Professional Documents

Culture Documents

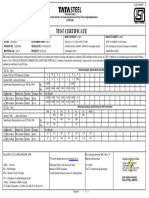

Test Certificate For High Carbon Steel Wire Rods: Iso 9001: 2015 Certified Company Iatf 16949:2016 Certified Company

Test Certificate For High Carbon Steel Wire Rods: Iso 9001: 2015 Certified Company Iatf 16949:2016 Certified Company

Uploaded by

SITARAM GANESHMALLOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Certificate For High Carbon Steel Wire Rods: Iso 9001: 2015 Certified Company Iatf 16949:2016 Certified Company

Test Certificate For High Carbon Steel Wire Rods: Iso 9001: 2015 Certified Company Iatf 16949:2016 Certified Company

Uploaded by

SITARAM GANESHMALLCopyright:

Available Formats

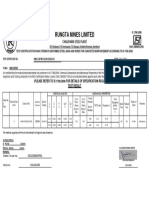

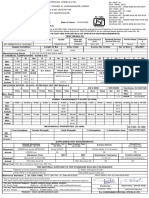

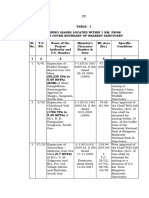

JINDAL STEEL & POWER LTD IS 7904:2018

BALKUDRA, PATRATU

District: RAMGARH

Jharkhand - 829143, INDIA

Mob No. +91 9771492002

Email ID - qcjspl.patratu@pat.jspl.com

CM/L - 5809681

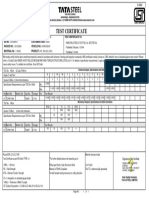

TEST CERTIFICATE FOR HIGH CARBON STEEL WIRE RODS

Test Certificate No.: 0000199803 ISO 9001 : 2015 CERTIFIED COMPANY Delivery No. : 71743999

TC Date : 09.01.2019 IATF 16949:2016 CERTIFIED COMPANY Purchase Order No. : mail dated Nov 12

Purchase Order Date : 13.11.2018

,- Supply Condition : As Rolled

De-Oxidation:Killed

We certified that the material described below fully conforms to IS 7904:2018 Chemical composition and Mechanical properties of the product, as tested in accordance with the Scheme of Testing and

Inspection contained in the BIS Certification Marks Licence No.CM/L - 5809681 are as indicated below against each Heat No.

(PLEASE REFER TO IS 7904:2018 FOR DETAILS OF SPECIFICATION REQUIREMENTS) "

Material - Carbon Steel / Grade- SWRH82A / Dia.- 5.50 mm

Chemical Properties

Heat No. No. of Coils Wt(MT) %C %Mn %Si %P %S %Al %Cr %V %B %Cu %Ni %Mo %Nb %Ti CE N2 ppm

Coils

B86801 11 27.198 0.81 0.51 0.17 0.013 0.003 0.003 0.012 0.001 0.0004 0.002 0.010 - 0.001 0.002 0.898 55

Mechanical Metallurgical Dimension

Heat No No. of Coil Wt(MT) YS UTS %EI %RA Impact Upset test AR Quench A-Th A-Tk B-Th B-Tk C-Th C-Tk D-Th D-Tk Grain Decarb Res Micro Avg Ovality Macro

Coils MPa MPa (J) hardness Hardness Size % .Pear. Structure Dimension (mm)

(HBW) (HRC) % (mm)

B86801 11 27.198 764.0 1132.0 - 36.0 - - - - 0.5 - - - - - 1.0 - 7.50 0.32 - Pearlite. 0.15 OK.

Grand 11 27.198

Total

Product ID

Heat No Coil No

B86801 C001 C002 C011 C016 C022 C026 C028 C030 C036 C039 C057

REDUCTION_RATIO :1146.50:1

*Th = Thin , Tk = Heavy . * Input Billet Size : 165 X 165 mm2 * "100% Mix-up test OK" ,* Res. Pear. = Resolvable Pearlite"

Note :- 1. The above sample(s) has/have been tested at temp.: At ambient temperature, 2.Uncertainty percentage : xxx, 3. The results relate only to the items tested, 4. This certificate shall not be reproduced in part or full without written

permission of the Management. 5. Sample(s) drawn by us (Sampling procedure : 2 samples to be tested for less than 100 TON heat and 3 samples to be tested for more than 100 TON heat), 6. All tests are performed as per proper standards.

7. Zr, Ca, As, Sn, N, H, O are not in our scope for chemical parameters and 0.2% Proof test, %El at max. force, Impact test, Microstructure, Macro test are not in our scope for mechanical parameters.

, fvsgvsvssv

.

.

Page 1 of 1

You might also like

- Test Certificate For Galvanized Steel CoilsDocument1 pageTest Certificate For Galvanized Steel CoilsS.SHANMUGA SABAREESAN100% (2)

- Jindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Document1 pageJindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Mohammad Adil50% (2)

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal50% (4)

- 2452169253-6x1500mm E250Document1 page2452169253-6x1500mm E250Mohd YaskeenNo ratings yet

- MTC Inv 053 PDFDocument1 pageMTC Inv 053 PDFBeshnu Garanaik100% (2)

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Test Certificate: Highway Industries Ltd. (Sahnewal)Document1 pageTest Certificate: Highway Industries Ltd. (Sahnewal)Deepak MehtaNo ratings yet

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech0992000% (1)

- Jindal Steel & Power LTD: Test CertificateDocument2 pagesJindal Steel & Power LTD: Test CertificateAmandeep Singh50% (2)

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Exhaust Temperature SpreadDocument5 pagesExhaust Temperature Spreadchdeepak96100% (8)

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- Test Certificate: Signature Not VerifiedDocument1 pageTest Certificate: Signature Not Verifiedreportdaily819No ratings yet

- CSP123D000021410 15 07 2023 (36) SRKDocument1 pageCSP123D000021410 15 07 2023 (36) SRKpmmahobaNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOshekarNo ratings yet

- JJ3223124887Document1 pageJJ3223124887पवन द्विवेदीNo ratings yet

- Jindal Aluminium Limited.: 19576 - 47.62X44.45X0.99 DOOR TOPDocument1 pageJindal Aluminium Limited.: 19576 - 47.62X44.45X0.99 DOOR TOPbharat.prakashrajNo ratings yet

- TC No 1201 StudDocument2 pagesTC No 1201 StudGaurav100% (1)

- 304 - Jindal MTC Slit CoilDocument1 page304 - Jindal MTC Slit CoilRakesh AsukarNo ratings yet

- TC Rungta 02Document1 pageTC Rungta 02pmmahobaNo ratings yet

- Aluminium Rod Material Detail PDFDocument1 pageAluminium Rod Material Detail PDFPradeep SNo ratings yet

- Bar No - 5763: Test CertificateDocument2 pagesBar No - 5763: Test CertificateDeepak HoleNo ratings yet

- Bar No - 5763: Test CertificateDocument2 pagesBar No - 5763: Test Certificateshrikant bhirudNo ratings yet

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 pageTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- Quotation / Proforma InvoiceDocument1 pageQuotation / Proforma InvoiceSubham DasNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- 12mm Diameter ReportsDocument2 pages12mm Diameter ReportsPRASAD THOMBARENo ratings yet

- Jindal Aluminium Limited.: 20805 - 40X18X0.91 WINDOW SECTIONDocument1 pageJindal Aluminium Limited.: 20805 - 40X18X0.91 WINDOW SECTIONbharat.prakashrajNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- Wo-Ec546wod7000042 Stay CableDocument3 pagesWo-Ec546wod7000042 Stay CableJkkhyhNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- HR 3.50MM July 2019Document1 pageHR 3.50MM July 2019satrughana patraNo ratings yet

- Jindal Aluminium Limited.: Chemical Composition PercentDocument1 pageJindal Aluminium Limited.: Chemical Composition Percentbharat.prakashrajNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (2)

- 0707711343Document2 pages0707711343venkata krishna reddy MorthlaNo ratings yet

- N.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposesDocument2 pagesN.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposessunilmoryaNo ratings yet

- Jindal Aluminium Limited.: 20033 - 63.5X38.1X1.01 PARTITION SECTION-SGDocument1 pageJindal Aluminium Limited.: 20033 - 63.5X38.1X1.01 PARTITION SECTION-SGbharat.prakashrajNo ratings yet

- Active Green Pi 29.11.23Document1 pageActive Green Pi 29.11.23a.satishNo ratings yet

- VARILLADocument1 pageVARILLAB. styllshNo ratings yet

- HMM Infra TCDocument1 pageHMM Infra TCraisingh085No ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- 3.1.5. Perfil H 6x15Document1 page3.1.5. Perfil H 6x15benedicto soto mestanzaNo ratings yet

- Ril Wear PlateDocument1 pageRil Wear Plateshindemitesh17No ratings yet

- Rydon Industries PVT LTD: Details of Inspection Description SpecificationDocument1 pageRydon Industries PVT LTD: Details of Inspection Description SpecificationmuthuselvanNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOarhamenterprises5401No ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- 'Invoice 12341231Document1 page'Invoice 12341231pateldhiraj532No ratings yet

- Banjo Beam - MTC 3.5 MM E 46Document1 pageBanjo Beam - MTC 3.5 MM E 46Rajhans PressingNo ratings yet

- Global Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiDocument1 pageGlobal Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiSonu Singh100% (1)

- BTech SyllabusDocument1 pageBTech SyllabusMadavan RNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- 84518-56 MM RevisedDocument1 page84518-56 MM RevisedDeepak MehtaNo ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- Consolidated MIRDocument4 pagesConsolidated MIRKarthik ErNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOvikram jainNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- Company Profile: Office: 141/9 DDM School Road, Tulshi Nagar Ward No. 2 Korba, Chattishgarh - 495677Document6 pagesCompany Profile: Office: 141/9 DDM School Road, Tulshi Nagar Ward No. 2 Korba, Chattishgarh - 495677SITARAM GANESHMALLNo ratings yet

- Make Organic: HealthDocument41 pagesMake Organic: HealthSITARAM GANESHMALLNo ratings yet

- RA Document RA Details: GEM/2021/B/1510260Document2 pagesRA Document RA Details: GEM/2021/B/1510260SITARAM GANESHMALLNo ratings yet

- GeM Bidding 2841821Document4 pagesGeM Bidding 2841821SITARAM GANESHMALLNo ratings yet

- Type of EnterpriseDocument3 pagesType of EnterpriseSITARAM GANESHMALLNo ratings yet

- 011CMEDDocument13 pages011CMEDphilip xeroNo ratings yet

- SupernaturalismDocument9 pagesSupernaturalismBack upNo ratings yet

- 7th Heart Sounds and MurmursDocument6 pages7th Heart Sounds and MurmursbabibubeboNo ratings yet

- P1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsDocument63 pagesP1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsHgoglezNo ratings yet

- American Lincoln MPV 60 Ecp Parts List FordDocument153 pagesAmerican Lincoln MPV 60 Ecp Parts List FordYew LimNo ratings yet

- Index: High-Grade KeyboardDocument15 pagesIndex: High-Grade KeyboardDavid Emanuel Dauo0% (1)

- Catalog-Basket ScreenDocument2 pagesCatalog-Basket ScreenBaskyNo ratings yet

- Instron 3367 Frerichs GuideDocument9 pagesInstron 3367 Frerichs GuideNexhat QehajaNo ratings yet

- 1 Soal PrediksiDocument371 pages1 Soal PrediksiJanuar IrawanNo ratings yet

- TP-Link WiFi 6E AXE5400 PCIe WiFi Card - User GuideDocument23 pagesTP-Link WiFi 6E AXE5400 PCIe WiFi Card - User GuidehelpfulNo ratings yet

- Chapter 1 - MAT668 - Students HandoutDocument36 pagesChapter 1 - MAT668 - Students Handout2021826386No ratings yet

- Wilson 2008 Comparative Taphonomy Micro Vertebrate Accumulations PALAIOSDocument9 pagesWilson 2008 Comparative Taphonomy Micro Vertebrate Accumulations PALAIOSNicolás FarroniNo ratings yet

- MCQ's of Industrial Hydraulics & Pneumatics Laboratory: B. One DirectionDocument3 pagesMCQ's of Industrial Hydraulics & Pneumatics Laboratory: B. One Directionyuvarajballal100% (4)

- P.5 English Revision Set 2 Namagunga Primary Boarding SchoolDocument14 pagesP.5 English Revision Set 2 Namagunga Primary Boarding SchoolnkugwafavourNo ratings yet

- MSDS Diamond Paste (Metprep)Document3 pagesMSDS Diamond Paste (Metprep)Claudia MmsNo ratings yet

- Dyna 86l 8086 P Training Development System With LCD PDFDocument1 pageDyna 86l 8086 P Training Development System With LCD PDFSoluchanNo ratings yet

- FAQ Lecture 1Document5 pagesFAQ Lecture 1Richard De Medeiros Castro100% (1)

- Tentative Schedule of Conference - ABSDocument5 pagesTentative Schedule of Conference - ABSSaskara JuarsaNo ratings yet

- Overall Analyses Character Analysis KinoDocument5 pagesOverall Analyses Character Analysis KinoGodfrey MuchaiNo ratings yet

- AGR516 Chapter 5 MutationDocument31 pagesAGR516 Chapter 5 MutationXwag 12No ratings yet

- Psychopathology Class Resource List William F. Doverspike, PHD BibliographyDocument115 pagesPsychopathology Class Resource List William F. Doverspike, PHD BibliographyJosé Luis SHNo ratings yet

- Chouvy 2014Document8 pagesChouvy 2014Fadwa BADRANANo ratings yet

- All Tables - Chapter 2 - WL - 77 To 188Document112 pagesAll Tables - Chapter 2 - WL - 77 To 188sdasorisaNo ratings yet

- The Scientific WorkDocument24 pagesThe Scientific WorkhumanNo ratings yet

- Corporate Briefing Notes - EPCL-1Document4 pagesCorporate Briefing Notes - EPCL-1Abdullah CheemaNo ratings yet

- Re29150 - 2005-07 - DBETBXDocument12 pagesRe29150 - 2005-07 - DBETBXCarlos AugustoNo ratings yet

- OTC-24958 MEIDP Owen Fracture Zone CrossingDocument16 pagesOTC-24958 MEIDP Owen Fracture Zone CrossingFrds123No ratings yet

- Global Ethical Issues Unit 3Document15 pagesGlobal Ethical Issues Unit 3aditi anandNo ratings yet

- Pragati Maidan Exhibition DetailsDocument10 pagesPragati Maidan Exhibition DetailsDr-Amit KumarNo ratings yet