Professional Documents

Culture Documents

Rexson Sh0910: Bond Protect Beautify

Rexson Sh0910: Bond Protect Beautify

Uploaded by

José Ángel Pérez OrtegaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rexson Sh0910: Bond Protect Beautify

Rexson Sh0910: Bond Protect Beautify

Uploaded by

José Ángel Pérez OrtegaCopyright:

Available Formats

Bond Protect Beautify

www.sames-kremlin.com

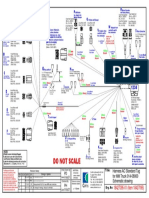

Equipment REXSON SH0910

REXSH0910-MO-MA-FO-SE Motor (MO) Material (MA) Foot (FO) Sealing (SE) Model

Shovel Pump

● Motor choices (Pressure ratio) MO=?

- Motor 7000 (18:1) 70 MO=72

- Motor 9000 (30:1) 90 MO=92

● Lower Material selection MA=?

- Mixed Materials CS MA=CS

- Stainless Steel SS MA=SS High Viscosity / Pumps

● Foot selection FO=?

- Follower plate (Ø=105mm) FP FO=FP

- Plain Cylinder PC FO=PC

● Seal package selection SE=?

- PTFE - Polytetrafluorothylene (Teflon like properties) 01 SE=01

- PTFE + FEP (Encapsulated O-Ring: Teflon like properties over Viton or Silicone) 02 SE=02

- PE - Polyethene (UHMWPE) 03 SE=03

- Leather 04 SE=04

- PTFEG (PTFE + Graphite compound) 05 SE=05

- PU (Polyurethane) 06 SE=06

- PTFEV (PTFE + Glass compound) 07 SE=07

- PEHD (UV ink) 08 SE=08

Accessories

Description Part number

Flat Seal Follower Plate for 200L Drums -Ø 571 (pump foot Ø105) 151519001

Double O-Ring Follower Plate for 200L drum -Ø 571 (pump foot Ø105) 1055170001

Double O-Ring PTFE-Coated Follower Plate for 200L drum -Ø 571 (pump foot Ø105) 1057370001

Double column elevator for 200 L. drums (not available in NA/China) 151090500

PUMPING BEYOND POSSIBLE.

1000 L. and 300 G. Follower plates (please contact us) ♦

Robust and reliable

Simple to maintain

Configurable and versatile

AUTOMOTIVE AGRICULTURAL CONSTRUCTION INDUSTRIAL

Markets

TRANSPORTATION

13 chemin de Malacher - CS 70086

38243 MEYLAN Cedex - FRANCE

Apply your Skills

Phone: +33 (0)4 76 41 60 60 - Fax: +33 (0)4 76 41 60 90

Airless® is a registered trademark : FR n ° 1 222 301

www.sames-kremlin.com

202109 - (NA 999.600.451) SAMES KREMLIN reserves the right to modify its equipment or specifications without further notice. Document, products and pictures shown are not contractual.

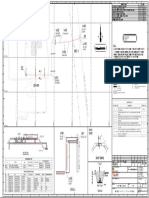

REXSON SH0910

Shovel Pump

Technologies

This High Viscosity Shovel Pump is for high pressure

applications. Used with Airless®, extrusion and filling

applications requiring high flow rates with a large

size footprint and long stroke.

Chevron Sealing Chop Check Switch Motor Cup Lub Triple Chrome Layer

The REXSON pumps of the high viscosity range have been designed with robustness in mind, and

the aim of offering a high degree of modularity to follow your application. Unlike liquid fluid

pumping, the high viscosity range imposes highly variable mechanical stresses from one product to

another.

PERFORMANCE Description

Double-acting shovel pumps are specifically designed to transfer fluid with a viscosity greater than M1 Power distributor: Wide passageway for maximum airflow

50,000 Cps and operate from 25,000 Cps for products whose particular rheology makes them L1 Upper Body: The upper part of the pump is of robust

difficult to pump. These pumps include a shovel that facilitates feeding the pump inlet, allowing it construction and must be able to withstand the maximum

to move high viscosity materials. pressures.

To create your own pump that will meet your application specifications, you will have to select: L2 Upper Valve: This valve material to pass from the lower

chamber allows to the upper chamber of the pump. A conical

valve is used to reduce pressure loss.

• The correct air motor according to the maximum pressure,

L3 Lower Valve: Uses a large conical valve to reduce the

• The construction materials according to the nature of the product, pressure loss through the pump and allow easy filling.

• The foot and mounting style according to the product packaging, and your L4 Shovel : Feeds the product to pump inlet. Allows the pump to

installation dispense high visocity material.

• The Seal pack (see the Documents tab to get all necessary information on our

website). PRODUCTIVITY

Our air motors are designed for maximum airflow with a pilot distributor to allow fast inversion . They M2 The Cover: Very easy to remove and to access the repair

are equipped with a large silencer to avoid water freezing at the motor outlet and can be parts

controlled (start / stop) from a remote air control.

M3 The P ulse Output: The motor can be easily monitored

These pumps are used as feeding equipment directly from open drums installed on a elevator using thanks to an air pulse occurring at each reversal.

a follower plate. Specific pumps can be used on manifold applications. L5 Motor adaptation flange: Unique and robust assembly of the

motor shaft connection to the pump shaft. Allows quick

adaptation to different air motors to vary the pressure ratio of the

pump.

Technical data table L6 Guard: To guarantee the safety of the operators, this guard

prevents contact with the moving shaft of the pump.

L7 Lower Body: The pump lower is adapted as needed to be

Designation Value Unit: metric (US) fixed on a follower plate, immersed in a bung drum, or simply

Maximum Fluid Pressure 180 (2,600) bar (psi) threaded for connection to a manifold.

Maximum Air Pressure 6 (87) bar (psi)

Pressure Ratio (depending on air motor size)

Viscosity

18:1, 30:1

>50,000 cps SUSTAINABILITY

Maximum Temperature 80 (176) °C (°F)

Fluid Volume per Cycle

Fluid Output at 15 cycles / mn

910

13,65 (3.60)

cc

l/mn (gal/mn)

M4 Brass guiding ring: Enduring and accurate guidance system

Fluid Output at 60 cycles / mn 54,60 (14.42) l/mn (gal/mn) M5 Camshaft inversion system: Very reliable reversal system

L8 Upper seals packing: Our pump range has a wide range of

Motor Type 7200, 9200

Air Inlet 3/4"BSP(F)

seal materials to suit all your needs.

Fluid Outlet 1-1/2"BSP(F)

Weight (fluid section only) 44 (97) kg (lbs) L9 Rod and Cylinder: The piston shaft and the cylinder are

Weight (air motor only) 26-35 (57.3-77.2) kg (lbs) made of triple chrome steel to ensure excellent abrasion

Fluid Inlet (follower plate) 105mm resistance.

Air Consumption upon air motor size (see catalog) ---

Stroke 200 (7.87) mm (inch)

Bond Protect Beautify www.sames-kremlin.com

You might also like

- Din 1624Document2 pagesDin 1624avinashchauhan2695No ratings yet

- PTW 09Document2 pagesPTW 09vishnu.reddy1369No ratings yet

- Work Shop LayoutDocument1 pageWork Shop LayoutNZNo ratings yet

- 13-11-20 18427095SCH (Rev G) MM AC Tug Standard Schematic - 014-08000Document1 page13-11-20 18427095SCH (Rev G) MM AC Tug Standard Schematic - 014-08000Deivid BezerraNo ratings yet

- PTW 54Document2 pagesPTW 54vishnu.reddy1369No ratings yet

- PTW 57Document2 pagesPTW 57vishnu.reddy1369No ratings yet

- Solc SMDocument1 pageSolc SMFábio MacedoNo ratings yet

- PTW 53Document2 pagesPTW 53vishnu.reddy1369No ratings yet

- Monterrico MT BTDocument1 pageMonterrico MT BTCésar Luis Castillo ChiletNo ratings yet

- Shrouded Headers: (2.00 MM) .0787" PITCH - TSH/TMMS SERIESDocument1 pageShrouded Headers: (2.00 MM) .0787" PITCH - TSH/TMMS SERIESFábio MacedoNo ratings yet

- Free Diseno de Maquinas T5 Gulag FreeDocument12 pagesFree Diseno de Maquinas T5 Gulag FreePablo GarciaNo ratings yet

- Fault 2 Tipikal-1Document1 pageFault 2 Tipikal-1Yosep GunawanNo ratings yet

- BH Pier-04Document1 pageBH Pier-04Shamsul IslamNo ratings yet

- H-12 Tiang Lampu SorotDocument1 pageH-12 Tiang Lampu Sorotyazeed yasminNo ratings yet

- Piping Updated-4Document4 pagesPiping Updated-4karuppan2525No ratings yet

- Chemical Resistance Chart FybrocDocument22 pagesChemical Resistance Chart Fybrocshahul_2k5No ratings yet

- PTW 04Document2 pagesPTW 04vishnu.reddy1369No ratings yet

- 00250650DLDL0011T Exde00 01Document1 page00250650DLDL0011T Exde00 01Arshed Jawad Al-mansoriNo ratings yet

- PTW 05Document2 pagesPTW 05vishnu.reddy1369No ratings yet

- BH Pier-02Document1 pageBH Pier-02Shamsul IslamNo ratings yet

- Bore LogDocument8 pagesBore LogShamsul IslamNo ratings yet

- Samtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueDocument1 pageSamtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueJohn AllenNo ratings yet

- PVDF - Chemical - Resistance - ChartDocument22 pagesPVDF - Chemical - Resistance - ChartИбрагим НурмамедовNo ratings yet

- PTW 55Document2 pagesPTW 55vishnu.reddy1369No ratings yet

- Attachment 2 - Multiflo® 420EXHV Pump Performance CurveDocument1 pageAttachment 2 - Multiflo® 420EXHV Pump Performance Curveachmadj1405No ratings yet

- PTW 02Document2 pagesPTW 02vishnu.reddy1369No ratings yet

- Shop Mall MapDocument1 pageShop Mall MapNur Hani SyafiqahNo ratings yet

- Assignment2 CIVE207 W24Document10 pagesAssignment2 CIVE207 W24Andrew WatsonNo ratings yet

- Traffic Direction: Mounting Bracket TDC-MB 1Document1 pageTraffic Direction: Mounting Bracket TDC-MB 1Ryyette AguirreNo ratings yet

- APD 812549 TVRI - INDOSAT 100 Mbps PLAN 1Document4 pagesAPD 812549 TVRI - INDOSAT 100 Mbps PLAN 1BALLYNo ratings yet

- U22 Valve List 2 - April 2024 (3 Units)Document3 pagesU22 Valve List 2 - April 2024 (3 Units)Mohd Effiezool YaserNo ratings yet

- Rajasthan Engineering Admission Process - 2016: Rajasthan Technical University, Kota, RajasthanDocument15 pagesRajasthan Engineering Admission Process - 2016: Rajasthan Technical University, Kota, Rajasthanparikshit purohitNo ratings yet

- Samtec QTH QSH DatasheetDocument1 pageSamtec QTH QSH Datasheetxoveda9371No ratings yet

- 11-10-0097-06-00ae-management-frame-analysisDocument18 pages11-10-0097-06-00ae-management-frame-analysisQuỳnh HồNo ratings yet

- Purchase Indent Format - Double PageDocument2 pagesPurchase Indent Format - Double Pagedilip9388No ratings yet

- Adobe Scan 29 Nov 2022Document1 pageAdobe Scan 29 Nov 2022Devendra TyagiNo ratings yet

- FTSH SMTDocument1 pageFTSH SMTppowerpower30No ratings yet

- PTW 52Document2 pagesPTW 52vishnu.reddy1369No ratings yet

- P&id For STP PlantDocument1 pageP&id For STP PlantHardik Khetani100% (1)

- 23045-GP-TWM-GF-XP-SD-205 - MepDocument1 page23045-GP-TWM-GF-XP-SD-205 - MepArun UdayabhanuNo ratings yet

- Hydraulic Pump Tech Spec-2020Document2 pagesHydraulic Pump Tech Spec-2020TylerNo ratings yet

- GM Canopy 100123Document1 pageGM Canopy 100123Edward Jr. ChoiNo ratings yet

- TR LV & IC 132kV - PhaseDocument1 pageTR LV & IC 132kV - PhaseDhanaji WakadeNo ratings yet

- Aluminium Alloys - GDC - PDCDocument4 pagesAluminium Alloys - GDC - PDCetamil87No ratings yet

- Makro2 UASDocument12 pagesMakro2 UASAkun AnonNo ratings yet

- Alliance SLD-09 Final 2022-ModelDocument1 pageAlliance SLD-09 Final 2022-ModelskclengineeringNo ratings yet

- Sbms Omni-Rwy-05-23 Sid 20210715Document1 pageSbms Omni-Rwy-05-23 Sid 20210715CMDT MatheusNo ratings yet

- BESS Feeder - OC PhaseDocument1 pageBESS Feeder - OC PhaseTosikur RahmanNo ratings yet

- Adobe Scan Jun 21, 2024Document3 pagesAdobe Scan Jun 21, 2024Gaurav NagpalNo ratings yet

- Rajasthan Pre Engineering Test - 2013: Board of Technical Education, Rajasthan, JodhpurDocument13 pagesRajasthan Pre Engineering Test - 2013: Board of Technical Education, Rajasthan, JodhpurBraj Mohan MathurNo ratings yet

- PTW 06Document2 pagesPTW 06vishnu.reddy1369No ratings yet

- Soil Bore LogDocument5 pagesSoil Bore LogPyramidion EngineeringNo ratings yet

- BH Pier-11Document1 pageBH Pier-11Shamsul IslamNo ratings yet

- RE-PDI PPT SLIDE 06-Nov To 10-Nov-23Document3 pagesRE-PDI PPT SLIDE 06-Nov To 10-Nov-23abbas razaNo ratings yet

- PISAU DUDUK CRUSHER NO 01-KopDocument1 pagePISAU DUDUK CRUSHER NO 01-KopDhani Kurnia RamdhaniNo ratings yet

- NPP0057 SHG CP13 FS El SD BM032 - 1Document1 pageNPP0057 SHG CP13 FS El SD BM032 - 1毕文强No ratings yet

- 10 GYAN PARK TELIPHONE NAGARDocument1 page10 GYAN PARK TELIPHONE NAGARlovsinghkldNo ratings yet

- 312759en ZaaDocument82 pages312759en ZaaHòa Nguyễn NgọcNo ratings yet

- Air Motors PDFDocument6 pagesAir Motors PDFBe HappyNo ratings yet

- ARO Industrial Chain HoistsDocument20 pagesARO Industrial Chain HoistsAhmedNo ratings yet

- Lutz CatalogueDocument76 pagesLutz CatalogueRonald Acu CNo ratings yet

- Air CarDocument29 pagesAir Carwacky_me100% (1)

- New Energy Technologies Issue 20Document100 pagesNew Energy Technologies Issue 20blameitontherain9877No ratings yet

- CP - EngineAir - enDocument16 pagesCP - EngineAir - encagrouptechNo ratings yet

- Bethlahem Institute of Engineering Karungal - 629 157: Internal Assessment Test - IDocument4 pagesBethlahem Institute of Engineering Karungal - 629 157: Internal Assessment Test - ICOMMANDER ALANNo ratings yet

- Air Motors: More Than ProductivityDocument34 pagesAir Motors: More Than ProductivityAntonio Carlos AlvesNo ratings yet

- Dynamic Analysis of Compressed Air Energy Storage in The CarDocument14 pagesDynamic Analysis of Compressed Air Energy Storage in The Carlokesh_045No ratings yet

- Modec Case StudiesDocument15 pagesModec Case Studiessamah eskanderNo ratings yet

- Original Manual: Type MF3iw - DVDocument37 pagesOriginal Manual: Type MF3iw - DVSuellen Fonseca100% (1)

- 74200Document20 pages74200tyustyusNo ratings yet

- Pneumatic For BTMTDocument192 pagesPneumatic For BTMTron Joshua QuirapNo ratings yet

- Actuators and Output DevicesDocument59 pagesActuators and Output DevicesvishnusankarNo ratings yet

- OIE 751 ROBOTICS Unit 2 Class 1 (26-8-2020)Document10 pagesOIE 751 ROBOTICS Unit 2 Class 1 (26-8-2020)MICHEL RAJ0% (1)

- Compressor Report Thesis VohraDocument95 pagesCompressor Report Thesis VohraWahab Vohra100% (1)

- Model Fa5 and Fa5T: Parts, Operation and Maintenance ManualDocument80 pagesModel Fa5 and Fa5T: Parts, Operation and Maintenance Manualalfredo_mtz_097100% (3)

- Work Instruction On Tube ExpansionDocument40 pagesWork Instruction On Tube Expansionjayaarnav100% (1)

- CompressorDocument62 pagesCompressorBalaji Kalai100% (1)

- Winches For Industrial Appliance: Product Leafl Ets Technical DataDocument44 pagesWinches For Industrial Appliance: Product Leafl Ets Technical DataJosé RoqueNo ratings yet

- Ficha Metre Eater BQDocument1 pageFicha Metre Eater BQcfr242No ratings yet

- Vdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsDocument8 pagesVdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsMohamed SadekNo ratings yet

- Diploma Projects 2018-2019Document4 pagesDiploma Projects 2018-2019RamsathayaNo ratings yet

- Review of Quasi-Turbine Engine: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument7 pagesReview of Quasi-Turbine Engine: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and Echnologypravesh singhNo ratings yet

- Close-Coupled Pumps: - Fixed Speed - Variable Speed - Pneumatic Models - Continuous Tubing - Loadsure ElementsDocument8 pagesClose-Coupled Pumps: - Fixed Speed - Variable Speed - Pneumatic Models - Continuous Tubing - Loadsure ElementsVruno Velasquez LNo ratings yet

- Ch.3 Air Compressor 18M PDFDocument20 pagesCh.3 Air Compressor 18M PDFVijayaprakashNo ratings yet

- Catálogo de Ferramentas TESCO para Locomotivas GE E EMDDocument159 pagesCatálogo de Ferramentas TESCO para Locomotivas GE E EMDMaurício Sousa100% (1)

- Lincoln Bombas Industriales PDFDocument40 pagesLincoln Bombas Industriales PDFJairo PaterninaNo ratings yet

- Air Motors: The Ultimate Power Tools The Ultimate Power ToolsDocument16 pagesAir Motors: The Ultimate Power Tools The Ultimate Power ToolsBe HappyNo ratings yet