Professional Documents

Culture Documents

Duramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow Chart

Duramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow Chart

Uploaded by

Yap Jian JieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow Chart

Duramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow Chart

Uploaded by

Yap Jian JieCopyright:

Available Formats

DURAMEDICAL SDN BHD ( Reg. No.

481909 U )

Oral DAM MANUFACTURING & QUALITY CONTROL, DESCRIPTION &

PROCESS FLOW CHART

PAGES ANNEXES ISSUE NO DATE

1 0F 4 NIL 1 1st Jan, 07

1. PURPOSE / OBJECTIVES

To provide a detail description of the Manufacturing and Quality Control steps undertaken

for the manufacturing of the Oral Dam in a Flow chart form.

2. SCOPE

Applicable through out the Product Realization process from the In-Coming Raw Material stage to the

Finished Product Shipment stage.

Responsibility Process Flow Description

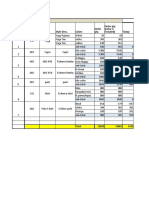

Approved Approved Approved 1.0) IN - COMING RAW MATERIAL ACCEPTANCE

Purchasing & Vendors Vendors Vendors

Store Function (Latex (Pack Mat 1.1) In - coming Raw materials ( Latex, Chemicals

Supply) (Chemical Supply) & packaging materials) are received and

Supply) quarantined pending incoming QC Inspection.

1.2) In - coming QC inspection carried out based

1.5 on established test methods.

1.1 1.3) In - coming raw materials that passed QC

Top Reviewed By Quarantine inspection are indicated with "Accept" sticker

Management Top Store and transferred to store for issuance to

Management production / packing upon request.

1.2 1.4) In - coming raw material that failed QC

QC Function Fail QC inspection are indicated with "ON HOLD"

Inspection 1.4 sticker pending Top management decision

In-Coming

QC for review and concession.

Inspection 1.5) In-coming raw materials that failed QC

inspection without concession granted are

indicated with "Reject" stickers and returned

Pass QC

1.3 to Vendors for replacement and appropriate

Inspection

Corrective / Preventive Actions requested

Store Store from vendors to prevent similar recurrences.

Function

2.0) LATEX COMPOUNDING AND ACCEPTANCE

2.1

Compounding Latex 2.1) Approved Latex and Chemicals are drawn from

Section Compounding the store for compounding activities.

2.4 2.2 2.2) Compounded Latex batch is QC inspected for

Total Solid Content (TSC), Viscosity, Chloroform

Number and Colour Shade based on established

Compounde

QC Function specifications.

d Latex QC

Inspection

Fail QC 2.3)The passed batch is indicated with a "QC Pass

Inspection Sticker" and approved to be used in the dipping

Pass QC line.

2.3 Inspection

2.4) The failed batch is re directed to the

Approved Latex Batch To be compounding section for appropriate adjustment

used in the Dipping Line

Approved Latex Batch To be

used in the Dipping Line prior a re QC inspection before acceptance.

DURAMEDICAL SDN BHD ( Reg. No. 481909 U )

Oral DAM MANUFACTURING & QUALITY CONTROL, DESCRIPTION &

PROCESS FLOW CHART

PAGES ANNEXES ISSUE NO DATE

2 0F 4 NIL 1 1st Jan, 07

Responsibility Process Flow Description

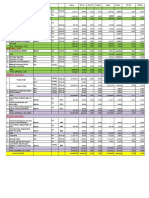

Dipping Dipping 3.0) DIPPING PROCESS

Section Process 3.1

3.1) Production of Oral dam starts with

casting latex onto the stainless steel revolving

Drying plate mould ( belt like ) to latex sheet before

Process 3.2 under going drying through a drying oven chamber.

3.6

3.2) The casted sheets are dried over a revolving

Powdering Powdering drier drum.

Section 3.3

Process

3.3) The latex sheets are powdered with talc powder.

Beyond

Specification 3.4

3.4) In process QC inspection carried out on dimension,

QC Section and visual inspection (randomly) are conducted to

3.7 determine the latex sheets' width, thickness and

In process

QC appearance are in accordance with the required

Inspection specifications.

Non 3.5) The products are rolled into roll form and the

Conforming QC inspection status is identified by appropriate

Product QC stickers ( pass / on hold / reject )

Segregated, Within

pending Specification 3.6) The noted deviation are informed to the dipping

Disposition

section for appropriate adjustments and to take

3.5 immediate corrective actions to prevent defective

products during dipping process.

3.7) The Non conforming product are identified

Rolling accordingly and segregated pending Disposition

Process

by the disposition authority.

3.8) The Rolled products are transferred to the store

for in process storage and retrieved from store for

Storage 3.8 the cutting process when required.

4.0) CUTTING PROCESS

Cutting

Section Cutting 4.1 4.1) The latex sheets are cut to the required length.

Process

4.2) In-process quality inspections are conducted on

4.2 the cut latex sheets based on periodic random

Non 4.4 sampling in accordance with in-house Spec.

QC Section Conforming

Product In process QC 4.3)The products within specification are forwarded to

Segregated, Inspection the next process, washing process.

pending

Disposition Beyond

Specification

Product In process QC

Segregated, Inspection

pending

Disposition Beyond

Specification 4.4) The Non conforming product are identified

Within accordingly and segregated pending Disposition

4.3 Specification by the disposition authority.

DURAMEDICAL SDN BHD ( Reg. No. 481909 U )

Oral DAM MANUFACTURING & QUALITY CONTROL, DESCRIPTION &

PROCESS FLOW CHART

PAGES ANNEXES ISSUE NO DATE

3 0F 4 NIL 1 1st Jan, 07

Responsibility Process Flow Description

5.0) WASHING & DRYING PROCESS

Washing

Washing 5.1

Section 5.1) The cut latex sheets are washed with water to

remove the powder.

5.2) The washed rubber sheets are tumbled dried

Drying & 5.2 in a drying tumbler to remove any residue

Adding of

Flavor moisture and the desired flavor / fragrance added

if required.

5.3) In-process quality inspections are carried out on

5.3 the dried Oral dam based on periodic

random sampling in accordance with in-house

Non 5.5

QC Section specifications.

Conforming

Inprocess

Product

QC 5.4)The products within specification are forwarded to

Segregated,

Inspection

pending the next process, Die - Cut process.

Disposition

Beyond

Specification Within 5.5) The Non conforming product are identified

Specification accordingly and segregated pending Disposition

by the disposition authority.

5.4

6.0) DIE-CUT PROCESS

6.1) The cut rubber sheets are stacked for the Die-

Stacking 6.1 cutting process.

Die-Cut 6.2) The stacked rubber sheets are die-cut to the

Section Die-Cut 6.2 required sizes and peeled into individual sheets.

6.3) In-process quality inspections are carried out on

6.3 the die-cut Oral dam based on periodic

random sampling in accordance with in-house

QC Section Non 6.5 specifications.

Conforming

Inprocess

Product

QC 6.4)The products within specification are forwarded to

Segregated,

Inspection the next process, Packing process.

pending

Disposition Beyond

Specification Within 6.5) The Non conforming product are identified

Specification accordingly and segregated pending Disposition

by the disposition authority.

6.4

7.0) PACKING PROCESS

Packing Packing

Process 7.1

Packing

Section Process 7.1 7.1) The Oral dams are packed into sealed

bags / boxes and shipping cartons with Lot

number and expiry date in accordance with

specified packing requirements.

DURAMEDICAL SDN BHD ( Reg. No. 481909 U )

Oral DAM MANUFACTURING & QUALITY CONTROL, DESCRIPTION &

PROCESS FLOW CHART

PAGES ANNEXES ISSUE NO DATE

4 0F 4 NIL 1 1st Jan, 07

Responsibility Process Flow Description

7.2) Post packing quality inspections are carried out

7.2 on the packed Oral dam based on

sampling plan in accordance with the in-house

QC Section Non 7.4 specifications.

Conforming

Post Packing

Product

QC Inspection 7.3)The products within specification are arranged to

Segregated,

pending be forwarded to the Finished goods store.

Disposition

Beyond Within 7.4) The Non conforming product are identified

Specification Specification accordingly and segregated pending Disposition

by the disposition authority.

7.3

Temporary Finished 7.5) The packed goods are transferred to the

Goods Store 7.5 Temporary Finished Goods Store pending

Pre-Shipment QA Inspection.

The failed

lot is 8.0) PRE-SHIPMENT QA INSPECTION

screened on 8.1

QA Dept a batch by 8.3 8.1)Pre-Shipment QA Inspection carried out on packed

batch basis Pre-Shipment Oral Dam. Sampling based on Lot size

and QA Inspection

in accordance with sampling plan ISO 2859-1.

replaced Pre-shipment inspection carried out according to

with New Beyond Within the product specifications specified in the Quality

batches and Specification Specification

(Failed) Plan.

subject to re (Passed)

QA Inspection includes - Dimensional Checks,

inspection Physical properties, Visual Inspection and

8.2 Packaging and Labeling requirements.

8.2)The lots within specification are considered as

pass and are transferred to Finished Goods

8.4 store and is ready for shipment.

Pre-Shipment

8.5 Test Report

(COR) 8.3)The failed lot, is screened on a batch by batch

Store basis and failed batches are replaced with new

Reject Store

Function batches and the new reconfigured lot is subject

to undergo pre-shipment inspection and testing.

Store Finished Goods 8.4) The failed batches are segregated out and

Function Store transferred to Reject Store as scraps.

8.5) For the Lots accepted at the Pre-shipment testing

stage, a Pre-shipment Test Report ( Certificate of

Release ) is issued by the QA Dept for shipment.

verifying the approval for shipment.

Shipment of 9.0) SHIPMENT

Mkt Dept & Finished Product

Store Function 9.1 9.1)The Oral dams are shipped based on

specified delivery dates.

END

You might also like

- Vendor Rejection and Debit PolicyDocument6 pagesVendor Rejection and Debit PolicysharanNo ratings yet

- Jan Carlzon - Case AnalysisDocument2 pagesJan Carlzon - Case AnalysisDaniyalNo ratings yet

- CTX510 Eco BA EN SI-v1.1 000Document207 pagesCTX510 Eco BA EN SI-v1.1 000Miliano Filho80% (5)

- Flow Chart For New Enquiry HandlingDocument1 pageFlow Chart For New Enquiry HandlingVinod Sale100% (1)

- MG 514 C Service ManualDocument100 pagesMG 514 C Service ManualMahmoud Yosri100% (3)

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- 23.sop - HRDDocument4 pages23.sop - HRDrishi gautamNo ratings yet

- Turtle Diagrams - Stores + ShippingDocument1 pageTurtle Diagrams - Stores + Shippingcem electromechNo ratings yet

- Centurion Power Cables (P) LTD.: 1.0 PurposeDocument4 pagesCenturion Power Cables (P) LTD.: 1.0 PurposetriveshNo ratings yet

- CNC HMC Acc CheckDocument2 pagesCNC HMC Acc CheckKalees WaranNo ratings yet

- Chintamani Metal Udhoy Pvt. Ltd. 4M Change BoardDocument6 pagesChintamani Metal Udhoy Pvt. Ltd. 4M Change Boardcmu qmsNo ratings yet

- Annex-1-Process Flow ChartDocument1 pageAnnex-1-Process Flow ChartDeepak DasNo ratings yet

- Supply Packaging Approve FormDocument1 pageSupply Packaging Approve Formcong daNo ratings yet

- Cost of Poor QualityDocument3 pagesCost of Poor QualityrajaNo ratings yet

- Past Defect History 2021Document10 pagesPast Defect History 2021RahulNo ratings yet

- Daily Production Report Cutting Order Qty. (Extra % Included)Document9 pagesDaily Production Report Cutting Order Qty. (Extra % Included)imtiazNo ratings yet

- Effective Problem SolvingDocument1 pageEffective Problem Solvingmuthuswamy77No ratings yet

- DWM FormatDocument4 pagesDWM Formatdharmendra ChaurasiaNo ratings yet

- DK Qap QHS 12-FR 03-R6 - CarDocument1 pageDK Qap QHS 12-FR 03-R6 - CarErlan Gus HermawanNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Bgl-Fm-Qa-10a Daily Rework RecordDocument1 pageBgl-Fm-Qa-10a Daily Rework RecordMohit SinghNo ratings yet

- Suppliers Quality Assurance Manual (PDFDrive)Document135 pagesSuppliers Quality Assurance Manual (PDFDrive)umtNo ratings yet

- 4M Change Intimation Sheet Abnormal SituationDocument1 page4M Change Intimation Sheet Abnormal SituationDhananjay Patil100% (1)

- Supplier Assesment MaxionDocument23 pagesSupplier Assesment Maxionesivaks2000No ratings yet

- QAV Checksheet 23.05.2022 LDocument10 pagesQAV Checksheet 23.05.2022 LNikhil SirNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- Suppliers Evaluation Form - Aluminium Suppliers-2007Document6 pagesSuppliers Evaluation Form - Aluminium Suppliers-2007savan anvekarNo ratings yet

- QP-55-03 Customer Complaint Suggestion Comment & SurveyDocument6 pagesQP-55-03 Customer Complaint Suggestion Comment & SurveySamsudin AhmadNo ratings yet

- Process Capability Plan FormDocument4 pagesProcess Capability Plan FormMani Rathinam RajamaniNo ratings yet

- PPAP Audit Check SheetDocument12 pagesPPAP Audit Check Sheetmahesh100% (1)

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- % Cont. Per AH % Sales % Cont. Per AH % Sales: A) Preventive CostDocument10 pages% Cont. Per AH % Sales % Cont. Per AH % Sales: A) Preventive CostmuthuselvanNo ratings yet

- Resume. ShyamDocument3 pagesResume. Shyamsunder2006No ratings yet

- Mahabal Metals Pvt. LTD.: Induction TrainingDocument3 pagesMahabal Metals Pvt. LTD.: Induction TrainingNitin KambleNo ratings yet

- System Audit Check SheetDocument8 pagesSystem Audit Check SheetFINAL QUALITYNo ratings yet

- 1) PPAP YHA VIBRACOUSTIC Production)Document31 pages1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalNo ratings yet

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNo ratings yet

- Checking AidsDocument2 pagesChecking AidsqualityNo ratings yet

- Rejection Record.Document10 pagesRejection Record.karan shahNo ratings yet

- Quality PlanDocument2 pagesQuality Planvipulsharma655No ratings yet

- Process Capability Study Report: U.T.L. L.T.LDocument7 pagesProcess Capability Study Report: U.T.L. L.T.Lt836549No ratings yet

- Inspection ProcedureDocument1 pageInspection ProcedureManu SharmaNo ratings yet

- Responsibility and Authority - QMSDocument47 pagesResponsibility and Authority - QMSDisha Shah50% (2)

- Control of Non-Conforming ProductsDocument10 pagesControl of Non-Conforming ProductsSachin KumbharNo ratings yet

- Departmental Wise Measurable Master - 2Document13 pagesDepartmental Wise Measurable Master - 2VenkatesanNo ratings yet

- Corrective Actions For Not Ok Charcteristics: Months - July13Document1 pageCorrective Actions For Not Ok Charcteristics: Months - July13shobha shelarNo ratings yet

- Standard Work Instruction Sheet: Work Description Key PointsDocument2 pagesStandard Work Instruction Sheet: Work Description Key PointsPauline KangNo ratings yet

- PFD and Pqcs of Can Rear BreakDocument16 pagesPFD and Pqcs of Can Rear BreakVikas KashyapNo ratings yet

- QMS Formats PDFDocument11 pagesQMS Formats PDFBhavin SukhadiyaNo ratings yet

- Machining PFMEADocument8 pagesMachining PFMEASuraj RawatNo ratings yet

- Quality Control Issue LogDocument11 pagesQuality Control Issue LogAshish ChackoNo ratings yet

- APQP Format NationalDocument53 pagesAPQP Format NationalqualityNo ratings yet

- In Process QC FormatDocument9 pagesIn Process QC FormatSunil ChaubeyNo ratings yet

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNo ratings yet

- Sundram Fasteners LTD, Autolec Division. Apqp Timing Plan - XXXXXXXXXXX (1111111) Date: XX - XX.XXXXDocument2 pagesSundram Fasteners LTD, Autolec Division. Apqp Timing Plan - XXXXXXXXXXX (1111111) Date: XX - XX.XXXXUdhayakumarNo ratings yet

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- SOP QualiityDocument28 pagesSOP QualiityUttam KumarNo ratings yet

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionNo ratings yet

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDocument25 pagesPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNo ratings yet

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- (Uco Efb Pome Mef) ReceivingDocument1 page(Uco Efb Pome Mef) ReceivingwaqiuddinNo ratings yet

- Gist of Speeches by Rbi GovernorsDocument51 pagesGist of Speeches by Rbi GovernorspraveenbitNo ratings yet

- Ali 2017Document25 pagesAli 2017daniloNo ratings yet

- Different Classifications of BanksDocument48 pagesDifferent Classifications of BanksNash DenverNo ratings yet

- Statute Amendments of SAFA 31-10-2018Document12 pagesStatute Amendments of SAFA 31-10-2018CityPressNo ratings yet

- Residency Niversity: S: P L R P T: A A P, F S C T P A, 1882Document7 pagesResidency Niversity: S: P L R P T: A A P, F S C T P A, 1882sunnyNo ratings yet

- Internship ReportDocument13 pagesInternship ReportdeoNo ratings yet

- Murphy USA - Tobacco Compliance Audit: Key ObjectivesDocument2 pagesMurphy USA - Tobacco Compliance Audit: Key ObjectivesDucks TeeNo ratings yet

- Indemnity FDR, DD, BCDocument14 pagesIndemnity FDR, DD, BCDhruvi MandeyNo ratings yet

- NirmaDocument87 pagesNirmaJamila KhokharNo ratings yet

- 2019 Ifrs GuideDocument5 pages2019 Ifrs GuideLouremie Delos Reyes MalabayabasNo ratings yet

- Approaches To Development Communication-DoneDocument16 pagesApproaches To Development Communication-DoneChiragNo ratings yet

- Precast Concrete Elements Production Line Quote 20230713Document9 pagesPrecast Concrete Elements Production Line Quote 20230713Reymond CañeteNo ratings yet

- The - Influence - of - Social - Media - On - Consumer - Behavior PDFDocument128 pagesThe - Influence - of - Social - Media - On - Consumer - Behavior PDFSokale100% (1)

- Corporate Presentation Powergrid-03!09!10Document20 pagesCorporate Presentation Powergrid-03!09!10pvragiriNo ratings yet

- Capstone II HP Final 1Document9 pagesCapstone II HP Final 1api-405850950No ratings yet

- Kinds of Economic SystemDocument31 pagesKinds of Economic SystemMuhammad QasimNo ratings yet

- Chap001 - Changing Role of Managerial Accounting in Global Business EnvironmentDocument31 pagesChap001 - Changing Role of Managerial Accounting in Global Business EnvironmentEmy Syah67% (3)

- YC Form SaaS AgreementDocument8 pagesYC Form SaaS AgreementYing Hang Eng100% (1)

- Toyota Important TTTTDocument1 pageToyota Important TTTTArmin AmiriNo ratings yet

- Tutorial PPE AnswerDocument2 pagesTutorial PPE AnswerAdventurousLifeNo ratings yet

- Aka God Int LTD 61 Rue Hedzranawoe BP 13909 Lome-Togo: (Incorporated in Singapore)Document1 pageAka God Int LTD 61 Rue Hedzranawoe BP 13909 Lome-Togo: (Incorporated in Singapore)Pierre kiniNo ratings yet

- Portfolio RevisionDocument24 pagesPortfolio RevisionrajunscNo ratings yet

- Bank Mandiri Credit RiskDocument2 pagesBank Mandiri Credit RiskEva TrianiNo ratings yet

- Espd ResponseDocument18 pagesEspd ResponseDaniel TaradaciucNo ratings yet

- Jignesh Jethva - 124703803Document4 pagesJignesh Jethva - 124703803asdasdNo ratings yet

- Maintenance Planning Standard - Book - PT Freeport McMoran 2009 - Final v.1.6Document431 pagesMaintenance Planning Standard - Book - PT Freeport McMoran 2009 - Final v.1.6Bayu SudarsonoNo ratings yet

- Criticism For Max WeberDocument18 pagesCriticism For Max WeberAisha KhanNo ratings yet