Professional Documents

Culture Documents

# 114 Changing Swivel Packing On Top Drive1

# 114 Changing Swivel Packing On Top Drive1

Uploaded by

HSE ManagerCopyright:

Available Formats

You might also like

- Backfilling Compaction JSADocument2 pagesBackfilling Compaction JSArashid zaman84% (25)

- The Rich Get Richer and The Poor Get PrisonDocument1 pageThe Rich Get Richer and The Poor Get PrisonGunasundaryChandramohanNo ratings yet

- Skid Steer (Generic) : Job Safety AnalysisDocument2 pagesSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNo ratings yet

- Hirac TableDocument6 pagesHirac TableNor Syazwani Sharudin100% (1)

- Pubs HPE OmniStack 4 1 3 For Vsphere Upgrade GuideDocument63 pagesPubs HPE OmniStack 4 1 3 For Vsphere Upgrade GuideYeraldo MarinNo ratings yet

- Method Statement Stone ColumnDocument10 pagesMethod Statement Stone ColumnSantosh ZunjarNo ratings yet

- Strategic Marketing Plan For WalmartDocument22 pagesStrategic Marketing Plan For WalmartEsther Kakai100% (1)

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Jsa Dismantling The Wooden Framework-NewDocument3 pagesJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdNo ratings yet

- African American InventorsDocument14 pagesAfrican American Inventorshandyhandline100% (2)

- Urdu To English DictionaryDocument231 pagesUrdu To English Dictionaryarun_beriwal67% (6)

- Ib Unit - The Arrival-Immigration-Visual ExperienceDocument6 pagesIb Unit - The Arrival-Immigration-Visual Experienceapi-284054906No ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 112 Change Solenoid On Top Drive1Document2 pages# 112 Change Solenoid On Top Drive1HSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 115 Changing Vavle in Choke ManifoldDocument2 pages# 115 Changing Vavle in Choke ManifoldHSE ManagerNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- Top Drive ConnectionsDocument1 pageTop Drive Connectionsghada gattouchNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Reducing Brush & Trees With Wood Chipper: Job Safety AnalysisDocument3 pagesReducing Brush & Trees With Wood Chipper: Job Safety AnalysisRetselisitsoeNo ratings yet

- Cable Splicing ENDocument4 pagesCable Splicing ENTilalNo ratings yet

- OSI EHS 002 B - SWMS Floor Chipping WorkDocument2 pagesOSI EHS 002 B - SWMS Floor Chipping Workranjithroshan143No ratings yet

- JSA - Clearing Brush Chain SawDocument2 pagesJSA - Clearing Brush Chain SawRetselisitsoe100% (1)

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- SWMS 3 Moving Plant On Construction SitesDocument7 pagesSWMS 3 Moving Plant On Construction SitesSyazli EimranNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- 1 - R.A. - 004 - ShutteringDocument4 pages1 - R.A. - 004 - ShutteringmahmoudabidaliNo ratings yet

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- S07 Tank Project - JSA - Erection of Scaffolding 2nd LevelDocument6 pagesS07 Tank Project - JSA - Erection of Scaffolding 2nd LevelKrishVy KumærNo ratings yet

- Safety Start With YouDocument39 pagesSafety Start With YouCarlos Alberto Ferreira FilhoNo ratings yet

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- Stop BP Gupco-ModifiedDocument20 pagesStop BP Gupco-ModifiedAhmed HashimNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- JSA Lube Survey General PlantDocument6 pagesJSA Lube Survey General Plantusman jamshaidNo ratings yet

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- JSA Teflon - U BoltDocument3 pagesJSA Teflon - U BoltHow Chin Engineering Sdn BhdNo ratings yet

- S03 Painting Works - JSA - Erection of ScaffoldingDocument6 pagesS03 Painting Works - JSA - Erection of ScaffoldingKrishVy KumærNo ratings yet

- SG7.09 Guide To Risk AssessmentDocument6 pagesSG7.09 Guide To Risk AssessmentMIKE HarwoodNo ratings yet

- Safety Engineering and JhaDocument29 pagesSafety Engineering and JhaDarren Dela CruzNo ratings yet

- Air Winch OperationDocument1 pageAir Winch OperationDQE040 HSSENo ratings yet

- Safety InductionDocument62 pagesSafety InductionQuest Certification B.KarthikeyanNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- Painting WorkDocument8 pagesPainting WorkNisanth Thulasidas100% (1)

- HSE-BMS-004 Supervisors TrainingDocument29 pagesHSE-BMS-004 Supervisors TrainingUche S Osigwe100% (1)

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- Material Shifting Through The Stair CaseDocument3 pagesMaterial Shifting Through The Stair Casemohammed sohailNo ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 112 Change Solenoid On Top Drive1Document2 pages# 112 Change Solenoid On Top Drive1HSE ManagerNo ratings yet

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- A High-Throughput Method For Dereplication and Assessment Ofmetabolite Distribution Insalviaspecies Using LC-MS/MSDocument12 pagesA High-Throughput Method For Dereplication and Assessment Ofmetabolite Distribution Insalviaspecies Using LC-MS/MSkostNo ratings yet

- Nature of Urban Interventions in Changing The OldDocument10 pagesNature of Urban Interventions in Changing The OldAneesha MuthurajNo ratings yet

- AP3456 Mathematics & Physics PDFDocument319 pagesAP3456 Mathematics & Physics PDFLaxmi Krishnadas0% (1)

- Curriculum Till DE-39 PDFDocument173 pagesCurriculum Till DE-39 PDFubaid umarNo ratings yet

- Title of The Paper: (Font: Arial 14Pts)Document3 pagesTitle of The Paper: (Font: Arial 14Pts)RN Builder IpohNo ratings yet

- Iit Jee (Links)Document5 pagesIit Jee (Links)Tarun MankadNo ratings yet

- 978 1 62948 492 1 - EbookDocument221 pages978 1 62948 492 1 - EbookAmparoNo ratings yet

- Cono Rc-45-Ii, Serie 52378Document50 pagesCono Rc-45-Ii, Serie 52378omar muñoz100% (1)

- Effect of Reciprocal Teaching and Motivation On Reading Comprehension2016Document5 pagesEffect of Reciprocal Teaching and Motivation On Reading Comprehension2016Aqila HafeezNo ratings yet

- ElicitingDocument4 pagesElicitingikomang agus sutejaNo ratings yet

- Routing Security - MUM - MikroTik PDFDocument120 pagesRouting Security - MUM - MikroTik PDFAlex EnriquezNo ratings yet

- QuestionDocument4 pagesQuestionKira NguyễnNo ratings yet

- QC DissertationDocument85 pagesQC DissertationAhmed MahmoudNo ratings yet

- Introduction To PBLDocument21 pagesIntroduction To PBLChipego NyirendaNo ratings yet

- A Detailed Lesson Plan in English 9: (Using Adverbs in Narration)Document8 pagesA Detailed Lesson Plan in English 9: (Using Adverbs in Narration)Faith Malinao100% (1)

- Power Dynamics in Shakespeare's The TempestDocument5 pagesPower Dynamics in Shakespeare's The TempestDavid GómezNo ratings yet

- Shirish - Kumar - Software - Engineer NewDocument1 pageShirish - Kumar - Software - Engineer NewAbhishek KumarNo ratings yet

- Panel Wood LaboratoryDocument4 pagesPanel Wood Laboratorymunawir anazliNo ratings yet

- Chapter 5 - Elasticity and Its ApplicationDocument37 pagesChapter 5 - Elasticity and Its ApplicationOktaviana MuktiNo ratings yet

- Counting Atoms Balancing Equations Law of Conservation of MassDocument20 pagesCounting Atoms Balancing Equations Law of Conservation of MassDaniel RichardsNo ratings yet

- English Literature AnthologyDocument25 pagesEnglish Literature AnthologyShrean RafiqNo ratings yet

- Lva1 App6892Document146 pagesLva1 App6892Adam Shahabuddin Abdul RazakNo ratings yet

- DSM Capital Market Days 300911 Leendert Staal PresentationDocument15 pagesDSM Capital Market Days 300911 Leendert Staal Presentationhau vuvanNo ratings yet

# 114 Changing Swivel Packing On Top Drive1

# 114 Changing Swivel Packing On Top Drive1

Uploaded by

HSE ManagerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

# 114 Changing Swivel Packing On Top Drive1

# 114 Changing Swivel Packing On Top Drive1

Uploaded by

HSE ManagerCopyright:

Available Formats

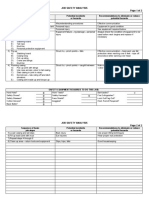

JOB SAFETY ANALYSIS

Page 1 of 2

Work Activity (Job): CHANGING SWIVEL PACKING ON TOP DRIVE

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

1) Pre-job meeting

A) Discussion of procedures Misunderstanding procedures Effective communication – review rig

Operating Manual

B) Prepare and inspect all tools and equipment Personal injury Equipment in good condition

C) Proper personal protective equipment Personal injury See equipment required below

2) Position top drive as low as possible lockout / Falls – personal injury – fatality Double check lockout / tagout of equipment

tagout top drive and mud pumps Do not stand under load or under work area

close upper and lower top drive valves

3) Lift person up to swivel packing in boatswain’s Falls – personal injury – fatality Inspect personal protective equipment and

chair with air hoist – hook anti-fall device to chair safety equipment

4) Break and back off upper and lower packing Struck by – falls – personal injury – fatality Inspect personal protective equipment and

nuts – left handed threads safety equipment

5) Remove swivel packing assembly – lower to rig Struck by – falls – personal injury – fatality Make sure tied onto equipment properly

floor with second air hoist

6) Pick up quick change swivel package assembly Struck by – falls – personal injury – fatality Make sure tied onto equipment properly

– inspect and grease if needed – lift to top drive

with air hoist

7) Install swivel packing assembly – make up Struck by – falls – personal injury – fatality Make sure tied onto equipment properly

packing nuts

Caution: do not over tighten and damage

assembly

8) Open upper top drive valve – remove lockout / Struck by – personal injury Ensure personnel stays clear of high

tagout on mud pumps and top drive – test swivel pressure lines – inform hands of lockout /

packing – readjust packing if needed tagout removal – effective communication

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Work Vests? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Back Belts? Sala Block

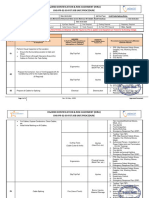

JOB SAFETY ANALYSIS

Page 2 of 2

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

9) Pick up and clean up all tools – return to Slips, trips, falls – struck by Keep work area clean – ensure tools are in

proper storage good working condition

10) Repack and inspect old swivel packing Personal injury – fatality Inspect equipment

assembly for next change

11) Clean work area Slips, trips, falls Good housekeeping

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Work Vests? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Back Belts? Sala Block

You might also like

- Backfilling Compaction JSADocument2 pagesBackfilling Compaction JSArashid zaman84% (25)

- The Rich Get Richer and The Poor Get PrisonDocument1 pageThe Rich Get Richer and The Poor Get PrisonGunasundaryChandramohanNo ratings yet

- Skid Steer (Generic) : Job Safety AnalysisDocument2 pagesSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNo ratings yet

- Hirac TableDocument6 pagesHirac TableNor Syazwani Sharudin100% (1)

- Pubs HPE OmniStack 4 1 3 For Vsphere Upgrade GuideDocument63 pagesPubs HPE OmniStack 4 1 3 For Vsphere Upgrade GuideYeraldo MarinNo ratings yet

- Method Statement Stone ColumnDocument10 pagesMethod Statement Stone ColumnSantosh ZunjarNo ratings yet

- Strategic Marketing Plan For WalmartDocument22 pagesStrategic Marketing Plan For WalmartEsther Kakai100% (1)

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Jsa Dismantling The Wooden Framework-NewDocument3 pagesJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdNo ratings yet

- African American InventorsDocument14 pagesAfrican American Inventorshandyhandline100% (2)

- Urdu To English DictionaryDocument231 pagesUrdu To English Dictionaryarun_beriwal67% (6)

- Ib Unit - The Arrival-Immigration-Visual ExperienceDocument6 pagesIb Unit - The Arrival-Immigration-Visual Experienceapi-284054906No ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 112 Change Solenoid On Top Drive1Document2 pages# 112 Change Solenoid On Top Drive1HSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 115 Changing Vavle in Choke ManifoldDocument2 pages# 115 Changing Vavle in Choke ManifoldHSE ManagerNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- Top Drive ConnectionsDocument1 pageTop Drive Connectionsghada gattouchNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Reducing Brush & Trees With Wood Chipper: Job Safety AnalysisDocument3 pagesReducing Brush & Trees With Wood Chipper: Job Safety AnalysisRetselisitsoeNo ratings yet

- Cable Splicing ENDocument4 pagesCable Splicing ENTilalNo ratings yet

- OSI EHS 002 B - SWMS Floor Chipping WorkDocument2 pagesOSI EHS 002 B - SWMS Floor Chipping Workranjithroshan143No ratings yet

- JSA - Clearing Brush Chain SawDocument2 pagesJSA - Clearing Brush Chain SawRetselisitsoe100% (1)

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- SWMS 3 Moving Plant On Construction SitesDocument7 pagesSWMS 3 Moving Plant On Construction SitesSyazli EimranNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- 1 - R.A. - 004 - ShutteringDocument4 pages1 - R.A. - 004 - ShutteringmahmoudabidaliNo ratings yet

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- S07 Tank Project - JSA - Erection of Scaffolding 2nd LevelDocument6 pagesS07 Tank Project - JSA - Erection of Scaffolding 2nd LevelKrishVy KumærNo ratings yet

- Safety Start With YouDocument39 pagesSafety Start With YouCarlos Alberto Ferreira FilhoNo ratings yet

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- Stop BP Gupco-ModifiedDocument20 pagesStop BP Gupco-ModifiedAhmed HashimNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- JSA Lube Survey General PlantDocument6 pagesJSA Lube Survey General Plantusman jamshaidNo ratings yet

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- JSA Teflon - U BoltDocument3 pagesJSA Teflon - U BoltHow Chin Engineering Sdn BhdNo ratings yet

- S03 Painting Works - JSA - Erection of ScaffoldingDocument6 pagesS03 Painting Works - JSA - Erection of ScaffoldingKrishVy KumærNo ratings yet

- SG7.09 Guide To Risk AssessmentDocument6 pagesSG7.09 Guide To Risk AssessmentMIKE HarwoodNo ratings yet

- Safety Engineering and JhaDocument29 pagesSafety Engineering and JhaDarren Dela CruzNo ratings yet

- Air Winch OperationDocument1 pageAir Winch OperationDQE040 HSSENo ratings yet

- Safety InductionDocument62 pagesSafety InductionQuest Certification B.KarthikeyanNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- Painting WorkDocument8 pagesPainting WorkNisanth Thulasidas100% (1)

- HSE-BMS-004 Supervisors TrainingDocument29 pagesHSE-BMS-004 Supervisors TrainingUche S Osigwe100% (1)

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- Material Shifting Through The Stair CaseDocument3 pagesMaterial Shifting Through The Stair Casemohammed sohailNo ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 112 Change Solenoid On Top Drive1Document2 pages# 112 Change Solenoid On Top Drive1HSE ManagerNo ratings yet

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- A High-Throughput Method For Dereplication and Assessment Ofmetabolite Distribution Insalviaspecies Using LC-MS/MSDocument12 pagesA High-Throughput Method For Dereplication and Assessment Ofmetabolite Distribution Insalviaspecies Using LC-MS/MSkostNo ratings yet

- Nature of Urban Interventions in Changing The OldDocument10 pagesNature of Urban Interventions in Changing The OldAneesha MuthurajNo ratings yet

- AP3456 Mathematics & Physics PDFDocument319 pagesAP3456 Mathematics & Physics PDFLaxmi Krishnadas0% (1)

- Curriculum Till DE-39 PDFDocument173 pagesCurriculum Till DE-39 PDFubaid umarNo ratings yet

- Title of The Paper: (Font: Arial 14Pts)Document3 pagesTitle of The Paper: (Font: Arial 14Pts)RN Builder IpohNo ratings yet

- Iit Jee (Links)Document5 pagesIit Jee (Links)Tarun MankadNo ratings yet

- 978 1 62948 492 1 - EbookDocument221 pages978 1 62948 492 1 - EbookAmparoNo ratings yet

- Cono Rc-45-Ii, Serie 52378Document50 pagesCono Rc-45-Ii, Serie 52378omar muñoz100% (1)

- Effect of Reciprocal Teaching and Motivation On Reading Comprehension2016Document5 pagesEffect of Reciprocal Teaching and Motivation On Reading Comprehension2016Aqila HafeezNo ratings yet

- ElicitingDocument4 pagesElicitingikomang agus sutejaNo ratings yet

- Routing Security - MUM - MikroTik PDFDocument120 pagesRouting Security - MUM - MikroTik PDFAlex EnriquezNo ratings yet

- QuestionDocument4 pagesQuestionKira NguyễnNo ratings yet

- QC DissertationDocument85 pagesQC DissertationAhmed MahmoudNo ratings yet

- Introduction To PBLDocument21 pagesIntroduction To PBLChipego NyirendaNo ratings yet

- A Detailed Lesson Plan in English 9: (Using Adverbs in Narration)Document8 pagesA Detailed Lesson Plan in English 9: (Using Adverbs in Narration)Faith Malinao100% (1)

- Power Dynamics in Shakespeare's The TempestDocument5 pagesPower Dynamics in Shakespeare's The TempestDavid GómezNo ratings yet

- Shirish - Kumar - Software - Engineer NewDocument1 pageShirish - Kumar - Software - Engineer NewAbhishek KumarNo ratings yet

- Panel Wood LaboratoryDocument4 pagesPanel Wood Laboratorymunawir anazliNo ratings yet

- Chapter 5 - Elasticity and Its ApplicationDocument37 pagesChapter 5 - Elasticity and Its ApplicationOktaviana MuktiNo ratings yet

- Counting Atoms Balancing Equations Law of Conservation of MassDocument20 pagesCounting Atoms Balancing Equations Law of Conservation of MassDaniel RichardsNo ratings yet

- English Literature AnthologyDocument25 pagesEnglish Literature AnthologyShrean RafiqNo ratings yet

- Lva1 App6892Document146 pagesLva1 App6892Adam Shahabuddin Abdul RazakNo ratings yet

- DSM Capital Market Days 300911 Leendert Staal PresentationDocument15 pagesDSM Capital Market Days 300911 Leendert Staal Presentationhau vuvanNo ratings yet