Professional Documents

Culture Documents

Well Control Training & Assessment: Sample Supervisor-Level Questions

Well Control Training & Assessment: Sample Supervisor-Level Questions

Uploaded by

She DoelsCopyright:

Available Formats

You might also like

- 10 - WellSharp Study Guide - Pre - Course - Rev 1Document6 pages10 - WellSharp Study Guide - Pre - Course - Rev 1mjm_1365No ratings yet

- IADC Wellsharp HomeworkDocument13 pagesIADC Wellsharp HomeworkalloriadNo ratings yet

- ADC WellSharp Supervisor Homework Exercises Final Revised 08 Oct 2015 PDFDocument118 pagesADC WellSharp Supervisor Homework Exercises Final Revised 08 Oct 2015 PDFصالح100% (4)

- 03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseDocument5 pages03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseAdolfo AnguloNo ratings yet

- AC-0018 Practical Assessor HandbookDocument24 pagesAC-0018 Practical Assessor HandbookRichard ReiersenNo ratings yet

- Driller Test With Answers PDFDocument26 pagesDriller Test With Answers PDFArpan Biswas100% (2)

- 02 - WellSharp Drilling Supervisor - Day 1 Pre - CourseDocument5 pages02 - WellSharp Drilling Supervisor - Day 1 Pre - CourseAdolfo Angulo100% (1)

- Electric: Circuit Problems With SolutionsDocument73 pagesElectric: Circuit Problems With Solutionspassed outNo ratings yet

- Iwcf Q&aDocument91 pagesIwcf Q&aKhaled AdelNo ratings yet

- Model MH 70: Hydraulic Piston Actuator Operation and Maintenance ManualDocument35 pagesModel MH 70: Hydraulic Piston Actuator Operation and Maintenance ManualAhmed Ousama100% (3)

- IWCF Test 2 With Answers: Driller'S Technical HandbookDocument25 pagesIWCF Test 2 With Answers: Driller'S Technical HandbookBeni N Solo75% (4)

- 05 - WellSharp Workover and Completion - Day 4 Pre - Course PDFDocument6 pages05 - WellSharp Workover and Completion - Day 4 Pre - Course PDFMarkus Landington100% (1)

- IWCF Set 1 - 6Document33 pagesIWCF Set 1 - 6Jeneesh Shanmughan100% (1)

- Exercise 3 AnswersDocument13 pagesExercise 3 AnswersadeelsnNo ratings yet

- Assignment Final)Document19 pagesAssignment Final)Pinkesh ShahNo ratings yet

- 2well Control - ExerciseDocument153 pages2well Control - ExerciseMostafa ElghifaryNo ratings yet

- Drilling Well Control Syllabus Level 3 and 4Document3 pagesDrilling Well Control Syllabus Level 3 and 4SahatnainggolanNo ratings yet

- Hse Plan Phe Onwj Pt. Pentraco Karya AdiprestasiDocument39 pagesHse Plan Phe Onwj Pt. Pentraco Karya AdiprestasiShe DoelsNo ratings yet

- Numerical Solution of Partial Differential Equations Solution ManualDocument84 pagesNumerical Solution of Partial Differential Equations Solution ManualGui San100% (1)

- API 650-Annex PDocument8 pagesAPI 650-Annex PSachinNo ratings yet

- Know Energy - P&P Test 2 With AnswersDocument21 pagesKnow Energy - P&P Test 2 With AnswerssyazwanNo ratings yet

- P and P 1 To 5 Quiz and AnswDocument19 pagesP and P 1 To 5 Quiz and AnswJeneesh Shanmughan100% (1)

- Last P and P Driller Excercis 2022Document78 pagesLast P and P Driller Excercis 2022Naresh Regulagadda100% (1)

- Chevron: Wellcap Plus Practice Test Surface/SubseaDocument15 pagesChevron: Wellcap Plus Practice Test Surface/SubseaBoedi Syafiq100% (1)

- Workover 1 Soal - 8 APR21.revDocument17 pagesWorkover 1 Soal - 8 APR21.revputujuliandikaNo ratings yet

- 18 - IWCF Homework Answers Day 1 - 1blank PDFDocument61 pages18 - IWCF Homework Answers Day 1 - 1blank PDFKenaouia BahaaNo ratings yet

- Oil Well Kicks Questions and Answers Part1Document7 pagesOil Well Kicks Questions and Answers Part1Rizwan FaridNo ratings yet

- Test P&PDocument13 pagesTest P&PMuhammad Ali0% (1)

- IADC 77 DRILLING Pretest 2 (Without A)Document15 pagesIADC 77 DRILLING Pretest 2 (Without A)Ariq Dicky100% (3)

- Iadc Drilling 1.10.20. - (77) W.outDocument14 pagesIadc Drilling 1.10.20. - (77) W.outsendi100% (1)

- Drillers CourseDocument92 pagesDrillers CourseAdel Hankour100% (1)

- P and P Quiz 1 at 2Document30 pagesP and P Quiz 1 at 2Jeneesh ShanmughanNo ratings yet

- Faizan Naikwadi PA 12 IWCF L3 & 4 Day 1 HomeworkDocument16 pagesFaizan Naikwadi PA 12 IWCF L3 & 4 Day 1 Homeworkparesh pawarNo ratings yet

- ET Question Bank 2020Document32 pagesET Question Bank 2020Manash Hazarika100% (1)

- Iwcf l3 4 PDFDocument2 pagesIwcf l3 4 PDFBENMAAMER AZOUAOU100% (1)

- IWCF Comb. Supv Equip. 02Document24 pagesIWCF Comb. Supv Equip. 02andrzema100% (3)

- IWCF Comb. Driller Equip. 01Document21 pagesIWCF Comb. Driller Equip. 01andrzema67% (3)

- IWCF ProblemsDocument21 pagesIWCF ProblemsTamlom100% (1)

- IWCF Surf. Equip Supv. 01Document23 pagesIWCF Surf. Equip Supv. 01andrzemaNo ratings yet

- P and P (EDC) PDFDocument62 pagesP and P (EDC) PDFAli mohammad50% (2)

- Assignment Co OperationsDocument20 pagesAssignment Co Operationsyasirism100% (2)

- Well Control ExerciseمهمDocument133 pagesWell Control ExerciseمهمAsad babil BabilNo ratings yet

- Surface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedDocument22 pagesSurface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedandrzemaNo ratings yet

- P & P AnswerDocument143 pagesP & P AnswerOmerNo ratings yet

- Driller Module Workbook 4 Sedco Forex Modular Training ProgramDocument3 pagesDriller Module Workbook 4 Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- Iwcf Exercise STC 1Document149 pagesIwcf Exercise STC 1ali jabbar100% (1)

- 27 - Iwcf Ss Sample Questions - AnswersDocument9 pages27 - Iwcf Ss Sample Questions - Answersshoaib Khalil100% (1)

- IWCF Comb. Supv Equip. 01Document25 pagesIWCF Comb. Supv Equip. 01andrzema100% (3)

- Well Control Questions and Answers Part 2Document8 pagesWell Control Questions and Answers Part 2Rizwan FaridNo ratings yet

- 23 - IWCF SO Sample QuestionsDocument6 pages23 - IWCF SO Sample QuestionsRichard ReiersenNo ratings yet

- EX-0035 Drilling - English API Forumla SheetDocument4 pagesEX-0035 Drilling - English API Forumla Sheetmohamed abbasNo ratings yet

- Equ Mock Test 1 Rev 1.5Document27 pagesEqu Mock Test 1 Rev 1.5Hany ZayedNo ratings yet

- P&Pof Intervention Pressure ControlDocument69 pagesP&Pof Intervention Pressure ControlRajat Khanna100% (4)

- Well Control Course Workbook 2001 Q1 PDFDocument96 pagesWell Control Course Workbook 2001 Q1 PDFdvbnjfdNo ratings yet

- Combined Driller Equipment Paper NO. 2.: All Questions Require Only ONE Answer Unless Otherwise StatedDocument23 pagesCombined Driller Equipment Paper NO. 2.: All Questions Require Only ONE Answer Unless Otherwise Statedandrzema100% (2)

- 5 Pressure Basics Problems, PROBLEMS 1-6Document31 pages5 Pressure Basics Problems, PROBLEMS 1-6Raul Dolo Quinones100% (1)

- Questions WellcontrolDocument10 pagesQuestions WellcontrolZ Babar KhanNo ratings yet

- Exercise Section - 1complDocument8 pagesExercise Section - 1complOperator Genggam100% (2)

- IADC Formula Sheet: X X X + + ÷ X + X - ÷ XDocument5 pagesIADC Formula Sheet: X X X + + ÷ X + X - ÷ XMarwa ElghifaryNo ratings yet

- Driller Workbook3Document4 pagesDriller Workbook3Kaleem UllahNo ratings yet

- Well Intervention QuizDocument4 pagesWell Intervention QuizAkol Majook50% (2)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- WellsafeDocument34 pagesWellsafeHendra Jurbon0% (1)

- Supervisor Extra Questions SolvedDocument5 pagesSupervisor Extra Questions Solvedhamdi1000No ratings yet

- Microsoft Word - Exercise 1Document27 pagesMicrosoft Word - Exercise 1KRNo ratings yet

- FORM - Sand Control Treatment - Check - ListDocument2 pagesFORM - Sand Control Treatment - Check - ListShe DoelsNo ratings yet

- Safety & Equipment List 19 Jan 2022Document1 pageSafety & Equipment List 19 Jan 2022She DoelsNo ratings yet

- Procedure Safety Objective & TargetDocument8 pagesProcedure Safety Objective & TargetShe DoelsNo ratings yet

- No. Batch Time Start Time Finish Polymer P090 (KG) Concentration (PPM) Viscosity (CP) Injection Rate (BPM)Document2 pagesNo. Batch Time Start Time Finish Polymer P090 (KG) Concentration (PPM) Viscosity (CP) Injection Rate (BPM)She DoelsNo ratings yet

- Procedure Management of ChangeDocument6 pagesProcedure Management of ChangeShe DoelsNo ratings yet

- JSA SC Treatment Injection SupervisionDocument3 pagesJSA SC Treatment Injection SupervisionShe DoelsNo ratings yet

- Spirits Analysis and Differentiated ACECESDocument5 pagesSpirits Analysis and Differentiated ACECEShoseatyourmamaNo ratings yet

- (Denise Eileen McCoskey, Emily Zakin) Bound by TheDocument356 pages(Denise Eileen McCoskey, Emily Zakin) Bound by TheZenia YébenesNo ratings yet

- PrabhatCables Listprice ConsolidatedDocument4 pagesPrabhatCables Listprice ConsolidatedPower RoboticsNo ratings yet

- Record R 62: Security Interlock As Access Control SystemDocument5 pagesRecord R 62: Security Interlock As Access Control SystemgerglendiazNo ratings yet

- Leadershipdevelopment BR DdiDocument12 pagesLeadershipdevelopment BR DdihrahmayadiNo ratings yet

- F172N&P POH Thielert Aircraft SystemsDocument114 pagesF172N&P POH Thielert Aircraft SystemsJuvet Baluyot BigcasNo ratings yet

- Leave Scheduler SystemDocument42 pagesLeave Scheduler SystemOkunade OluwafemiNo ratings yet

- STD 9 CH 4 Climate PDFDocument104 pagesSTD 9 CH 4 Climate PDFTushar VazeNo ratings yet

- ASME PTC 30-1991 Air Cooled Heat ExchangersDocument19 pagesASME PTC 30-1991 Air Cooled Heat ExchangersShanNo ratings yet

- K Ali EntpDocument2 pagesK Ali Entpanim singhNo ratings yet

- Checklist For Diamond DA62: Comments Explaining Edition # 1.2Document18 pagesChecklist For Diamond DA62: Comments Explaining Edition # 1.2DJ Douglas100% (1)

- 295-Article Text-2269-1-10-20210624Document7 pages295-Article Text-2269-1-10-20210624Rahmat AlfajriNo ratings yet

- Fosroc - Nitocote PE 135Document8 pagesFosroc - Nitocote PE 135guru sathya bharathyNo ratings yet

- Gráfico de Operação XCMG 110tonDocument25 pagesGráfico de Operação XCMG 110tonRENATO SVANCHEVCNo ratings yet

- Mae 5310: Combustion Fundamentals: Laminar Premixed Flames Example, Applications and CommentsDocument22 pagesMae 5310: Combustion Fundamentals: Laminar Premixed Flames Example, Applications and CommentsAlex KeaneNo ratings yet

- Children'S Hour Philippines, Inc. Project Proposal Template 1. Project TitleDocument7 pagesChildren'S Hour Philippines, Inc. Project Proposal Template 1. Project TitleHani RedobladoNo ratings yet

- HD Retrovision - TV Compatibility List 2017-12-11Document7 pagesHD Retrovision - TV Compatibility List 2017-12-11Edison Marcial Aliaga LozanoNo ratings yet

- Shallow Water Acoustic Networks Full ReportDocument26 pagesShallow Water Acoustic Networks Full ReportSimmi JoshiNo ratings yet

- Ccna Report On Project WanDocument60 pagesCcna Report On Project Wanmanoum2No ratings yet

- Ict Adding VideosDocument2 pagesIct Adding VideosShenSy100% (1)

- Ebrahim 2016Document31 pagesEbrahim 2016Afrizal DanaNo ratings yet

- Remotesensing 14 03908Document17 pagesRemotesensing 14 03908Tekletsadik TeketelNo ratings yet

- v16 - GE-1015 Jane's Aero Engine March 2000Document11 pagesv16 - GE-1015 Jane's Aero Engine March 2000Marcelo Roberti Rocha FantaguzziNo ratings yet

- Amt in Household and ServicesDocument25 pagesAmt in Household and ServicesShabby Gay TroganiNo ratings yet

- Exalco Albio 102 Curtain Wall SystemsDocument92 pagesExalco Albio 102 Curtain Wall SystemsAdmir MatoshiNo ratings yet

Well Control Training & Assessment: Sample Supervisor-Level Questions

Well Control Training & Assessment: Sample Supervisor-Level Questions

Uploaded by

She DoelsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Well Control Training & Assessment: Sample Supervisor-Level Questions

Well Control Training & Assessment: Sample Supervisor-Level Questions

Uploaded by

She DoelsCopyright:

Available Formats

Well Control Training & Assessment

Sample Supervisor-Level Questions

The questions in the document are a sample of Supervisor level questions that

will be included in the testing database.

These questions are still under review by an industry committee and may

therefore be revised.

Also included in the Supervisor final test will be a number of questions from the

Driller level database. These can be identified from the curricula where the

learning objectives are the same for both Driller and Supervisor levels.

Please use the Acronyms and Glossary of Terms document to assist with the

terminology in use.

Rev. 0 March 2015

IADC’s Well Control Training & Assessment

1. A well is shut in. What is the casing pressure in this static u-tube?

Well Information:

Drill Pipe pressure reads 0 psi.

Well Depth = 12,000’ TVD/ 12,225 MD

Drill String full of 8.3 ppg water

Annulus full of 6.0 ppg gas/water mixture

a. 1,435 psi

b. 1,462 psi

c. 3,744 psi

d. 5,179 psi

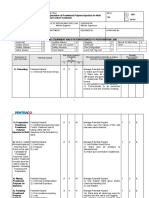

2. A rig crew shut in on a 2.5 ppg kick with a 20 bbl gain. Using the kick

tolerance window below, can the crew successfully shut in and circulate the

kick out of the well without fracturing the well’s weak point?

a. Yes

b. No

Sample Supervisor-Level Questions, Rev. 0 2 March 2015

IADC’s Well Control Training & Assessment

3. The drilling program requires a formation integrity test (FIT) to 15.2 ppg

Equivalent Mud Weight (EMW) at the casing shoe.

Shoe Depth = 4,000’ (TVD); 5,500’ (MD).

Mud Weight = 9.5 ppg.

What surface pressure is required to test the shoe to the 15.2 ppg EMW?

a. 1,976 psi

b. 1,186 psi

c. 1,630 psi

d. 2,382 psi

4. At what pressure (at surface) does leak-off begin to take place in the graph

below?

1200

Pump Pressure

1000

800

600

400 Vertical Depth = 8500 ft.

Mud Weight = 12.3 ppg

200

Volume Pumped

a. 800 psi

b. 1,050 psi

c. 1,200 psi

d. 900 psi

Sample Supervisor-Level Questions, Rev. 0 3 March 2015

IADC’s Well Control Training & Assessment

5. What is meant by a kick tolerance of 25 barrels?

a. A gas kick of 25 bbls is the maximum that can be shut-in and

circulated out without possible lost circulation.

b. A salt-water kick of 25 bbls is the maximum that can be shut-in

and bullheaded without possible lost circulation.

c. A gas kick of 25 bbls is the maximum that can be circulated out

without bursting the casing at surface.

d. A salt-water kick of 25 bbls is the maximum that can be circulated

out without bursting the casing at surface.

6. A well is shut in and a gas kick migrates 1000 feet with no expansion in the

annulus.

Well Information:

Gas Volume = 20 bbl

Total Depth = 6,000′ MD and TVD

Casing Shoe = 2,200′ MD and TVD

Open Hole = 8.5″

Mud Weight = 8.33 ppg

What is the increase in bottom hole pressure due to gas migration? Assume no

losses to the formation.

a. 433 psi

b. 952 psi

c. 2,165 psi

d. 2,598 psi

7. A gas kick is being circulated out using the Drillers Method.

What will happen to the bottom hole pressure if the gas bubble is not allowed

to expand as it is circulated up the hole?

a. It will increase.

b. Stay the same.

c. It will decrease.

Sample Supervisor-Level Questions, Rev. 0 4 March 2015

IADC’s Well Control Training & Assessment

8. During a trip out it is calculated that 5 bbls has been swabbed into the well. A

flow check is negative. It is decided to continue with the trip. If the kick is gas

what may happen in the well?

a. Gas may migrate and expand causing reduction in hydrostatic

pressure.

b. Gas will stay in position and be pushed back into the formation

when you run back in the hole.

c. Gas will migrate but not expand so hydrostatic pressure will stay

constant.

d. Gas will migrate and expand causing hydrostatic pressure to

increase.

9. The Driller has swabbed 5 bbls into the well. The bit is returned to bottom

and bottoms-up is being circulated. The pit level is slowly increasing, as

bottoms-up is getting closer to surface. What is a safe action to take?

a. Shut in the well and continue circulation through the choke using

1st circulation of the Drillers method.

b. Continue circulating with well open but switch on vacuum

degasser.

c. Shut in well, record SIDPP and use Wait & Weight method to kill

the well.

d. Shut in the well and use the Volumetric method to remove gas

from the well.

10. In an open well, what situation could cause the following problems?

• Pit gain

• Reduced hydrostatics

• Riser/Casing unloading

• Decrease in Bottom Hole Pressure

a. Ballooning

b. Gas Migration

c. High Equivalent Circulating Density

d. Partial Lost Circulation

11. What is the danger when a gas kick is circulated through the choke manifold?

a. The increased volume can overload the mud gas separator.

b. The gas will change to a liquid and increase pit level.

c. The increased volume of gas at the mud gas separator will increase

the bottom hole pressure.

d. The gas will cause a temperature increase at the remote choke and

damage rubber seals.

Sample Supervisor-Level Questions, Rev. 0 5 March 2015

IADC’s Well Control Training & Assessment

12. How does wellbore temperature affect mud weight down hole?

a. Increased temperature will increase Mud weight downhole.

b. Increased temperature will decrease Mud weight downhole.

c. Mud weight will not be affected by wellbore temperature.

13. How does increasing pressure affect Oil Based Mud (OBM) density?

a. No effect on density

b. Increases density

c. Decreases density

14. What are “hydrates”?

a. Hydrates are a solid, frozen mixture of oil and water.

b. Hydrates are a solid, frozen mixture of water and gas.

c. Hydrates are a solid, frozen mixture of oil and gas.

d. Hydrates are a solid, frozen mixture of methanol and water.

15. When killing a well with a horizontal section, what will happen if you use a

vertical kill sheet to circulate out the kick?

a. The strokes to the bit will be wrong.

b. You will be applying too little pressure to the well.

c. The FCP is more difficult to calculate.

d. You will be applying too much pressure to the well.

16. A kick is taken in a horizontal well. SIDPP = SICP. Influx is circulated out

using the Driller’s Method. Why does the Casing pressure increase quite

rapidly when the influx is circulated out of the horizontal section and into the

vertical section?

a. ECD is much greater in the horizontal section.

b. This is because kill mud was not pumped from the start of the kill.

c. This is normal for any well when Driller’s Method is used.

d. There is no loss of hydrostatic head until gas arrives at the inclined

or vertical section of the well.

17. Kill mud is being circulated down the drill string in a horizontal well. The

pumps are stopped and the well is shut in as the kill mud reaches the start of

the horizontal section (2000 feet. long).

What would you expect the Shut In Drill Pipe Pressure to be?

a. Zero.

b. The same as the original Shut In Drill Pipe Pressure.

c. The same as the Shut In Casing Pressure.

d. Original SIDPP less the hydrostatic of 2000 feet of mud

hydrostatic.

Sample Supervisor-Level Questions, Rev. 0 6 March 2015

IADC’s Well Control Training & Assessment

18. You are circulating kill mud to the bit with the Weight and Wait method. The

drillstring is tapered. Drillpipe length is 10,000 feet with:

0 to 5000 feet is 6 5/8 inch drillpipe

5000 to 10,000 feet is 5-inch drillpipe

Total Strokes to Bit = 2100 strokes

ICP = 800 psi

FCP = 425 psi

If the pressure step-down graph/schedule is made based on an average

18 psi per 100 strokes pumped what would be the effect on bottom hole

pressure after pumping kill mud down to the top of the 5-inch drillpipe?

a. Bottom hole pressure will be too high.

b. Bottom hole pressure will be too low.

c. Bottom hole pressure will be correct.

19. You have successfully shut-in on a kick. Which of the following would not be

the responsibility of the Derrickhand to monitor?

a. Mud Weight in all pits.

b. Pressures on Choke.

c. Pit levels and measuring devices.

d. Any leaks at pumps or lines.

20. You are performing a Negative Test (API: Inflow Test). The drill string has

been displaced with a light fluid and the pressure has been bled off the drill

pipe. The volume that flowed back from the drill pipe during bleed-off was

three times more than calculated. Pressure returns on the standpipe when

the drill pipe is shut in.

What is your evaluation of the test?

a. Not enough information to make an informed decision.

b. Successful test. Continue with planned operations.

c. Failed test. Shut the well in and notify Management.

21. While drilling ahead, your Derrick Hand calls and says they are going to

transfer 20 bbls to the active pit within 5 minutes. After 15 minutes you

notice that your pit level has gone up by 25 bbls. What is the safest action to

take?

a. Keep drilling, Derrickhand added too much mud and didn’t know.

b. Call Derrickhand and see if he left a valve open or added too much.

c. Flow check and then call Derrickhand to check added volume.

d. Shut in well and bullhead 5 bbls of fluid into the formation.

Sample Supervisor-Level Questions, Rev. 0 7 March 2015

IADC’s Well Control Training & Assessment

22. A kick has been taken at TD and will be circulated out using the Drillers

Method. You have one active pit (10 foot deep) with 180 bbls capacity.

Kick size = 10 bbls

TD/TVD = 4800feet

Mud weight in well = 9.9 ppg

SIDPP = 250 psi

SICP = 350 psi

Maximum predicted surface casing pressure during kill = 500 psi

What is the maximum mud level allowed in the pit before starting the

circulation?

a. 5.5 foot deep

b. 6.5 foot deep

c. 7.5 foot deep

d. 8.5 foot deep

23. You have successfully shut-in on a kick. As a Supervisor, which of the

following is an important responsibility for you to complete?

a. Verify Mud Weight in and out.

b. Check Pit Levels and lineups.

c. Mixing Kill Weight Mud

d. Communicate/Plan with crew.

24. You start-up a kill and the initial drill pipe pressure is 150 psi higher than

calculated. You adjust the choke to get calculated ICP on the drill pipe gauge.

What will happen to BHP?

a. BHP will decrease to the correct value to balance formation

pressure.

b. BHP will decrease below formation pressure and the well will be

underbalance.

c. There will be no change to BHP as the choke adjustment is only

removing annular friction loss.

d. There will be no change to BHP as the choke adjustment is only

removing drill string friction loss.

Sample Supervisor-Level Questions, Rev. 0 8 March 2015

IADC’s Well Control Training & Assessment

25. A well has been shut in on a floating rig. The choke line is filled with fresh

water.

Well data:

Rig Floor to Mudline 4400’

Weight of fresh water 8.35 ppg

Mud weight 12.2 ppg

SICP 1450 psi

Before starting to kill the well the choke line is displaced to 12.2 ppg mud.

What will be the new SICP?

a. 1,030 psi

b. 608 psi

c. 570 psi

d. 881 psi

26. A loss of Equivalent Circulating Density may be an indication that the well

has become underbalanced.

What Downhole tool would be the best choice to measure ECD while drilling?

a. A rotary steerable tool.

b. An Adjustable Gauge Stabilizer (AGS) tool.

c. A Pressure While Drilling (PWD) tool.

d. Any “Memory” type tool.

27. What is a transition zone?

a. A section of formation where fluid pressures are changing.

b. A change in the formation from high permeability to low

permeability.

c. The position in a reservoir where gas transitions to oil or water.

d. Depth where the formations are strong enough to be shut-in with

the BOP.

28. Which of the following actions should be taken when drilling through a

transition zone?

a. Monitor Shakers for “cavings.”

b. Reduce RPM.

c. Reduce WOB.

d. Fingerprint connections for flowback trends.

e. Increase time between mud weight checks.

Sample Supervisor-Level Questions, Rev. 0 9 March 2015

IADC’s Well Control Training & Assessment

29. The well has been losing mud while drilling the last stand. At the connection

the well continues to flow after the pumps have been switched off. You

suspect the formation is ‘Ballooning’. What is the first action to take?

a. Shut the well in.

b. Bleed 5 bbls back to trip tank and check if flowback speed reduces.

c. Immediately start pumping to restore BHP.

d. Make connection, return to drilling and add LCM to the mud.

30. The well has been shut in on a swabbed-in kick. The bit is 1800 feet off

bottom. What action should be taken?

a. Begin the Wait and Weight method immediately.

b. Start stripping out of the hole and keeping the hole full.

c. Begin to Lubricate and bleed to kill the well.

d. Strip to bottom before starting well kill operations.

31. How can you tell the difference between a kick and a ballooning formation?

a. There will be shut in pressures for a kick, no pressures for

ballooning.

b. If you bleed-off some shut-in pressure then shut the well back in,

the pressure will build back up with a kick, but not with

ballooning.

c. You can’t tell the difference between the two until you pump

bottoms up.

d. A ballooning formation will always result in a pit gain but not for a

kick.

32. Your crew is pulling a 300 foot (non-shearable) wireline tool from the hole.

The Dynamic Positioning Operator (DPO) has just informed of a problem

with station keeping. This condition should last for about 15-20 minutes.

Do you have any instructions for the Driller and Wireline Operator?

a. No. This is a stability issue not a downhole problem.

b. No. There is no foreseeable impact on operations.

c. Yes. Stop pulling the tool immediately and shut-in.

d. Yes. Stop pulling when the tool is just below the BOP.

Sample Supervisor-Level Questions, Rev. 0 10 March 2015

IADC’s Well Control Training & Assessment

33. Delayed flowback has been documented for the last five connections while

drilling. The Driller believed that the flowback time was too long and closed

the well in. There is 150 psi on the Drill Pipe and the Annulus. The Driller has

bled off 50 psi. SIDPP returned to 150 psi. SICP is 175.

What is your assessment of the current situation?

a. This is ballooning. Bleed off and drill ahead.

b. This is a kick. Record pressures and prepare for a kill.

c. This is mud compressibility. Bleed off and drill ahead.

d. This is the result of gas migration. Start the Volumetric Method.

34. If a self-fill float in casing gets plugged and the casing does not get filled, what

are the well control risks?

a. If the plug suddenly clears the mud level in the annulus will drop.

b. Losses may occur due to higher mud level in the annulus.

c. You will not be able to reverse circulate to kill the well.

d. You will not be able to pump LCM.

35. What is a ‘negative’ pressure test?

a. A test on a barrier where pressure is reduced to a value lower than

the other side of the barrier.

b. A test on a barrier where pressure is increased to a value higher

than the other side of the barrier.

c. A test where the barrier is made to fail.

d. A test where a barrier is tested until there is leak-off.

36. What is the definition of riser margin

a. The MW increase below the mud line needed to compensate for

the removal of the riser.

b. The MW increase needed to keep the well static while tripping

BHA in the riser.

c. The additional mud weight above seawater weight required to

balance the well with the riser connected.

37. Using the below information, calculate Riser Margin.

• Water Depth = 5,500 foot

• TVD of Well = 12,000 foot

• Air Gap = 75 foot

• Mud Weight = 12.4 ppg

• Sea Water Gradient = .445 psi/foot

a. 15.9 ppg.

b. 15.6 ppg.

c. 15.7 ppg.

d. 15.5 ppg

Sample Supervisor-Level Questions, Rev. 0 11 March 2015

IADC’s Well Control Training & Assessment

38. Which of the following is true regarding kick detection during wireline

operations?

a. The well should be put on the trip tank to monitor displacement as

wireline is run in/out of the hole.

b. The well should be lined up to active pits due to the large

displacement volumes of wireline tools.

c. There is no need to monitor the well during wireline operations

because the well is static.

d. Wireline operations can only take place using a lubricator

assembly when logging open hole sections.

39. Which of the following is a “physical barrier”

a. Proper BOP shut in procedure

b. Periodic well control drills

c. Monitoring the trip tank

d. A cement plug

40. If a kick is swabbed in, which type of barrier has failed?

a. Permanent mechanical barrier

b. Operational barrier

c. Temporary mechanical barrier

d. Tested barrier

41. What situation would affect your flow gauge while drilling ahead?

a. Depth of the water.

b. Cuttings build-up in the flowline.

c. Faulty pit level indicator.

d. Hydrostatic Pressure.

42. You are drilling ahead on a deep-water Drill Ship and notice a kick indicator.

Which of the following could affect the flow check?

a. Rig Movement.

b. Current Mud Weight.

c. Loop current.

d. Riser Margin.

Sample Supervisor-Level Questions, Rev. 0 12 March 2015

IADC’s Well Control Training & Assessment

43. What is the reason for having Well Control Drills?

a. To train crewmembers in their responsibilities during a kick in a

safe and efficient manner.

b. To meet Governmental regulations and policies surrounding

operations of well control.

c. To train crew members to be able to have the fastest documented

times to close in a well.

d. To train crewmembers to remember that something could happen

at any time.

44. Which of the following statements is a good operating practice in a top-hole

section that has the risk of gas bearing formations?

a. Control drill.

b. Maintain high ROP to finish the risky section as quickly as possible.

c. Regularly pump light sweeps.

d. Never use a drill pipe float.

45. A 9 5/8” pilot hole is being drilled, without a Riser, from a floating rig during

the top-hole section of the well.

Well data:

Well depth 1500’

Water depth 975’

Air gap 75’

Sea water weight 8.6 ppg

Annular Pressure Loss while drilling 25 psi

At 1500’, a shallow gas formation is encountered. The estimated pore

pressure in this formation is 650 psi. Which statement best describes the

situation?

a. The well is overbalanced even if the pumps are shut down.

b. It is impossible to control the well without marine riser installed.

c. The gas will enter the well because it is already underbalanced.

d. The well is overbalanced as long as the pumps are running at

drilling speed.

46. What data is very important to know if you have a Shear Ram in your BOP

Stack?

a. Volume to fully close on an open well

b. Opening pressure

c. Size and strength of tubulars the ram can shear

d. Hang-off weight

Sample Supervisor-Level Questions, Rev. 0 13 March 2015

IADC’s Well Control Training & Assessment

47. You are running a slick non-shearable tool in the hole and the well flows

when the tool is across the BOP stack. What is the quickest action the Driller

can take to shut in the well?

a. Make up safety valve in string and close the Annular.

b. Pick up a joint or stand of shearable pipe.

c. Drop the string in the hole.

d. Start circulating to use ECD to stop the kick.

48. You are running casing with a float assembly. Casing is across the BOP and at

the rotary. An influx is detected. Which of the following shut-in procedures

should you follow?

a. Close annular, install casing swage, open choke valve on BOP.

b. Install casing swage, open choke valve on BOP, close annular.

c. Close blind shears, install casing swage, open choke valve on BOP.

d. Install casing swage, close Variable bore rams, open choke valve on

BOP.

49. Well has been shut-in on a kick.

Shut-in drill pipe pressure is : 400 psi

Shut-in casing pressure is : 600 psi

Both pressures start rising due to gas migration. If drill pipe pressure is held

constant at 400 psi, what will happen to the bottom hole pressure?

a. Increase

b. Decrease

c. Stay the same

50. You have taken a kick but the mud engineer informs you that there is not

enough barite to kill the well. The shut in pressures have stabilized. While

waiting on new stocks of barite the shut in pressures are slowly increasing by

100 psi every 30 minutes. What course of action would you take?

a. Bullhead with current mud weight to push gas formation fluids

back into the formation.

b. Use the first circulation of the Drillers method.

c. Increase mud weight as much as possible and circulate to the Bit to

reduce SIDPP.

d. Bleed of mud by holding Casing pressure constant at SICP.

Sample Supervisor-Level Questions, Rev. 0 14 March 2015

IADC’s Well Control Training & Assessment

51. Mud that remains static in the choke and/or kill lines of a deepwater subsea

stack may have an effect on shut-in pressure readings.

What statement best describes what could happen if the mud remains static?

a. The higher gel strength at depth may cause the surface pressure to

be lower than it should be.

b. The lower gel strength at depth may cause the surface pressures to

be lower than it should be.

c. Gel strength has no effect on shut-in pressure - only mud density

has an effect.

52. A well is shut in with the bit 100’ off bottom and the influx is calculated to be

on-bottom. SIDPP is 250 psi. What would be the expected SICP?

a. Higher than SIDPP

b. The same as SIDPP

c. Lower than SIDPP

53. Which of the following parameters affect the value of Shut In Casing Pressure

after a well is shut in during a kick?

a. The formation fluid pressure (pore pressure).

b. Slow Circulating Rate Pressure.

c. Choke line length.

d. Drill string capacity per foot.

54. What is “Shut In Drill Pipe Pressure (SIDPP)”?

a. The formation fluid pressure.

b. The mud hydrostatic pressure in the drill string.

c. The pressure underbalance in the drill string.

d. The pressure on the annulus.

55. You shut in a well on a kick with the bit on-bottom. Which pressure gauge

reading do you use to calculate the formation pressure?

a. The drill pipe pressure gauge on the choke panel.

b. The casing pressure gauge on the choke panel.

c. The drill pipe pressure gauge on the Driller’s panel.

d. The choke manifold pressure gauge.

Sample Supervisor-Level Questions, Rev. 0 15 March 2015

IADC’s Well Control Training & Assessment

56. A well is shut in on a kick and the shut-in pressures on the gauges have

stabilized. The SIDPP reads 350 psi and the SICP reads 900 psi. What is

happening in the u-tube?

a. Not balanced; bottom hole pressure (BHP) on the annular side is

higher than on the drill pipe side of the U-tube.

b. Not balanced due to contamination by well fluids.

c. The U-tube is balanced.

d. The well is not completely full of mud and there is more bottom

hole pressure on the drill pipe side of the U-tube.

57. A well is shut in after taking a 25 bbl kick with 300 psi SIDPP and 650 psi

SICP. If the well had been shut in on a 10 bbl kick, how would shut in

pressure be affected?

a. SIDPP would be lower.

b. SICP would be higher.

c. SICP would be the same.

d. SIDPP would be the same.

58. Part of the way through the 1st Circulation of the Driller’s Method, the pump

was shut down and the well was shut in. What is the overbalance in the well?

Well Information:

Current SIDPP = 625 psi

Current SICP = 975 psi

Initial Circulating Pressure = 1420 psi

Initial SIDPP = 600 psi

Initial SICP = 835 psi

a. 795 psi overbalanced

b. 25 psi overbalanced

c. 140 psi overbalanced

d. 445 psi overbalanced

59. During the second circulation of the Drillers method the pump is shut down

when kill mud weight has been circulated to the bit.

What should the casing pressure read?

a. The difference in hydrostatic pressure between KWM and OMW

plus SICP.

b. Original SICP.

c. Original SIDPP.

d. The difference in hydrostatic pressure between KWM and OMW

minus SICP.

Sample Supervisor-Level Questions, Rev. 0 16 March 2015

IADC’s Well Control Training & Assessment

60. You are on a floating rig. You have just attempted to shut the well in on drill

pipe using the upper annular. You have lined the Riser up on the trip tank

and are showing a slow gain and your shut-in pressures are not stabilizing.

What action should be taken next?

a. Call the Derrickman to go check the trip tank valves for leaks.

b. None, it is the mud relaxing from the temperature differential.

c. Call the mechanic to check the gauges on the choke panel.

d. Close another BOP element and monitor trip tank and pressures.

61. What is a kill plan?

a. Document stating duties, procedures, lines of communication and

safety requirements.

b. Document stating kill method to use and barite stock levels.

c. A completed Kill Sheet.

d. Final report to town on the completed kill operation with updated

chemical stock levels.

62. What is the danger of adding the safety-margin to the mud weight?

a. Cannot be removed easily if pressure gets close to MAASP.

b. Increases MAASP at the shoe.

c. Reduces actual ICP below calculated value.

d. Drill pipe pressure is harder to control with the choke.

63. You have shut-in on a well and are planning a kill operation. The Mud

Engineer estimates it will take 3200 sacks of barite to weight up the fluid

system to kill weight. The rig has 3000 sacks of barite onsite and more will

not arrive for 3 days.

Shut in pressures have increased since the well was shut in indicating gas

migration. The shoe strength is a concern if pressures continue to build.

Which Kill Method would be the best to implement?

a. Drillers Method of Well Control.

b. Wait-and-Weight Method of Well Control.

c. Begin to Lubricate and Bleed.

d. Kill the well with Reverse Circulation.

Sample Supervisor-Level Questions, Rev. 0 17 March 2015

IADC’s Well Control Training & Assessment

64. Which of the following is the most important reason for good handover

procedures between crews during Well Control Operations?

a. Ensure continuity in operations and pass on trend information to

identify potential problems.

b. To allow blame to be assigned in the event of an incident during

well kill operations.

c. It is a regulatory form that must be completed and turned into the

local regulatory agency.

d. Handover procedures are not considered important during well

control operations.

65. You are successfully conducting the first circulation of the Drillers method.

Drill pipe pressure has been maintained at Initial Circulating Pressure of 560

psi. Choke pressure has been holding around 460psi for the last 15 minutes.

You notice a sudden spike in Drill pipe pressure to 698 psi. Choke pressure

stays the same at 460 psi.

What type of problem has most likely occurred?

a. You have a washout in the drill pipe.

b. The choke is plugging up.

c. A bit nozzle has washed out.

d. A bit nozzle has plugged.

66. How do you recognize a choke washout?

a. The drill pipe and casing pressures both fall even though you are

closing the choke.

b. There is an increase in casing pressure with no change in the drill

pipe pressure.

c. There is a rapid rise in the drill pipe pressure with no change in

the casing pressure.

d. The drill pipe and casing pressures both rise even though you

closed the choke.

67. A leaking BOP element is identified as a risk to well integrity during a kill

operation. What action would you take to minimize this risk?

a. Monitor mud level above the BOPs on the trip tank.

b. Increase closing pressure to maximum value.

c. Monitor active pit levels for mud level increases.

d. Place BOP 4-way valve in Neutral position.

Sample Supervisor-Level Questions, Rev. 0 18 March 2015

IADC’s Well Control Training & Assessment

68. You are circulating out a kick in a deep well and the casing pressure

approaches the MAASP while the influx is still in the open hole. What is the

first thing you must do?

a. Minimize any extra pressure in the annulus without allowing the

bottom hole pressure to fall below the pore pressure.

b. Keep the casing pressure at the MAASP by opening the choke.

c. Start pumping mud down the drill string at 1 ppg higher than you

need to kill.

d. Continue pumping at the same SPM. The MAASP is only a problem

when the influx is inside casing.

69. A bit nozzle plugs during the execution of the Wait and Weight method.

What is the correct response?

a. Note the increase in drill pipe pressure. Recalculate SCR pressure,

FCP, and the drill pipe pressure schedule.

b. Add the increase in DPP to each value on the drill pipe pressure

schedule and continue circulating.

c. Open the choke to hold drill pipe pressure constant.

d. Continue to follow the drill pipe pressure schedule with no

modification.

70. A gas kick is being circulated out using the Wait and Weight Method.

What will happen to the bottom hole pressure on this subsea stack if SPM is

increased while holding casing pressure constant? (Ignore pressure losses in

the annulus).

a. Stay the same.

b. Increase.

c. Decrease.

71. A kick is being circulated out at 30 SPM and the Final Circulating Pressure is

650 psi.

What will happen to bottom hole pressure if the pump speed is increased

to 35 SPM while holding drill pipe pressure at 650 psi?

a. It will decrease.

b. It will stay the same.

c. It will increase.

72. During a well kill, Kill Mud is pumped to the bit while holding drill pipe

pressure constant. What is the effect on Bottom Hole Pressure?

a. Increase.

b. Decrease.

c. Stay the same.

Sample Supervisor-Level Questions, Rev. 0 19 March 2015

IADC’s Well Control Training & Assessment

73. On the kill sheet why do we calculate the volume of open hole from the bit up

to the shoe?

a. It is useful for calculating how much gas expansion will occur.

b. It is part of the exercise to calculate volumes of the stage in the

annulus.

c. This is used to estimate the maximum casing pressure.

d. To know when the influx has entered the casing.

74. You have shut in on a kick and completed the first circulation of the Drillers

Method. Pumps were shut down and well closed, while waiting to start up the

second circulation. The following was documented:

Shut In Drill Pipe Shut in Casing (SICP)

(SIDPP)

Original Shut in 260 psi 320 psi

Pressure

After First Circulation 285 psi 285 psi

What can be determined by this?

a. Nothing, the Kill Weight Mud (KWM) hasn’t been pumped yet, so

the well isn’t killed.

b. There is still a kick in the well, providing less hydrostatics on the

annulus side of the well.

c. There is trapped pressure that can be kept as a safety margin or

bled off upon startup.

d. Kill Weight Mud is causing a U-tube effect between the Drill String

and the Annulus.

75. During the 2nd Circulation of the Driller’s Method on a subsea BOP stack,

KWM is approximately half way up the choke line. The choke operator is

unable to hold DPP constant at the FCP because the choke is 100% open.

What happens to the BHP as you continue to pump KWM?

a. Increase.

b. Decrease.

c. No change.

Sample Supervisor-Level Questions, Rev. 0 20 March 2015

IADC’s Well Control Training & Assessment

76. A shut-in well is about to be killed with a floating rig. Choke line friction is

high. Using the information below, what will be the effect on bottom hole

pressure after start-up?

Well Information

SIDPP = 180 psi

SICP = 210 psi

SCR at 30 SPM = 240 psi

Choke Line Friction = 410 psi

a. 420 psi increase.

b. 450 psi decrease.

c. 200 psi increase.

d. Bottom hole pressure will stay the same.

77. What is the main principle of circulating out a kick?

a. To maintain a bottom hole pressure at least equal to the formation

pressure.

b. To have an overbalance pressure as close to the fracture pressure

as possible.

c. To use the highest pump rate possible.

d. To reverse circulate to remove the influx faster.

78. The Driller's Method is used to circulate out a salt-water influx. What will

happen to the casing pressure as the influx moves up the annulus?

a. Casing pressure will slowly decrease as influx moves up the

annulus.

b. Salt water will behave in the same way as a gas influx.

c. As influx expands Casing Pressure will increase.

d. Casing pressure will only change due to changes in annular size.

79. Which of the following statements is true for a subsea BOP operation?

a. The surface line volume (pump to Rig Floor) does not need to be

considered when starting the kill.

b. Bring pumps up to speed holding the casing pressure constant.

c. Maintain the drill pipe pressure constant when bringing the pumps

up to kill speed.

d. Bring pumps up to speed adjusting static casing pressure to

dynamic casing pressure.

Sample Supervisor-Level Questions, Rev. 0 21 March 2015

IADC’s Well Control Training & Assessment

80. What is the objective of the 1st Circulation of the Driller’s Method?

a. Circulate out the influx using original mud weight.

b. Displace the drill string and annulus with kill weight mud.

c. Circulate out the influx while displacing the drill string and

annulus with kill weight mud.

81. What can be done to reduce the effects of high choke line friction when killing

a well?

a. Use the Driller’s method.

b. Use a fast pump rate.

c. Take returns up both choke and kill lines.

d. Dump all returns directly overboard.

82. During the Wait and Weight procedure, how do you control bottom hole

pressure once Kill Weight Mud (KWM) is in the annulus?

a. Hold casing pressure constant.

b. Follow a casing pressure schedule.

c. Hold drill pipe pressure constant at FCP.

d. Follow a drill pipe pressure schedule.

83. Based on the information below, what will happen to casing shoe pressure if

the Wait and Weight method is used instead to the Drillers Method?

Well Information

Hole Depth – 10,000 feet.

Shoe Depth – 8,830 feet

Surface to Bit Strokes – 1,630 strokes

Bit to Shoe Strokes – 1,300 strokes

Bit to Surface Strokes – 6,480 strokes

SIDPP – 500 psi

SICP – 800 psi

Current fluid weight – 10.3 ppg

Kill Fluid Density – 11.3 ppg

MAASP – 1300 psi

Pit Gain – 28 bbl

a. Shoe pressure will be higher.

b. Shoe pressure will be lower.

c. Shoe pressure will be the same.

Sample Supervisor-Level Questions, Rev. 0 22 March 2015

IADC’s Well Control Training & Assessment

84. Well Data:

Hole Dimensions

Depth (TVD) 12,090 feet

9 5/8" Casing shoe 8,800 feet

Hole size 8½ inch

Current mud weight 13.5 ppg

Internal Capacities

6 1/2" Drill collars (length 900 feet) 0.00768 bbl/foot

5" Drill pipe - capacity 0.01776 bbl/foot

5" Drill pipe - metal displacement 0.00650 bbl/foot

5" Drill pipe- closed end displacement 0.02426 bbl/foot

Annular Capacities

Open hole / Drill collar 0.0292 bbl/foot

Open hole / Drill pipe 0.0459 bbl/foot

Casing / Drill pipe 0.0505 bbl/foot

LOT

Mud weight 12 ppg

Leak off pressure 2700 psi

Pump Details

Pump Output 0.109 bbl/stk

SCR at 40 SPM 550 psi

Shut in data

SIDPP 200 psi

SICP 600 psi

Pit gain 15 bbls

Calculate:

1. Maximum allowable mud weight before ppg

kick

2. MAASP before kick psi

3. Strokes from surface to bit strokes

4. Kill mud weight ppg

5. Initial circulating pressure psi

6. Final circulating pressure psi

7. MAASP after well has been killed psi

8. Pressure drop per one-tenth of strokes psi/10th

to Bit increment

Sample Supervisor-Level Questions, Rev. 0 23 March 2015

IADC’s Well Control Training & Assessment

85. Well Data:

Hole Dimensions

Depth (TVD) 12,090 feet

9 5/8" Casing shoe 8,800 feet

Hole size 8½ inch

Current mud weight 13.5 ppg

Air gap 80 feet

Water depth 740 feet

Internal Capacities

6 ½ " Drill collars (length 900 feet) 0.00768 bbl/foot

5" Drill pipe - capacity 0.01776 bbl/foot

5" Drill pipe - metal displacement 0.00650 bbl/foot

5" Drill pipe- closed end displacement 0.02426 bbl/foot

Choke line 0.006 bbl/foot

Marine riser 0.39 bbl/foot

Annular Capacities

Open hole / Drill collar 0.0292 bbl/foot

Open hole / Drill pipe 0.0459 bbl/foot

Casing / Drill pipe 0.0505 bbl/foot

LOT

Mud weight 12 ppg

Leak off pressure 2700 psi

Pump Details

Pump output 0.109 bbl/stk

SCR (riser) at 40 SPM 550 psi

SCR (choke line) at 40 SPM 850 psi

Shut in data

SIDPP 200 psi

SICP 600 psi

Pit gain 15 bbls

See questions on next page.

Sample Supervisor-Level Questions, Rev. 0 24 March 2015

IADC’s Well Control Training & Assessment

Questions:

1. Maximum allowable mud weight prior to ppg

kick

2. MAASP prior to kick psi

3. Strokes from surface to bit strokes

4. Strokes to displace choke line ppg

5. Kill mud weight psi

6. Initial circulating pressure psi

7. Final circulating pressure psi

8. Dynamic casing pressure after pump psi

start-up

9. MAASP after well has been killed psi

10. Pressure drop per one-tenth of strokes to psi/10th

Bit increment

86. A well is shut-in with stabilized Shut-in Casing Pressure (SICP) of 500psi and

0psi on the Drillpipe gauge. To obtain the Shut-in Drillpipe Pressure (SIDPP),

the Driller pumped at 5 strokes per minute until float was bumped and

pump shut down. The gauges are now reading the pressures shown..

What is the actual Shut-in Drillpipe Pressure?

a. 360 psi

b. 500 psi

c. 580 psi

d. 280 psi

Sample Supervisor-Level Questions, Rev. 0 25 March 2015

IADC’s Well Control Training & Assessment

87. When starting a kill operation on a Jack Up, the choke pressure is kept constant

whilst bringing the pump up to speed. The drill pipe gauge reads 150 psi higher

than the calculated Initial Circulating Pressure (ICP).

What is the correct action to take?

a. There will now be 150 psi overbalance on the bottom. Nothing

needs to be done.

b. Continue to circulate with the new ICP and adjust the drill pipe

pressure graph.

c. Open the choke and let the standpipe pressure drop to the

calculated value (ICP).

d. Decrease pump speed to reduce pump pressure by 150 psi.

88. You have just brought pumps up to kill speed on a floating rig. (The choke

line friction is 250 psi.)

How much overbalance is on the well?

a. 250 psi

b. 350 psi

c. None

d. 100 psi

Sample Supervisor-Level Questions, Rev. 0 26 March 2015

IADC’s Well Control Training & Assessment

89. Kill mud is returning at the end of a kill operation on a surface stack rig. The

well is shut down but drillpipe and casing show 100psi on the gauges. How

would you determine if the extra pressure is ‘trapped’ pressure?

a. Bleed off 50 psi at the choke then monitor pressure to see if it is

static or builds back up to 100psi.

b. Bleed off 100 psi, open up the well and check for flow.

c. Start circulating surface to bit strokes then shut down and re-

check the pressures.

d. Increase mud weight by equivalent of 100psi and circulate around

the well.

90. During a trip out, the well kicks due to swabbing. The pipe is stripped back to

bottom. What mud weight will control the well?

a. The original mud weight.

b. Kill Mud weight based on SIDPP before stripping.

c. Kill Mud weight based on SICP before stripping.

d. Kill Mud weight based on difference between SIDPP and SICP

before stripping.

91. What is the objective of the Volumetric Method?

a. Reduce surface pressure by removing mud.

b. Reduce surface casing pressure by increasing hydrostatic pressure

in the annulus.

c. Allow gas to migrate and expand to surface while allowing an

increase in casing pressure to compensate for gas expansion.

92. When stripping to bottom, which of the following actions should be taken?

a. Bleed off a volume of mud equal to 100 psi of hydrostatic head.

b. Bleed off a volume of mud equal to the closed end displacement of

the pipe stripped into the well.

c. Bleed off a volume of mud equal to the metal displacement of the

pipe stripped into the well.

d. Bleed off a volume of mud equal to the open-end displacement of

the pipe stripped into the well.

93. What are the key elements of Bullheading?

a. Pumping into a shut-in well to force formation fluids back into the

formation.

b. Forcing pipe into a hole under pressure using hydraulic jacks.

c. Circulating formation fluids out of a well using a choke and

circulating system.

d. Pumping fluid into the top of a well and bleeding gas in a step by

step fashion.

Sample Supervisor-Level Questions, Rev. 0 27 March 2015

You might also like

- 10 - WellSharp Study Guide - Pre - Course - Rev 1Document6 pages10 - WellSharp Study Guide - Pre - Course - Rev 1mjm_1365No ratings yet

- IADC Wellsharp HomeworkDocument13 pagesIADC Wellsharp HomeworkalloriadNo ratings yet

- ADC WellSharp Supervisor Homework Exercises Final Revised 08 Oct 2015 PDFDocument118 pagesADC WellSharp Supervisor Homework Exercises Final Revised 08 Oct 2015 PDFصالح100% (4)

- 03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseDocument5 pages03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseAdolfo AnguloNo ratings yet

- AC-0018 Practical Assessor HandbookDocument24 pagesAC-0018 Practical Assessor HandbookRichard ReiersenNo ratings yet

- Driller Test With Answers PDFDocument26 pagesDriller Test With Answers PDFArpan Biswas100% (2)

- 02 - WellSharp Drilling Supervisor - Day 1 Pre - CourseDocument5 pages02 - WellSharp Drilling Supervisor - Day 1 Pre - CourseAdolfo Angulo100% (1)

- Electric: Circuit Problems With SolutionsDocument73 pagesElectric: Circuit Problems With Solutionspassed outNo ratings yet

- Iwcf Q&aDocument91 pagesIwcf Q&aKhaled AdelNo ratings yet

- Model MH 70: Hydraulic Piston Actuator Operation and Maintenance ManualDocument35 pagesModel MH 70: Hydraulic Piston Actuator Operation and Maintenance ManualAhmed Ousama100% (3)

- IWCF Test 2 With Answers: Driller'S Technical HandbookDocument25 pagesIWCF Test 2 With Answers: Driller'S Technical HandbookBeni N Solo75% (4)

- 05 - WellSharp Workover and Completion - Day 4 Pre - Course PDFDocument6 pages05 - WellSharp Workover and Completion - Day 4 Pre - Course PDFMarkus Landington100% (1)

- IWCF Set 1 - 6Document33 pagesIWCF Set 1 - 6Jeneesh Shanmughan100% (1)

- Exercise 3 AnswersDocument13 pagesExercise 3 AnswersadeelsnNo ratings yet

- Assignment Final)Document19 pagesAssignment Final)Pinkesh ShahNo ratings yet

- 2well Control - ExerciseDocument153 pages2well Control - ExerciseMostafa ElghifaryNo ratings yet

- Drilling Well Control Syllabus Level 3 and 4Document3 pagesDrilling Well Control Syllabus Level 3 and 4SahatnainggolanNo ratings yet

- Hse Plan Phe Onwj Pt. Pentraco Karya AdiprestasiDocument39 pagesHse Plan Phe Onwj Pt. Pentraco Karya AdiprestasiShe DoelsNo ratings yet

- Numerical Solution of Partial Differential Equations Solution ManualDocument84 pagesNumerical Solution of Partial Differential Equations Solution ManualGui San100% (1)

- API 650-Annex PDocument8 pagesAPI 650-Annex PSachinNo ratings yet

- Know Energy - P&P Test 2 With AnswersDocument21 pagesKnow Energy - P&P Test 2 With AnswerssyazwanNo ratings yet

- P and P 1 To 5 Quiz and AnswDocument19 pagesP and P 1 To 5 Quiz and AnswJeneesh Shanmughan100% (1)

- Last P and P Driller Excercis 2022Document78 pagesLast P and P Driller Excercis 2022Naresh Regulagadda100% (1)

- Chevron: Wellcap Plus Practice Test Surface/SubseaDocument15 pagesChevron: Wellcap Plus Practice Test Surface/SubseaBoedi Syafiq100% (1)

- Workover 1 Soal - 8 APR21.revDocument17 pagesWorkover 1 Soal - 8 APR21.revputujuliandikaNo ratings yet

- 18 - IWCF Homework Answers Day 1 - 1blank PDFDocument61 pages18 - IWCF Homework Answers Day 1 - 1blank PDFKenaouia BahaaNo ratings yet

- Oil Well Kicks Questions and Answers Part1Document7 pagesOil Well Kicks Questions and Answers Part1Rizwan FaridNo ratings yet

- Test P&PDocument13 pagesTest P&PMuhammad Ali0% (1)

- IADC 77 DRILLING Pretest 2 (Without A)Document15 pagesIADC 77 DRILLING Pretest 2 (Without A)Ariq Dicky100% (3)

- Iadc Drilling 1.10.20. - (77) W.outDocument14 pagesIadc Drilling 1.10.20. - (77) W.outsendi100% (1)

- Drillers CourseDocument92 pagesDrillers CourseAdel Hankour100% (1)

- P and P Quiz 1 at 2Document30 pagesP and P Quiz 1 at 2Jeneesh ShanmughanNo ratings yet

- Faizan Naikwadi PA 12 IWCF L3 & 4 Day 1 HomeworkDocument16 pagesFaizan Naikwadi PA 12 IWCF L3 & 4 Day 1 Homeworkparesh pawarNo ratings yet

- ET Question Bank 2020Document32 pagesET Question Bank 2020Manash Hazarika100% (1)

- Iwcf l3 4 PDFDocument2 pagesIwcf l3 4 PDFBENMAAMER AZOUAOU100% (1)

- IWCF Comb. Supv Equip. 02Document24 pagesIWCF Comb. Supv Equip. 02andrzema100% (3)

- IWCF Comb. Driller Equip. 01Document21 pagesIWCF Comb. Driller Equip. 01andrzema67% (3)

- IWCF ProblemsDocument21 pagesIWCF ProblemsTamlom100% (1)

- IWCF Surf. Equip Supv. 01Document23 pagesIWCF Surf. Equip Supv. 01andrzemaNo ratings yet

- P and P (EDC) PDFDocument62 pagesP and P (EDC) PDFAli mohammad50% (2)

- Assignment Co OperationsDocument20 pagesAssignment Co Operationsyasirism100% (2)

- Well Control ExerciseمهمDocument133 pagesWell Control ExerciseمهمAsad babil BabilNo ratings yet

- Surface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedDocument22 pagesSurface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedandrzemaNo ratings yet

- P & P AnswerDocument143 pagesP & P AnswerOmerNo ratings yet

- Driller Module Workbook 4 Sedco Forex Modular Training ProgramDocument3 pagesDriller Module Workbook 4 Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- Iwcf Exercise STC 1Document149 pagesIwcf Exercise STC 1ali jabbar100% (1)

- 27 - Iwcf Ss Sample Questions - AnswersDocument9 pages27 - Iwcf Ss Sample Questions - Answersshoaib Khalil100% (1)

- IWCF Comb. Supv Equip. 01Document25 pagesIWCF Comb. Supv Equip. 01andrzema100% (3)

- Well Control Questions and Answers Part 2Document8 pagesWell Control Questions and Answers Part 2Rizwan FaridNo ratings yet

- 23 - IWCF SO Sample QuestionsDocument6 pages23 - IWCF SO Sample QuestionsRichard ReiersenNo ratings yet

- EX-0035 Drilling - English API Forumla SheetDocument4 pagesEX-0035 Drilling - English API Forumla Sheetmohamed abbasNo ratings yet

- Equ Mock Test 1 Rev 1.5Document27 pagesEqu Mock Test 1 Rev 1.5Hany ZayedNo ratings yet

- P&Pof Intervention Pressure ControlDocument69 pagesP&Pof Intervention Pressure ControlRajat Khanna100% (4)

- Well Control Course Workbook 2001 Q1 PDFDocument96 pagesWell Control Course Workbook 2001 Q1 PDFdvbnjfdNo ratings yet

- Combined Driller Equipment Paper NO. 2.: All Questions Require Only ONE Answer Unless Otherwise StatedDocument23 pagesCombined Driller Equipment Paper NO. 2.: All Questions Require Only ONE Answer Unless Otherwise Statedandrzema100% (2)

- 5 Pressure Basics Problems, PROBLEMS 1-6Document31 pages5 Pressure Basics Problems, PROBLEMS 1-6Raul Dolo Quinones100% (1)

- Questions WellcontrolDocument10 pagesQuestions WellcontrolZ Babar KhanNo ratings yet

- Exercise Section - 1complDocument8 pagesExercise Section - 1complOperator Genggam100% (2)

- IADC Formula Sheet: X X X + + ÷ X + X - ÷ XDocument5 pagesIADC Formula Sheet: X X X + + ÷ X + X - ÷ XMarwa ElghifaryNo ratings yet

- Driller Workbook3Document4 pagesDriller Workbook3Kaleem UllahNo ratings yet

- Well Intervention QuizDocument4 pagesWell Intervention QuizAkol Majook50% (2)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- WellsafeDocument34 pagesWellsafeHendra Jurbon0% (1)

- Supervisor Extra Questions SolvedDocument5 pagesSupervisor Extra Questions Solvedhamdi1000No ratings yet

- Microsoft Word - Exercise 1Document27 pagesMicrosoft Word - Exercise 1KRNo ratings yet

- FORM - Sand Control Treatment - Check - ListDocument2 pagesFORM - Sand Control Treatment - Check - ListShe DoelsNo ratings yet

- Safety & Equipment List 19 Jan 2022Document1 pageSafety & Equipment List 19 Jan 2022She DoelsNo ratings yet

- Procedure Safety Objective & TargetDocument8 pagesProcedure Safety Objective & TargetShe DoelsNo ratings yet

- No. Batch Time Start Time Finish Polymer P090 (KG) Concentration (PPM) Viscosity (CP) Injection Rate (BPM)Document2 pagesNo. Batch Time Start Time Finish Polymer P090 (KG) Concentration (PPM) Viscosity (CP) Injection Rate (BPM)She DoelsNo ratings yet

- Procedure Management of ChangeDocument6 pagesProcedure Management of ChangeShe DoelsNo ratings yet

- JSA SC Treatment Injection SupervisionDocument3 pagesJSA SC Treatment Injection SupervisionShe DoelsNo ratings yet

- Spirits Analysis and Differentiated ACECESDocument5 pagesSpirits Analysis and Differentiated ACECEShoseatyourmamaNo ratings yet

- (Denise Eileen McCoskey, Emily Zakin) Bound by TheDocument356 pages(Denise Eileen McCoskey, Emily Zakin) Bound by TheZenia YébenesNo ratings yet

- PrabhatCables Listprice ConsolidatedDocument4 pagesPrabhatCables Listprice ConsolidatedPower RoboticsNo ratings yet

- Record R 62: Security Interlock As Access Control SystemDocument5 pagesRecord R 62: Security Interlock As Access Control SystemgerglendiazNo ratings yet

- Leadershipdevelopment BR DdiDocument12 pagesLeadershipdevelopment BR DdihrahmayadiNo ratings yet

- F172N&P POH Thielert Aircraft SystemsDocument114 pagesF172N&P POH Thielert Aircraft SystemsJuvet Baluyot BigcasNo ratings yet

- Leave Scheduler SystemDocument42 pagesLeave Scheduler SystemOkunade OluwafemiNo ratings yet

- STD 9 CH 4 Climate PDFDocument104 pagesSTD 9 CH 4 Climate PDFTushar VazeNo ratings yet

- ASME PTC 30-1991 Air Cooled Heat ExchangersDocument19 pagesASME PTC 30-1991 Air Cooled Heat ExchangersShanNo ratings yet

- K Ali EntpDocument2 pagesK Ali Entpanim singhNo ratings yet

- Checklist For Diamond DA62: Comments Explaining Edition # 1.2Document18 pagesChecklist For Diamond DA62: Comments Explaining Edition # 1.2DJ Douglas100% (1)

- 295-Article Text-2269-1-10-20210624Document7 pages295-Article Text-2269-1-10-20210624Rahmat AlfajriNo ratings yet

- Fosroc - Nitocote PE 135Document8 pagesFosroc - Nitocote PE 135guru sathya bharathyNo ratings yet

- Gráfico de Operação XCMG 110tonDocument25 pagesGráfico de Operação XCMG 110tonRENATO SVANCHEVCNo ratings yet

- Mae 5310: Combustion Fundamentals: Laminar Premixed Flames Example, Applications and CommentsDocument22 pagesMae 5310: Combustion Fundamentals: Laminar Premixed Flames Example, Applications and CommentsAlex KeaneNo ratings yet

- Children'S Hour Philippines, Inc. Project Proposal Template 1. Project TitleDocument7 pagesChildren'S Hour Philippines, Inc. Project Proposal Template 1. Project TitleHani RedobladoNo ratings yet

- HD Retrovision - TV Compatibility List 2017-12-11Document7 pagesHD Retrovision - TV Compatibility List 2017-12-11Edison Marcial Aliaga LozanoNo ratings yet

- Shallow Water Acoustic Networks Full ReportDocument26 pagesShallow Water Acoustic Networks Full ReportSimmi JoshiNo ratings yet

- Ccna Report On Project WanDocument60 pagesCcna Report On Project Wanmanoum2No ratings yet

- Ict Adding VideosDocument2 pagesIct Adding VideosShenSy100% (1)

- Ebrahim 2016Document31 pagesEbrahim 2016Afrizal DanaNo ratings yet

- Remotesensing 14 03908Document17 pagesRemotesensing 14 03908Tekletsadik TeketelNo ratings yet

- v16 - GE-1015 Jane's Aero Engine March 2000Document11 pagesv16 - GE-1015 Jane's Aero Engine March 2000Marcelo Roberti Rocha FantaguzziNo ratings yet

- Amt in Household and ServicesDocument25 pagesAmt in Household and ServicesShabby Gay TroganiNo ratings yet

- Exalco Albio 102 Curtain Wall SystemsDocument92 pagesExalco Albio 102 Curtain Wall SystemsAdmir MatoshiNo ratings yet