Professional Documents

Culture Documents

Falck Onsite: Lifting Plan (As Required by Reg 8 LOLER)

Falck Onsite: Lifting Plan (As Required by Reg 8 LOLER)

Uploaded by

Tasia DiCopyright:

Available Formats

You might also like

- Sample Lift PlanDocument4 pagesSample Lift Planikponmwonsa100% (1)

- Overhead Crane CLPDocument5 pagesOverhead Crane CLPmarvin100% (1)

- TBA NA: Lifting and Hoisting PlanDocument4 pagesTBA NA: Lifting and Hoisting Planikponmwonsa75% (4)

- 015-Lifting Plan Method & Risk AssessmentDocument3 pages015-Lifting Plan Method & Risk AssessmentMAB AliNo ratings yet

- Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasFrom EverandCargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasRating: 5 out of 5 stars5/5 (11)

- Crane Lift Plan: Company Name Project: ClientDocument5 pagesCrane Lift Plan: Company Name Project: Clientscottie Mailau100% (2)

- Lifting PlanDocument2 pagesLifting PlanBHANWARA RAM100% (1)

- Rigging Study & Lifting Plan For Oil Storage Tank at NaimatDocument15 pagesRigging Study & Lifting Plan For Oil Storage Tank at NaimatEngr Arfan Ali Dhamraho100% (4)

- Oral Communication in Context 1st Quarter Week 1Document4 pagesOral Communication in Context 1st Quarter Week 1Valerie Cruz - Ocampo100% (7)

- Standard Lift Plan TemplateDocument2 pagesStandard Lift Plan TemplateInbarajNo ratings yet

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- Lifting Plan For UnloadingDocument5 pagesLifting Plan For Unloadingkhaled redaNo ratings yet

- Opito Rigger TrainingDocument61 pagesOpito Rigger TrainingTasia Di100% (2)

- Petroleum Development Oman L.L.C.: Method Statement For Lifting OperationDocument2 pagesPetroleum Development Oman L.L.C.: Method Statement For Lifting Operationpreventing becej0% (1)

- Generic Method Statement For Routine LiftingDocument3 pagesGeneric Method Statement For Routine Liftingmuhammad umarNo ratings yet

- Lifting PlanDocument10 pagesLifting PlanEko Kurniawan100% (4)

- B18 Rigging Plan For Heavy Lifting: Radius 6 MDocument2 pagesB18 Rigging Plan For Heavy Lifting: Radius 6 MAli Ahmed PathanNo ratings yet

- Lifting Plan CTC1 - R-14-31 TonDocument5 pagesLifting Plan CTC1 - R-14-31 TonKalai Mani KaruppiahNo ratings yet

- Specific Lifting Pland - OHS-PR-009 - FM-01-051. Rv2Document2 pagesSpecific Lifting Pland - OHS-PR-009 - FM-01-051. Rv2cmrig74No ratings yet

- IRP Lift Plan RevisedDocument8 pagesIRP Lift Plan RevisedKaavi MaharajNo ratings yet

- Petroleum Development Oman: Lift Plan For Lifting OperationDocument7 pagesPetroleum Development Oman: Lift Plan For Lifting OperationVuthpalachaitanya KrishnaNo ratings yet

- MOBILE CRANE Grove RT58D CLPDocument9 pagesMOBILE CRANE Grove RT58D CLPahmed sleemNo ratings yet

- SPLASH Lifting Plan 175040419Document2 pagesSPLASH Lifting Plan 175040419mohamed atef100% (1)

- Lifting Plan For Erection of 2nd To 6th r.1Document10 pagesLifting Plan For Erection of 2nd To 6th r.1Rhannie GarciaNo ratings yet

- Mobile Crane Lifting Plan - Routine Operation1Document2 pagesMobile Crane Lifting Plan - Routine Operation1Becha MouradNo ratings yet

- Maj Concslb 043 0Document3 pagesMaj Concslb 043 0Mohammed JassimNo ratings yet

- Form Lifting ChecklistDocument1 pageForm Lifting ChecklistRaymond TuazonNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- Lifting PlanDocument2 pagesLifting PlanThewry KurkoNo ratings yet

- Lifting PlanDocument9 pagesLifting Plansatyabrath dhalNo ratings yet

- Gas Turbine and Generator UnloadingDocument9 pagesGas Turbine and Generator Unloadingamritrj444No ratings yet

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk AssessmentSayed Darwish100% (1)

- Routine Lift Plan Check ListDocument1 pageRoutine Lift Plan Check Listmohamed atefNo ratings yet

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDocument4 pagesLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNo ratings yet

- Lifting Plan For CranesDocument9 pagesLifting Plan For CranesBibin JohnNo ratings yet

- Lifting Plan Checklist and Method Statement SkeletonDocument7 pagesLifting Plan Checklist and Method Statement SkeletonPronoia EnterprisesNo ratings yet

- LiftingDocument5 pagesLiftingBoma IpaliboNo ratings yet

- Permit To Lift - Application FormDocument2 pagesPermit To Lift - Application FormRajooNo ratings yet

- GEC WW HSE GDE 03E TPL01 Rev00 - Lifting Check List - XLSX TemplateDocument1 pageGEC WW HSE GDE 03E TPL01 Rev00 - Lifting Check List - XLSX TemplateArturo Alejandro Maldonado VelásquezNo ratings yet

- Lifting Plan SampleDocument3 pagesLifting Plan SampleBaher MohamedNo ratings yet

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk AssessmentMuhammad BabarNo ratings yet

- Crane Lifting Plan Method Statement and Risk Assessment 1Document4 pagesCrane Lifting Plan Method Statement and Risk Assessment 1Muhammad BabarNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- Routine Lift PlanDocument7 pagesRoutine Lift PlanHussein HishamNo ratings yet

- Forklift Loading Stem StocksDocument4 pagesForklift Loading Stem Stocksreda mesbahNo ratings yet

- Crane Lift PermitDocument2 pagesCrane Lift Permitgullipalli srinivasa raoNo ratings yet

- M OSH 011 Lifting PlanDocument3 pagesM OSH 011 Lifting Planmulugeta114985No ratings yet

- Lifting Operation Inspection ChecklistDocument1 pageLifting Operation Inspection ChecklistIqbal HossainNo ratings yet

- Complicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationDocument1 pageComplicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationAva GhaziNo ratings yet

- SOP 13 Slew Crane OperationsDocument6 pagesSOP 13 Slew Crane OperationsakhmadbayNo ratings yet

- Lifting Plan - Crane Lifting Operation 11 4Document4 pagesLifting Plan - Crane Lifting Operation 11 4chikannosNo ratings yet

- Permit To LiftDocument2 pagesPermit To Liftgodspower brunoNo ratings yet

- Crane OperationDocument2 pagesCrane OperationnoniebellNo ratings yet

- Point of Work Lifting Assessment POWLA 1 1Document1 pagePoint of Work Lifting Assessment POWLA 1 1Samier MohamedNo ratings yet

- Portsaid Tunnels Project: Critical Lift ChecklistDocument2 pagesPortsaid Tunnels Project: Critical Lift ChecklistMuhammad Ahmed Abd Elmonem100% (1)

- Format Permit & SOPDocument8 pagesFormat Permit & SOPAdvent ManurungNo ratings yet

- Critical Lift Plan For Overhead Cranes: (Net Load)Document6 pagesCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- 015-Lifting Plan Method & Risk AssessmentDocument3 pages015-Lifting Plan Method & Risk AssessmentSarabjit Singh SanghaNo ratings yet

- Critical Lift Plan For Forklifts: G. Pre-Lift Checklist (Yes) N/A (NO)Document15 pagesCritical Lift Plan For Forklifts: G. Pre-Lift Checklist (Yes) N/A (NO)Edward HutaurukNo ratings yet

- Lifting PlanDocument3 pagesLifting PlanMuhammad Ali FahrudinNo ratings yet

- Unit 2. Feelings (SB)Document12 pagesUnit 2. Feelings (SB)Tasia DiNo ratings yet

- Alternative Fuels Online SlidesDocument254 pagesAlternative Fuels Online SlidesTasia DiNo ratings yet

- Valionienė, E., Belova, J., Belakova, O., Mickienė, R., Varnienė, M., Kutka, G. (2019) - Management of Seaport Terminal OperationDocument246 pagesValionienė, E., Belova, J., Belakova, O., Mickienė, R., Varnienė, M., Kutka, G. (2019) - Management of Seaport Terminal OperationTasia DiNo ratings yet

- Dangerous Goods - Air AwarenessDocument106 pagesDangerous Goods - Air AwarenessTasia DiNo ratings yet

- Scientific GlassDocument9 pagesScientific GlassLajwanti M Jethwani100% (1)

- Math 2 Plane and Solid MensurationDocument8 pagesMath 2 Plane and Solid Mensurationbernadette domoloanNo ratings yet

- 2501 06 SlidingDocument6 pages2501 06 SlidingKiara Ticangan Argel0% (1)

- Confusion of 12 Am or PM For NoonDocument3 pagesConfusion of 12 Am or PM For NoonGolamKibriabipuNo ratings yet

- Nature of Light Test 1 1Document12 pagesNature of Light Test 1 1api-280710159No ratings yet

- Final NCP LeptospirosisDocument6 pagesFinal NCP LeptospirosisKeith Austin100% (1)

- ITP - Ballast, Sub-Ballast, Sand Rev 0Document4 pagesITP - Ballast, Sub-Ballast, Sand Rev 0paklanNo ratings yet

- 20 Good Qualities That Every Reporter and SubDocument8 pages20 Good Qualities That Every Reporter and SubDeepu JoseNo ratings yet

- Abap All ProgramsDocument261 pagesAbap All Programsßåññü LämåNo ratings yet

- Waning Gibbous On 26 July 2005 TuesdayDocument1 pageWaning Gibbous On 26 July 2005 TuesdayRali RaliNo ratings yet

- InvensysCAD - Creo Behavioral Modeling ExtensionDocument3 pagesInvensysCAD - Creo Behavioral Modeling ExtensionanilpagarNo ratings yet

- Seismic Analysis of Structures - IIIDocument152 pagesSeismic Analysis of Structures - IIITusharDatta100% (4)

- Fatigue FactorsDocument112 pagesFatigue FactorsAntónio Pinto PereiraNo ratings yet

- Ba LabTouch Aw E 004106 02 LRDocument40 pagesBa LabTouch Aw E 004106 02 LRmoriz52No ratings yet

- Rooms Division DepartmentDocument7 pagesRooms Division Departmentlil_jinkz09No ratings yet

- Keysight 16196A/B/C/D Parallel Electrode SMD Test Fixture: Operation and Service ManualDocument81 pagesKeysight 16196A/B/C/D Parallel Electrode SMD Test Fixture: Operation and Service ManualKhang VũNo ratings yet

- Template Erasmus MundusDocument3 pagesTemplate Erasmus MundusLenya RyanNo ratings yet

- Chalfant's March 16 Kindergarten NewsletterDocument1 pageChalfant's March 16 Kindergarten Newsletterapi-245243970No ratings yet

- Verbal & Non Verbal CommunicationDocument0 pagesVerbal & Non Verbal Communicationvisha183240No ratings yet

- Resume Carla MusaDocument1 pageResume Carla MusaAnonymous gYwVFwNo ratings yet

- Instal 0Document5 pagesInstal 0api-3756103No ratings yet

- Creencias y Actitudes PDFDocument39 pagesCreencias y Actitudes PDFCarmina HernandezNo ratings yet

- Soalan Kbat Mat t5 2015Document6 pagesSoalan Kbat Mat t5 2015Omar Danni AhmadNo ratings yet

- M-Series Prog and Ops-Dec2011Document380 pagesM-Series Prog and Ops-Dec2011Bob100% (1)

- Normality Tests: NCSS Statistical SoftwareDocument8 pagesNormality Tests: NCSS Statistical SoftwareBalqish Ar-RoffiahNo ratings yet

- 02 Updated - ABDM3574 - CW Appendices - 202301Document3 pages02 Updated - ABDM3574 - CW Appendices - 202301tandz-pb21No ratings yet

- The Optimists Daughter Research PaperDocument5 pagesThe Optimists Daughter Research Papersvfziasif100% (1)

- 10 Things Happy People Do DifferentlyDocument2 pages10 Things Happy People Do DifferentlyropesNo ratings yet

- Text and Cloze DeletionDocument6 pagesText and Cloze DeletionCipo LlettiNo ratings yet

Falck Onsite: Lifting Plan (As Required by Reg 8 LOLER)

Falck Onsite: Lifting Plan (As Required by Reg 8 LOLER)

Uploaded by

Tasia DiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Falck Onsite: Lifting Plan (As Required by Reg 8 LOLER)

Falck Onsite: Lifting Plan (As Required by Reg 8 LOLER)

Uploaded by

Tasia DiCopyright:

Available Formats

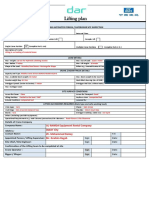

Falck Onsite

Lifting Plan (As required by Reg 8 LOLER)

Location: Falck Onsite Date:

Description of Load: Weight of load:

Task:

1. Weight of load unknown 8. Load has sharp edges 15. Hazards to personnel

2. High centre of gravity 9. Extremely heavy load 16. Communications

3. Unstable load 10. No lift point above load 17. Tag lines required

4. Awkward size/shape 11. Restricted headroom 18. Poor light conditions

5. Fragile load 12. Confined work area 19. Test lift

6. No dedicated lift points 13. Conflicting operations 20. PTW restrictions

7. No dedicated rigging 14. Lift equipment condition 21. Other (Specify)

Step by step lifting plan (including any key personnel and their responsibilities):

1. Banksman to check rigging loft for availability, suitability and serviceability of all equipment

2. Banksman to conduct toolbox talk prior to task, including a walk around the area and setting up barriers

3. Select suitable equipment, load to be slung under supervision of the Banksman, move crane into position (do

not lower hook)

4. Banksman to check slinging of load. If Banksman is happy, lower crane hook towards the load, slingers to

attach load to crane hook

5. Ensure slingers are in a safe position, Banksman to check crane alignment, conduct test lift and ensure load

stability

6. Test lift conducted, move load in a safe and controlled manner, sling angle to remain at 90° or less, slingers to

control movement by means of taglines

7. Once load arrives at landing area, lower slowly check positioning of slingers, conduct test drop

8. Once test drop has been confirmed, lower load completely and slingers to de-rig when safe to do so

9. Check all equipment for damage and return to rigging loft (report any damaged equipment immediately)

10. Conduct detailed de-brief

(Continue over to provide additional information & sketches)

Personnel Required: Crane Banksman 2x Slingers

(e.g. Crane Op, Banksman) Op

Communications Method: (Tick) Hand signals: X Verbal: Radio:

Required materials list:

Risk Assessment performed? Yes: X Ref No. (if applicable): RA-FO 002 (attach copy to plan)

Final checklist – if you answer ‘yes’ to all the ‘applicable’ questions below then the lift may proceed

1 Have all identified hazards been risk assessed? Have suitable controls been put in place? Yes X N/A

2 Is lifting equipment correctly rated and certified with all slings and lift points visually checked? Yes X N/A

3 Has the lift path been selected and cleared of obstructions and/or conflicting operations? Yes X N/A

4 Is the laydown area(s) adequate in both size and load bearing capacity? Yes X N/A

5 Are suitable materials available for protection of the load/slings while landing the load (eg timber)? Yes X N/A

6 Have barriers been positioned and/or suitable warnings issued to prevent unauthorised access? Yes X N/A

7 Have you confirmed the laydown area is within the operating range of the crane? Yes X N/A

8 Have weather conditions and their effect on the safety of the lift been taken into consideration? Yes X N/A

9 Has a meeting been held to discuss, plan and do all personnel involved fully understand the plan and Yes X N/A

has all relevant information been passed on to all parties?

Lift planned by: Anthony Swales Signature:

Position: L.A.P

You might also like

- Sample Lift PlanDocument4 pagesSample Lift Planikponmwonsa100% (1)

- Overhead Crane CLPDocument5 pagesOverhead Crane CLPmarvin100% (1)

- TBA NA: Lifting and Hoisting PlanDocument4 pagesTBA NA: Lifting and Hoisting Planikponmwonsa75% (4)

- 015-Lifting Plan Method & Risk AssessmentDocument3 pages015-Lifting Plan Method & Risk AssessmentMAB AliNo ratings yet

- Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasFrom EverandCargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasRating: 5 out of 5 stars5/5 (11)

- Crane Lift Plan: Company Name Project: ClientDocument5 pagesCrane Lift Plan: Company Name Project: Clientscottie Mailau100% (2)

- Lifting PlanDocument2 pagesLifting PlanBHANWARA RAM100% (1)

- Rigging Study & Lifting Plan For Oil Storage Tank at NaimatDocument15 pagesRigging Study & Lifting Plan For Oil Storage Tank at NaimatEngr Arfan Ali Dhamraho100% (4)

- Oral Communication in Context 1st Quarter Week 1Document4 pagesOral Communication in Context 1st Quarter Week 1Valerie Cruz - Ocampo100% (7)

- Standard Lift Plan TemplateDocument2 pagesStandard Lift Plan TemplateInbarajNo ratings yet

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- Lifting Plan For UnloadingDocument5 pagesLifting Plan For Unloadingkhaled redaNo ratings yet

- Opito Rigger TrainingDocument61 pagesOpito Rigger TrainingTasia Di100% (2)

- Petroleum Development Oman L.L.C.: Method Statement For Lifting OperationDocument2 pagesPetroleum Development Oman L.L.C.: Method Statement For Lifting Operationpreventing becej0% (1)

- Generic Method Statement For Routine LiftingDocument3 pagesGeneric Method Statement For Routine Liftingmuhammad umarNo ratings yet

- Lifting PlanDocument10 pagesLifting PlanEko Kurniawan100% (4)

- B18 Rigging Plan For Heavy Lifting: Radius 6 MDocument2 pagesB18 Rigging Plan For Heavy Lifting: Radius 6 MAli Ahmed PathanNo ratings yet

- Lifting Plan CTC1 - R-14-31 TonDocument5 pagesLifting Plan CTC1 - R-14-31 TonKalai Mani KaruppiahNo ratings yet

- Specific Lifting Pland - OHS-PR-009 - FM-01-051. Rv2Document2 pagesSpecific Lifting Pland - OHS-PR-009 - FM-01-051. Rv2cmrig74No ratings yet

- IRP Lift Plan RevisedDocument8 pagesIRP Lift Plan RevisedKaavi MaharajNo ratings yet

- Petroleum Development Oman: Lift Plan For Lifting OperationDocument7 pagesPetroleum Development Oman: Lift Plan For Lifting OperationVuthpalachaitanya KrishnaNo ratings yet

- MOBILE CRANE Grove RT58D CLPDocument9 pagesMOBILE CRANE Grove RT58D CLPahmed sleemNo ratings yet

- SPLASH Lifting Plan 175040419Document2 pagesSPLASH Lifting Plan 175040419mohamed atef100% (1)

- Lifting Plan For Erection of 2nd To 6th r.1Document10 pagesLifting Plan For Erection of 2nd To 6th r.1Rhannie GarciaNo ratings yet

- Mobile Crane Lifting Plan - Routine Operation1Document2 pagesMobile Crane Lifting Plan - Routine Operation1Becha MouradNo ratings yet

- Maj Concslb 043 0Document3 pagesMaj Concslb 043 0Mohammed JassimNo ratings yet

- Form Lifting ChecklistDocument1 pageForm Lifting ChecklistRaymond TuazonNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- Lifting PlanDocument2 pagesLifting PlanThewry KurkoNo ratings yet

- Lifting PlanDocument9 pagesLifting Plansatyabrath dhalNo ratings yet

- Gas Turbine and Generator UnloadingDocument9 pagesGas Turbine and Generator Unloadingamritrj444No ratings yet

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk AssessmentSayed Darwish100% (1)

- Routine Lift Plan Check ListDocument1 pageRoutine Lift Plan Check Listmohamed atefNo ratings yet

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDocument4 pagesLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNo ratings yet

- Lifting Plan For CranesDocument9 pagesLifting Plan For CranesBibin JohnNo ratings yet

- Lifting Plan Checklist and Method Statement SkeletonDocument7 pagesLifting Plan Checklist and Method Statement SkeletonPronoia EnterprisesNo ratings yet

- LiftingDocument5 pagesLiftingBoma IpaliboNo ratings yet

- Permit To Lift - Application FormDocument2 pagesPermit To Lift - Application FormRajooNo ratings yet

- GEC WW HSE GDE 03E TPL01 Rev00 - Lifting Check List - XLSX TemplateDocument1 pageGEC WW HSE GDE 03E TPL01 Rev00 - Lifting Check List - XLSX TemplateArturo Alejandro Maldonado VelásquezNo ratings yet

- Lifting Plan SampleDocument3 pagesLifting Plan SampleBaher MohamedNo ratings yet

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk AssessmentMuhammad BabarNo ratings yet

- Crane Lifting Plan Method Statement and Risk Assessment 1Document4 pagesCrane Lifting Plan Method Statement and Risk Assessment 1Muhammad BabarNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- Routine Lift PlanDocument7 pagesRoutine Lift PlanHussein HishamNo ratings yet

- Forklift Loading Stem StocksDocument4 pagesForklift Loading Stem Stocksreda mesbahNo ratings yet

- Crane Lift PermitDocument2 pagesCrane Lift Permitgullipalli srinivasa raoNo ratings yet

- M OSH 011 Lifting PlanDocument3 pagesM OSH 011 Lifting Planmulugeta114985No ratings yet

- Lifting Operation Inspection ChecklistDocument1 pageLifting Operation Inspection ChecklistIqbal HossainNo ratings yet

- Complicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationDocument1 pageComplicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationAva GhaziNo ratings yet

- SOP 13 Slew Crane OperationsDocument6 pagesSOP 13 Slew Crane OperationsakhmadbayNo ratings yet

- Lifting Plan - Crane Lifting Operation 11 4Document4 pagesLifting Plan - Crane Lifting Operation 11 4chikannosNo ratings yet

- Permit To LiftDocument2 pagesPermit To Liftgodspower brunoNo ratings yet

- Crane OperationDocument2 pagesCrane OperationnoniebellNo ratings yet

- Point of Work Lifting Assessment POWLA 1 1Document1 pagePoint of Work Lifting Assessment POWLA 1 1Samier MohamedNo ratings yet

- Portsaid Tunnels Project: Critical Lift ChecklistDocument2 pagesPortsaid Tunnels Project: Critical Lift ChecklistMuhammad Ahmed Abd Elmonem100% (1)

- Format Permit & SOPDocument8 pagesFormat Permit & SOPAdvent ManurungNo ratings yet

- Critical Lift Plan For Overhead Cranes: (Net Load)Document6 pagesCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- 015-Lifting Plan Method & Risk AssessmentDocument3 pages015-Lifting Plan Method & Risk AssessmentSarabjit Singh SanghaNo ratings yet

- Critical Lift Plan For Forklifts: G. Pre-Lift Checklist (Yes) N/A (NO)Document15 pagesCritical Lift Plan For Forklifts: G. Pre-Lift Checklist (Yes) N/A (NO)Edward HutaurukNo ratings yet

- Lifting PlanDocument3 pagesLifting PlanMuhammad Ali FahrudinNo ratings yet

- Unit 2. Feelings (SB)Document12 pagesUnit 2. Feelings (SB)Tasia DiNo ratings yet

- Alternative Fuels Online SlidesDocument254 pagesAlternative Fuels Online SlidesTasia DiNo ratings yet

- Valionienė, E., Belova, J., Belakova, O., Mickienė, R., Varnienė, M., Kutka, G. (2019) - Management of Seaport Terminal OperationDocument246 pagesValionienė, E., Belova, J., Belakova, O., Mickienė, R., Varnienė, M., Kutka, G. (2019) - Management of Seaport Terminal OperationTasia DiNo ratings yet

- Dangerous Goods - Air AwarenessDocument106 pagesDangerous Goods - Air AwarenessTasia DiNo ratings yet

- Scientific GlassDocument9 pagesScientific GlassLajwanti M Jethwani100% (1)

- Math 2 Plane and Solid MensurationDocument8 pagesMath 2 Plane and Solid Mensurationbernadette domoloanNo ratings yet

- 2501 06 SlidingDocument6 pages2501 06 SlidingKiara Ticangan Argel0% (1)

- Confusion of 12 Am or PM For NoonDocument3 pagesConfusion of 12 Am or PM For NoonGolamKibriabipuNo ratings yet

- Nature of Light Test 1 1Document12 pagesNature of Light Test 1 1api-280710159No ratings yet

- Final NCP LeptospirosisDocument6 pagesFinal NCP LeptospirosisKeith Austin100% (1)

- ITP - Ballast, Sub-Ballast, Sand Rev 0Document4 pagesITP - Ballast, Sub-Ballast, Sand Rev 0paklanNo ratings yet

- 20 Good Qualities That Every Reporter and SubDocument8 pages20 Good Qualities That Every Reporter and SubDeepu JoseNo ratings yet

- Abap All ProgramsDocument261 pagesAbap All Programsßåññü LämåNo ratings yet

- Waning Gibbous On 26 July 2005 TuesdayDocument1 pageWaning Gibbous On 26 July 2005 TuesdayRali RaliNo ratings yet

- InvensysCAD - Creo Behavioral Modeling ExtensionDocument3 pagesInvensysCAD - Creo Behavioral Modeling ExtensionanilpagarNo ratings yet

- Seismic Analysis of Structures - IIIDocument152 pagesSeismic Analysis of Structures - IIITusharDatta100% (4)

- Fatigue FactorsDocument112 pagesFatigue FactorsAntónio Pinto PereiraNo ratings yet

- Ba LabTouch Aw E 004106 02 LRDocument40 pagesBa LabTouch Aw E 004106 02 LRmoriz52No ratings yet

- Rooms Division DepartmentDocument7 pagesRooms Division Departmentlil_jinkz09No ratings yet

- Keysight 16196A/B/C/D Parallel Electrode SMD Test Fixture: Operation and Service ManualDocument81 pagesKeysight 16196A/B/C/D Parallel Electrode SMD Test Fixture: Operation and Service ManualKhang VũNo ratings yet

- Template Erasmus MundusDocument3 pagesTemplate Erasmus MundusLenya RyanNo ratings yet

- Chalfant's March 16 Kindergarten NewsletterDocument1 pageChalfant's March 16 Kindergarten Newsletterapi-245243970No ratings yet

- Verbal & Non Verbal CommunicationDocument0 pagesVerbal & Non Verbal Communicationvisha183240No ratings yet

- Resume Carla MusaDocument1 pageResume Carla MusaAnonymous gYwVFwNo ratings yet

- Instal 0Document5 pagesInstal 0api-3756103No ratings yet

- Creencias y Actitudes PDFDocument39 pagesCreencias y Actitudes PDFCarmina HernandezNo ratings yet

- Soalan Kbat Mat t5 2015Document6 pagesSoalan Kbat Mat t5 2015Omar Danni AhmadNo ratings yet

- M-Series Prog and Ops-Dec2011Document380 pagesM-Series Prog and Ops-Dec2011Bob100% (1)

- Normality Tests: NCSS Statistical SoftwareDocument8 pagesNormality Tests: NCSS Statistical SoftwareBalqish Ar-RoffiahNo ratings yet

- 02 Updated - ABDM3574 - CW Appendices - 202301Document3 pages02 Updated - ABDM3574 - CW Appendices - 202301tandz-pb21No ratings yet

- The Optimists Daughter Research PaperDocument5 pagesThe Optimists Daughter Research Papersvfziasif100% (1)

- 10 Things Happy People Do DifferentlyDocument2 pages10 Things Happy People Do DifferentlyropesNo ratings yet

- Text and Cloze DeletionDocument6 pagesText and Cloze DeletionCipo LlettiNo ratings yet