Professional Documents

Culture Documents

Tankguard Storage (EIL) - PQT

Tankguard Storage (EIL) - PQT

Uploaded by

EILA545 QAQC0 ratings0% found this document useful (0 votes)

15 views4 pagesOriginal Title

Tankguard Storage(EIL) - PQT

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

15 views4 pagesTankguard Storage (EIL) - PQT

Tankguard Storage (EIL) - PQT

Uploaded by

EILA545 QAQCCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

Sieaeaen aren Mmaserl oleae

Univesity under Secion-2 of UGC Act 1956, EERIE

ROW UT

ESS eee ee eens

+ ICT/DPSE/RNJ Date: Jan 24, 2017

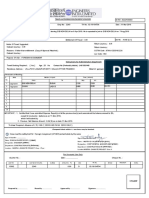

TEST REPORT FOR LIQUID PAINT

‘To: Jotun India Private Limited, Pune, India.

Sample Description: Tankguard Storage

Generic Type: Phenolic/Novolac Epoxy Coating

EIL Standard Specification For Surface Preparation & Protective Coatings- F15

Sr. ‘Test parameter Test Standard | Unit Resulis

No

1._| Specific Gravity ‘ASTM D 1475 1.65

2. | Uniformity in film produetion7) ASTM D 823 rm film on

Dipping properties dipping

3._| Volatile Content 1S 101- part 2 % 30.95 i}

4. | Density TS T01- part I section | g/t 1.632

71993

3._| Film Characteristic | Even

6. | Solid Content by weight [ASTM D 2369 % 69.05

7. | Drying Time (Surface Dry & | ASTM D 1640/18 | hr 24 and7

Hard Dry) 101 Part 3

8._| Storage Stability ASTM D 1849 |_| Moderate Setilin

9. | DFT feoat ‘As per SSPC am 200

guideline

he result contains in this test certificate are only related the sample tested. This test

is intepded for your guidance and not valid for legal purpose or advertisement

Sor in Paint Technology,

of Polymer and Surface Engineering,

Head, Cepatment of Polymer & Surface Engin

INSTITUTE OF CHEMICAL TECHNOLOGY

(unvta vo Secon Sef UGCA

ite Status & Conte of Excelence - Gov. of Maharashtra

Mating, Mantel -40 018,

al: initals

SEPT

Elite Status & Centre of Excellence - Gavernimient of Maharashtra

Ref. No.: ICT/DPSE/RNJ Date: Jan 24, 2017

‘TEST REPORT FOR COATED PANEL

‘To: Jotun India Private Limited, Pune, India.

Sample Description: Tankguard Storage

Generic Type: Phenolic/Novolac Epoxy Coating

EIL Standard Specification For Surface Preparation & Protective Coatings- F15

Surface Preparation: Sa 2 ¥% (ISO 8501-1)

Paint System: Tankguard Storage, Light Red

DFT: 125 microns

fre Test Test Standard | TNT Results

I Flexibility ASTM D 522 100 X 150 X 1 PASS

2 Hardness ASTM D 3363 75 X 150X5 OH

3 Abrasion Resistance ASTM D 4060 100 X 100 X 5 95 mg/1000 cycle

Remark: The result contains

this test certificate are only related the sample tested. This test

certificate is intended for your guidance and not valid for legal purpose or advertisement.

Professor in Paint Technology,

Department of Polymer and Surface Engineering,

ead, Deparment

f Polymer & Surface Engineering

INSTITUTE OF CeMICAL TECHNOLOGY

(une nc Sion 30S Fe! 85)

Ele Slatus & Centre of Excolence- Gov of Maharashtra

Matunga,Munba -¢00 08

Ref. No.t ICT/DPSE/RNI Date: Jan 24, 2017

‘TEST REPORT FOR COATED PANEL,

To: Jotun India Private Limited, Pune, India.

Sample Description: Tankguard Storage

Generic Type: Phenolic/Novolac Epoxy Coating

EIL Standard Specification For Surface Preparation & Protective Coatings F1S

Surface Preparation: Sa 2 % (ISO 8501-1)

Paint System: Tankguard Storage, Light Grey DFT: 100 microns

Tank guard Storage, Light Red DFT: 100 microns

‘Tankguard Storage, Light Grey DFT: 100 microns

7

Sr. Panel Dimension

or Test Test Standard | Havendinenion | Results

1 | Pull off Adhesion ASTMD4sai | 75X150X5 | 1240MPa

2 | 00e4 humidity test duration | agra p2247 | 75X150XS Pass

Cyclic corrosion test, duration | 1807253 &

3 _| 4200 hes astm syoq_| 75% 150X5 Pass

4 [10% & 40 %NaoH, 1000hr | Agra D 1308 | 75X150X5 Pass

exposure

5 | 10%H2804, 168 hrexposure | ASTMD 1308 | 75x 150X5 Pass

6 | 10% Nitric Acid test 168 hts | ASTMD1308 | 75x 150X5 Pass

7 | Xylene, 4 weeks duration ASTMD 1308 | 75X 1S0X5 Pass

8 | Acetone, 4 weeks duration | ASTMD 1308 | 75x 150X5 Pass

9 | Ethanol, 4 weeks duration ASTMD 1308 | 75X 150X5 Pass

10 | Kerosene, 4 weeks duration | ASTMD1308 | 75% 150X5 Pass

‘Tankguard Storage (F15) :- Page | of 2

LL | Sea water, 2000 hrs ASTMD 1308 | 75X 150X5 Pass

12 | 25% Ammonium sulphate,

ASTMD 1308 | 75x 1S0XS Pass

500 is

15. | 25% Sediumearbonate, 00 | astmip 1308 | 75x 1505 Pass

14 | Glacial Acetic Acid ASTMD 1308 | 75 1S0X5 Pass

15. | MEK Rub Test ASTMD 5402 | 75X150X5 | >500cycle

Resistance To demineralized

wg) | Resietanee To gecinemle ASTMD870 | 75X150X5 Pass

Dry Heat resistance ASTM D 2485

7 | upto 200 °c Method B. BAIR: Pass

“Thermal shock test- 5 eycles of

1g. | 120°C for 30 minutes followed | ASTM D 2485

by quenching in water for 15 Method A eS Pass

minutes

5

1p | Low temperature test @ 30°C — RES a

for 30 minutes

Cathodic Disbondment, for 28

20 |G,

lays

DINEN 10289 | 100X100xX5 | 3.1 mmr

Remark: The result contains in this test certificate are only related the sample tested. This test

certificate is jgtended for your guidance and not valid for legal purpose or advertisement,

Heal, Depariment of Poymer & Surface Engineering

INSTITUTE OF CHENICAL TECHNOLOGY

(Untesty ender Seston- 3 of UGC Act 1956) Tankguard Stor F15) = 2of2

Elite Status & Centre of Excelience - Govt. of Maharashtra es Re Se

tung, Mumbal-400 018.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EIL Procedure For Technical Audit - 5-1940-8020 Rev. 5Document26 pagesEIL Procedure For Technical Audit - 5-1940-8020 Rev. 5EILA545 QAQCNo ratings yet

- Sor 8108Document39 pagesSor 8108EILA545 QAQCNo ratings yet

- Astm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LDocument2 pagesAstm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LEILA545 QAQCNo ratings yet

- Piping Spec. For A23LDocument11 pagesPiping Spec. For A23LEILA545 QAQCNo ratings yet

- 0.5 La 614 1129 A23kDocument1 page0.5 La 614 1129 A23kEILA545 QAQCNo ratings yet

- ALKYLATION LINE SCHEDULE - A545-142-02-LSC-001 - Rev-9Document68 pagesALKYLATION LINE SCHEDULE - A545-142-02-LSC-001 - Rev-9EILA545 QAQCNo ratings yet

- Weld Joint Fouling With Support Pad - Branch ConnectionDocument2 pagesWeld Joint Fouling With Support Pad - Branch ConnectionEILA545 QAQCNo ratings yet

- Part List & Materials of ConstructionDocument2 pagesPart List & Materials of ConstructionEILA545 QAQCNo ratings yet

- Dokumen - Tips Nace-Tm0177Document36 pagesDokumen - Tips Nace-Tm0177EILA545 QAQCNo ratings yet

- Haji Ali Time Sheet Oct-2021Document4 pagesHaji Ali Time Sheet Oct-2021EILA545 QAQCNo ratings yet

- WPS-91 Rev-00Document18 pagesWPS-91 Rev-00EILA545 QAQCNo ratings yet

- GQ NiaziDocument2 pagesGQ NiaziEILA545 QAQCNo ratings yet

- One-Line Diagram - OLV1 (Load Flow Analysis) : Scheme-1Document1 pageOne-Line Diagram - OLV1 (Load Flow Analysis) : Scheme-1EILA545 QAQCNo ratings yet

- Document No: A545-Page 1 of 9Document9 pagesDocument No: A545-Page 1 of 9EILA545 QAQCNo ratings yet

- Project Approvals: A545-00-161-RFM-HTR-LS-0598/R1Document7 pagesProject Approvals: A545-00-161-RFM-HTR-LS-0598/R1EILA545 QAQCNo ratings yet

- FWD: Design Clarification For SS Piping Support-RegDocument2 pagesFWD: Design Clarification For SS Piping Support-RegEILA545 QAQCNo ratings yet

- 101&111-CT-PR-7641 &7642-5125 &5126 (Vol 01 of 61)Document250 pages101&111-CT-PR-7641 &7642-5125 &5126 (Vol 01 of 61)EILA545 QAQCNo ratings yet

- Document No: A545-Page 1 of 4Document4 pagesDocument No: A545-Page 1 of 4EILA545 QAQCNo ratings yet

- Procedure For Ferrite TestDocument5 pagesProcedure For Ferrite TestEILA545 QAQCNo ratings yet

- Sinoma Minutes of MeetingDocument1 pageSinoma Minutes of MeetingEILA545 QAQCNo ratings yet

- GA of Fabric Expansion BellowDocument17 pagesGA of Fabric Expansion BellowEILA545 QAQCNo ratings yet

- Tank 100% PWHT ProcedureDocument32 pagesTank 100% PWHT ProcedureEILA545 QAQC100% (1)

- Site Welders Register As On 08.08.20Document12 pagesSite Welders Register As On 08.08.20EILA545 QAQCNo ratings yet

- Tank Calibration Procedure by EORDR MethodDocument9 pagesTank Calibration Procedure by EORDR MethodEILA545 QAQCNo ratings yet

- P1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BDocument16 pagesP1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BEILA545 QAQCNo ratings yet

- Document No: A545-Page 1 of 2Document2 pagesDocument No: A545-Page 1 of 2EILA545 QAQCNo ratings yet

- P1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkDocument9 pagesP1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkEILA545 QAQCNo ratings yet

- RT AccepDocument1 pageRT AccepEILA545 QAQCNo ratings yet

- Document Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkDocument16 pagesDocument Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkEILA545 QAQCNo ratings yet