Professional Documents

Culture Documents

Enhancement of Mechanical Properties of Concrete by Using Nanoparticles

Enhancement of Mechanical Properties of Concrete by Using Nanoparticles

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enhancement of Mechanical Properties of Concrete by Using Nanoparticles

Enhancement of Mechanical Properties of Concrete by Using Nanoparticles

Copyright:

Available Formats

Volume 6, Issue 11, November – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Enhancement of Mechanical Properties

of Concrete by using Nanoparticles

Jamana Shankar Sharma Pradyumn Dashora

Civil Engineering Department Assistant Professor, Civil Engineering Department

Pacific University Pacific University

Udaipur, Rajasthan Udaipur, Rajasthan

Abstract:- The Nano Technology is one of the emerging properties of concrete can be improved like compressive

field in Civil Engineering as well as other domains too. strength, ductility, tensile strength etc. The enhancement of

The Nano technology offers us sustainable materials durability takes place because of using very tiny particles

which are cost effective and eco friendly, can be used in which are capable to improve the surface area of concrete.

various forms. In present scenario many researchers are Along with that there will be reduction of permeability of

working for construction material to enhance the concrete and enhancement of shrinkage property too.

durability and mechanical strength of existing material

by using nano material like nano silica, Alumina etc. In the series of nano particle, the nano silica and

aluminum oxide are predominantly used to enhance the

Nano technology can be utilized for many physical and chemical properties of concrete. That also

applications in construction but mainly used in provides greater stability against few phenomenons like

Structural Engineering. We can enhance the production sulphate attack, abrasion of material, corrosion etc. The

of industry by reducing the problems faced at present Nano Technology is having lead role in the development of

time with a cost effective manner. Construction Industry concrete and improving the feasibility area of using concrete

is one of the major sectors where this can be very with greater advantages.

beneficial on broad scale.

II. MATERIALS

Keywords:- Nano-technology; Nano-Silica; Mechanical

Properties; Compressive Strength; Split Tensile Strength. A. Materials

a) Nano Material:

I. INTRODUCTION Nano Silica (SiO2) have been used in this study

because of having excellent bonding property and its

The nanotechnology is new emerging technology. In mechanical strength as well. The reactivity of nano material

this new emerging technology, the particles have been used is very high therefore the high surface area to volume ratio

which having size in between 1 to 100 nano meter. These is the key value that we need to consider in mix design.

are used enhance the workability and stability of concrete.

Nano size particles are made up of thousands of atom The uses of nano material with concrete are increasing

combined in the form of a particular group. We can control widely. Further there is much need to observe and make it

the size, shape and % of content in mix design for better possible for industry ready. By trial and error and observing

outcome of the study. This technology basically deals with ample amount of observation, trying to reach as per the

the micro structure of concrete and bonding between the vision to adopt this new technology.

different elements used to prepare it. The molecular study of

design mix is carried out by advance techniques and Density of Nano Silica: 2634 kg/m3

technology. Size of particles: Less than 15 Micron

Molar Mass of SiO2: 59.0843 g/mol

The physical and chemical properties of nano particles

having great impact on performance of concrete. The main Nano silica is used because of having excellent add as

advantage of nano particles is to increase the surface area of your property and further add this to sealant can be

concrete as comparison with normal design mix. It is the converted into net structure. The particles of Nanosilica are

multidimensional approach to get the better out come and too small therefore it is used to improve the effect of

based on pure trial and error method. Many researchers have bonding between the particles used in the mix. Because of

been working on this new technique and trying to expand the development of new material like hydrophobic Silicon

the scope and uses of concrete in construction industry. It oxide these address can be easily joined with different

requires definitely a multidisciplinary approach by the material like plastic magnesium and iron.

experts, scientist and researchers etc.

The nano silica particles having large specific area.

One of the main advantages of using this concrete is The porosity of the nano silica particles also very high and

that it reduces the energy consumption and the overall good surface activity. it has power to use this as a catalyst to

performance of concrete also increases by incorporating enhance the performance of concrete in extraordinary

nano particles. The Nano technology is mainly based on two manner. As reinforcing agent Silicon dioxide nanoparticles

criteria i.e. Self Sensing Capacity and Self Powered are used. it is also anti aging and changes color and can

Property. By adding nano particles, various mechanical produce different color adhesive material.

IJISRT21NOV280 www.ijisrt.com 344

Volume 6, Issue 11, November – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The Silicon dioxide having some rheological properties d) Admixture:

therefore it is used to protect the material from corrosion To increase the stability and higher Cohesion

phenomena and silica is highly Effective bonding material between the ingredients of the concrete, we used high water

which having ingredient including pozzolonic element reducer and high performance admixture. The chemical

which is very fine material and this material can also have a admixtures must be added in the range of 0.2 to 1.5 % by

good impact on concrete to increase durability and weight of cement. The dose of admixture must not be added

mechanical strength of concrete. more or less than the requirement otherwise adverse effect

on the concrete can be seen immediately or after some time.

b) Cement: We have used Conproof Superplast R301 – Superplasticizer

Portland cement of good quality is required to fulfill for reducing water and increasing the strength of Concrete.

requirement of designing concrete using Nano silica. The

good quality of cement enhances the workability and III. METHODS AND EXPERIMENTAL DATA

strength of concrete. If there is some fault in the cement

quality then there will be definitely fluctuations in achieving A. Concrete Mix Design

compressive strength and its performance. The criteria of the In the concrete mix design, the water cement ratio is the

cement which is the basic requirement are given below: key factor which is having greater impact on the strength of

the concrete we have used. Total three different water

Maximum Fineness: 4000 gm/cm2. cement ratio has taken in this study for the development of

Minimum 7 days Mortar cube strength: 29.27 N/mm2 durable and stable concrete. The value of water cement ratio

Mortar Air Content: 8-10 % is taken in this study as 0.4, 0.3 and 0.25 and for that we

have casted nine cubes to determine the compressive

c) Fine and Coarse Aggregate: strength after 7 days, 14 days, 21 days and 28 days to study

The quality of fine aggregate and coarse aggregate the outcome and behavior of concrete for a particular mix

directly depends on the quality and property of the material. that we have design. We also got the information and

The mixing of fine and coarse aggregate must be in a observation about effect of Nano silica on mechanical

particular manner; so, the target strength can be achieved. strength of the concrete.

The concrete strength depends on the uniformity of material.

The fineness modulus of the fine aggregate is in between 2.5 The nano silica is added 10% and 15% with the

to 3.5. The Concrete must be given particular vibration for replacement of cement. In both proportion concrete cubes

equal distribution of the material. The aggregate having were casted and tested the compressive strength. The

sizes 10 mm are used in this study and that was locally compressive strength data have been taken after 7 days 14

available in the market. days 21 days and 28 days. Further, comparative study was

done and mix design was done as per Indian Standard

10262:2009 confirming all the criteria suggested in the code.

Testing:

a) Compressive Strength Test:

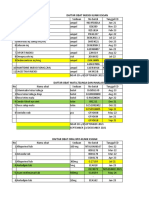

The Following data were observed as per mix design and proportion calculated.

Mix Design Nano W/C Compressive Strength of Concrete Cube (N/mm2)

Proportion Silica (%) Ratio 7 Days 14 Days 21 Days 28 Days

M-50 (0.75:1:1.25) 0.4 26.2 35.5 38.2 44.25

Conventional 0 0.3 30.5 40.25 42.5 48.5

Concrete 0.25 24 33.25 37.7 42.5

0.4 27.5 37.25 42.5 45.25

M-50 (0.75:1:1.25) 10 0.3 32.5 41.25 45.2 52.2

0.25 25.2 35.2 39.5 43.25

0.4 25.3 35.2 40.2 42.25

M-50 (0.75:1:1.25) 15 0.3 30.4 36.5 40.5 43.5

0.25 25.5 34.6 40.5 42.5

Table 1: Compressive Strength Testing Observations of Concrete on different Proportion

IJISRT21NOV280 www.ijisrt.com 345

Volume 6, Issue 11, November – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Graph 1:- CS comparison graph with different W/C ratio

b) Split Tensile Strength Test: prepared firs. The diameter of the cylindrical mould used in

This test is used to determine the tensile strength of this test is 150 mm and length 300 mm as per Indian

concrete. The test is performed on concrete cylinder and the Standard specification. During the process various tools are

values are taken across the vertical diameter of that cylinder needed like diamond, grinding machine, compressive testing

by applying loads as per the mix design. The specimen is machine, cap fixture, PI tape, ruler etc.

Replacement of Split Tensile Strength Values in

Mix Proportion Cement by Nano (N/mm2)

Silica (%) 7 Days 14 Days 28 Days

Mix-50 (0.75:1:1.25)

00 4.47 6.08 7.29

Conventional Concrete

Mix-50 (0.75:1:1.25) 10 4.85 6.18 7.78

Mix-50 (0.75:1:1.25) 15 4.35 5.50 6.30

Table 2: Split tensile strength on different trials

c)

d) Flexural Strength Test: and two third span of the total length of the specimen. Beam

This test is used to calculate the tensile strength of is tested as per the wet standard of the concrete.

concrete. Mainly we calculate how much load can be

resisted by a beam under bending. For performing this The Ultimate load is observed where the specimen

experiment, a mould is taken having size 150 mm x 150 mm fails under given loading condition and finally modulus of

and length 700 mm. This test is mainly performed on three rupture is calculated.

point loading phenomena. The loads are applied at one third

Flexural Tensile Strength Value

Nano Silica (%)

Mix Proportion (N/mm2)

Replacement

7 Days 14 Days 28 Days

Mix-50 (0.75:1:1.25)

00 6.10 8.00 9.70

Conventional Concrete

Mix-50 (0.75:1:1.25) 10 6.50 8.25 10.55

Mix-50 (0.75:1:1.25) 15 6.00 7.30 8.70

e) Rebound Hammer test: Schmidt hammer with controlled spring mass that slide on

Rebound hammer test is the Non Destructive Test the instrument member that is called plunger.

which is used to calculate compressive strength of the

concrete member without dismantles. This is also called as

IJISRT21NOV280 www.ijisrt.com 346

Volume 6, Issue 11, November – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Graph 2:- Comparison between Rebound Hammer Result

f) Ultrasonic Pulse Velocity Test: concrete and it's uniformity of ingredient. If the higher

This test is performed to assess the quality of velocities achieve that means the concrete mass is not good

concrete in terms of uniform mass, mass density, equal enough and if the lower velocity achieved that means the

distribution of material. This method is mainly based on concrete mass having uniformity in all the dimensions. This

Ultrasonic waves passes through to the concrete member test is performed without any physical disintegration of

and the time taken in this process shows the quality of concrete member.

Pulse Velocity Value (Km/Sec)

Specimen No. Quality Grade

Direct Method Semi Direct Method

1 4.1 4.1 Good

2 4.2 3.9 Good

3 3.9 3.7 Good

4 4.0 4.1 Good

5 4.0 3.2 Good

Table 4: Pulse Velocity Test observations and Result

IV. CONCLUSIONS REFERENCES

The Following conclusions are made as per the data [1.] Salomaa, Amrinsyah Nasutionb , Iswandi Imranb ,

observed during this study: Mikrajuddin Abdullahb, “Improvement of concrete

durability by nanomaterials”, ScienceDirect Journal

By adding nano silica (SiO2) the mechanical strength and

Performance of concrete can be enhanced. 2015.

The compressive strength of concrete found maximum [2.] Arti S. Pharande1, Dr. Geetha K. Jayaraj, Sanjeev

52.2 MPa at 28 days by adding 10% of Nano silica as a Raje, “Nano Technology in Concrete- A Brief

replacement of cement. Review”, International Research Journal of

By adding 10% Nanosilica in the concrete can provide Engineering and Technology, 2019.

better resistance to sulphate attack. [3.] Chenglong Zhuang and Yu Chen, “The effect of

The observed value of split tensile strength is 7.8 N/mm 2 nano-SiO2 on concrete properties: a review”, De

by adding 10% Nanosilica as we increase the amount of

Gruyter publications, 2019.

silica the value of tensile strength got started decreasing.

[4.] Sen Du, Junliang Wu, Othman AlShareedah,

The value of flexural strength was 10.5 N/mm 2 by adding

10% of nanosilica further this strength getting decreases and Xianming Shi, “Nanotechnology in Cement-

when we increase the amount of nanosilica than 10%. Based Materials: A Review of Durability,

The observation based on non destructive test shows the Modeling, and Advanced Characterization”,

Concrete possesses good quality of Homogeneity and Multidisciplinary Digital Publishing Institute

equal Distribution of particle. The Dispersion and matrix (MDPI), 2019.

of Ingredient found was perfect. [5.] Bibhuti Bhusan Mukharjee & Sudhirkumar V.

The cost of this concrete is justifiable in mass production.

Barai, “Influence of Incorporation of Colloidal

It will be worth for construction industries using it in mass

execution work. Nano-Silica on Behaviour of Concrete”, Iranian

Journal of Science and Technology, 2020.

IJISRT21NOV280 www.ijisrt.com 347

Volume 6, Issue 11, November – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[6.] F. Pacheco-Torgal and Said Jalali b,

“Nanotechnology: Advantages and drawbacks in the

field of construction and building materials”,

science direct publications, 2010.

[7.] Oladipupo S. Olafusi, Emmanuel R. Sadiku,

Jacques Snyman, Julius M. Ndambuki & Williams

K. Kupolati, “Application of nanotechnology in

concrete and supplementary cementitious materials:

a review for sustainable construction”, Materials

Science: Sustainable Building Materials, the

Netherlands, 2019.

[8.] N. Silvstre and Jorge de Brito, “Review on concrete

nanotechnology”, European Journal of

Environmental and Civil Engineering, June 2015.

[9.] Rawa Ahmed and NiyaziUgurKockal,

“Nanoparticles used as an ingredient in different

types of concrete”, A Springer Nature Journal, April

2021.

[10.] MuhdNorhasriMuhdSidek, marshahamidah and

MohdFadzil Arshad, “Applications of using nano

material in concrete: A review”, Research gate

journal, February 2017.

[11.] Sen Du, Junliang Wu, Othman AlShareedah,

and Xianming Shi, “Nanotechnology in Cement-

Based Materials: A Review of Durability,

Modeling, and Advanced Characterization”, MDPI

Publications, August 2019.

[12.] Decheng Feng, NingXie, Chunwei Gong, Zhen

Leng, Huigang Xiao, Hui Li and Xianming Shi,

“Portland Cement Paste Modified by TiO2

Nanoparticles: A Microstructure Perspective”, ACS

Publications, July 2013.

[13.] Premjeet G. Jadhav, K. B. Mahajan, V. R. Khadse

and A. J. Chaudhari, “Nanotechnology around

Human life: A Review” , Journal of Engineering

Science, April 2020.

IJISRT21NOV280 www.ijisrt.com 348

You might also like

- Comparison Between 2d and 3d Behaviour of Sheet Piles by Finite Element MethodDocument16 pagesComparison Between 2d and 3d Behaviour of Sheet Piles by Finite Element MethodtavialimNo ratings yet

- Mol1, April 2021Document20 pagesMol1, April 2021jur peerdenNo ratings yet

- CGWAVE Analysis: SMS 13.0 TutorialDocument7 pagesCGWAVE Analysis: SMS 13.0 TutorialjanuNo ratings yet

- Geotechnics: Marcin Cudny, Lech BałachowskiDocument52 pagesGeotechnics: Marcin Cudny, Lech Bałachowskisharath1199No ratings yet

- Title: Numerical Modelling of Small Groups of Stone ColumnsDocument251 pagesTitle: Numerical Modelling of Small Groups of Stone ColumnsThaung Myint OoNo ratings yet

- 3D Simulation of Mechanized Tunnel Excavation PDFDocument14 pages3D Simulation of Mechanized Tunnel Excavation PDFChin Thau WuiNo ratings yet

- The Use of Geosynthetics in Road Construction (Case Study - Geotextile)Document48 pagesThe Use of Geosynthetics in Road Construction (Case Study - Geotextile)Suresh DevarajanNo ratings yet

- Who Should Choose The TBMDocument4 pagesWho Should Choose The TBMDEBASIS BARMANNo ratings yet

- 2005 084Document5 pages2005 084Anonymous v1blzDsEWANo ratings yet

- 1.masonry Lecture New1Document36 pages1.masonry Lecture New1yassery kifuku0% (1)

- 2014 Bo Zhou PHD Thesis ImportantDocument227 pages2014 Bo Zhou PHD Thesis ImportantMasihullah EbadiNo ratings yet

- Mohamed Fathi 2014 Thesis PDFDocument283 pagesMohamed Fathi 2014 Thesis PDFDevendra Pratap SinghNo ratings yet

- Etd 1267Document190 pagesEtd 1267Lê Anh KhoaNo ratings yet

- Session 3b - Shear Strength of Discontinuities - DR Louis WONGDocument45 pagesSession 3b - Shear Strength of Discontinuities - DR Louis WONGHinLapYuNo ratings yet

- Application of Hyperstatic Reaction Method For Designing of Tunnel Permanent Lining, Part I: 2D Numerical ModellingDocument11 pagesApplication of Hyperstatic Reaction Method For Designing of Tunnel Permanent Lining, Part I: 2D Numerical ModellingIngrid Irreño PalomoNo ratings yet

- Shape Accel ArrayDocument22 pagesShape Accel Arraydirafly3566No ratings yet

- Engineering Structures: K.G.S. Dilrukshi, W.P.S. Dias, R.K.N.D. RajapakseDocument12 pagesEngineering Structures: K.G.S. Dilrukshi, W.P.S. Dias, R.K.N.D. RajapaksepaulkohanNo ratings yet

- Sustainability in Geotechnical Engineering, 2015 PDFDocument9 pagesSustainability in Geotechnical Engineering, 2015 PDFSergio Andres Martinez CamachoNo ratings yet

- Pfa Mix Design PaperDocument13 pagesPfa Mix Design PaperBarry AndersonNo ratings yet

- Mechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersDocument11 pagesMechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersCristianAMejiaNo ratings yet

- Određivanje Beff Prema EC2Document2 pagesOdređivanje Beff Prema EC2Emir BajramovicNo ratings yet

- Simulating The Dynamic ResponseDocument42 pagesSimulating The Dynamic ResponsekareemsalahNo ratings yet

- Compressive Stress Strain Relationship of Steel Fibre-Reinforced Concrete at Early AgeDocument14 pagesCompressive Stress Strain Relationship of Steel Fibre-Reinforced Concrete at Early AgesonugaurNo ratings yet

- Numerical Simulation of Wave Propagation in Soil MediaDocument6 pagesNumerical Simulation of Wave Propagation in Soil MediaNarayan RoyNo ratings yet

- C.T. Lab Manual 2019-20 New1Document52 pagesC.T. Lab Manual 2019-20 New1James DNo ratings yet

- Fundamentals of Micromechanics of Solids by Jianmin Qu, Mohammed CherkaouiDocument397 pagesFundamentals of Micromechanics of Solids by Jianmin Qu, Mohammed CherkaouiTatavarthy Swethan100% (2)

- Conprint 3DDocument30 pagesConprint 3DManu S NadesanNo ratings yet

- Tutorial Notes For Structural Dynamics - First PartDocument53 pagesTutorial Notes For Structural Dynamics - First PartDavid CivilEngineerNo ratings yet

- Mol 2, September 2020Document16 pagesMol 2, September 2020Frode van der DriftNo ratings yet

- (Cezary Madryas, Andrzej Kolonko, Arkadiusz SzotDocument335 pages(Cezary Madryas, Andrzej Kolonko, Arkadiusz Szotjacknguyen11_2No ratings yet

- Analysis of Geotextile in Road Embankment Using Plaxis 2d: Ankit Atkole, Tanmay Gharat, Ajit Agale, Bhavesh AdkarDocument5 pagesAnalysis of Geotextile in Road Embankment Using Plaxis 2d: Ankit Atkole, Tanmay Gharat, Ajit Agale, Bhavesh AdkarVIVA-TECH IJRINo ratings yet

- Non Linear Finite Element Analysis On Shear Strength and Crack Control of HFRC Deep Beams HENOCK ALEMAYEHUDocument124 pagesNon Linear Finite Element Analysis On Shear Strength and Crack Control of HFRC Deep Beams HENOCK ALEMAYEHUHenock AlemayehuNo ratings yet

- Numerical Modeling of Geosynthetic-Encased Stone Column-Reinforced GroundDocument11 pagesNumerical Modeling of Geosynthetic-Encased Stone Column-Reinforced GroundPMHNo ratings yet

- Coir Geotextiles Are Eco Friendly and Economical Solution For Soil ErosionDocument6 pagesCoir Geotextiles Are Eco Friendly and Economical Solution For Soil ErosionKrishna PrasadNo ratings yet

- Schweiger (2002) Benchmarking - in - Geotechnics-1 - Part-I PDFDocument26 pagesSchweiger (2002) Benchmarking - in - Geotechnics-1 - Part-I PDFjorge.jimenezNo ratings yet

- A Review On Stabilization of Indian Soils For Road Construction by Using Jute FiberDocument4 pagesA Review On Stabilization of Indian Soils For Road Construction by Using Jute FiberAdvanced Research PublicationsNo ratings yet

- 4880 4 1971 Reff2020Document29 pages4880 4 1971 Reff2020RandhirNo ratings yet

- Sway Characteristics of Brick Infilled Reinforced Concrete Building Frame Under Lateral LoadingDocument89 pagesSway Characteristics of Brick Infilled Reinforced Concrete Building Frame Under Lateral Loadingmd ashraful alamNo ratings yet

- Dynamic Analysis of Non-Planar Coupled Shear WallsDocument371 pagesDynamic Analysis of Non-Planar Coupled Shear WallsAxmed ShirwacNo ratings yet

- ZTV-InG, Part 1-10 ARS 13 - 2012 Status - 2012 - 03.PDF EngDocument5 pagesZTV-InG, Part 1-10 ARS 13 - 2012 Status - 2012 - 03.PDF EngSahiduj Jaman SajuNo ratings yet

- Design Considerations in Repair of Structures: Current Load DistributionDocument41 pagesDesign Considerations in Repair of Structures: Current Load Distributionfotographia BFFNo ratings yet

- EC2 2023 - Eurocode 2 Design of Concrete Structures BS en 1992-1-1 2023Document408 pagesEC2 2023 - Eurocode 2 Design of Concrete Structures BS en 1992-1-1 2023riwafa3581No ratings yet

- 3d ConcreteDocument20 pages3d ConcreteManu S NadesanNo ratings yet

- Seismic Analysis Comparison of G 11 Storey Conventional RC Frame Structure and Mivan StructureDocument6 pagesSeismic Analysis Comparison of G 11 Storey Conventional RC Frame Structure and Mivan StructureEditor IJTSRD100% (1)

- Soil Constitutive Model 1Document20 pagesSoil Constitutive Model 1adnan-651358No ratings yet

- Influence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabDocument18 pagesInfluence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabShaker QaidiNo ratings yet

- Experimental Investigation of Shell Foundations On Dry Sand: Adel Hanna and Mohamed Abdel-RahmanDocument11 pagesExperimental Investigation of Shell Foundations On Dry Sand: Adel Hanna and Mohamed Abdel-RahmanATISH KUMAR DASNo ratings yet

- Mechanical Properties of Plastic Concrete Containing BentoniteDocument7 pagesMechanical Properties of Plastic Concrete Containing Bentonitejuan munera100% (1)

- Shear Strength and Deformation Parameters of Rockfill Related To Particle Size PDFDocument8 pagesShear Strength and Deformation Parameters of Rockfill Related To Particle Size PDFSergio CalderonNo ratings yet

- Sustainability Design For Raft & Piled-Raft Foundations - Green Initiative!Document8 pagesSustainability Design For Raft & Piled-Raft Foundations - Green Initiative!정주호No ratings yet

- IRC ProposalDocument50 pagesIRC ProposalashwinmjoshiNo ratings yet

- 6 Hoek Brown ModelDocument6 pages6 Hoek Brown ModelVa Ni SkyNo ratings yet

- Menard FormulaDocument1 pageMenard FormulasreymomNo ratings yet

- Asadzadeh - Direct Shear Testing On A Rockfill MaterialDocument18 pagesAsadzadeh - Direct Shear Testing On A Rockfill MaterialDavid CastañoNo ratings yet

- Large-Scale Direct Shear Testing of Geocell Reinforced SoilDocument6 pagesLarge-Scale Direct Shear Testing of Geocell Reinforced SoilnarutowhatsupNo ratings yet

- The Soniscope - A Device For Field Testing of ConcreteDocument11 pagesThe Soniscope - A Device For Field Testing of ConcreteEu mesmoNo ratings yet

- Iare RrsDocument180 pagesIare RrsDhuha ANo ratings yet

- Advance Soil Mechanics: Elastic, Plastic and Elasto-Plastic BehaviourDocument52 pagesAdvance Soil Mechanics: Elastic, Plastic and Elasto-Plastic BehaviourzuluagagaNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Analysis of Opaque, Peel-Off and Flex Rejects in the Electro Plating Process Using the Six Sigma Dmaic MethodDocument18 pagesAnalysis of Opaque, Peel-Off and Flex Rejects in the Electro Plating Process Using the Six Sigma Dmaic MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Study to Effect of Reminiscence Therapy on Psychological Well-Being among Elderly Residing in Selected Old Age HomeDocument5 pagesA Study to Effect of Reminiscence Therapy on Psychological Well-Being among Elderly Residing in Selected Old Age HomeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of Project Management using CPM (Critical Path Method) and Pert (Project Evaluation and Review Technique) in the Nava House Bekasi Cluster Housing Development ProjectDocument12 pagesApplication of Project Management using CPM (Critical Path Method) and Pert (Project Evaluation and Review Technique) in the Nava House Bekasi Cluster Housing Development ProjectInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Comprehensive Review on the Therapeutic Potential of PectinDocument6 pagesA Comprehensive Review on the Therapeutic Potential of PectinInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of the Economic Order Quantity (EOQ) Method on the Supply of Chemical Materials in the Laboratory of PT. Fajar Surya Wisesa TbkDocument15 pagesApplication of the Economic Order Quantity (EOQ) Method on the Supply of Chemical Materials in the Laboratory of PT. Fajar Surya Wisesa TbkInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Rare Complication: Cardiac Arrest and Pulmonary Embolism in Polyarteritis NodosaDocument5 pagesA Rare Complication: Cardiac Arrest and Pulmonary Embolism in Polyarteritis NodosaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Integrated Border Security System on Human Trafficking in Bangladesh: The Mediating Effect of the Use of Advanced TechnologyDocument12 pagesThe Impact of Integrated Border Security System on Human Trafficking in Bangladesh: The Mediating Effect of the Use of Advanced TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quality Control to Reduce Appearance Defects at PT. Musical InstrumentDocument11 pagesQuality Control to Reduce Appearance Defects at PT. Musical InstrumentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Forecasting PM10 Concentrations Using Artificial Neural Network in Imphal CityDocument10 pagesForecasting PM10 Concentrations Using Artificial Neural Network in Imphal CityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Carton Packaging Quality Control Using Statistical Quality Control Methods at PT XYZDocument10 pagesAnalysis of Carton Packaging Quality Control Using Statistical Quality Control Methods at PT XYZInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quizlet's Usefulness for Vocabulary Learning: Perceptions of High-Level and Low-Level Chinese College EFL LearnersDocument5 pagesQuizlet's Usefulness for Vocabulary Learning: Perceptions of High-Level and Low-Level Chinese College EFL LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing Estimating the Charge Level in Electric Vehicles: Leveraging Force Fluctuation and Regenerative Braking DataDocument6 pagesEnhancing Estimating the Charge Level in Electric Vehicles: Leveraging Force Fluctuation and Regenerative Braking DataInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Entrepreneurial Adult Education as a Catalyst for Youth Employability in Disadvantaged AreasDocument9 pagesEntrepreneurial Adult Education as a Catalyst for Youth Employability in Disadvantaged AreasInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Role of Leadership Training in Developing Effective Police SupervisorsDocument17 pagesThe Role of Leadership Training in Developing Effective Police SupervisorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Health Care - An Android Application Implementation and Analyzing user Experience Using PythonDocument7 pagesHealth Care - An Android Application Implementation and Analyzing user Experience Using PythonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intrusion Detection System with Ensemble Machine Learning Approaches using VotingClassifierDocument4 pagesIntrusion Detection System with Ensemble Machine Learning Approaches using VotingClassifierInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Synthetic and Natural Vitamin C Modulation of Leaded Paint-Induced Nephrotoxicity of Automobile Painters in Ile-Ife, Nigeria.Document21 pagesSynthetic and Natural Vitamin C Modulation of Leaded Paint-Induced Nephrotoxicity of Automobile Painters in Ile-Ife, Nigeria.International Journal of Innovative Science and Research TechnologyNo ratings yet

- Visitor Perception Related to the Quality of Service in Todo Tourism VillageDocument10 pagesVisitor Perception Related to the Quality of Service in Todo Tourism VillageInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gravity Investigations Applied to the Geological Framework Study of the Mambasa Territory in Democratic Republic of CongoDocument9 pagesGravity Investigations Applied to the Geological Framework Study of the Mambasa Territory in Democratic Republic of CongoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Developing Digital Fluency in Early Education: Narratives of Elementary School TeachersDocument11 pagesDeveloping Digital Fluency in Early Education: Narratives of Elementary School TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A New Model of Rating to Evaluate Start-ups in Emerging Indian MarketDocument7 pagesA New Model of Rating to Evaluate Start-ups in Emerging Indian MarketInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Proof of Concept Using BLE to Optimize Patients Turnaround Time (PTAT) in Health CareDocument14 pagesA Proof of Concept Using BLE to Optimize Patients Turnaround Time (PTAT) in Health CareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Financial Prudence as Determinant of Employees’ Interest in Graduate StudyDocument13 pagesFinancial Prudence as Determinant of Employees’ Interest in Graduate StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Implementation of Software-Defined ReceiverDocument8 pagesDesign and Implementation of Software-Defined ReceiverInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Optimizing Bio-Implant Materials for Femur Bone Replacement:A Multi-Criteria Analysis and Finite Element StudyDocument5 pagesOptimizing Bio-Implant Materials for Femur Bone Replacement:A Multi-Criteria Analysis and Finite Element StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Crop Monitoring System with Water Moisture Levels Using ControllerDocument8 pagesCrop Monitoring System with Water Moisture Levels Using ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Inclusive Leadership in the South African Police Service (SAPS)Document26 pagesInclusive Leadership in the South African Police Service (SAPS)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Naturopathic Approaches to Relieving Constipation: Effective Natural Treatments and TherapiesDocument9 pagesNaturopathic Approaches to Relieving Constipation: Effective Natural Treatments and TherapiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fahfi/Mochaina Illegal Gambling Activities and its Average Turnover within Limpopo ProvinceDocument8 pagesFahfi/Mochaina Illegal Gambling Activities and its Average Turnover within Limpopo ProvinceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Year Wise Analysis and Prediction of Gold RatesDocument8 pagesYear Wise Analysis and Prediction of Gold RatesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hasil Stok Opname Untuk Bap (Fix)Document35 pagesHasil Stok Opname Untuk Bap (Fix)WARDA NABIELANo ratings yet

- BJT Lab ExperimentDocument7 pagesBJT Lab ExperimentAhmad ShahNo ratings yet

- Rotabolt Tension Control James WalkerDocument12 pagesRotabolt Tension Control James Walkercvishwas1159No ratings yet

- Sumg100 GasDocument32 pagesSumg100 Gascomunicacion socialNo ratings yet

- FC Sem 3 Science in Every Day LifeDocument12 pagesFC Sem 3 Science in Every Day LifeHamza GhadiallyNo ratings yet

- Locust Test Report: Request StatisticsDocument3 pagesLocust Test Report: Request StatisticsParikansh AhluwaliaNo ratings yet

- HDEV MidtermDocument6 pagesHDEV Midtermkaitlyn100% (1)

- Basic Skills PercentsDocument20 pagesBasic Skills Percentsapi-304903453No ratings yet

- LASER CommunicationDocument16 pagesLASER CommunicationarjunknarayanNo ratings yet

- Fac1601 - Fasset Classes - Part 4Document2 pagesFac1601 - Fasset Classes - Part 4Abdullah SalieNo ratings yet

- Ice Melting Methods For Overhead LinesDocument28 pagesIce Melting Methods For Overhead LinesKirana Shree100% (1)

- Newsletter 14th December 2023.282584862Document27 pagesNewsletter 14th December 2023.282584862elvisNo ratings yet

- Adverbs PlaceDocument2 pagesAdverbs PlaceLuizNo ratings yet

- 98 EntrepreneurshipDocument11 pages98 Entrepreneurshipdolly gorlakorakanaNo ratings yet

- Delta Marketing TrendsDocument7 pagesDelta Marketing TrendsCandy SaberNo ratings yet

- Adiabatic Saturation Temperature of AirDocument2 pagesAdiabatic Saturation Temperature of AirRahul ChandrawarNo ratings yet

- Schools of Criminology A Comparative AnalysisDocument9 pagesSchools of Criminology A Comparative AnalysisSudeep MishraNo ratings yet

- From Novice To Expert Theory - Lucille Alkhaldi BSN RNDocument11 pagesFrom Novice To Expert Theory - Lucille Alkhaldi BSN RNmaha_alkhaldi100% (1)

- Seven Basic Toolsof Quality Control The Appropriate Techniquesfor Solving Quality Problemsinthe OrganizationsDocument11 pagesSeven Basic Toolsof Quality Control The Appropriate Techniquesfor Solving Quality Problemsinthe OrganizationsNigel LimNo ratings yet

- Management Theories and Case StudyDocument5 pagesManagement Theories and Case StudyStephanie KrystelNo ratings yet

- Comparison Subpart Q Vs New FTL 030314Document20 pagesComparison Subpart Q Vs New FTL 030314TomaszUchańskiNo ratings yet

- The History of Drug Laws in The United StatesDocument6 pagesThe History of Drug Laws in The United StatesAnonymous VdMiv3W9DNo ratings yet

- Old English, Norwegian, Islandic Rune PoemsDocument6 pagesOld English, Norwegian, Islandic Rune Poemsseixxx666No ratings yet

- Medi-Gas Check Full Range CatalogueDocument20 pagesMedi-Gas Check Full Range CatalogueShamshad HussainNo ratings yet

- Weisman (1996) A Concept Analysis of EmpathyDocument7 pagesWeisman (1996) A Concept Analysis of EmpathyBenjamin Varas ArnelloNo ratings yet

- Mobile Washing System - OverviewDocument13 pagesMobile Washing System - OverviewAbdul HadiNo ratings yet

- Kuwait PICU Taskforce DKA V1 5 June 2022Document2 pagesKuwait PICU Taskforce DKA V1 5 June 2022Emad MashaalNo ratings yet

- 25 Common Surgical ConditionsDocument3 pages25 Common Surgical ConditionsMu AbNo ratings yet

- Investors Sentiment in India SurveyDocument12 pagesInvestors Sentiment in India SurveyZainab FathimaNo ratings yet

- G10-2nd-Q-review Sheets-Chem-Chap7, 8.1, 8.2Document8 pagesG10-2nd-Q-review Sheets-Chem-Chap7, 8.1, 8.2Karim Ahmed100% (1)