDocument6 pagesTechnical Specification: B Em9henjBartek HajaNo ratings yet

- How To Make A Shoji Screen PDFDocument2 pagesHow To Make A Shoji Screen PDFJames MyersNo ratings yet

- 192 063002 NX Series CatalogueDocument18 pages192 063002 NX Series Cataloguetranhuutri1987quangngaiNo ratings yet

- CEMP Electric Motors Size 355Document6 pagesCEMP Electric Motors Size 355Сергій ТарасенкоNo ratings yet

- Teknovak Presentation PDFDocument22 pagesTeknovak Presentation PDFSinan YıldızNo ratings yet

- MIKRO 220/220 R Classic/cooled: Microlitre CentrifugesDocument10 pagesMIKRO 220/220 R Classic/cooled: Microlitre Centrifugesخورخى ليما دوائر المحكمةNo ratings yet

- All Offerings 2017Document8 pagesAll Offerings 2017Andres SanchezNo ratings yet

- Centrifuge Digtor22CDocument9 pagesCentrifuge Digtor22Cbilal khan0% (1)

- Tank Sppecs.Document2 pagesTank Sppecs.sunil601No ratings yet

- 0185-1100-US 1V1 Product OverviewDocument36 pages0185-1100-US 1V1 Product OverviewAlexander Aristizábal PeñalozaNo ratings yet

- Nicrofer 3220 3220h eDocument15 pagesNicrofer 3220 3220h eKevinCollinNo ratings yet

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- Tanque Movil CriogenicoDocument2 pagesTanque Movil Criogenicoisidromundarain67No ratings yet

- CATALO VetivDocument240 pagesCATALO VetivHữu CôngNo ratings yet

- Movinor LN enDocument4 pagesMovinor LN enAlbert de la FuenteNo ratings yet

- Ador BookletDocument22 pagesAdor Bookletgssrraju0% (1)

- Gear Racks Product Catalog EN PDFDocument31 pagesGear Racks Product Catalog EN PDFFer VFNo ratings yet

- DS Special Purpose Fuse Links HelioProtection Photovoltaic Fuses NH 800VAC GR ENDocument14 pagesDS Special Purpose Fuse Links HelioProtection Photovoltaic Fuses NH 800VAC GR ENFiras ouhichiNo ratings yet

- May Nen IntermechDocument2 pagesMay Nen IntermechUchiha SaitamaNo ratings yet

- Nikkon Argento K09360-MP Series S439Document2 pagesNikkon Argento K09360-MP Series S439Ir. Royhaizad Mohamad IsmailNo ratings yet

- Tender Spec IronerDocument1 pageTender Spec IronerrajevskumarNo ratings yet

- Renold SugarDocument8 pagesRenold SugarVolodymуr VorobetsNo ratings yet

- Tracer Overview BrochureDocument8 pagesTracer Overview BrochureWoodrow FoxNo ratings yet

- S1 TITAN Overview BrochureDocument8 pagesS1 TITAN Overview BrochurebenmedNo ratings yet

- Bakery Deck Oven 125Document2 pagesBakery Deck Oven 125Reedwan GaniyuNo ratings yet

- Ad4 2Document8 pagesAd4 2Lê Viết HàNo ratings yet

- Technical Specification Simba S7 D Atlas CopcopDocument4 pagesTechnical Specification Simba S7 D Atlas CopcopPedro Espinoza HuahuacondoriNo ratings yet

- MC1081 Ranger Selection GuideDocument2 pagesMC1081 Ranger Selection GuideMiguel AngelNo ratings yet

- CompanypresentationDocument25 pagesCompanypresentationkamran kainporNo ratings yet

- KTex BrochureDocument12 pagesKTex BrochureEndra BudimansyahNo ratings yet

- KCRA - Double-Sided Ceramic Round Insert: Features and BenefitsDocument6 pagesKCRA - Double-Sided Ceramic Round Insert: Features and BenefitsMehdy HosseiniNo ratings yet

- Integrated Refrigeration Design GuideDocument22 pagesIntegrated Refrigeration Design GuideGicu VahnovanNo ratings yet

- Power Mig 210 MP: Multi-Process Welding MachineDocument6 pagesPower Mig 210 MP: Multi-Process Welding MachinecarlosNo ratings yet

- Overhead Conveyor Products PDFDocument16 pagesOverhead Conveyor Products PDFPierre Hopkins100% (1)

- Fitel s123c Specifications Spec SheetDocument4 pagesFitel s123c Specifications Spec SheetLUIS FELIPE LIZCANO MARINNo ratings yet

- Datasheet: TV7H 235-11Z-M20Document7 pagesDatasheet: TV7H 235-11Z-M20Bruno HauckNo ratings yet

- Nadella Needle Bearings WL101EDocument230 pagesNadella Needle Bearings WL101EZALA chandrasinhNo ratings yet

- En PS-50-65 200 260 330TP2Document4 pagesEn PS-50-65 200 260 330TP2blueee archiveNo ratings yet

- Cree XSP1Type2Document2 pagesCree XSP1Type2Marcos GonzalesNo ratings yet

- Technical DrawingDocument6 pagesTechnical DrawingRosyad AminNo ratings yet

- Catalogo ServoDocument9 pagesCatalogo ServoOMAR DAVID BERNAL CUASPANo ratings yet

- Angelus 10PDocument2 pagesAngelus 10Pegoddoy23No ratings yet

- Precision Titanium Metal Tubes Engineered For Safety-Critical Nuclear Power ApplicationsDocument6 pagesPrecision Titanium Metal Tubes Engineered For Safety-Critical Nuclear Power ApplicationsZhu DanielNo ratings yet

- Hibon - SN Ingersoll Rand BlowerDocument7 pagesHibon - SN Ingersoll Rand BlowermarquezsiemNo ratings yet

- XLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeDocument1 pageXLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeLEMAGA GROUPNo ratings yet

- Wipro - ClearRay Price List 15th May 2022Document16 pagesWipro - ClearRay Price List 15th May 2022MURALINo ratings yet

- OmegaX BrochureDocument13 pagesOmegaX BrochureAlessandroNo ratings yet

- Scule Pentru Industria AerospațialăDocument28 pagesScule Pentru Industria AerospațialăPascu Tiberiu CiprianNo ratings yet

- Nitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEDocument51 pagesNitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEPushparaj Vignesh100% (1)

- Sandvik Stationary Crusher BorchureDocument1 pageSandvik Stationary Crusher BorchureBenjamin MurphyNo ratings yet

- StreetlightsDocument7 pagesStreetlightsvortosNo ratings yet

- Gas Nitriding and Ferritic Nitrocarburizing - Nitriding SolutionsDocument8 pagesGas Nitriding and Ferritic Nitrocarburizing - Nitriding SolutionsCharlie BondNo ratings yet

- Oilfield Mechanical Rig Power: SpecificationsDocument4 pagesOilfield Mechanical Rig Power: Specificationslinkangjun0621No ratings yet

- MR Radicure D Electric Conveyor Dryer Product BrochureDocument2 pagesMR Radicure D Electric Conveyor Dryer Product BrochureBIRUK DAWITNo ratings yet

- Ugigrip Stainless Steel Concrete Reinforcing Bars: Technical Data SheetDocument6 pagesUgigrip Stainless Steel Concrete Reinforcing Bars: Technical Data SheetAlexandros GiNo ratings yet

- New Giant Nitrider: Furnace Has A Cuboid Work Zone Measuring 17' X 8.5' X 7' and Can Run Loads Weighing Up To 55,000 LbsDocument1 pageNew Giant Nitrider: Furnace Has A Cuboid Work Zone Measuring 17' X 8.5' X 7' and Can Run Loads Weighing Up To 55,000 LbsAhmed Abou SamraNo ratings yet

- BOOMERL1DDocument3 pagesBOOMERL1DOsscar HerreraNo ratings yet

- Lincoln TIG DradenDocument47 pagesLincoln TIG DradencemalNo ratings yet

- Siqura Siqura Ex PTZ SeriesDocument5 pagesSiqura Siqura Ex PTZ SeriesKibar Rizky InterprimaNo ratings yet

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- VW 13750 2016Document16 pagesVW 13750 2016Bartek HajaNo ratings yet

- Iso 8993 2010 en PDFDocument6 pagesIso 8993 2010 en PDFBartek Haja100% (1)

- Iso 4628 3 2003 en FR PDFDocument8 pagesIso 4628 3 2003 en FR PDFBartek Haja100% (1)

- MS 4062 Rev A 2008Document6 pagesMS 4062 Rev A 2008Bartek HajaNo ratings yet

- Letters IELTSDocument20 pagesLetters IELTSBartek HajaNo ratings yet

- ISO 4020 ExtractDocument2 pagesISO 4020 ExtractBartek HajaNo ratings yet

- Coating TableDocument1 pageCoating TableBartek HajaNo ratings yet

- Issuer & Norm Modality / Abbreviation Metal Coat Thickness in MDocument10 pagesIssuer & Norm Modality / Abbreviation Metal Coat Thickness in MBartek HajaNo ratings yet

- Issuer & Norm Modality / Abbreviation Metal Coat Thickness in MDocument10 pagesIssuer & Norm Modality / Abbreviation Metal Coat Thickness in MBartek HajaNo ratings yet

- Welding DefectsDocument77 pagesWelding DefectsBalakumar100% (1)

- Steel Forgings, Carbon and Alloy, For General Industrial UseDocument9 pagesSteel Forgings, Carbon and Alloy, For General Industrial UseHugo SiqueiraNo ratings yet

- SpecificationDocument13 pagesSpecificationPaula Marie AgripaNo ratings yet

- Hana 200 OpenDocument5 pagesHana 200 OpenSurjeet Singh SaranNo ratings yet

- Chap 4Document51 pagesChap 4Swe Zin Zaw MyintNo ratings yet

- Based Hardfacing Alloys: Cobalt & NickelDocument20 pagesBased Hardfacing Alloys: Cobalt & NickelsabrunoNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- Refining 06 Hydrotreating Process CompleteDocument31 pagesRefining 06 Hydrotreating Process CompletetalhawasimNo ratings yet

- Int Ceiling Finishes - BQ PDFDocument1 pageInt Ceiling Finishes - BQ PDFYing YiNo ratings yet

- الیاف سوزنی 450 گرمی جوشیDocument1 pageالیاف سوزنی 450 گرمی جوشیabolfazlmp9No ratings yet

- Nitocote EP405: Constructive SolutionsDocument4 pagesNitocote EP405: Constructive SolutionsrayNo ratings yet

- Casting, Rolling, Forging, ExtrusionDocument60 pagesCasting, Rolling, Forging, ExtrusionHARIKRISHNAN SRNo ratings yet

- Composite Stone Veneer: Installation GuideDocument13 pagesComposite Stone Veneer: Installation GuideRajNo ratings yet

- Energrease LS-EP SeriesDocument2 pagesEnergrease LS-EP SeriesOscar CruzNo ratings yet

- Article Info: Dinamika Teknik Mesin Dinamika Teknik Mesin 9 (2) (2019) 80-85Document6 pagesArticle Info: Dinamika Teknik Mesin Dinamika Teknik Mesin 9 (2) (2019) 80-85Aswar ATSNo ratings yet

- Outline of Diesel Hydrotreating Unit (DHT Unit)Document4 pagesOutline of Diesel Hydrotreating Unit (DHT Unit)Anwar SadatNo ratings yet

- Insulation SeminarDocument55 pagesInsulation SeminarDelta akathehuskyNo ratings yet

- EMCO F1 ManualDocument308 pagesEMCO F1 ManualClinton Koo100% (1)

- The Hydrogenation of Nitrobenzene To Aniline: A New MechanismDocument3 pagesThe Hydrogenation of Nitrobenzene To Aniline: A New MechanismAljebre MohmedNo ratings yet

- Casting ProcessDocument72 pagesCasting ProcessFRO MusicNo ratings yet

- Heat TreatmentDocument13 pagesHeat Treatmentmissing wonderNo ratings yet

- Elevator ChainsDocument153 pagesElevator ChainsLuc TellierNo ratings yet

- Tee 003Document4 pagesTee 003Nasrien KadirNo ratings yet

- Reaming Speeds and Feeds PDFDocument1 pageReaming Speeds and Feeds PDFWarrior TempurNo ratings yet

- Acetylene How Products Are MadeDocument3 pagesAcetylene How Products Are MadeJoy MukherjeNo ratings yet

- Spray Paint CatalogueDocument8 pagesSpray Paint CatalogueSamraj Polytex100% (1)

- Anti-Splash Tape: To Purchase Call - 732-247-2300Document2 pagesAnti-Splash Tape: To Purchase Call - 732-247-2300pngchanhNo ratings yet

- Astm A269 A269mDocument5 pagesAstm A269 A269mwataneta valveNo ratings yet

NX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing System

NX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing System

Uploaded by

Bartek HajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing System

NX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing System

Uploaded by

Bartek HajaCopyright:

Available Formats

NX PIT-TYPE FURNACES

The NX Turnkey Nitriding/Nitrocarburizing

System features a selection of medium to very large

heavy-duty NX pit furnaces, a Nitrex control system,

process controller with specialized software and poten-

tial-controlled nitriding technology known as NITREG®

and its derivatives.

ADVANCED FURNACE DESIGN

The NX furnace is designed to operate in a totally

automatic fashion as part of a Nitrex turnkey nitriding

system. All phases of the process such as purging,

heating, nitriding, and cooling are accomplished in one

uninterrupted cycle. *AMS 2759/12

The retort furnace is equipped with an internal recircu- compliance optional

lation fan and a cooling air blower. A specially designed

retort and heating elements guarantee long and

reliable service. The hot gas recirculation fan provides

fast load heat-up rate and guarantees excellent tem-

perature and nitriding uniformity necessary for good PROCESS CONTROL

repeatability. The closed-loop process control enables the system

to respond automatically to the changes in nitriding

conditions that occur during the process cycle.

The furnace’s main features are:

The Nitrex process controller continuously receives

• Separate heating zones for accurate temperature

data from the furnace atmosphere sensors and ad-

control.

justs the process parameters in order to maintain the

• Light ceramic fiber insulation for fast and efficient preset value of the nitriding potential.

heating as well as cooling

The control software also includes a powerful process

• Kanthal A-1 heating elements builder menu along with troubleshooting, emergency

• Retort made of refractory alloy and calibration menus to aid the user in maintaining

• Silicone cover seal for gas tight retort and operating the nitriding installation.

• Furnace locking ring (with actuator for larger fur-

nace sizes)

• Actuated cover lifting device PROCESS TECHNOLOGY

The NITREG® family of technologies offers individually

• Easy servicing and maintenance

customized processes for different applications and

materials with desired and repeatable results.

COOLING OPTION

An accelerated cooling system is available that can sub-

stantially reduce cooling time compared to conven-

tional cooling. This results in a shorter total process

time and an improved utilization rate of the furnace. Nitreg® Potential controlled gas nitriding

Nitreg®-C Potential controlled nitrocarburizing

Cooling Coil

Option

Nitriding of stainless steels &

Nitreg®-S

nickel-based alloys

Nitreg®-Ti Nitriding of titanium alloys

In-process post-nitriding or

ONC®

post–nitrocarburizing oxidation

Nitriding of stainless steels with no

Nano-STM

loss of corrosion resistance

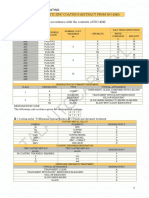

NX PIT-TYPE FURNACES

Standard models*

Rack Size

Load Furnace Furnace Required Min. Height

Model

Diameter Height Capacity Diameter Height Pit Depth Clearance

(A) (B) (C) (D) (E) (F)

NX-615 23½” 59” 2200 lbs 58” 116” 59” 128”

NX-620 23½” 78¾” 2600 lbs 58” 136” 79” 148”

NX-815 31½” 59” 3300 lbs 66” 112” 59” 128”

NX-820 31½” 78¾” 3850 lbs 66” 135” 79” 149”

NX-825 31½” 98½” 4400 lbs 66” 155” 98” 168”

NX-1015 39” 59” 4400 lbs 74” 116” 59” 128”

NX-1020 39” 78¾” 5500 lbs 74” 136” 79” 148”

NX-1025 39” 98½” 6600 lbs 74” 156” 98” 168”

NX-1215 47¼” 59” 6600 lbs 86” 116” 59” 128”

NX-1220 47¼” 78¾” 8400 lbs 86” 136” 79” 148”

NX-1225 47¼” 98½” 9900 lbs 86” 156” 98” 168”

NX-1230 47¼” 118” 11,570 lbs 86” 175” 118” 187”

NX-1625 61” 98½” 13,200 lbs 94” 157” 98” 174”

NX-1630 61” 118” 15,400 lbs 94” 185” 118” 190”

NX-1635 61” 137¾” 17,600 lbs 94” 204” 138” 209”

NX-1645 61” 177” 22,000 lbs 94” 244” 177” 249”

Copyright © Nitrex Metal Inc. (Broc030 rev 8). Nitrex Metal reserves to right to make changes without notice.

* For non-standard sizes, please contact Nitrex for details

Dia.

Dia.

A

F C

D

E

NORTH AMERICA POLAND CHINA

T: +1-514 335 7191 T: +48 32 296 6630 T: +86 (0) 10 6257 3050

F: +1 514 335 4160 F: +48 32 296 6620 F: +86 (0) 10 6252 9914

nitrex@nitrex.com nitrex.europe@nitrex.com nitrex.china@nitrex.com

www.nitrex.com

You might also like

- CP System Deep Well Anode Groundbed For PipelineDocument5 pagesCP System Deep Well Anode Groundbed For PipelineMastram HatheshNo ratings yet

- VW TL 217 2016Document8 pagesVW TL 217 2016Bartek HajaNo ratings yet

- 2012 Remington Defense CatalogDocument18 pages2012 Remington Defense CatalogMario Lopez100% (1)

- Technical Specification: B Em9henjDocument6 pagesTechnical Specification: B Em9henjBartek HajaNo ratings yet

- How To Make A Shoji Screen PDFDocument2 pagesHow To Make A Shoji Screen PDFJames MyersNo ratings yet

- 192 063002 NX Series CatalogueDocument18 pages192 063002 NX Series Cataloguetranhuutri1987quangngaiNo ratings yet

- CEMP Electric Motors Size 355Document6 pagesCEMP Electric Motors Size 355Сергій ТарасенкоNo ratings yet

- Teknovak Presentation PDFDocument22 pagesTeknovak Presentation PDFSinan YıldızNo ratings yet

- MIKRO 220/220 R Classic/cooled: Microlitre CentrifugesDocument10 pagesMIKRO 220/220 R Classic/cooled: Microlitre Centrifugesخورخى ليما دوائر المحكمةNo ratings yet

- All Offerings 2017Document8 pagesAll Offerings 2017Andres SanchezNo ratings yet

- Centrifuge Digtor22CDocument9 pagesCentrifuge Digtor22Cbilal khan0% (1)

- Tank Sppecs.Document2 pagesTank Sppecs.sunil601No ratings yet

- 0185-1100-US 1V1 Product OverviewDocument36 pages0185-1100-US 1V1 Product OverviewAlexander Aristizábal PeñalozaNo ratings yet

- Nicrofer 3220 3220h eDocument15 pagesNicrofer 3220 3220h eKevinCollinNo ratings yet

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- Tanque Movil CriogenicoDocument2 pagesTanque Movil Criogenicoisidromundarain67No ratings yet

- CATALO VetivDocument240 pagesCATALO VetivHữu CôngNo ratings yet

- Movinor LN enDocument4 pagesMovinor LN enAlbert de la FuenteNo ratings yet

- Ador BookletDocument22 pagesAdor Bookletgssrraju0% (1)

- Gear Racks Product Catalog EN PDFDocument31 pagesGear Racks Product Catalog EN PDFFer VFNo ratings yet

- DS Special Purpose Fuse Links HelioProtection Photovoltaic Fuses NH 800VAC GR ENDocument14 pagesDS Special Purpose Fuse Links HelioProtection Photovoltaic Fuses NH 800VAC GR ENFiras ouhichiNo ratings yet

- May Nen IntermechDocument2 pagesMay Nen IntermechUchiha SaitamaNo ratings yet

- Nikkon Argento K09360-MP Series S439Document2 pagesNikkon Argento K09360-MP Series S439Ir. Royhaizad Mohamad IsmailNo ratings yet

- Tender Spec IronerDocument1 pageTender Spec IronerrajevskumarNo ratings yet

- Renold SugarDocument8 pagesRenold SugarVolodymуr VorobetsNo ratings yet

- Tracer Overview BrochureDocument8 pagesTracer Overview BrochureWoodrow FoxNo ratings yet

- S1 TITAN Overview BrochureDocument8 pagesS1 TITAN Overview BrochurebenmedNo ratings yet

- Bakery Deck Oven 125Document2 pagesBakery Deck Oven 125Reedwan GaniyuNo ratings yet

- Ad4 2Document8 pagesAd4 2Lê Viết HàNo ratings yet

- Technical Specification Simba S7 D Atlas CopcopDocument4 pagesTechnical Specification Simba S7 D Atlas CopcopPedro Espinoza HuahuacondoriNo ratings yet

- MC1081 Ranger Selection GuideDocument2 pagesMC1081 Ranger Selection GuideMiguel AngelNo ratings yet

- CompanypresentationDocument25 pagesCompanypresentationkamran kainporNo ratings yet

- KTex BrochureDocument12 pagesKTex BrochureEndra BudimansyahNo ratings yet

- KCRA - Double-Sided Ceramic Round Insert: Features and BenefitsDocument6 pagesKCRA - Double-Sided Ceramic Round Insert: Features and BenefitsMehdy HosseiniNo ratings yet

- Integrated Refrigeration Design GuideDocument22 pagesIntegrated Refrigeration Design GuideGicu VahnovanNo ratings yet

- Power Mig 210 MP: Multi-Process Welding MachineDocument6 pagesPower Mig 210 MP: Multi-Process Welding MachinecarlosNo ratings yet

- Overhead Conveyor Products PDFDocument16 pagesOverhead Conveyor Products PDFPierre Hopkins100% (1)

- Fitel s123c Specifications Spec SheetDocument4 pagesFitel s123c Specifications Spec SheetLUIS FELIPE LIZCANO MARINNo ratings yet

- Datasheet: TV7H 235-11Z-M20Document7 pagesDatasheet: TV7H 235-11Z-M20Bruno HauckNo ratings yet

- Nadella Needle Bearings WL101EDocument230 pagesNadella Needle Bearings WL101EZALA chandrasinhNo ratings yet

- En PS-50-65 200 260 330TP2Document4 pagesEn PS-50-65 200 260 330TP2blueee archiveNo ratings yet

- Cree XSP1Type2Document2 pagesCree XSP1Type2Marcos GonzalesNo ratings yet

- Technical DrawingDocument6 pagesTechnical DrawingRosyad AminNo ratings yet

- Catalogo ServoDocument9 pagesCatalogo ServoOMAR DAVID BERNAL CUASPANo ratings yet

- Angelus 10PDocument2 pagesAngelus 10Pegoddoy23No ratings yet

- Precision Titanium Metal Tubes Engineered For Safety-Critical Nuclear Power ApplicationsDocument6 pagesPrecision Titanium Metal Tubes Engineered For Safety-Critical Nuclear Power ApplicationsZhu DanielNo ratings yet

- Hibon - SN Ingersoll Rand BlowerDocument7 pagesHibon - SN Ingersoll Rand BlowermarquezsiemNo ratings yet

- XLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeDocument1 pageXLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeLEMAGA GROUPNo ratings yet

- Wipro - ClearRay Price List 15th May 2022Document16 pagesWipro - ClearRay Price List 15th May 2022MURALINo ratings yet

- OmegaX BrochureDocument13 pagesOmegaX BrochureAlessandroNo ratings yet

- Scule Pentru Industria AerospațialăDocument28 pagesScule Pentru Industria AerospațialăPascu Tiberiu CiprianNo ratings yet

- Nitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEDocument51 pagesNitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEPushparaj Vignesh100% (1)

- Sandvik Stationary Crusher BorchureDocument1 pageSandvik Stationary Crusher BorchureBenjamin MurphyNo ratings yet

- StreetlightsDocument7 pagesStreetlightsvortosNo ratings yet

- Gas Nitriding and Ferritic Nitrocarburizing - Nitriding SolutionsDocument8 pagesGas Nitriding and Ferritic Nitrocarburizing - Nitriding SolutionsCharlie BondNo ratings yet

- Oilfield Mechanical Rig Power: SpecificationsDocument4 pagesOilfield Mechanical Rig Power: Specificationslinkangjun0621No ratings yet

- MR Radicure D Electric Conveyor Dryer Product BrochureDocument2 pagesMR Radicure D Electric Conveyor Dryer Product BrochureBIRUK DAWITNo ratings yet

- Ugigrip Stainless Steel Concrete Reinforcing Bars: Technical Data SheetDocument6 pagesUgigrip Stainless Steel Concrete Reinforcing Bars: Technical Data SheetAlexandros GiNo ratings yet

- New Giant Nitrider: Furnace Has A Cuboid Work Zone Measuring 17' X 8.5' X 7' and Can Run Loads Weighing Up To 55,000 LbsDocument1 pageNew Giant Nitrider: Furnace Has A Cuboid Work Zone Measuring 17' X 8.5' X 7' and Can Run Loads Weighing Up To 55,000 LbsAhmed Abou SamraNo ratings yet

- BOOMERL1DDocument3 pagesBOOMERL1DOsscar HerreraNo ratings yet

- Lincoln TIG DradenDocument47 pagesLincoln TIG DradencemalNo ratings yet

- Siqura Siqura Ex PTZ SeriesDocument5 pagesSiqura Siqura Ex PTZ SeriesKibar Rizky InterprimaNo ratings yet

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- VW 13750 2016Document16 pagesVW 13750 2016Bartek HajaNo ratings yet

- Iso 8993 2010 en PDFDocument6 pagesIso 8993 2010 en PDFBartek Haja100% (1)

- Iso 4628 3 2003 en FR PDFDocument8 pagesIso 4628 3 2003 en FR PDFBartek Haja100% (1)

- MS 4062 Rev A 2008Document6 pagesMS 4062 Rev A 2008Bartek HajaNo ratings yet

- Letters IELTSDocument20 pagesLetters IELTSBartek HajaNo ratings yet

- ISO 4020 ExtractDocument2 pagesISO 4020 ExtractBartek HajaNo ratings yet

- Coating TableDocument1 pageCoating TableBartek HajaNo ratings yet

- Issuer & Norm Modality / Abbreviation Metal Coat Thickness in MDocument10 pagesIssuer & Norm Modality / Abbreviation Metal Coat Thickness in MBartek HajaNo ratings yet

- Issuer & Norm Modality / Abbreviation Metal Coat Thickness in MDocument10 pagesIssuer & Norm Modality / Abbreviation Metal Coat Thickness in MBartek HajaNo ratings yet

- Welding DefectsDocument77 pagesWelding DefectsBalakumar100% (1)

- Steel Forgings, Carbon and Alloy, For General Industrial UseDocument9 pagesSteel Forgings, Carbon and Alloy, For General Industrial UseHugo SiqueiraNo ratings yet

- SpecificationDocument13 pagesSpecificationPaula Marie AgripaNo ratings yet

- Hana 200 OpenDocument5 pagesHana 200 OpenSurjeet Singh SaranNo ratings yet

- Chap 4Document51 pagesChap 4Swe Zin Zaw MyintNo ratings yet

- Based Hardfacing Alloys: Cobalt & NickelDocument20 pagesBased Hardfacing Alloys: Cobalt & NickelsabrunoNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- Refining 06 Hydrotreating Process CompleteDocument31 pagesRefining 06 Hydrotreating Process CompletetalhawasimNo ratings yet

- Int Ceiling Finishes - BQ PDFDocument1 pageInt Ceiling Finishes - BQ PDFYing YiNo ratings yet

- الیاف سوزنی 450 گرمی جوشیDocument1 pageالیاف سوزنی 450 گرمی جوشیabolfazlmp9No ratings yet

- Nitocote EP405: Constructive SolutionsDocument4 pagesNitocote EP405: Constructive SolutionsrayNo ratings yet

- Casting, Rolling, Forging, ExtrusionDocument60 pagesCasting, Rolling, Forging, ExtrusionHARIKRISHNAN SRNo ratings yet

- Composite Stone Veneer: Installation GuideDocument13 pagesComposite Stone Veneer: Installation GuideRajNo ratings yet

- Energrease LS-EP SeriesDocument2 pagesEnergrease LS-EP SeriesOscar CruzNo ratings yet

- Article Info: Dinamika Teknik Mesin Dinamika Teknik Mesin 9 (2) (2019) 80-85Document6 pagesArticle Info: Dinamika Teknik Mesin Dinamika Teknik Mesin 9 (2) (2019) 80-85Aswar ATSNo ratings yet

- Outline of Diesel Hydrotreating Unit (DHT Unit)Document4 pagesOutline of Diesel Hydrotreating Unit (DHT Unit)Anwar SadatNo ratings yet

- Insulation SeminarDocument55 pagesInsulation SeminarDelta akathehuskyNo ratings yet

- EMCO F1 ManualDocument308 pagesEMCO F1 ManualClinton Koo100% (1)

- The Hydrogenation of Nitrobenzene To Aniline: A New MechanismDocument3 pagesThe Hydrogenation of Nitrobenzene To Aniline: A New MechanismAljebre MohmedNo ratings yet

- Casting ProcessDocument72 pagesCasting ProcessFRO MusicNo ratings yet

- Heat TreatmentDocument13 pagesHeat Treatmentmissing wonderNo ratings yet

- Elevator ChainsDocument153 pagesElevator ChainsLuc TellierNo ratings yet

- Tee 003Document4 pagesTee 003Nasrien KadirNo ratings yet

- Reaming Speeds and Feeds PDFDocument1 pageReaming Speeds and Feeds PDFWarrior TempurNo ratings yet

- Acetylene How Products Are MadeDocument3 pagesAcetylene How Products Are MadeJoy MukherjeNo ratings yet

- Spray Paint CatalogueDocument8 pagesSpray Paint CatalogueSamraj Polytex100% (1)

- Anti-Splash Tape: To Purchase Call - 732-247-2300Document2 pagesAnti-Splash Tape: To Purchase Call - 732-247-2300pngchanhNo ratings yet

- Astm A269 A269mDocument5 pagesAstm A269 A269mwataneta valveNo ratings yet