Professional Documents

Culture Documents

Yokogawa UT35-UT32A - Part1

Yokogawa UT35-UT32A - Part1

Uploaded by

Fajar PrawiroCopyright:

Available Formats

You might also like

- Product Specification Sheets: Tempered Water Marine A/C SystemsDocument32 pagesProduct Specification Sheets: Tempered Water Marine A/C SystemsninatenaNo ratings yet

- Operation Guide: 3. How To InstallDocument12 pagesOperation Guide: 3. How To InstallOscar AraucoNo ratings yet

- Panduan Penggunaan Fungsion Generator DS1000E (D) UserGuide En-2Document166 pagesPanduan Penggunaan Fungsion Generator DS1000E (D) UserGuide En-2JuLian Kenzi SakaNo ratings yet

- Osciloscópio Rigol - User's Guide DS1000DDocument162 pagesOsciloscópio Rigol - User's Guide DS1000DacautomacaoecontroleNo ratings yet

- Libra S11 and S12 User Manual: EnglishDocument30 pagesLibra S11 and S12 User Manual: Englishafonso397No ratings yet

- DM3058 UserGuide enDocument138 pagesDM3058 UserGuide enLuis CarlosNo ratings yet

- DM3058 UserGuide ENDocument138 pagesDM3058 UserGuide ENLuis CarlosNo ratings yet

- Instruction Manual: LX70/700 High Speed Counter ModuleDocument22 pagesInstruction Manual: LX70/700 High Speed Counter ModuleVirendra ZopeNo ratings yet

- 95-8582 Det Tronics - X3301-3 PDFDocument8 pages95-8582 Det Tronics - X3301-3 PDFAdhemar RodoNo ratings yet

- Temp Scanner-Modbus Details PDFDocument35 pagesTemp Scanner-Modbus Details PDFGIRINo ratings yet

- User Manual: SDS1000 Series Digital Storage Oscilloscope Version No.: V 1.2Document148 pagesUser Manual: SDS1000 Series Digital Storage Oscilloscope Version No.: V 1.2juampicNo ratings yet

- Manual Osciloscopio Rigol DS1000E (D) UserGuide enDocument166 pagesManual Osciloscopio Rigol DS1000E (D) UserGuide enAYUA0223100% (1)

- Insight II Type 95dss3 Integrated Flame Scanner CU 113Document64 pagesInsight II Type 95dss3 Integrated Flame Scanner CU 113mohamedNo ratings yet

- Leybold Quick-Start Guide For IO InterfaceDocument2 pagesLeybold Quick-Start Guide For IO InterfaceSelva KumarNo ratings yet

- 7UT612Document360 pages7UT612Ketan TankNo ratings yet

- 7UT613 63xDocument514 pages7UT613 63xdenisseNo ratings yet

- 7UT612 Manual V40R01 76Document360 pages7UT612 Manual V40R01 76chanweichangNo ratings yet

- Siprotec 7ut61Document360 pagesSiprotec 7ut61coleiro100% (1)

- 1794 IO Modules FlexIO DQ PDFDocument28 pages1794 IO Modules FlexIO DQ PDFLizbeth Soto CastilloNo ratings yet

- PDX AU Programming GuideDocument71 pagesPDX AU Programming GuideravensarcillaNo ratings yet

- Manual Programacao MG-SP4000.português-EP23 - BRDocument82 pagesManual Programacao MG-SP4000.português-EP23 - BRninhorg75% (4)

- Simon XT Installation GuideDocument8 pagesSimon XT Installation Guideonguyen73No ratings yet

- 10-3514-505-STHS-03 Stratos HSSD-2 Installers HandbookDocument86 pages10-3514-505-STHS-03 Stratos HSSD-2 Installers HandbookRizwan IqbalNo ratings yet

- 10-3514-505-LSHS-02 LaserSense HSSD-2 Detector Installers HandbookDocument86 pages10-3514-505-LSHS-02 LaserSense HSSD-2 Detector Installers HandbookMohamed SayedNo ratings yet

- Manual n1050 v10x F EnglishDocument10 pagesManual n1050 v10x F EnglishmilosNo ratings yet

- 7SA6xx Manual A1 V4.0 enDocument792 pages7SA6xx Manual A1 V4.0 enpedromiguelsanchezNo ratings yet

- P-9910B Hand Held Programmer: DescriptionDocument1 pageP-9910B Hand Held Programmer: DescriptionMohamed AzimNo ratings yet

- Mirrowstic 3codeDocument16 pagesMirrowstic 3codeJesús EspinosaNo ratings yet

- Manual Novus n1200Document12 pagesManual Novus n1200Aldrin HernandezNo ratings yet

- Flexvu Universal Display Model Ud10 Model Ud10 With CGS: Safety ManualDocument6 pagesFlexvu Universal Display Model Ud10 Model Ud10 With CGS: Safety ManualCheloX LNo ratings yet

- OsciloscopioDocument148 pagesOsciloscopioDeiby F Arango MotoaNo ratings yet

- N1200 Controller: Universal Controller - Instructions Manual - V2.0X G Safety Alerts Configuration / FeaturesDocument12 pagesN1200 Controller: Universal Controller - Instructions Manual - V2.0X G Safety Alerts Configuration / FeaturesJosé CostaNo ratings yet

- 95 8668 3.1 (UD10 Safety)Document6 pages95 8668 3.1 (UD10 Safety)Cosme Alberto Alcantar GarciaNo ratings yet

- 19011517 SC - A02 (《H5U系列可编程逻辑控制器用户手册 英文》)Document23 pages19011517 SC - A02 (《H5U系列可编程逻辑控制器用户手册 英文》)Tiny tinyNo ratings yet

- 32 Zone Wireless Transceiver Security Systems: MG5000 V4.5 MG5050 V4.5Document72 pages32 Zone Wireless Transceiver Security Systems: MG5000 V4.5 MG5050 V4.5Bogdan SpatariuNo ratings yet

- Yokogawa Ut32a Temperature Controller Quick ReferenceDocument12 pagesYokogawa Ut32a Temperature Controller Quick ReferenceDilesh PillaiNo ratings yet

- Panelview 800 Hmi Terminals: Installation InstructionsDocument28 pagesPanelview 800 Hmi Terminals: Installation InstructionsRoyNo ratings yet

- Controller N1200: Universal Controller - Instructions Manual - V2.0X Safety Alerts Configuration / FeaturesDocument13 pagesController N1200: Universal Controller - Instructions Manual - V2.0X Safety Alerts Configuration / FeaturesAdonay HenriquezNo ratings yet

- Iskra MT 440Document8 pagesIskra MT 440Ussama Rajput100% (1)

- Intric 1-2 TRC 1-2-4 MITTO 2-4: Self-Learning Rolling-Code Radio Controls 433.92 MHZ FrequencyDocument7 pagesIntric 1-2 TRC 1-2-4 MITTO 2-4: Self-Learning Rolling-Code Radio Controls 433.92 MHZ FrequencyPaulo Alexandre0% (1)

- Catalog F90 relayDocument14 pagesCatalog F90 relayRHETT BUTLERNo ratings yet

- Instruction Manual SPU II Hard Alarm Output Contacts: July 2009 Part No. 4416.223 Revision.1Document12 pagesInstruction Manual SPU II Hard Alarm Output Contacts: July 2009 Part No. 4416.223 Revision.1SATISHNo ratings yet

- Instruction Manual: LX70/700 A/D Conversion ModuleDocument22 pagesInstruction Manual: LX70/700 A/D Conversion ModuleVirendra ZopeNo ratings yet

- 7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsDocument2 pages7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsAakash JunejaNo ratings yet

- UM33A Digital Indicator With Alarms Operation Guide - IM05P03D21-11EN - 020Document8 pagesUM33A Digital Indicator With Alarms Operation Guide - IM05P03D21-11EN - 020Albert KristianNo ratings yet

- Safety Function: Light Curtain With Muting (Two Sensor L-Type) and Configurable Safety RelayDocument54 pagesSafety Function: Light Curtain With Muting (Two Sensor L-Type) and Configurable Safety RelayMarcelo AlvaresNo ratings yet

- Hoja de Datos PLC 1762:L4Document35 pagesHoja de Datos PLC 1762:L4Martin GuzmanNo ratings yet

- 440N-Z21US2JN9 User Manual PDFDocument8 pages440N-Z21US2JN9 User Manual PDFLizbeth Soto CastilloNo ratings yet

- Icstt rm280 - en PDocument42 pagesIcstt rm280 - en PmuthuNo ratings yet

- Ds - Tb82-En - G Manual Abb ConductividadDocument12 pagesDs - Tb82-En - G Manual Abb ConductividadJacob Molina MolinaNo ratings yet

- dd40NTV II 12 09Document36 pagesdd40NTV II 12 09Pablo QuirogaNo ratings yet

- 4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance TestDocument24 pages4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance Testpoci11No ratings yet

- Hantek 1000 SeriesDocument104 pagesHantek 1000 SeriesthayanarvNo ratings yet

- MicroLogix 1000Document174 pagesMicroLogix 1000Alexander MasiasNo ratings yet

- Making PIC Microcontroller Instruments and ControllersFrom EverandMaking PIC Microcontroller Instruments and ControllersNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- IoT Projects with Arduino Nano 33 BLE Sense: Step-By-Step Projects for BeginnersFrom EverandIoT Projects with Arduino Nano 33 BLE Sense: Step-By-Step Projects for BeginnersNo ratings yet

- Beginning Arduino Nano 33 IoT: Step-By-Step Internet of Things ProjectsFrom EverandBeginning Arduino Nano 33 IoT: Step-By-Step Internet of Things ProjectsNo ratings yet

- Yokogawa UT35-UT32A - Part3Document2 pagesYokogawa UT35-UT32A - Part3Fajar PrawiroNo ratings yet

- Yokogawa UT35-UT32A - Part2Document2 pagesYokogawa UT35-UT32A - Part2Fajar PrawiroNo ratings yet

- S Two-Control: 0.5 3 SS C Ontrol: 0.5Document2 pagesS Two-Control: 0.5 3 SS C Ontrol: 0.5Fajar PrawiroNo ratings yet

- Tambah/Insert Data: QrlabelDocument1 pageTambah/Insert Data: QrlabelFajar PrawiroNo ratings yet

- Generator StartupDocument2 pagesGenerator StartupFajar PrawiroNo ratings yet

- SiskomDocument2 pagesSiskomFajar PrawiroNo ratings yet

- Electrical SymbolDocument1 pageElectrical Symbol5223043305No ratings yet

- NetBackup 5340 Appliance Hardware Installation GuideDocument83 pagesNetBackup 5340 Appliance Hardware Installation Guidejarg200690No ratings yet

- ADB 45016 001 - Do3NNZcDocument2 pagesADB 45016 001 - Do3NNZcVic MelendezNo ratings yet

- Adwaith Final College Review Final FinalDocument20 pagesAdwaith Final College Review Final FinalmailadwaitharunNo ratings yet

- MatrixDocument22 pagesMatrixMark Jonell EsguerraNo ratings yet

- SDI82X DS T140039 en BDocument2 pagesSDI82X DS T140039 en BmanutencaoraengenhariaNo ratings yet

- ZPL40 ZPL50 ZPL70 LA-B181P r0.5 0218 r0.5 0325Document61 pagesZPL40 ZPL50 ZPL70 LA-B181P r0.5 0218 r0.5 0325Telefono TallerNo ratings yet

- Pascal StringsDocument5 pagesPascal StringsPutra PrasetyaNo ratings yet

- Resume Tata Consultancy ServicesDocument3 pagesResume Tata Consultancy ServicesSubhashini 29No ratings yet

- Notifier NFS-640 Programming ManualDocument116 pagesNotifier NFS-640 Programming ManualxiaolanNo ratings yet

- Test 1 - Matrices: PART A - 6 Questions, 1 Mark Each (6x1)Document2 pagesTest 1 - Matrices: PART A - 6 Questions, 1 Mark Each (6x1)sanand11No ratings yet

- 6.3.3.6 Packet Tracer - Configuring Router-on-a-Stick Inter-VLAN Routing Instructions - ILMDocument4 pages6.3.3.6 Packet Tracer - Configuring Router-on-a-Stick Inter-VLAN Routing Instructions - ILMJarekNo ratings yet

- Digitization Brochure DET NEWDocument4 pagesDigitization Brochure DET NEWSairam DigitaledgeIndiaNo ratings yet

- 1.automatic Engine Locking System For Drunk and Drivers MSP430Document3 pages1.automatic Engine Locking System For Drunk and Drivers MSP430Hamed Raza80% (5)

- 1 NSTEP User Manual For The CourtDocument13 pages1 NSTEP User Manual For The CourtSCJCOURT ZAHEERABADNo ratings yet

- Mtech: Pallapu Manoj Kumar Email: BackgroundDocument5 pagesMtech: Pallapu Manoj Kumar Email: BackgroundRaj MotikiNo ratings yet

- File and Resource AttacksDocument61 pagesFile and Resource AttacksAbdul Mateen UkkundNo ratings yet

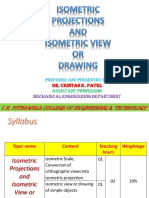

- 8.isometric Projections and Isometric View or DrawingDocument39 pages8.isometric Projections and Isometric View or DrawingMahek JariwalaNo ratings yet

- Youjie 4600 - User-ManualDocument144 pagesYoujie 4600 - User-ManualVaseaPupkinNo ratings yet

- Interface A Seven Segment Display To An ArduinoDocument7 pagesInterface A Seven Segment Display To An ArduinospgmaniarunagiriNo ratings yet

- GPT-4 Architecture, Infrastructure, Training Dataset, Costs, Vision, MoEDocument4 pagesGPT-4 Architecture, Infrastructure, Training Dataset, Costs, Vision, MoEjohn clarityNo ratings yet

- Design and Simulation of Fog Computing Model For Smart FarmingDocument6 pagesDesign and Simulation of Fog Computing Model For Smart FarmingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Assignment 4Document2 pagesAssignment 4Satish Kumar ChauhanNo ratings yet

- 1 - APM 303 - Presentation - ENDocument43 pages1 - APM 303 - Presentation - ENChhoan NhunNo ratings yet

- Logo Maker and Brand Kit Build Agreement - FinalDocument56 pagesLogo Maker and Brand Kit Build Agreement - Finalkawish farooqiNo ratings yet

- The 1090Mhz Riddle: Junzi SunDocument49 pagesThe 1090Mhz Riddle: Junzi SunRiccardo RicciNo ratings yet

- Jteft 08 00313Document5 pagesJteft 08 00313Shane DorianNo ratings yet

- ERM Performance Tuning Pricing and Order Form See Tutorial Tab Below For Sample of Accompaning Learning Book and Video'sDocument7 pagesERM Performance Tuning Pricing and Order Form See Tutorial Tab Below For Sample of Accompaning Learning Book and Video'sabdulmajid aljonadiNo ratings yet

- Year I, Semester II (2016/2017) : # Course Title Course Code CR - Hr. Ects Grade GPTDocument5 pagesYear I, Semester II (2016/2017) : # Course Title Course Code CR - Hr. Ects Grade GPTWubalemNo ratings yet

- Cyber Security AwarenessDocument6 pagesCyber Security AwarenessArya Adhi NugrahaNo ratings yet

Yokogawa UT35-UT32A - Part1

Yokogawa UT35-UT32A - Part1

Uploaded by

Fajar PrawiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yokogawa UT35-UT32A - Part1

Yokogawa UT35-UT32A - Part1

Uploaded by

Fajar PrawiroCopyright:

Available Formats

*1: English, German, French, and Spanish are available for the guide display.

■ Safety, Protection, and Modi cation of the Product *2: The /LP option can be specified in the combination of Type 2 code (any of “0” or “1”) and RZ WR ,QVWDOO

Operation UT35A, UT32A Type 3 code (any of “0” or “1”.)

(1) In order to protect the system controlled by this product and the product itself, *3: The /HA option can be specified only when the Type 1 code is “-0” or “-2.”

Digital Indicating Controller (Panel Mounting Type) and to ensure safe operation, observe the safety precautions described in the

Guide *4: When the /CT option is specified, the UT35A does not conform to the safety standards (UL ■ ,QVWDOODWLRQ /RFDWLRQ

Operation Guide onal operation guide. Use of the instrument in a manner not prescribed herein may and CSA) and CE marking (Products with /CT option are not intended for EEA-market).

ti

Func ment

nce F PS P H H S F I F H S HF IH H HH H The instrument should be installed in indoor locations meeting the following

IM 05P01D31-11EN Installation and Wiring Enha

device. We assume no liability for safety, or responsibility for the product's quality, ■ 87 6WDQGDUG RGH 0RGHO conditions:

performance or functionality should users fail to observe these instructions when ,QVWUXPHQWHG SDQHO

«Standard Code Model» 5th Edition : Mar. 2016 2SWLRQ

operating the product. 0RGHO Suf x code 'HVFULSWLRQ This instrument is designed to be mounted in an instrumented panel. Mount the

FRGH

(2) Installation of protection and/or safety circuits with respect to a lightning instrument in a location where its terminals will not inadvertently be touched.

Digital Indicating Controller (Power supply: 100-240

protector; protective equipment for the system controlled by the product and the 87 V AC) (provided with retransmission output or 15 V :HOO YHQWLODWHG ORFDWLRQV

This operation guide describes installation, wiring, and other tasks required to make the product itself; foolproof or fail-safe design of a process or line using the system DC loop power supply, 2 DIs, and 3 DOs)

Mount the instrument in well ventilated locations to prevent the instrument’s inter-

controller ready for operation. controlled by the product or the product itself; and/or the design and installation 6 SH

of other protective and safety circuits are to be appropriately implemented as the nal temperature from rising.

For details of the each function, refer to the electronic manual. Manuals can be 3 S S SH

downloaded or viewed at the following URL. F PH HHP HFH Heating/cooling type

However, make sure that the terminal portions are not exposed to wind. Exposure

(3) Be sure to use the spare parts approved by YOKOGAWA when replacing parts Type 1: P F H H HPSH H H FF F HH H P P -

Dual-loop type (please see the Operation Guide IM

http://www.yokogawa.com/ns/ut/im/ F '

or consumables. 05P08D31-11EN.) tiple indicating controllers, see the external dimensions/panel cutout dimensions

F

(4) This product is not designed or manufactured to be used in critical applications 9 UT32A Digital Indicating Controller (Entry model) F I If mounting other instruments adjacent to the instrument, comply with

RQWHQWV that directly affect or threaten human lives. Such applications include nuclear (please see the Operation Guide IM 05P01F31- these panel cutout dimensions to provide suf cient clearance between the instruments.

power equipment, devices using radioactivity, railway facilities, aviation 5 11EN.)

/RFDWLRQV ZLWK OLWWOH PHFKDQLFDO YLEUDWLRQ

6 IH 3 HF equipment, air navigation facilities, aviation facilities, and medical equipment. None

Type 2: Install the instrument in a location subject to little mechanical vibration.

2. Model and Suf x Codes If so used, it is the user’s responsibility to include in the system additional RS-485 communication (Max. 38.4 kbps, 2-wire/4-wire) (*1)

equipment and devices that ensure personnel safety. F RUL RQWDO ORFDWLRQ

2 additional DIs and 2 additional DOs

(5) Modi cation of the product is strictly prohibited. Mount the instrument horizontally and ensure that it is level, with no inclination to

4. Hardware Speci cations Type 3: None

(6) This product is intended to be handled by skilled/trained personnel for electric devices. Open networks

the right or left.

5. How to Connect Wires CC-Link communication (with Modbus master function) (*2)

(7) This product is UL Recognized Component. In order to comply with UL standards, English (Default. Can be switched to other language by the setting.)

6. Terminal Wiring Diagrams

end-products are necessary to be designed by those who have knowledge of the

German (Default. Can be switched to other language by the setting.) Front panel

requirements. Display language (*3) Keep this angle

French (Default. Can be switched to other language by the setting.) of controller within 30°

,QWURGXFWLRQ Spanish (Default. Can be switched to other language by the setting.)

White (Light gray)

Thank you for purchasing the UT35A, UT32A Digital Indicating Controller. Case color

l 3RZHU 6XSSO Black (Light charcoal gray) 30° Rear of

This operation guide describes the basic operations of the UT35A and UT32A. The (QVXUH WKDW WKH LQVWUXPHQW V VXSSO YROWD H PDWFKHV WKH YROWD H Fixed code Always "-00" (for Standard Code Model) controller

guide should be provided to the end user of this product. RI WKH SRZHU VXSSO EHIRUH WXUQLQ 21 WKH SRZHU /3 24 V DC loop power supply (*4)

Be sure to read this operation guide before using the product in order to ensure WARNING l 'R 1RW 8VH LQ DQ ( SORVLYH WPRVSKHUH Heater break alarm (*5)

F HF SH 'R QRW RSHUDWH WKH LQVWUXPHQW LQ ORFDWLRQV ZLWK FRPEXVWLEOH ' Power supply 24 V AC/DC

For details of each function, refer to the electronic manual. Before using the product, RU H SORVLYH DVHV RU VWHDP 2SHUDWLRQ LQ VXFK HQYLURQPHQWV If the instrument is moved from a location with low temperature and low humidity

7 Coating (*6)

refer to the table of Model and Suf x Codes to make sure that the delivered product FRQVWLWXWHV DQ H WUHPH VDIHW KD DUG 8VH RI WKH LQVWUXPHQW LQ 9 Terminal cover to a place with high temperature and high humidity, or if the temperature changes

is consistent with the model and suf x codes you ordered. Also make sure that the HQYLURQPHQWV ZLWK KL K FRQFHQWUDWLRQV RI FRUURVLYH DV 6 Mount on DIN rail (without the display parts and keys) rapidly, condensation will result. Moreover, in the case of thermocouple inputs,

following items are included in the package. 62; HWF IRU H WHQGHG SHULRGV RI WLPH PD FDXVH D IDLOXUH Option codes

(In case of the Standard type, the Position proportion-

l 'R 1RW 5HPRYH ,QWHUQDO 8QLW al type, or the Heating/cooling type, please see the

measurement errors will result. To avoid such a situation, leave the instrument in the

0'/ new environment under ambient conditions for more than 1 hour prior to using it.

• Digital Indicating Controller (the model you ordered) x1 7KH LQWHUQDO XQLW VKRXOG QRW EH UHPRYHG E DQ RQH RWKHU WKDQ Operation Guide IM 05P01D81-11EN. In case of the

2.2 : V VHUYLFH SHUVRQQHO 7KHUH DUH GDQ HURXV KL K YROWD H Dual-loop type, please see the Operation Guide IM

6H I F H x1 05P08D81-11EN.)

• Unit Label (L4502VZ) x1 SDUWV LQVLGH GGLWLRQDOO GR QRW UHSODFH WKH IXVH E RXUVHOI Do not mount the instrument in the following locations:

Non-isolated remote input (please see the Operation

l 'DPD H WR WKH 3URWHFWLYH RQVWUXFWLRQ 563

• Tag Label (L4502VE) x1 Guide IM 05P01D31-81EN.) 2XWGRRUV

(Only when ordered.) 2SHUDWLRQ RI WKH LQVWUXPHQW LQ D PDQQHU QRW VSHFLILHG LQ WKH

RSHUDWLRQ XLGH PD GDPD H LWV SURWHFWLYH FRQVWUXFWLRQ *1: When the /LP option is specified, the RS-485 communication of the Type 2 code “1” is 2-wire system. /RFDWLRQV VXEMHFW WR GLUHFW VXQOL KW RU FORVH WR D KHDWHU

• Operation Guide (this document) x6 (A3 size) Install the instrument in a location with stable temperatures that remain close to an

*2: The type 3 code “3” can be specified only when the Type 1 code is “-0” and the Type 2 code is “0.”

(Installation and Wiring, Initial Settings, Operations, and Parameters) *3: English, German, French, and Spanish are available for the guide display. average temperature of 23°C. Do not mount it in locations subject to direct sunlight

*4: The /LP option can be specified in the combination of Type 1 code (any of “-0” or “-1”), Type

or close to a heater. Doing so adversely affects the instrument.

l Target Readers 2 code (any of “0” or “1”) and Type 3 code “0.”

*5: The /HA option can be specified in the combination of Type1 code “-0” or “-2.” and Type 3 code “0.” /RFDWLRQV ZLWK VXEVWDQWLDO DPRXQWV RI RLO IXPHV VWHDP PRLVWXUH GXVW RU

This guide is intended for the following personnel; 7KLV LQVWUXPHQW LV DQ (0 FODVV SURGXFW ,Q D GRPHVWLF HQYLURQ *6: When the /CT option is specified, the UT32A does not conform to the safety standards (UL FRUURVLYH DVHV

• Engineers responsible for installation, wiring, and maintenance of the equipment. PHQW WKLV SURGXFW PD FDXVH UDGLR LQWHUIHUHQFH LQ ZKLFK FDVH WKH and CSA) and CE marking (Products with /CT option are not intended for EEA-market). The presence of oily fumes, steam, moisture, dust, or corrosive gases adversely

• Personnel responsible for normal daily operation of the equipment. XVHU QHHGV WR WDNH DGHTXDWH PHDVXUHV

affects the instrument. Do not mount the instrument in locations subject to any of

CAUTION ■ FFHVVRULHV VROG VHSDUDWHO these substances.

6DIHW 3UHFDXWLRQV The following is an accessory sold separately. • Areas near electromagnetic eld generating sources

Do not place magnets or tools that generate magnetism near the instrument. If the

The following symbol is used on the instrument. It indicates the possibility of injury • LL50A Parameter Setting Software instrument is used in locations close to a strong electromagnetic eld generating

to the user or damage to the instrument, and signi es that the user must refer to the

2. Model and Suf x Codes

0RGHO Suf x code 'HVFULSWLRQ source, the magnetic eld may cause measurement errors.

operation guide or user’s manual for special instructions. The same symbol is used in

// Parameter Setting Software • Locations where the display is dif cult to see

the operation guide and user’s manual on pages that the user needs to refer to, together

with the term “WARNING” or “CAUTION.” ■ 87 6WDQGDUG RGH 0RGHO The instrument uses an LCD for the display unit, and this can be dif cult to see

• External Precision Resistor

2SWLRQ from extremely oblique angles. Mount the instrument in a location where it can be

0RGHO Suf x code 'HVFULSWLRQ 0RGHO Suf x code 'HVFULSWLRQ

FRGH seen as much as possible from the front.

Digital Indicating Controller (Power supply: 100-240 V ; See the General Speci cations (*) Resistance Module

DOOV DWWHQWLRQ WR DFWLRQV RU FRQGLWLRQV WKDW FRXOG FDXVH VHULRXV • Areas close to ammable articles

87 AC) (provided with retransmission output or 15 V DC

RU IDWDO LQMXU WR WKH XVHU DQG LQGLFDWHV SUHFDXWLRQV WKDW VKRXOG EH loop power supply, 2 DIs, and 3 DOs) *: Necessary to input the current signal to the voltage input terminal. Absolutely do not place the instrument directly on am-

WDNHQ WR SUHYHQW VXFK RFFXUUHQFHV Type 1: 6 SH • Terminal Cover mable surfaces. If such a circumstance is unavoidable 150 mm

WARNING F 3 S S SH For UT35A: Model UTAP001; For UT32A: Model UTAP002 and the instrument must be placed close to a ammable

F Heating/cooling type item, provide a shield for it made of 1.43 mm thick plated 150 mm 150 mm

None Note: Manuals can be downloaded from a website. URL: http://www.yokogawa.com/ns/ut/im/ HH PP F S H HH S FH I 150 mm

Type 2: F H

DOOV DWWHQWLRQ WR DFWLRQV RU FRQGLWLRQV WKDW FRXOG FDXVH LQMXU WR 2 additional DIs, 2 additional DOs least 150 mm between it and the instrument on the top,

F

WKH XVHU RU GDPD H WR WKH LQVWUXPHQW RU SURSHUW DQG LQGLFDWHV SUH 5 additional DIs, 5 additional DOs Part number: L4502TP (2 pcs for upper and lower sides) bottom, and sides.

FDXWLRQV WKDW VKRXOG EH WDNHQ WR SUHYHQW VXFK RFFXUUHQFHV None UHDV VXEMHFW WR EHLQ VSODVKHG ZLWK ZDWHU

CAUTION RS-485 communication (Max.38.4 kbps, 2-wire/4-wire)

Type 3: Open Ethernet communication (with serial gateway function)

AC H CC-Link communication (with Modbus master function) H VXUH WR WXUQ 2)) WKH SRZHU VXSSO WR WKH FRQWUROOHU EHIRUH LQ

AC/DC PROFIBUS-DP communication (with Modbus master function) VWDOOLQ LW RQ WKH SDQHO WR DYRLG DQ HOHFWULF VKRFN

DeviceNet communication (with Modbus master function)

WARNING

The equipment wholly protected by double insulation or reinforced insulation. English (Default. Can be switched to other language by the setting.)

German (Default. Can be switched to other language by the setting.)

Display language (*1)

French (Default. Can be switched to other language by the setting.)

Functional grounding terminals Spanish (Default. Can be switched to other language by the setting.)

(Do not use this terminal as a protective grounding terminal). White (Light gray) YOKOGAWA ELECTRIC CORPORATION

Case color

Black (Light charcoal gray) Network Solutions Business Division

Fixed code Always "-00" (for Standard Code Model) 2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 JAPAN

/3 24 V DC loop power supply (*2) YOKOGAWA CORPORATION OF AMERICA

Identi es important information required to operate the instrument.

Heater break alarm (*3) Head office and for product sales

' Power supply 24 V AC/DC 2 Dart Road, Newnan, Georgia 30265, USA

■ :DUQLQ DQG 'LVFODLPHU 7 Coating (*4) YOKOGAWA EUROPE B.V.

Option codes 9 Terminal cover Headquarters

(1) YOKOGAWA makes no warranties regarding the product except those stated in Mount on DIN rail (without the display parts and keys) Euroweg 2, 3825 HD Amersfoort, THE NETHERLANDS

the WARRANTY that is provided separately. 0'/ (please see the Operation Guide IM 05P01D81-

(2) The product is provided on an "as is" basis. YOKOGAWA assumes no liability to 11EN.) www.yokogawa.com/ns

any person or entity for any loss or damage, direct or indirect, arising from the Non-isolated remote input (please see the Operation

563

use of the product or from any unpredictable defect of the product. Guide IM 05P01D31-81EN.) All Rights Reserved, Copyright © 2010 Yokogawa Electric Corporation

,0 3 ' (1 SD H

• Allowable signal source resistance: Note: The control output should always be used with a load of 10 mA or more.

■ 0RXQWLQ WKH ,QVWUXPHQW 0DLQ 8QLW 4. Hardware Speci cations The alarm output should always be used with a load of 1 mA or more.

TC or mV input: 250 Ω or less

Provide an instrumented panel steel sheet of 1 to 10 mm thickness. Effects of signal source resistance: 0.1 µV/Ω or less

After opening the mounting hole on the panel, follow the procedures below to install DC voltage input: 2 kΩ or less

■ Transistor Contact Output Speci cations

the controller: Effects of signal source resistance: About 0.01%/100 Ω • Number of outputs: See the table of Model and Suf x Codes.

7KLV LQVWUXPHQW LV IRU 0HDVXUHPHQW DWH RU 1R

1) Insert the controller into the opening from the front of the panel so that the • Allowable wiring resistance: • Output type: Open collector (SINK current)

'R QRW XVH LW IRU PHDVXUHPHQWV LQ ORFDWLRQV IDOOLQ XQGHU 0HDVXUH

terminal board on the rear is at the far side. RTD input: Max. 150 Ω/wire (The conductor resistance between the three wires • Output contact rating: Max. 24 V DC, 50 mA

PHQW DWH RULHV 1R 1R DQG 1R

2) Set the brackets in place on the top and bottom of the controller as shown in the gure WARNING shall be equal.) • Output time resolution: Min. 200 ms

below, then tighten the screws of the brackets. Take care not to overtighten them. Wiring resistance effect: ±0.1ºC/10 Ω • Use: Alarm output, FAIL output, etc.

• Allowable input voltage/current:

Panel Bracket Internal Wiring TC, mV, mA and RTD input: ±10 V DC ■ Position Proportional Output Speci cations

(top mounting hardware) II

III T V input: ±20 V DC

Entrance IV O( I ) • Position signal input:

Cable

mA input: ±40 mA

Outlet • Noise rejection ratio: Slide resistance: 100 Ω to 2.5 kΩ of total resistance

Direction to insert the

controller Normal mode: 40 dB or more (at 50/60 Hz) 100% side and slide line: with disconnection detection

Terminal board

Insert the controller Common mode: 120 dB or more (at 50/60 Hz) 0% side: without disconnection detection

into the opening at ,( (1 6 /8/

DWH RU (1 5HPDUNV Current input: 4 to 20 mA (with disconnection detection)

the front of the panel. For 100-240 V AC, the power frequency can be set manually. Automatic

H HPH PH HPH SH I PH F F HF - detection is also available. • Sampling period: 50 ms

Insert a screwdriver into the No.1 O (Other)

Category I ly connected to MAINS. For 24 V AC/DC, the power frequency can be set manually. • Measurement resolution: 0.1% of input span

brackets to tighten the screws.

H HPH H HPH PH HPH SH I PH F F HF • Reference junction compensation error: • Position proportional relay output:

No.2

Category II Category II connected to the low-voltage installation. UT35A: contact point 1a; 2 points, 250 V AC, 3 A or 30 V DC, 3 A (resistance load)

Appropriate ±1.0ºC (15 to 35ºC), ±1.5ºC (-10 to 15ºC and 35 to 50ºC)

H HPH H HPH For measurements performed in the building instal- UT32A: contact point 1a; 2 points, 240 V AC, 3 A or 30 V DC, 3 A (resistance load)

Bracket tightening torque: No.3 • Applicable standards: JIS/IEC/DIN (ITS-90) for TC and RTD

Category III Category III

(bottom mounting hardware) 0.25 N•m Note: This should always be used with a load of 10 mA or more.

H HPH H HPH PH HPH SH I PH H FH I H

No.4

Category IV Category IV low-voltage installation. ■ Contact Input Speci cations

■ Heater Break Alarm Speci cations

■ Input Speci cations • Number of inputs: See the table of Model and Suf x Codes.

• Number of inputs: 2

7L KWHQ WKH VFUHZV ZLWK DSSURSULDWH WL KWHQLQ WRUTXH ZLWKLQ 1P • Input type: No-voltage contact input or transistor contact input

• Number of outputs: 2 (transistor contact output)

2WKHUZLVH LW PD FDXVH WKH FDVH GHIRUPDWLRQ RU WKH EUDFNHW GDPD H • Input contact rating: 12 V DC, 10 mA or more

●Universal Input (Equipped as standard) • Use: Measures the heater current using an external current transformer (CT) and

0DNH VXUH WKDW IRUHL Q PDWHULDOV GR QRW HQWHU WKH LQVLGH RI WKH Use a contact with a minimum on-current of 1 mA or less.

CAUTION • Number of inputs: 1 generates a heater break alarm when the measured value is less than the break

LQVWUXPHQW WKURX K WKH FDVH V VOLW KROHV • ON/OFF detection:

• Input type, instrument range, and measurement accuracy: See the table below, detection value.

No-voltage contact input:

,QVWUXPHQW 5DQ H • Current transformer input resistance: About 9.4 Ω

,QSXW 7 SH FFXUDF

Contact resistance of 1 kΩ or less is determined as “ON” and contact

) Current transformer input range: 0.0 to 0.1 Arms (0.12 Arms or more cannot be applied.)

■ ( WHUQDO 'LPHQVLRQV DQG 3DQHO XWRXW 'LPHQVLRQV resistance of 50 kΩ or more as “OFF.”

-270.0 to 1370.0ºC -450.0 to 2500.0ºF ±0.1% of instrument range ±1 digit for • Heater current setting range: OFF, 0.1 to 300.0 Arms

Transistor contact input:

Unit: mm (approx. inch) K -270.0 to 1000.0ºC -450.0 to 2300.0ºF 0°C or more Heater current measured value display range: 0.0 to 360.0 Arms

UT35A 11 ±0.2% of instrument range ±1 digit for Input voltage of 2 V or less is determined as “ON” and leakage current must

(0.43) -200.0 to 500.0ºC -200.0 to 1000.0ºF less than 0°C Note: The CT ratio can be set. CT ratio setting range: 1 to 3300

96 (3.78) 65 (2.56) Bracket not exceed 100 µA when “OFF.”

Terminal cover -200.0 to 1200.0ºC -300.0 to 2300.0ºF ±2% of instrument range ±1 digit for • Recommended CT: CT from U.R.D., Ltd.

20 (0.79) • Minimum status detection hold time: Control period +50 ms CTL-6-S-H: CT ratio 800, measurable current range: 0.1 to 80.0 Arms

-270.0 to 400.0ºC -450.0 to 750.0ºF less than -200.0°C of thermocouple K

±1% of instrument range ±1 digit for • Use: SP switch, operation mode switch, and event input CTL-12L-30: CT ratio 3000, measurable current range: 0.1 to 180.0 Arms

0.0 to 400.0ºC -200.0 to 750.0ºF less than -200.0°C of thermocouple T

±0.15% of instrument range ±1 digit

• Heater current measurement period: 200 ms

■ Analog Output Speci cations • Heater current measurement accuracy: ±5% of current transformer input range

for 400°C or more

0.0 to 1800.0ºC 32 to 3300ºF

±5% of instrument range ±1 digit for • Number of outputs: span ± 1digit (CT error is not included.)

96 (3.78)

less than 400°C

91.6 (3.61)

94.6 (3.72)

105.2 (4.14)

Control output: 1 Heater current detection resolution: Within 1/250 of current transformer input range span

6 0.0 to 1700.0ºC 32 to 3100ºF

±0.15% of instrument range ±1 digit Cooling-side control output of Heating/cooling type (Retransmission output • Break detection On-time: Min. 0.2 second (for time proportional output)

R 0.0 to 1700.0ºC 32 to 3100ºF

±0.1% of instrument range ±1 digit terminal): 1

Bracket Thermo- N -200.0 to 1300.0ºC -300.0 to 2400.0ºF ±0.25% of instrument range ±1 digit • Output type: Current output or voltage pulse output ■ 24 V DC Loop Power Supply Speci cations

F SH for less than 0°C

1 to 10 mm (0.04 to 0.39 inch) (panel thickness) • Current output: 4 to 20 mA DC or 0 to 20 mA DC/load resistance of 600 Ω or less

E -270.0 to 1000.0ºC -450.0 to 1800.0ºF ±0.1% of instrument range ±1 digit for • Use: Power is supplied to a 2-wire transmitter.

• General mounting • Side-by-side close mounting • Current output accuracy: ±0.1% of span (±5% of span for 1 mA or less)

+0.8 L -200.0 to 900.0ºC -300.0 to 1600.0ºF 0°C or more • Power supply: 21.6 to 28.0 V DC

117 (4.61) min. [(N-1)×96+92] 0 ±0.2% of instrument range ±1 digit for The accuracy is that in the standard operating conditions: 23±2°C, 55±10%RH,

-200.0 to 400.0ºC -300.0 to 750.0ºF • Rated current: 4 to 20 mA DC

([(N-1)×3.78+3.62] +0.03 ) less than 0°C and power frequency at 50/60 Hz.

0 U • Maximum supply current: About 30 mA (with short-circuit current limiting circuit.)

0.0 to 400.0ºC -200.0 to 1000.0ºF ±1.5% of instrument range ±1 digit for • Voltage pulse output:

less than -200.0°C of thermocouple E.

+0.8 Use: Time proportional output

92 0 ±0.2% of instrument range ±1 digit

+0.03 W 0.0 to 2300.0ºC 32 to 4200ºF ■ Safety and EMC Standards

(3.62 0 ) (Note 2) On-voltage: 12 V or more/load resistance of 600 Ω or more

3 H 0.0 to 1390.0ºC 32.0 to 2500.0ºF ±0.1% of instrument range ±1 digit Off-voltage: 0.1 V DC or less • Safety:

(53) (2.09) 145 (5.71)

min. ±0.5% of instrument range ±1 digit for Time resolution: 10 ms or 0.1% of output, whichever is larger Compliant with IEC/EN 61010-1 (CE), IEC/EN 61010-2-201 (CE), IEC/EN 61010-

“N” stands for the number of controllers to be 800°C or more 2-030 (CE), approved by CAN/CSA C22.2 No. 61010-1 (CSA), approved by UL

+0.8 PR20-40 0.0 to 1900.0ºC 32 to 3400ºF

92 0 installed. Accuracy is not guaranteed for less

+0.03 than 800°C.

61010-1.

(3.62 0 ) However, the measured value applies if N≥5. ■ Retransmission Output Speci cations Installation category: II

W97Re3- 0.0 to 2000.0ºC 32 to 3600ºF ±0.2% of instrument range ±1 digit

+0.8

Normal tolerance: W75Re25 • Number of outputs: Retransmission output; 1, shared with 15 V DC loop power Pollution degree: 2

92 0 (25) ±(value of JIS B 0401-1998 tolerance class IT18)/2 ±0.1% of instrument range ±1 digit Measurement category: I (CAT I) (UL, CSA)

+0.03 (0.98) -200.0 to 500.0ºC -300.0 to 1000.0ºF supply or Cooling-side control output.

(3.62 0 ) JPt100 (Note 1) O (Other) (CE)

• Current output: 4 to 20 mA DC or 0 to 20 mA DC/ load resistance of 600 Ω or less

-150.00 to 150.00ºC -200.0 to 300.0ºF ±0.1% of instrument range ±1 digit Rated measurement input voltage: Max. 10 V DC

RTD • Current output accuracy (conversion accuracy from PV display on the set scale):

-200.0 to 850.0ºC -300.0 to 1560.0ºF ±0.1% of instrument range ±1 digit Rated transient overvoltage: 1500 V (*)

UT32A Unit: mm (approx. inch) ±0.1% of span (±5% of span for 1 mA or less) * This is a reference safety standard value for measurement category I of CSA/UL 61010-

48 (1.89) Pt100 -200.0 to 500.0ºC -300.0 to 1000.0ºF (Note 1)

11 (0.43) 65 (2.56) Bracket Terminal cover The accuracy is that in the standard operating conditions: 23±2°C, 55±10%RH, 1, and for measurement category O of IEC/EN 61010-2-030. This value is not necessarily a

-150.00 to 150.00ºC -200.0 to 300.0ºF ±0.1% of instrument range ±1 digit

20 (0.79) and power frequency at 50/60 Hz. guarantee of instrument performance.

0.400 to 2.000 V

This is not conversion accuracy through input and output but the performance of • EMC standards:

Standard signal 1.000 to 5.000 V

P S HI Compliant with CE marking

4.00 to 20.00 mA

EN 61326-1 Class A, Table 2 (For use in industrial locations),

0.000 to 2.000 V EN 61326-2-3

±0.1% of instrument range ±1 digit ■ 15 V DC Loop Power Supply Speci cations

0.00 to 10.00 V * The instrument continues to operate at a measurement accuracy of within ±20% of the

(Shared with retransmission output or Cooling-side control output.)

96 (3.78)

DC voltage/current 0.00 to 20.00 mA range during testing.

91.6 (3.61)

94.6 (3.72)

105.2 (4.14)

-10.00 to 20.00 mV • Power supply: 14.5 to 18.0 V DC EN 55011 Class A, Group 1

0.0 to 100.0 mV • Maximum supply current: About 21 mA (with short-circuit current limiting circuit) EN 61000-3-2 Class A

The accuracy is that in the standard operating conditions: 23±2°C, 55±10%RH, and power EN 61000-3-3

Bracket frequency at 50/60 Hz. ■ Step Response Time Speci cations EMC Regulatory Arrangement in Australia and New Zealand (for all model includ-

1 to 10 mm (0.04 to 0.39 inch) (panel thickness) Note 1: ±0.3°C ±1 digit in the range between 0 and 100°C, ±0.5°C ±1 digit in the range ing LL50A)

between -100 and 200°C. Within 1 s (63% of analog output response time when a step change of 10 to 90% of EN 55011 Class A, Group 1

• General mounting • Side-by-side close mounting

+0.6 Note 2: W: W-5% Re/W-26% Re(Hoskins Mfg.Co.). ASTM E988 input span is applied) • KC marking:

70 (2.76) [(N-1)×48+45] 0

min. +0.02

Electromagnetic wave interference prevention standard, electromagnetic wave

([(N-1)×1.89+1.77] 0 ) • Input sampling (control) period: 200 ms ■ Relay Contact Output Speci cations S HF F PS FH

• Burnout detection:

92 +0.8

0 Functions at TC, RTD, and standard signal. • Contact type and number of outputs: ■ Construction, Installation, and Wiring

(3.62+0.03 ) Upscale, downscale, and off can be speci ed. Control output: contact point 1c; 1 point

0 • Dust-proof and drip-proof: IP66 (for front panel) (Not available for side-by-side

145 (5.71) For standard signal, burnout is determined to have occurred if it is 0.1 V or 0.4 Heating/cooling type: contact point 1a; 2 points for both heating and cooling sides

(53) (2.09) min. mA or less. Alarm output: contact point 1a; 3 points (common is independent) close mounting.)

“N” stands for the number of controllers to be • Input bias current: 0.05 µA (for TC or RTD) • Contact rating: • Material: Polycarbonate (Flame retardancy: UL94V-0)

92 +0.8

0 installed. • Measured current (RTD): About 0.16 mA Contact point 1c (control output): 250 V AC, 3 A or 30 V DC, 3A (resistance load) • Case color: White (Light gray) or Black (Light charcoal gray)

(3.62+0.03

0 ) However, the measured value applies if N 5. • Input resistance: Contact point 1a (control output): 240 V AC, 3A or 30 V DC, 3A (resistance load) • Weight: 0.5 kg or less

Normal tolerance: TC or mV input: 1 MΩ or more Contact point 1a (alarm output): 240 V AC, 1A or 30 V DC, 1 A (resistance load) • External dimensions (mm):

+0.6

45 0 (25) ±(value of JIS B 0401-1998 tolerance class IT18)/2 V input: About 1 MΩ • Use: Time proportional output, alarm output, FAIL output, etc. UT35A: 96 (W) × 96 (H) × 65 (depth from the panel face)

+0.02 (0.98) mA input: About 250 Ω UT32A: 48 (W) × 96 (H) × 65 (depth from the panel face)

(1.77 0 ) • Time resolution of control output: 10 ms or 0.1% of output, whichever is larger

(Depth except the projection on the rear panel)

,0 3 ' (1 SD H

You might also like

- Product Specification Sheets: Tempered Water Marine A/C SystemsDocument32 pagesProduct Specification Sheets: Tempered Water Marine A/C SystemsninatenaNo ratings yet

- Operation Guide: 3. How To InstallDocument12 pagesOperation Guide: 3. How To InstallOscar AraucoNo ratings yet

- Panduan Penggunaan Fungsion Generator DS1000E (D) UserGuide En-2Document166 pagesPanduan Penggunaan Fungsion Generator DS1000E (D) UserGuide En-2JuLian Kenzi SakaNo ratings yet

- Osciloscópio Rigol - User's Guide DS1000DDocument162 pagesOsciloscópio Rigol - User's Guide DS1000DacautomacaoecontroleNo ratings yet

- Libra S11 and S12 User Manual: EnglishDocument30 pagesLibra S11 and S12 User Manual: Englishafonso397No ratings yet

- DM3058 UserGuide enDocument138 pagesDM3058 UserGuide enLuis CarlosNo ratings yet

- DM3058 UserGuide ENDocument138 pagesDM3058 UserGuide ENLuis CarlosNo ratings yet

- Instruction Manual: LX70/700 High Speed Counter ModuleDocument22 pagesInstruction Manual: LX70/700 High Speed Counter ModuleVirendra ZopeNo ratings yet

- 95-8582 Det Tronics - X3301-3 PDFDocument8 pages95-8582 Det Tronics - X3301-3 PDFAdhemar RodoNo ratings yet

- Temp Scanner-Modbus Details PDFDocument35 pagesTemp Scanner-Modbus Details PDFGIRINo ratings yet

- User Manual: SDS1000 Series Digital Storage Oscilloscope Version No.: V 1.2Document148 pagesUser Manual: SDS1000 Series Digital Storage Oscilloscope Version No.: V 1.2juampicNo ratings yet

- Manual Osciloscopio Rigol DS1000E (D) UserGuide enDocument166 pagesManual Osciloscopio Rigol DS1000E (D) UserGuide enAYUA0223100% (1)

- Insight II Type 95dss3 Integrated Flame Scanner CU 113Document64 pagesInsight II Type 95dss3 Integrated Flame Scanner CU 113mohamedNo ratings yet

- Leybold Quick-Start Guide For IO InterfaceDocument2 pagesLeybold Quick-Start Guide For IO InterfaceSelva KumarNo ratings yet

- 7UT612Document360 pages7UT612Ketan TankNo ratings yet

- 7UT613 63xDocument514 pages7UT613 63xdenisseNo ratings yet

- 7UT612 Manual V40R01 76Document360 pages7UT612 Manual V40R01 76chanweichangNo ratings yet

- Siprotec 7ut61Document360 pagesSiprotec 7ut61coleiro100% (1)

- 1794 IO Modules FlexIO DQ PDFDocument28 pages1794 IO Modules FlexIO DQ PDFLizbeth Soto CastilloNo ratings yet

- PDX AU Programming GuideDocument71 pagesPDX AU Programming GuideravensarcillaNo ratings yet

- Manual Programacao MG-SP4000.português-EP23 - BRDocument82 pagesManual Programacao MG-SP4000.português-EP23 - BRninhorg75% (4)

- Simon XT Installation GuideDocument8 pagesSimon XT Installation Guideonguyen73No ratings yet

- 10-3514-505-STHS-03 Stratos HSSD-2 Installers HandbookDocument86 pages10-3514-505-STHS-03 Stratos HSSD-2 Installers HandbookRizwan IqbalNo ratings yet

- 10-3514-505-LSHS-02 LaserSense HSSD-2 Detector Installers HandbookDocument86 pages10-3514-505-LSHS-02 LaserSense HSSD-2 Detector Installers HandbookMohamed SayedNo ratings yet

- Manual n1050 v10x F EnglishDocument10 pagesManual n1050 v10x F EnglishmilosNo ratings yet

- 7SA6xx Manual A1 V4.0 enDocument792 pages7SA6xx Manual A1 V4.0 enpedromiguelsanchezNo ratings yet

- P-9910B Hand Held Programmer: DescriptionDocument1 pageP-9910B Hand Held Programmer: DescriptionMohamed AzimNo ratings yet

- Mirrowstic 3codeDocument16 pagesMirrowstic 3codeJesús EspinosaNo ratings yet

- Manual Novus n1200Document12 pagesManual Novus n1200Aldrin HernandezNo ratings yet

- Flexvu Universal Display Model Ud10 Model Ud10 With CGS: Safety ManualDocument6 pagesFlexvu Universal Display Model Ud10 Model Ud10 With CGS: Safety ManualCheloX LNo ratings yet

- OsciloscopioDocument148 pagesOsciloscopioDeiby F Arango MotoaNo ratings yet

- N1200 Controller: Universal Controller - Instructions Manual - V2.0X G Safety Alerts Configuration / FeaturesDocument12 pagesN1200 Controller: Universal Controller - Instructions Manual - V2.0X G Safety Alerts Configuration / FeaturesJosé CostaNo ratings yet

- 95 8668 3.1 (UD10 Safety)Document6 pages95 8668 3.1 (UD10 Safety)Cosme Alberto Alcantar GarciaNo ratings yet

- 19011517 SC - A02 (《H5U系列可编程逻辑控制器用户手册 英文》)Document23 pages19011517 SC - A02 (《H5U系列可编程逻辑控制器用户手册 英文》)Tiny tinyNo ratings yet

- 32 Zone Wireless Transceiver Security Systems: MG5000 V4.5 MG5050 V4.5Document72 pages32 Zone Wireless Transceiver Security Systems: MG5000 V4.5 MG5050 V4.5Bogdan SpatariuNo ratings yet

- Yokogawa Ut32a Temperature Controller Quick ReferenceDocument12 pagesYokogawa Ut32a Temperature Controller Quick ReferenceDilesh PillaiNo ratings yet

- Panelview 800 Hmi Terminals: Installation InstructionsDocument28 pagesPanelview 800 Hmi Terminals: Installation InstructionsRoyNo ratings yet

- Controller N1200: Universal Controller - Instructions Manual - V2.0X Safety Alerts Configuration / FeaturesDocument13 pagesController N1200: Universal Controller - Instructions Manual - V2.0X Safety Alerts Configuration / FeaturesAdonay HenriquezNo ratings yet

- Iskra MT 440Document8 pagesIskra MT 440Ussama Rajput100% (1)

- Intric 1-2 TRC 1-2-4 MITTO 2-4: Self-Learning Rolling-Code Radio Controls 433.92 MHZ FrequencyDocument7 pagesIntric 1-2 TRC 1-2-4 MITTO 2-4: Self-Learning Rolling-Code Radio Controls 433.92 MHZ FrequencyPaulo Alexandre0% (1)

- Catalog F90 relayDocument14 pagesCatalog F90 relayRHETT BUTLERNo ratings yet

- Instruction Manual SPU II Hard Alarm Output Contacts: July 2009 Part No. 4416.223 Revision.1Document12 pagesInstruction Manual SPU II Hard Alarm Output Contacts: July 2009 Part No. 4416.223 Revision.1SATISHNo ratings yet

- Instruction Manual: LX70/700 A/D Conversion ModuleDocument22 pagesInstruction Manual: LX70/700 A/D Conversion ModuleVirendra ZopeNo ratings yet

- 7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsDocument2 pages7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsAakash JunejaNo ratings yet

- UM33A Digital Indicator With Alarms Operation Guide - IM05P03D21-11EN - 020Document8 pagesUM33A Digital Indicator With Alarms Operation Guide - IM05P03D21-11EN - 020Albert KristianNo ratings yet

- Safety Function: Light Curtain With Muting (Two Sensor L-Type) and Configurable Safety RelayDocument54 pagesSafety Function: Light Curtain With Muting (Two Sensor L-Type) and Configurable Safety RelayMarcelo AlvaresNo ratings yet

- Hoja de Datos PLC 1762:L4Document35 pagesHoja de Datos PLC 1762:L4Martin GuzmanNo ratings yet

- 440N-Z21US2JN9 User Manual PDFDocument8 pages440N-Z21US2JN9 User Manual PDFLizbeth Soto CastilloNo ratings yet

- Icstt rm280 - en PDocument42 pagesIcstt rm280 - en PmuthuNo ratings yet

- Ds - Tb82-En - G Manual Abb ConductividadDocument12 pagesDs - Tb82-En - G Manual Abb ConductividadJacob Molina MolinaNo ratings yet

- dd40NTV II 12 09Document36 pagesdd40NTV II 12 09Pablo QuirogaNo ratings yet

- 4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance TestDocument24 pages4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance Testpoci11No ratings yet

- Hantek 1000 SeriesDocument104 pagesHantek 1000 SeriesthayanarvNo ratings yet

- MicroLogix 1000Document174 pagesMicroLogix 1000Alexander MasiasNo ratings yet

- Making PIC Microcontroller Instruments and ControllersFrom EverandMaking PIC Microcontroller Instruments and ControllersNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- IoT Projects with Arduino Nano 33 BLE Sense: Step-By-Step Projects for BeginnersFrom EverandIoT Projects with Arduino Nano 33 BLE Sense: Step-By-Step Projects for BeginnersNo ratings yet

- Beginning Arduino Nano 33 IoT: Step-By-Step Internet of Things ProjectsFrom EverandBeginning Arduino Nano 33 IoT: Step-By-Step Internet of Things ProjectsNo ratings yet

- Yokogawa UT35-UT32A - Part3Document2 pagesYokogawa UT35-UT32A - Part3Fajar PrawiroNo ratings yet

- Yokogawa UT35-UT32A - Part2Document2 pagesYokogawa UT35-UT32A - Part2Fajar PrawiroNo ratings yet

- S Two-Control: 0.5 3 SS C Ontrol: 0.5Document2 pagesS Two-Control: 0.5 3 SS C Ontrol: 0.5Fajar PrawiroNo ratings yet

- Tambah/Insert Data: QrlabelDocument1 pageTambah/Insert Data: QrlabelFajar PrawiroNo ratings yet

- Generator StartupDocument2 pagesGenerator StartupFajar PrawiroNo ratings yet

- SiskomDocument2 pagesSiskomFajar PrawiroNo ratings yet

- Electrical SymbolDocument1 pageElectrical Symbol5223043305No ratings yet

- NetBackup 5340 Appliance Hardware Installation GuideDocument83 pagesNetBackup 5340 Appliance Hardware Installation Guidejarg200690No ratings yet

- ADB 45016 001 - Do3NNZcDocument2 pagesADB 45016 001 - Do3NNZcVic MelendezNo ratings yet

- Adwaith Final College Review Final FinalDocument20 pagesAdwaith Final College Review Final FinalmailadwaitharunNo ratings yet

- MatrixDocument22 pagesMatrixMark Jonell EsguerraNo ratings yet

- SDI82X DS T140039 en BDocument2 pagesSDI82X DS T140039 en BmanutencaoraengenhariaNo ratings yet

- ZPL40 ZPL50 ZPL70 LA-B181P r0.5 0218 r0.5 0325Document61 pagesZPL40 ZPL50 ZPL70 LA-B181P r0.5 0218 r0.5 0325Telefono TallerNo ratings yet

- Pascal StringsDocument5 pagesPascal StringsPutra PrasetyaNo ratings yet

- Resume Tata Consultancy ServicesDocument3 pagesResume Tata Consultancy ServicesSubhashini 29No ratings yet

- Notifier NFS-640 Programming ManualDocument116 pagesNotifier NFS-640 Programming ManualxiaolanNo ratings yet

- Test 1 - Matrices: PART A - 6 Questions, 1 Mark Each (6x1)Document2 pagesTest 1 - Matrices: PART A - 6 Questions, 1 Mark Each (6x1)sanand11No ratings yet

- 6.3.3.6 Packet Tracer - Configuring Router-on-a-Stick Inter-VLAN Routing Instructions - ILMDocument4 pages6.3.3.6 Packet Tracer - Configuring Router-on-a-Stick Inter-VLAN Routing Instructions - ILMJarekNo ratings yet

- Digitization Brochure DET NEWDocument4 pagesDigitization Brochure DET NEWSairam DigitaledgeIndiaNo ratings yet

- 1.automatic Engine Locking System For Drunk and Drivers MSP430Document3 pages1.automatic Engine Locking System For Drunk and Drivers MSP430Hamed Raza80% (5)

- 1 NSTEP User Manual For The CourtDocument13 pages1 NSTEP User Manual For The CourtSCJCOURT ZAHEERABADNo ratings yet

- Mtech: Pallapu Manoj Kumar Email: BackgroundDocument5 pagesMtech: Pallapu Manoj Kumar Email: BackgroundRaj MotikiNo ratings yet

- File and Resource AttacksDocument61 pagesFile and Resource AttacksAbdul Mateen UkkundNo ratings yet

- 8.isometric Projections and Isometric View or DrawingDocument39 pages8.isometric Projections and Isometric View or DrawingMahek JariwalaNo ratings yet

- Youjie 4600 - User-ManualDocument144 pagesYoujie 4600 - User-ManualVaseaPupkinNo ratings yet

- Interface A Seven Segment Display To An ArduinoDocument7 pagesInterface A Seven Segment Display To An ArduinospgmaniarunagiriNo ratings yet

- GPT-4 Architecture, Infrastructure, Training Dataset, Costs, Vision, MoEDocument4 pagesGPT-4 Architecture, Infrastructure, Training Dataset, Costs, Vision, MoEjohn clarityNo ratings yet

- Design and Simulation of Fog Computing Model For Smart FarmingDocument6 pagesDesign and Simulation of Fog Computing Model For Smart FarmingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Assignment 4Document2 pagesAssignment 4Satish Kumar ChauhanNo ratings yet

- 1 - APM 303 - Presentation - ENDocument43 pages1 - APM 303 - Presentation - ENChhoan NhunNo ratings yet

- Logo Maker and Brand Kit Build Agreement - FinalDocument56 pagesLogo Maker and Brand Kit Build Agreement - Finalkawish farooqiNo ratings yet

- The 1090Mhz Riddle: Junzi SunDocument49 pagesThe 1090Mhz Riddle: Junzi SunRiccardo RicciNo ratings yet

- Jteft 08 00313Document5 pagesJteft 08 00313Shane DorianNo ratings yet

- ERM Performance Tuning Pricing and Order Form See Tutorial Tab Below For Sample of Accompaning Learning Book and Video'sDocument7 pagesERM Performance Tuning Pricing and Order Form See Tutorial Tab Below For Sample of Accompaning Learning Book and Video'sabdulmajid aljonadiNo ratings yet

- Year I, Semester II (2016/2017) : # Course Title Course Code CR - Hr. Ects Grade GPTDocument5 pagesYear I, Semester II (2016/2017) : # Course Title Course Code CR - Hr. Ects Grade GPTWubalemNo ratings yet

- Cyber Security AwarenessDocument6 pagesCyber Security AwarenessArya Adhi NugrahaNo ratings yet