Professional Documents

Culture Documents

EA25-250-datasheet - Polymer Ammonia

EA25-250-datasheet - Polymer Ammonia

Uploaded by

kratosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EA25-250-datasheet - Polymer Ammonia

EA25-250-datasheet - Polymer Ammonia

Uploaded by

kratosCopyright:

Available Formats

Electric actuators type EA25-250

Small & Light

Product description

The electric actuators type EA25, EA45,

EA120 and EA250 are not only excellently Benefits/Features

equipped, they also feature very high peak

• Position feedback via relays

torques ranging from 25 Nm to 250 Nm.

(OPEN/CLOSE/MIDDLE)

Therefore they are able to automate a wide

range of valves. • Heating element to prevent condensation

• Optical position indicator with LED status

Function monitoring

Electric actuators are used to operate valves • Third position between "OPEN" and

with a rotating angle from 90° to 180°. The "CLOSE" optional

actuators can be installed on any common • Relay output for "ready to operate"

valves with interface according to ISO 5211. • 7-segment error display

• Integrated emergency manual override with

Accessories allow using them not only as an

magnetic lock

on/off actuator but also in continuous

operation. • Robust PP-GF housing with very good

chemical resistance

Applications • Long service life due to robust design and

superior electronics

• Chemical Process Industry

• Flexible configuration thanks to modular

• Water Treatment

concept

• Refrigeration

• Numerous monitoring and control options

• Easy handling

• Can be used anywhere thanks to universal

power supply and standard interfaces

01.2016, GF Piping Systems 1

Technical data

The standard version of the EA25/45/120/250 electric actuator consists of the following elements:

Nr. Description

1 Shaft for emergency manual override hand crank

2 Power supply with cover at 230V version

3 Digital position detection

4 Control for OPEN/CLOSE/MIDDLE

5 DC motor

6 Optical position indicator

7 Light tube for LED status feedback

8 7-segment error display

Position feedback via relays for

9 OPEN/CLOSE/MIDDLE

10 Heating element (temperature threshold regulator)

11 Buttons for end position adjustment

12 Signal output "ready-to-operate"

13 Connection options for DIN plugs or cable glands

Spezification

Combinations EA25 2-way ball valve type 546 to DN50

3-way ball valve type 543 up to DN50

EA45 2-way ball valve type 546 DN65

Butterfly valve types 567 and 578, types 038 and 039 up to DN65

EA120 2-way ball valve type 546 DN80/DN100

Butterfly valve types 567 and 578, types 038 and 039 DN80-DN200

EA250 Butterfly valve types 567 and 578, types 038 and 039 DN250/300

Rated voltage AC 100 – 230 V, 50/60 Hz

AC/DC 24 V, 50/60 Hz

Rated voltage tolerance ± 15%

1)

Protection class IP 65 (IP67) per EN 60529

Contamination level 2 according to EN 61010-1

Overload protection Current/time-dependent (resetting)

Overvoltage category II

Ambient temperature -10 °C to +50 °C

Allowable humidity Max. 90 % relative humidity, non-condensing

Housing material PP-GF for very good chemical resistance

1)

When used with cable glands and vertical installation.

01.2016, GF Piping Systems 2

EA25 EA45 EA120 EA250

Rated output AC: 35 VA at AC: 55 VA at AC: 50 VA at AC: 60 VA at

100 – 230 V 100 – 230 V 100 – 230 V 100 – 230 V

AC/DC: 40 VA at AC/DC: 60 VA at AC/DC: 55 VA at AC/DC: 65 VA at

24 V 24 V 24 V 24 V

Rated torque Mdn. (peak) 10 (25) Nm 20 (45) Nm 60 (120) Nm 100 (250) Nm

Duty cycle 100% 50 % 50 % 35 %

Cycle time s/90° at Mdn. 5s 6s 15 s 20 s

Connection F05 F05 F07 F07

Tested cycles (at 20 °C 250 000 100 000 100 000 75 000

and Mdn.)

Weight 2.1 kg 2.2 kg 3.6 kg 5.0 kg

Actuating angle Max. 355°, set to 90°

Options

Electrical ball valves

Type 179 - 184

Type 179 – 184 ball valves are based on the type 546 ball valve and the EA25 (DN10 – DN50),

EA45 (DN65) or EA120 (DN80 – DN100) electric actuator. The 179 – 184 series is designed for

applications with special process requirements.

Ball valve, Actuator Ball valve, Dimensions Materials Standards

electric electric hand-operated

Type 179 EA25/45/120 Type 546 DN10 – DN100 PVC-U, PVC-C, ABS ISO/DIN

Type 180 EA25/45/120 Type 546 DN10 – DN100 PP ISO/DIN

Type 181 EA25/45/120 Type 546 DN10 – DN100 PVDF ISO/DIN

Type 182 EA25/45/120 Type 546 DN10 – DN100 PVC-U, PVC-C ASTM/ANSI

Type 183 EA25/45/120 Type 546 DN10 – DN100 PVC-U BS

Type 184 EA25/45/120 Type 546 DN10 – DN100 PVC-U JIS

Type 167 - 170

Type 167 – 170 ball valves are based on the type 543 ball valve and the EA25 electric actuator.

Ball valve, Actuator Ball valve, Dimensions Materials Standards

electric electric hand-operated

Type 167 EA25 Type 543 horizontal DN10 – DN50 PVC-U, ABS ISO/DIN,

ASTM/ANSI, JIS

Type 168 EA25 Type 543 horizontal DN10 – DN50 PP ISO/DIN

Type 170 EA25 Type 543 vertical DN10 – DN50 PVC-U ISO/DIN, JIS

01.2016, GF Piping Systems 3

Butterfly valves, electric

Type 145 - 147

The type 145 electric butterfly valve is intended for wafer style installation and is adaptable to a

variety of applications. With the optional positioner, its functional options range from a simple

open/close valve to a precise flow control device.

The type 146/147 electric butterfly valve is intended for lug type or wafer style installation and is

adaptable to a variety of applications. With the optional positioner, its functional options range from

a simple open/close valve to a precise flow control device.

Butterfly valve, Actuator, Butterfly valve, Dimensions Materials Standards

electric electric hand-operated

Type 145 EA45/120/250 Type 567 DN50 – DN300 All All standards

Type 146 EA45/120/250 Type 578 DN50 – DN300 All ISO/DIN

Type 147 EA45/120/250 Type 578 DN50 – DN300 All ASTM/ANSI

Dimensions

EA L1 L2 L3 L4 L5 L6 L7 L8 L9 H1 H2

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

EA25 150 83 108 64 122 16 49 33 33 167 189

EA45 150 83 108 64 122 16 49 33 33 167 189

EA120 150 83 108 64 122 16 49 33 33 190 212

EA250 150 83 108 64 122 16 49 33 33 200 221

01.2016, GF Piping Systems 4

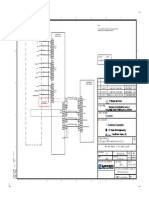

Connection diagram for standard version

Actuator activation Feedback signals

Optical position indicator

The position indicator shows the valve position. The valve positions can be read on the fitted cover.

When the cover is fitted, the following image can be seen (Example ball valve):

2-Way 3-Way horizontal (L) 3-Way vertical (L)

Image of

position

indicator in

valve position 1

Valve function D

B A B A

C C

Actuating angle 0° - 90° 0° - 90° 0° - 180°

Valve position 1 A – B (OPEN) A – C (Flow right side, outlet B – C (Flow left side,

See image to the front) See image bottom outlet) See image

Valve position 2 C – D (CLOSE) B – C (Flow left side, outlet A – C (Flow right side,

to the front) bottom outlet)

By teaching in a „Middle position“ different possibilities can be achieved depending on the valve

and the application. For example:

• 2-way ball valve: Middle position describes a position, limiting the 100% flow for instance only

half.

• 3-way ball valve: Middle position describes a position of the ball in which both passages are

slightly opened.

• 3-way ball valve: Middle position describes a position of the ball which closes both passages.

01.2016, GF Piping Systems 5

Ball valve 3-way horizontal 3-way horizontal 3-way vertikal

and ball-type (L-ball) (L-ball) (L-ball)

Function of the middle CLOSE (on both sides no „Mixing“ (both passages CLOSE (on both sides no

position flow) slightly opened) flow)

Actuating angle 0° – 180° 0° - 90° 0° - 180°

Position 1 A – C (OPEN right) A – C (OPEN right) B (-C) (OPEN left)

Position 2 B – C (OPEN left) 90° A/C – B/C (partly (C-) D (CLOSE) 90°

Position 3 B – D (CLOSE) 180° opened) 45° A (-C) (OPEN right) 180°

B – C (OPEN left) 90°

(Function of the middle position as „Mixing“ with the 3-way ball valve vertical is only possible with the T-ball)

LED status feedback

The LED status feedback shows the valve positions and the current status of the actuator. The

following table shows the colour assignment of the LED:

Color Meaning

Red OPEN

Green CLOSED

White MIDDLE

Flashes white Actuator moves

Flashes yellow Error

Flashes blue Adjustment mode

Green/yellow Setpoint value reached (at positioner)

Turquoise Adjustment run / operation of colour inversion

If the plant standard requires an inversion of the colour assignment, the customer can adjust this afterwards.

01.2016, GF Piping Systems 6

You might also like

- Kidde Co2 Product Manual 050128 PDFDocument299 pagesKidde Co2 Product Manual 050128 PDFFIRMANSYAHNo ratings yet

- Volume Tank Sizing For Shutdown Valve ActuatorDocument2 pagesVolume Tank Sizing For Shutdown Valve ActuatorHardik Acharya100% (1)

- Valve StandardsDocument14 pagesValve StandardskandhasamykarthickNo ratings yet

- Type EA15 IOMDocument7 pagesType EA15 IOMAlan CNo ratings yet

- PTC Thermistor Relay Series - PD-225Document3 pagesPTC Thermistor Relay Series - PD-225dhir.221016No ratings yet

- Series 50 SpecificationsDocument10 pagesSeries 50 Specificationspeter manthraNo ratings yet

- WSP22G Ola1 - 400 P 120601 e 01Document4 pagesWSP22G Ola1 - 400 P 120601 e 01Eng-Mohammed SalemNo ratings yet

- Data Sheet 3WL1212-2DG76-4GG4-Z R21+T40: ModelDocument7 pagesData Sheet 3WL1212-2DG76-4GG4-Z R21+T40: ModelMARIAMNo ratings yet

- 3WL12122DG764GG4-Z R21+T40 Datasheet enDocument7 pages3WL12122DG764GG4-Z R21+T40 Datasheet enMARIAMNo ratings yet

- 7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DataDocument7 pages7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DatasoltaniNo ratings yet

- Electrical Actuator 21 31 42 Datasheet English PDFDocument4 pagesElectrical Actuator 21 31 42 Datasheet English PDFHeru Purwanto HeruNo ratings yet

- Valvula Proporcional Série d633 e d634Document16 pagesValvula Proporcional Série d633 e d634Lucas Vinícius CostaNo ratings yet

- 3WL12324DG321AA2 Datasheet enDocument5 pages3WL12324DG321AA2 Datasheet enzia6182No ratings yet

- Solenoid Poppet Valve - 2/2-, 3/2-And 3/4-Way Construction - Q 40 L/min - P 350 BarDocument2 pagesSolenoid Poppet Valve - 2/2-, 3/2-And 3/4-Way Construction - Q 40 L/min - P 350 BarTruong KhacNo ratings yet

- Usph 2011Document3 pagesUsph 2011Victor AdamitaNo ratings yet

- 3RB30361UW1 Datasheet enDocument5 pages3RB30361UW1 Datasheet enCarlos EscobarNo ratings yet

- 4/3 and 4/2 Directional Spool Valves, ISO Size 02: 1 DescriptionDocument5 pages4/3 and 4/2 Directional Spool Valves, ISO Size 02: 1 DescriptionDark CenobiteNo ratings yet

- 7pa22 23 Catalog Sip E6Document3 pages7pa22 23 Catalog Sip E6feromagnetizamNo ratings yet

- 2/2 4/4 Solenoid Directional Seat Valve, ISO Size 03: 1 DescriptionDocument8 pages2/2 4/4 Solenoid Directional Seat Valve, ISO Size 03: 1 DescriptionWilliam RodrigoNo ratings yet

- Harmony Timer Relays - RE11LAMWDocument7 pagesHarmony Timer Relays - RE11LAMWrobera zelekeNo ratings yet

- 3VL27061SP330AA0 Datasheet enDocument4 pages3VL27061SP330AA0 Datasheet enJuan Carlos ParedesNo ratings yet

- 3RB20661GC2 Datasheet enDocument5 pages3RB20661GC2 Datasheet enjunclarcNo ratings yet

- PLASTOMATIC EBVA DesinfeccionDocument4 pagesPLASTOMATIC EBVA DesinfeccionMaicol Smite Sosa LondoñoNo ratings yet

- HLG 320H 24Document7 pagesHLG 320H 24Hoowert Lee Suaña GonzalesNo ratings yet

- Actuador Electrico ValworxDocument11 pagesActuador Electrico ValworxFernando GómezNo ratings yet

- Cn05, Cn10 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating ControlDocument8 pagesCn05, Cn10 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating ControlLindEtjulietcapulet KplesetmontagueNo ratings yet

- Data Sheet 5SJ4101-7HG42: ModelDocument4 pagesData Sheet 5SJ4101-7HG42: ModelFaiz 3BNo ratings yet

- Data Sheet 5SJ4101-8HG40: ModelDocument4 pagesData Sheet 5SJ4101-8HG40: ModelFaiz 3BNo ratings yet

- 7PA22/23 Auxiliary Relays For Various ApplicationsDocument3 pages7PA22/23 Auxiliary Relays For Various ApplicationsVictor Manuel BonettoNo ratings yet

- 7PA22 23 Catalog SIP-2008 enDocument4 pages7PA22 23 Catalog SIP-2008 enpetarlNo ratings yet

- 3UG45111AP20 Datasheet enDocument4 pages3UG45111AP20 Datasheet enfemosNo ratings yet

- 7ts16 Catalog Sip E6Document2 pages7ts16 Catalog Sip E6mohsen zanganehNo ratings yet

- Belimo PRBUP-3-T Datasheet En-UsDocument3 pagesBelimo PRBUP-3-T Datasheet En-UsNiltonNo ratings yet

- SYNERGY - Profile (Electricals)Document9 pagesSYNERGY - Profile (Electricals)kuraimundNo ratings yet

- 3UG45121BR20 Datasheet enDocument5 pages3UG45121BR20 Datasheet enAlex BocanceaNo ratings yet

- MVH3K Datasheet ENG PDFDocument3 pagesMVH3K Datasheet ENG PDFSyed Mohammad NaveedNo ratings yet

- 2/2 Solenoid Cartridge Valve, Size 10: 1 DescriptionDocument5 pages2/2 Solenoid Cartridge Valve, Size 10: 1 Descriptionsandeep100% (1)

- 3RU21161JB0 Datasheet enDocument6 pages3RU21161JB0 Datasheet enCantera TaspanaNo ratings yet

- 3RU21161JB0 Datasheet enDocument6 pages3RU21161JB0 Datasheet enCantera TaspanaNo ratings yet

- Atuador SauterDocument7 pagesAtuador SauterLidemberg LimaNo ratings yet

- 3UG46331AL30 Datasheet enDocument4 pages3UG46331AL30 Datasheet enAntonioNo ratings yet

- Prca S2 T 200Document6 pagesPrca S2 T 200RoxanneNo ratings yet

- Siemens 3VL2716 1AA33 0AA0 DatasheetDocument5 pagesSiemens 3VL2716 1AA33 0AA0 DatasheetAriel TorresNo ratings yet

- Safety Relay LC ControllerDocument5 pagesSafety Relay LC ControlleraguilavmNo ratings yet

- NL1150D 24Document1 pageNL1150D 24carolinammiyashiroNo ratings yet

- 3SK12111BB40 Datasheet enDocument5 pages3SK12111BB40 Datasheet enRahmad SusenoNo ratings yet

- 3VL77101SB362PE1-Z - M22 - Datasheet - en (2) - 2Document5 pages3VL77101SB362PE1-Z - M22 - Datasheet - en (2) - 2Muhammad Haris BaigNo ratings yet

- 3RF29500KA16 Datasheet en PDFDocument5 pages3RF29500KA16 Datasheet en PDFkarthick UNo ratings yet

- PRCA S2 T - DatasheetDocument4 pagesPRCA S2 T - DatasheetaniketNo ratings yet

- Manual de ValvulaDocument16 pagesManual de ValvulaRene CalliriNo ratings yet

- 9037HG32LZ20: Product DatasheetDocument2 pages9037HG32LZ20: Product DatasheetNarcisse AhiantaNo ratings yet

- Siemens 3ru21464kb0Document5 pagesSiemens 3ru21464kb0Hema HemaNo ratings yet

- Electric Actuator EPI2Document6 pagesElectric Actuator EPI2ilkinNo ratings yet

- DS8640 8640 6524 27 Eu enDocument15 pagesDS8640 8640 6524 27 Eu enLucas Vinícius CostaNo ratings yet

- 3RU51464JB0 Datasheet enDocument4 pages3RU51464JB0 Datasheet enTrong Hung NguyenNo ratings yet

- Technical Data Sheet SFA-S2Document4 pagesTechnical Data Sheet SFA-S2moNo ratings yet

- 7TS16 Annunciation Relay: Function OverviewDocument2 pages7TS16 Annunciation Relay: Function OverviewVictor Manuel BonettoNo ratings yet

- 3RW50562AB14 Datasheet enDocument9 pages3RW50562AB14 Datasheet enHernan Eduardo Solorza GonzalezNo ratings yet

- Belimo SFA-S2 Datasheet En-GbDocument4 pagesBelimo SFA-S2 Datasheet En-GbDimas Agil Roeseno KambunaNo ratings yet

- Terminal Diagram - AnalogDocument2 pagesTerminal Diagram - AnalogkratosNo ratings yet

- Approved For Construction: B&V DWG No. Rev. TitleDocument1 pageApproved For Construction: B&V DWG No. Rev. TitlekratosNo ratings yet

- Terminal Diagram - DigitalDocument2 pagesTerminal Diagram - DigitalkratosNo ratings yet

- BCP and ATT Flow CalDocument73 pagesBCP and ATT Flow CalkratosNo ratings yet

- Approved For Construction: BK BUDocument1 pageApproved For Construction: BK BUkratosNo ratings yet

- Controlnet Network Configuration: User ManualDocument91 pagesControlnet Network Configuration: User ManualkratosNo ratings yet

- KSB Valves - For - Water-Data PDFDocument16 pagesKSB Valves - For - Water-Data PDFPaul MaposaNo ratings yet

- Electric Actuator Butterfly Valve ZIPDocument5 pagesElectric Actuator Butterfly Valve ZIPwoodali9115991100% (1)

- Water Sewage Gas: Plus Gate ValveDocument4 pagesWater Sewage Gas: Plus Gate ValveAhmedRamadanNo ratings yet

- MB An Normen Din Iso enDocument2 pagesMB An Normen Din Iso enanon_787210543No ratings yet

- Pentair Biffi EFS 2000 Electric ActuatorDocument24 pagesPentair Biffi EFS 2000 Electric ActuatorblloewyNo ratings yet

- Saf T Gard ActuatorsDocument14 pagesSaf T Gard ActuatorsRicardo FuentesNo ratings yet

- Electric Actuator Guide: B Ernard ControlsDocument22 pagesElectric Actuator Guide: B Ernard ControlsIhabNo ratings yet

- Mechanical Diaphragm Metering Punps: General FeaturesDocument3 pagesMechanical Diaphragm Metering Punps: General Featuresphandang_tNo ratings yet

- BMS Point ScheduleDocument5 pagesBMS Point ScheduleNguyen Tran QuynhNo ratings yet

- Electrical Actuators: Motors Are GenerallyDocument5 pagesElectrical Actuators: Motors Are GenerallyRutvikNo ratings yet

- Engine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Document2 pagesEngine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Allan LariosaNo ratings yet

- SC/V - Valve Actuator Spring Return: Instruction Manual 5018Document49 pagesSC/V - Valve Actuator Spring Return: Instruction Manual 5018kaicyemNo ratings yet

- 318C PDFDocument4 pages318C PDFTidjani SallNo ratings yet

- Manual Eim Tec2 Electric Actuator Model 500 Iom en 86464Document102 pagesManual Eim Tec2 Electric Actuator Model 500 Iom en 86464Anton HidayatNo ratings yet

- Control Valve Actuators and PositionersDocument23 pagesControl Valve Actuators and PositionersPg LisenNo ratings yet

- SC13003-C9001-U10-0002-Commissioning Plan Procedure For MBOP - 24-08-2015 PDFDocument70 pagesSC13003-C9001-U10-0002-Commissioning Plan Procedure For MBOP - 24-08-2015 PDFArya Bima Aji KusumaNo ratings yet

- 170 172 176 RegadaDocument8 pages170 172 176 RegadaOreavu BuzauNo ratings yet

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet

- MuconIDV Brochure F 1Document24 pagesMuconIDV Brochure F 1abs0001No ratings yet

- Honeywell Motorized Butterfly ValveDocument6 pagesHoneywell Motorized Butterfly ValveMathivananNo ratings yet

- Electric Quarter Turn Actuator: Flange F04 F05 F07Document2 pagesElectric Quarter Turn Actuator: Flange F04 F05 F07melad yousefNo ratings yet

- ARI Armaturen ANSI Valves (One-Stop-Shop)Document8 pagesARI Armaturen ANSI Valves (One-Stop-Shop)Ryan120708No ratings yet

- Piping and Instrumentation Diagram (P&id)Document95 pagesPiping and Instrumentation Diagram (P&id)Ahmed Abd ElmegeedNo ratings yet

- Ledeen Actuator General Catalogue - Entire LineDocument24 pagesLedeen Actuator General Catalogue - Entire LineJair LamasNo ratings yet

- Flame DetectorDocument140 pagesFlame DetectorcanhgachienNo ratings yet

- EU Type Examination Certificate CML 19ATEX1192X Issue 0Document8 pagesEU Type Examination Certificate CML 19ATEX1192X Issue 0secondharbour ChinaNo ratings yet

- Auma - PB Modular Range enDocument84 pagesAuma - PB Modular Range enbenyakiNo ratings yet