Professional Documents

Culture Documents

Moldex Moldcon Pns 14 Technical Data Sheet: I. Product Description

Moldex Moldcon Pns 14 Technical Data Sheet: I. Product Description

Uploaded by

RobbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moldex Moldcon Pns 14 Technical Data Sheet: I. Product Description

Moldex Moldcon Pns 14 Technical Data Sheet: I. Product Description

Uploaded by

RobbCopyright:

Available Formats

MOLDEX MOLDCON PNS 14 TECHNICAL DATA SHEET

Polyvinyl Chloride pipes and fittings for rigid uPVC electrical conduit.

I. PRODUCT DESCRIPTION

Basic use:

MOLDEX Moldcon uPVC electrical conduits can be used in residential, commercial and industrial

application for protection of wires and power cables.

JOINTING

MOLDEX Moldcon uPVC conduit pipes and fittings are joined by PVC solvent cement. There is a full

component of uPVC injection molded as well as fabricated fittings available for electrical wires and cable

protection. The pipes and fittings are available in sizes 20mm to 160mm.

II. TECHNICAL DATA

APPLICABLE STANDARDS

Thickwall electrical conduits in accordance with PNS 14 with sizes 20mm, 25mm, 32mm, 40mm, 50mm,

63mm, 75mm, 90mm, 110mm, 160mm and 225mm diameter.

A. MATERIAL AND COMPOUND

Table 86 Composition and Materials

MOLDEX Moldcon uPVC conduit pipes and fittings are thermoplastic materials made with PVC

compound meeting the requirements of class 12454B or 12454C classification as stipulated under ASTM

D 1784.

ii. Grade

MOLDEX uPVC pipes and fittings conduit and fittings are available in different diameter from 20mm to

160mm.

iii. Limitation

MOLDEX uPVC conduit and fittings are intended to be used in electrical cables and wires protection.

PVC pipes are affected by ultraviolet radiation. Pigments and stabilizers are added to make pipes and

fittings resistant to ultraviolet degradation. Pipes and fittings may be exposed to sunlight during

installation, however, prolonged exposure is not advised.

iv. Color

The color of the conduit pipes and fittings are RED ORANGE

B. DIMENSIONS

Outside Diameter and Wall Thickness

The conduit conforms to the outside diameter and wall thickness specified in Table 1 when tested in

accordance with PNS ISO 3126

Table 1 – Pipe Dimensions

Tolerances Minimum Wall Thickness Socket length *

Nominal

Outside For mean For max and

Min

Diameter outside min on Thin wall Tolerances Thick Wall Tolerances

L

diameter ovality

20 +0.2 +/- 0.5 1.5 +0.35 2.2 +0.42 16.0

25 +0.2 +/- 0.5 1.5 +0.35 2.3 +0.43 18.5

32 +0.2 +/- 0.5 1.5 +0.35 2.4 +0.44 22.0

40 +0.2 +/- 0.5 1.5 +0.35 2.4 +0.44 26.0

50 +0.2 +/- 0.6 1.5 +0.35 2.4 +0.47 31.0

63 +0.2 +/- 0.8 1.5 +0.35 2.5 +0.48 37.5

75 +0.3 +/- 0.9 1.8 +0.38 2.9 +0.49 43.5

90 +0.3 +/- 0.9 2.2 +0.42 3.5 +0.52 51.0

110 +0.4 +/- 1.4 2.7 +0.47 4.2 +0.62 61.0

160 +0.4 +/- 2.0 3.9 +0.59 6.1 +0.81 86.0

225 +0.7 +/- 2.7 N/A N/A 10.80 +1.28 154.0

* Socket Length, L = 0.5 de + 6mm

*225mm from specification of PNS 65

C. PHYSICAL AND MECHANICAL CHARACTERISTICS

i. Physical and Mechanical Properties

The conduit conforms to the physical and mechanical properties specified in Table 2.

Table 2 – Physical and Mechanical Properties

Property Value Test Method

Vicat Softening temperature, °C, min 76 PNS/ISO 2507-1

Heat reversion*, %, max 5 PNS ISO 2505-1

Water absorption, g/m2, max (optional) 40 PNS/ISO 8361-1

Tensile Strength at 28°C, MPa, min 27.5

PNS ISO 6259-1

Elongation at break, %, min 15

* After heat reversion test, the conduit shall show no signs of cracks, cavities or blisters.

ii. Resistance to burning

When the conduit is held in the flame for one minute, the flame extinguishes itself in less than 30 seconds

after the removal of the flame.

iii. Resistance to external blows

The true impact rate of the batch at 28°C does not exceed 10 percent when tested in accordance with

PNS ISO 3127.

IV. MARKINGS

The conduit shall be permanently marked with the following information spaced at intervals of not more

than one meter or at least once per pipe.

a. Name of Product

b. Application (Electrical conduit / Thin wall or Thick wall)

c. Nominal outside diameter in mm

d. Manufacturer’s name or trademark

e. The words “Made in the Philippines” or “Made in PHL”

You might also like

- Comparison Between Api Standard 5L - 45TH & 46TH - Rev. 1Document17 pagesComparison Between Api Standard 5L - 45TH & 46TH - Rev. 1Rushabh Kapadia100% (2)

- UEENEEI157A+Inotech Controls+Handbook - V2 - 3Document142 pagesUEENEEI157A+Inotech Controls+Handbook - V2 - 3Kim N Lewis100% (3)

- Poem AnalysisDocument4 pagesPoem AnalysisCharles Ting67% (3)

- PNS 260 2002 - Annealed Copper Wires Specification - Solid - THHN - THW - TWDocument8 pagesPNS 260 2002 - Annealed Copper Wires Specification - Solid - THHN - THW - TWshivam dwivediNo ratings yet

- COUPP - 60 Hydraulic Hose Failure AnalysisDocument26 pagesCOUPP - 60 Hydraulic Hose Failure AnalysisRomulus Situ MorankNo ratings yet

- FLRYW-B Cable: ConstructionDocument1 pageFLRYW-B Cable: ConstructionElbruz AugurNo ratings yet

- Pontofocal Textos Regulamentos PHL 38Document11 pagesPontofocal Textos Regulamentos PHL 38Bruce DoyaoenNo ratings yet

- FG7 (O) R Rev009Document3 pagesFG7 (O) R Rev009Armin HajdarovićNo ratings yet

- Cu / PVC / PVC: Construction DataDocument4 pagesCu / PVC / PVC: Construction Datagalih santosoNo ratings yet

- Well Tube 1050514Document12 pagesWell Tube 1050514Mustafa AlhoubaniNo ratings yet

- LV TNB Aerial Bundle Cable ABC 1kvDocument2 pagesLV TNB Aerial Bundle Cable ABC 1kvUntuk DiaNo ratings yet

- EN 253 Pre-InsulatedDocument4 pagesEN 253 Pre-Insulatedlela84kNo ratings yet

- Veriflex Intercon 1.8-3kV Cable - 1Document2 pagesVeriflex Intercon 1.8-3kV Cable - 1anastasia abengoaNo ratings yet

- PHL38 en 1 1Document11 pagesPHL38 en 1 1Carlyle MombaelNo ratings yet

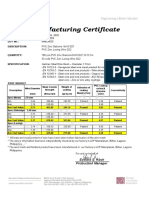

- Manufacturing Certificate: Edward S. Koch Production ManagerDocument1 pageManufacturing Certificate: Edward S. Koch Production ManagerSuntharathevan RamasamyNo ratings yet

- 1) 1C LSZHDocument44 pages1) 1C LSZHvicko2828No ratings yet

- Modicon M171 - M172 - TM172E12RDocument11 pagesModicon M171 - M172 - TM172E12RPaulo PereiraNo ratings yet

- Tesys D Ladr2Document3 pagesTesys D Ladr2Electrical DistributionNo ratings yet

- TeSys D - LADT0Document3 pagesTeSys D - LADT0Syed Mohammad NaveedNo ratings yet

- NYY - 3 CoreDocument1 pageNYY - 3 CoreMulyadi MulNo ratings yet

- NYY 1 X (1.5-500) MM 0.6/1 KVDocument5 pagesNYY 1 X (1.5-500) MM 0.6/1 KVFebi HerdianaNo ratings yet

- Pump Cable 300mDocument2 pagesPump Cable 300mheri fauziNo ratings yet

- Photovoltaic PV1-F DC Solar Cable: ApplicationDocument17 pagesPhotovoltaic PV1-F DC Solar Cable: Applicationkser82No ratings yet

- TC - 115630Document1 pageTC - 115630THPNo ratings yet

- Standard Direct Buried CableDocument6 pagesStandard Direct Buried CableZeckrey JikurunNo ratings yet

- N2XY (FRC) - 3 CoreDocument1 pageN2XY (FRC) - 3 CoreMulyadi MulNo ratings yet

- Flr13y B CableDocument2 pagesFlr13y B CableNico Nico Nico NicoNo ratings yet

- Gudang Listrik Building 6th Jl. Salemba Raya No. 19 Jakarta 10440 Phone 021 - 3929696 (Hunting) WWW - Samudrakaryamulia.co - IdDocument6 pagesGudang Listrik Building 6th Jl. Salemba Raya No. 19 Jakarta 10440 Phone 021 - 3929696 (Hunting) WWW - Samudrakaryamulia.co - Idbumilestari12No ratings yet

- CPVC Pipe Write UpDocument13 pagesCPVC Pipe Write UpSekharNo ratings yet

- Astm d1785Document5 pagesAstm d1785Shiyam RajNo ratings yet

- 3p Atk Foam 35d Dop Ce en 2016Document3 pages3p Atk Foam 35d Dop Ce en 2016Nicu MercoreNo ratings yet

- PS2501-1 To PS2501-4Document4 pagesPS2501-1 To PS2501-4enriquevazquez27No ratings yet

- TeSys D - LADS2 PDFDocument2 pagesTeSys D - LADS2 PDFLeonardo Andres MagiNo ratings yet

- 5.3 Concentric Conductor, PVC Insulated and Sheathed 0.6 / 1 KV Power CablesDocument2 pages5.3 Concentric Conductor, PVC Insulated and Sheathed 0.6 / 1 KV Power CablesJerrykid NguyenNo ratings yet

- Instalpress2015 PDFDocument56 pagesInstalpress2015 PDFamijoski6051No ratings yet

- Kabelmetal NYYDocument1 pageKabelmetal NYYDudi MulyadiNo ratings yet

- UPG PIPE - Catalogs-2022Document39 pagesUPG PIPE - Catalogs-2022Sopheareak ChhanNo ratings yet

- LADT2 DATASHEET WW en-WWDocument2 pagesLADT2 DATASHEET WW en-WWLeonardo Andres MagiNo ratings yet

- Flowtech Pvcpipe Productspecs WebDocument4 pagesFlowtech Pvcpipe Productspecs Webtimothymasebo627No ratings yet

- Ptfe WiresDocument2 pagesPtfe WiresKEERTI PANDEYNo ratings yet

- TDS Thermo 32Document2 pagesTDS Thermo 32Boris Popov100% (1)

- C-15-TCPUSE-D-AI6 Product SpecificationsDocument2 pagesC-15-TCPUSE-D-AI6 Product Specificationscastro.sitemaNo ratings yet

- Smart Tube ConduitDocument8 pagesSmart Tube ConduitMatthew Ho Choon LimNo ratings yet

- 8.1 Smartube G.I ConduitDocument8 pages8.1 Smartube G.I ConduitAHMAD HAFIZAL MOHD YAMINNo ratings yet

- Flr12y B CableDocument2 pagesFlr12y B CableNico Nico Nico NicoNo ratings yet

- Extreme Copper PCBsDocument12 pagesExtreme Copper PCBsskgNo ratings yet

- For More Information Please Call 1-800-Belden1: General DescriptionDocument4 pagesFor More Information Please Call 1-800-Belden1: General DescriptionErwin SinuratNo ratings yet

- Fire Sprinkler Pipe BrochureDocument8 pagesFire Sprinkler Pipe BrochureINGENIERIA8 FYSNo ratings yet

- Schneider Electric - TeSys-Control-Relays - CA2SKE20M7Document3 pagesSchneider Electric - TeSys-Control-Relays - CA2SKE20M7nolisapuayNo ratings yet

- Geomat Tech Data SheetDocument1 pageGeomat Tech Data SheetclangatNo ratings yet

- BITE-LOK Tube Fittings PDFDocument92 pagesBITE-LOK Tube Fittings PDFQUYEN TRANNo ratings yet

- Flyer Radox 155S FLR PDFDocument2 pagesFlyer Radox 155S FLR PDFVencislav SlavovNo ratings yet

- Ca3sk20bd DatasheetDocument2 pagesCa3sk20bd DatasheetElectrical DistributionNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- Tdoct2014b EngDocument2 pagesTdoct2014b Engmahmoud abuelmgdNo ratings yet

- Huawei LampSite SolutionDocument32 pagesHuawei LampSite SolutionJason Mendoza100% (1)

- TeSys K - LA1KN22Document2 pagesTeSys K - LA1KN22Kuenley TiNy OndeNo ratings yet

- Cantral Cable MSDocument44 pagesCantral Cable MSshikinNo ratings yet

- Keystone - 1C - PVCDocument2 pagesKeystone - 1C - PVCYongJun LiuNo ratings yet

- Cable 07rn8-f 750v Epr-Cpe Blue-ElcosubDocument2 pagesCable 07rn8-f 750v Epr-Cpe Blue-ElcosubMiguel MontalvánNo ratings yet

- Modicon m171 m172 Tm172pdg18rDocument13 pagesModicon m171 m172 Tm172pdg18rrafaelmelo89No ratings yet

- Vicplas Product BrochureDocument52 pagesVicplas Product BrochureSopheareak ChhanNo ratings yet

- M3382 Spec (Fusible Link)Document4 pagesM3382 Spec (Fusible Link)DamonNo ratings yet

- Project Dissertation Report On Sales Pattern of AMUL Dairy Products W.R.T. A Distributor and RetailersDocument52 pagesProject Dissertation Report On Sales Pattern of AMUL Dairy Products W.R.T. A Distributor and RetailersjeevNo ratings yet

- THDC Institute of Hydropower Engineering and TechnologyDocument3 pagesTHDC Institute of Hydropower Engineering and TechnologyAnsh AroraNo ratings yet

- Installation Manual-A: TK 51286-2-IM (Rev. 3, 02/06)Document60 pagesInstallation Manual-A: TK 51286-2-IM (Rev. 3, 02/06)GIOVANNENo ratings yet

- Asme Code PresntDocument41 pagesAsme Code PresntPrasanth PadmanabhanNo ratings yet

- Lab Education English Mock Exam - Question Answer BookDocument14 pagesLab Education English Mock Exam - Question Answer BookMichelle ChungNo ratings yet

- Methodology in The New MillenniumDocument15 pagesMethodology in The New Millenniumerzsebetkacso67% (3)

- K68i PC ManualDocument101 pagesK68i PC ManualjjcanoolivaresNo ratings yet

- SAP Proj Builder Previewer PDFDocument24 pagesSAP Proj Builder Previewer PDFPradeep JagirdarNo ratings yet

- Durastor Tank Brochure PDFDocument8 pagesDurastor Tank Brochure PDFhamadaniNo ratings yet

- Evaluation Exam QuestionsDocument10 pagesEvaluation Exam QuestionsKemp MooreNo ratings yet

- Neurological Development From Birth To Six YearsDocument143 pagesNeurological Development From Birth To Six YearsWaleska SakibNo ratings yet

- SS Ind A21 BVX002 - Approval of Permanent Joining Procedure and PersonnelDocument1 pageSS Ind A21 BVX002 - Approval of Permanent Joining Procedure and PersonnelTuTuy AnNo ratings yet

- Lived Experiences of Muslim High SchoolDocument12 pagesLived Experiences of Muslim High SchoolJustine ReveloNo ratings yet

- Canopen Tutorial: Siemens Industry Online SupportDocument38 pagesCanopen Tutorial: Siemens Industry Online SupportHumberto MendozaNo ratings yet

- AWS Associate Solutions Architect Study - ACloud - GuruDocument70 pagesAWS Associate Solutions Architect Study - ACloud - Guruzinedine boubakerNo ratings yet

- 6-8 Sa1 Date SheetDocument3 pages6-8 Sa1 Date SheetRKS708No ratings yet

- Steam Air Ejector Performance and Its Dimensional ParametersDocument296 pagesSteam Air Ejector Performance and Its Dimensional ParametersGuru Raja Ragavendran NagarajanNo ratings yet

- The Inner World in The Outer World 565089838Document266 pagesThe Inner World in The Outer World 565089838ramonaNo ratings yet

- Evaluation Rating Sheet For Charts Poster Drill Flash Card and ManipulativesDocument3 pagesEvaluation Rating Sheet For Charts Poster Drill Flash Card and ManipulativesMaricris Bagnes SaludNo ratings yet

- Centers For Disease Control and Prevention's Sexually Transmitted Diseases Infection GuidelinesDocument6 pagesCenters For Disease Control and Prevention's Sexually Transmitted Diseases Infection GuidelinesabhinavrautNo ratings yet

- Astm A313 2003Document7 pagesAstm A313 2003ArefkhanNo ratings yet

- Telemedicine Conference 15 Des 2020Document4 pagesTelemedicine Conference 15 Des 2020rafaelNo ratings yet

- Duane Big EagleDocument3 pagesDuane Big EagleSergio StaniulisNo ratings yet

- BỘ ĐỀ IELTS SPEAKING QUÝ 1-2023Document14 pagesBỘ ĐỀ IELTS SPEAKING QUÝ 1-2023phuongNo ratings yet

- MB0050 - Research MethodologyDocument8 pagesMB0050 - Research MethodologyAnish NairNo ratings yet

- MK17C01-Group 3-MKT328m-Final Report DIFFERENTDocument14 pagesMK17C01-Group 3-MKT328m-Final Report DIFFERENTTran Minh Quy (K17 QN)No ratings yet