Professional Documents

Culture Documents

Helpful Hints For Saw Users: 13 (H.S.S. Metal-Working Saws)

Helpful Hints For Saw Users: 13 (H.S.S. Metal-Working Saws)

Uploaded by

uripssgmailOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helpful Hints For Saw Users: 13 (H.S.S. Metal-Working Saws)

Helpful Hints For Saw Users: 13 (H.S.S. Metal-Working Saws)

Uploaded by

uripssgmailCopyright:

Available Formats

13

Helpful Hints For Saw Users (H.S.S. Metal-Working Saws)

These are general suggestions for conventional machines on where to start, and must be varied to meet a particular application. We do not assume

any liability in the following statements.

These STOCK saws will do the job. Variations, such as number of teeth, rake angle, clearance angle, bevel, side clearance, material, land, etc. may

do it better, but set-up charges and lead time must be considered.

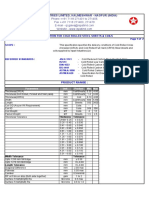

SPEEDS — With a good set-up the speeds in the table below should be attainable

— Reduce the speed for hard (over Rockwell c30) and abrasive materials, and for deep cuts.

— Increase the speed for “free-machining” and non-ferrous metals.

Saws: M-2 Steel, Ground Teeth, 0° Rake Angle

Material Saw

to be cut Diameter: 1-3/4” 2-1/4” 2-3/4” 3” 4” Coolant

Teeth - R.P.M. Teeth - R.P.M. Teeth - R.P.M. Teeth - R.P.M. Teeth - R.P.M.

Mild Steel 64 - 450 60 - 350 56 - 275 56 - 250 72 - 200 Cutting Oil

Alloy Steel 64 - 200 60 - 175 56 - 150 56 - 125 72 - 100 “

Stainless Steel 64 - 200 60 - 175 56 - 150 56 - 125 72 - 100 “

Steel Castings 64 - 200 60 - 175 44 - 150 44 - 125 60 - 100 “

Steel Forgings 64 - 450 60 - 350 56 - 275 56 - 250 72 - 200 “

Monel 64 - 200 60 - 175 56 - 150 56 - 125 72 - 100 “

Aluminum 64 - 2000 60 - 1750 44 - 1350 44 - 1250 60 - 950 Soluble Oil

Bronze 64 - 750 60 - 600 44 - 500 44 - 450 60 - 350 “

Yellow Brass 64 - 2500 60 - 2000 44 - 1600 44 - 1500 60 - 1100 “

Copper 64 - 1750 60 - 1350 44 - 1100 44 - 1000 60 - 750 “

Malleable Iron 64 - 350 60 - 250 56 - 200 56 - 200 72 - 150 “

Cast Iron 64 - 450 60 - 350 44 - 275 44 - 250 60 - 200 Dry

Die Castings 64 - 2500 60 - 2000 44 - 1600 44 - 1500 60 - 1100 “

Brittle Plastics 64 - 1000 60 - 900 56 - 700 56 - 650 72 - 500 “

Flexible Plastics Use Set Teeth (Hub saw with maximum side clearance for very thin cuts)

(There should be at least 2 teeth engaged in the cut.)

Increase Number of Teeth For: Decrease Number of Teeth For:

— Thin Material — Sandy Castings — Chip Clearance and Tooth Strength

— Thin Cuts (under .025”) — Thin Castings (Consider MSL & SMF type saws.)

— Slow Spindle Speeds — Work Hardened — Deep Cuts (over 1/4”)

— Hard Material — Hard Spots — High Speeds

— Free Cutting Material

FEEDS — will vary from .0002” to .002” per tooth. We suggest starting with the cutter described above and trying to arrive at the condition described

under “Cutting Fluids” by varying the Feed and Speed. A straw color is the limit. The saw loses its temper when it starts turning blue.

CUTTING FLUIDS — (to cool, lubricate, and wash the chips away. Use Flood. Do not use Mist Units.)

Cutting Oil — Follow Manufacturer’s Instructions - or - use a 4% sulphur homogenized cutting oil.

Soluble Oil — Follow Manufacturer’s Instructions - or - use 40-1 solution of soluble oil — (Mix thoroughly in a 4 - 1 solution before adding

to tank.) Increase speed and feed until the lubricant starts to give off a slight vapor (smoke).

Frequently saws are run too slow, causing rubbing and premature wear.

DISH — (Side-Clearance or Hollow Grind) Increase it for stainless steel and tenacious metals such as copper, zinc, tin or lead.

MOUNTING OF SAWS — Breakage — Wobble — Rubbing: These problems may be caused by the way the washers are mounted on either side

of the saw. — Washers drive the saw, in the absence of a driving key, and must always be clean, flat and bur-free. A speck of

dirt will let the saw wobble and cut oversize. If a saw breaks, it may score the washers. Check marks around the saw hole for:

Dirt, Shiny Spots (as small as a pinpoint, indicating chips imbedded under the washers), and Circular Skid Marks, which indicate

the nut is not tight. — Thin saws should especially be supported by washers as large as possible. — Nut must be wrench-tight.

— If the saw blade pauses momentarily in its rotation while the feed advances, it will break. — Washers must be of equal diam-

eter or they will flex out the dish and cause one side of the teeth to rub.

Continued Next Page

MARTINDALE • PO Box 430 • Cleveland, OH 44107

Phone (216) 521-8567 • Fax Local 521-9476 / USA & Canada (800) 344-9191

E-Mail: sales@martindaleco.com

Web Site: www.martindaleco.com 02/05

14

Helpful Hints For Saw Users (H.S.S. Metal-Working Saws)

(Continued)

TEETH — Deep cuts and soft material require fewer teeth (for chip clearance) and stronger teeth (landed). — Thin material requires more teeth (at

least 2 teeth engaged in cut). — Hard materials and narrow slots (under .025”) likewise require more teeth. — Alternately

beveled teeth keep chips from sticking in the cut and in the tooth gullets. — Rake Angles: On center for iron and steel, 5° nega-

tive for yel low brass, from 5° to 10° positive for other soft materials.

BREAKAGE — In addition to causes noted under “MOUNTING OF SAWS”: Teeth break when starting a cut at too fast a feed, spindle bearings worn,

drive belts loose or sheaves worn, indexing before saw has cleared the slot, work-piece not tight, or the saw is dull (even the best

eventually wear out).

KEYWAYS — No keyways are furnished on saws under .020”. Thin saws will warp in the heat treating and grinding processes. Locked up between

good supporting washers, they will run true.

HUBS — will allow maximum side clearance when attempting to cut wood or plastics. They are helpful when spacing saws on an arbor.

RESHARPENING — In addition to grinding the tips of the teeth, all marks must be removed from the sides of the teeth. This can be done by grind-

ing the diameter below the marks or, as we do, by grinding the tips and clean-up grinding the sides. Either way the thickness is

reduced because of the hollow grind that is necessary for even the shallowest of cuts.

VIBRATION AND CHATTER — Arbor bent or worn undersize. — Work-piece improperly supported, particularly watch on thin material. — Teeth

too coarse/fine. — Speed too slow. — Climb milling, “Up-milling” is preferred, but climb milling may help on small parts to keep

them from being ripped from the clamping fixture. It may also reduce the bur. — Dull tool / Wrong clearance angles. — Feed

too slow.

EXCESSIVE WEAR — Seizing: Not enough coolant in the right place. — Not enough side clearance. — Cutter speed too fast and feed too slow.

The work may glaze and the saw will rub.

TOLERANCES — are expensive, don’t over-specify.

STEELS — M-2 is the best if the set-up is proper. We do have available saws from M-42 along with various surface treatments such as Titanium

Nitride.

SUGGESTION — If a saw is working well, send it to us and we will duplicate it. — If a saw is not working well, send us a used blade. We can some

times make recommendations from the marks on the saw.

Helpful Hints For Saw Users

(Mica Undercutting Saws & V-Cutters)

COMMUTATOR UNDERCUTTING

After the commutator has been satisfactorily resurfaced, the mica insulation separating the copper segments must

be undercut. Undercutting is one operation that is most easily accomplished with the armature removed from the

machine. Various tools are available, however, that enable undercutting to be performed on a commutator “in place”

without undue hardship.

Of the various undercutting practices used, only the two most common methods will be discussed herein.

There are three basic types of slots that can be produced by the use of circular cutters. The U-slot, the V-slot and

the Compound-angle slot.

Continued Next Page

MARTINDALE • PO Box 430 • Cleveland, OH 44107

Phone (216) 521-8567 • Fax Local 521-9476 / USA & Canada (800) 344-9191

E-Mail: sales@martindaleco.com

Web Site: www.martindaleco.com 02/05

15

Helpful Hints For Saw Users

(Mica Undercutting Saws & V-Cutters) (Continued)

U-SLOT

The U-slot (as shown in Fig. 1) is generally preferred if the slots are accessible for easy cleaning. These slots have

the advantage, if done carefully, of being effective until the commutator has worn down the full depth of the undercut.

The slot should be cut to a depth of 1/32 (.032) inch, or not more than 3/64 (.046) inch. If cut too deep, accumulated

dust will not be thrown out by the centrifugal action of the rotating commutator.

Saw Cut

Copper

Type “U” Slot

Mica Fig. 1

When using a circular cutter, the width of the cutter is chosen to exceed slightly the thickness of the mica. It is rec-

ommended that the SAW THICKNESS be figured on the basis of the mica thickness plus .003” (.08mm). This will

allow the saw to remove the full width of the mica pus .0015” (.04mm) of copper on each side of the mica slot. If

unable to determine the mica width, the use of a feeler gauge can best determine the required saw thickness.

Consequently, some copper is cut or dragged off the bar during undercutting, (as shown in Fig. 2).

Bevel to Remove

Rough Edge Caused

Rough Edge

by Undercutting Slotting Off Center

Leaves Mica Fins

Fig. 2

In addition to leaving a jagged edge projecting from the commutator bar, the edge of the bar becomes somewhat

work-hardened and hence will not wear down uniformly. Therefore, the edges of the bars must be chamfered by using

a suitable slotting file or a specialty shaped scraper. ** See Martindale slotting scrapers. **

A chamfered face of approximately 1/64 inch is usually adequate to remove any roughness or edge hardening that

could be disturbing to the brush faces.

V-SLOT

V-slots keep slots free from dust accumulations at low speeds, and do not require a separate operation for cham-

fering of the bar edges. V-slots are usually made with either a slotting file, or a “V” tooth circular cutter.

Usual practice is to use a circular cutter having an included angle between cutting edges such that a cut made 1/16

inch deep will also leave 1/32 inch free copper above the mica. The “V” tooth circular cutter are available with 40°,

50° or 60° angles between the cutting edges.

Saw Cut Copper

Type “V” Slot

Mica

Continued Next Page

MARTINDALE • PO Box 430 • Cleveland, OH 44107

Phone (216) 521-8567 • Fax Local 521-9476 / USA & Canada (800) 344-9191

E-Mail: sales@martindaleco.com

Web Site: www.martindaleco.com 11/07

16

Helpful Hints For Saw Users

(Mica Undercutting Saws & V-Cutters) (Continued)

To obtain a 1/16 inch deep cut with 1/32 inch free copper above the mica, the following table may be used:

Thickness of Mica Angle of “V”-cutter

.023 inch 40°

.029 inch 50°

.036 inch 60°

The necessity of accurately centering the circular cutter on the mica is readily apparent. Mica fins in V-slots being

wedge-shaped, are more difficult to remove than the fins of uniform thickness left at the sides of U-slots by inaccu-

rate centering of the circular cutter.

Mica Fins Are Left in Slots

That Are:

Too Shallow -or- Off Center

COMPOUND LAND

The teeth on the compound land mica saw are alternately ground to a special taper which reduces the impact on

each individual tooth and produces chips of just slightly over half the width of the mica slot thereby eliminating the

tendency to clog. When undercutting with a compound land saw the bottom of the slot will appear to be flat.

However, as a result of the reverse taper on alternate teeth, the slot will have a slight pyramid or convex surface.

This type of saw operates cooler and cleans better thereby prolonging the saw life with resulting economy to the

user.

Saw Cut

Copper

Compound Land

Mica

After a commutator has been undercut, it should be very carefully inspected to assure that all copper particles have

been removed, that the bars have been carefully chamfered, and that all sharp edges and burs have been elimi-

nated. Then each slot should be individually checked and reworked as necessary to remove any traces of fin or side

mica.

Finally, the surface should be lightly polished with a fine-grain commutator stone. **A more popular method is the

use of a rubber bond cleaning stone, which will properly finish the surface and leave the proper filming required.

MARTINDALE • PO Box 430 • Cleveland, OH 44107

Phone (216) 521-8567 • Fax Local 521-9476 / USA & Canada (800) 344-9191

E-Mail: sales@martindaleco.com

Web Site: www.martindaleco.com 11/07

You might also like

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- Masonry Details That WorkDocument169 pagesMasonry Details That Workcabpcabp100% (2)

- Klauke Tools Cable Crimping Die Sets CatalogueDocument302 pagesKlauke Tools Cable Crimping Die Sets Cataloguesahala123No ratings yet

- Steel SpecDocument82 pagesSteel Specmglp54No ratings yet

- Tapping Feed and Speed Viking Drill and ToolDocument1 pageTapping Feed and Speed Viking Drill and ToolDaniele TropepeNo ratings yet

- Pilana Metal Cutting Tools enDocument32 pagesPilana Metal Cutting Tools enBryan ThorntonNo ratings yet

- 2021 Master CatalogDocument330 pages2021 Master Cataloggeetha raniNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Strip Cladding StripsDocument20 pagesStrip Cladding StripsMahesh DeshmukhNo ratings yet

- Cemented Tunsten Carbide Metalforming Grades ChartDocument2 pagesCemented Tunsten Carbide Metalforming Grades Chartflytorahul100% (3)

- Basic Scroll Saw PDFDocument14 pagesBasic Scroll Saw PDFDaguliNo ratings yet

- Flexible Abrasive DiskDocument1 pageFlexible Abrasive DiskRamli AnovaNo ratings yet

- Outokumpu Machining Guideline Ultra 254SMODocument2 pagesOutokumpu Machining Guideline Ultra 254SMOzhiqianxuNo ratings yet

- 10 Sanding Machines en - Diciembre.20Document52 pages10 Sanding Machines en - Diciembre.20Henrique GabrielNo ratings yet

- Karya Silix Product Catalog All LR140917Document24 pagesKarya Silix Product Catalog All LR140917KakasNo ratings yet

- A 400 HB Wear Resistant Steel: StandardDocument4 pagesA 400 HB Wear Resistant Steel: StandardVíctor SandovskyNo ratings yet

- SSAB Machining Strenx 2017Document28 pagesSSAB Machining Strenx 2017RogerNo ratings yet

- SW 0350Document1 pageSW 0350Nazar KompaniethNo ratings yet

- Steel Gems - Company ProfileDocument2 pagesSteel Gems - Company ProfileravinaatthwalNo ratings yet

- Annular Cutter Feeds and SpeedsDocument1 pageAnnular Cutter Feeds and SpeedsAnonymous JzEb8CXErNo ratings yet

- Carbon Hollow Bar: (32 To 250 MM OD) (254 To 610 MM OD)Document2 pagesCarbon Hollow Bar: (32 To 250 MM OD) (254 To 610 MM OD)Richard Vica CalvoNo ratings yet

- Specification For Cold Rolled Sheet SteelsDocument1 pageSpecification For Cold Rolled Sheet SteelsVinoth ShankarNo ratings yet

- Cutting SpeedDocument5 pagesCutting Speedokooy erusNo ratings yet

- Tire Rubber Blades BrochureDocument4 pagesTire Rubber Blades BrochureRavinder GuptaNo ratings yet

- FourCut ENG 2020 GroovingDocument16 pagesFourCut ENG 2020 Groovingsaepudin 40No ratings yet

- Milling Parameters: N (RPM) (VC (M/min) 1000) / 3.14 Ø d1 (MM) )Document4 pagesMilling Parameters: N (RPM) (VC (M/min) 1000) / 3.14 Ø d1 (MM) )Damir PrstenkovNo ratings yet

- SWOSC-V Steel Wire - EN VDSiCr - EN 10270-2 - Suzuki GarphyttanDocument4 pagesSWOSC-V Steel Wire - EN VDSiCr - EN 10270-2 - Suzuki GarphyttanPrasadNo ratings yet

- Grinding Wheels: Electric or Power Grinder Are UsedDocument3 pagesGrinding Wheels: Electric or Power Grinder Are UsedJayson cheekNo ratings yet

- 2013 Lone Wolf KnivesDocument9 pages2013 Lone Wolf KnivesMario LopezNo ratings yet

- BohlerDocument2 pagesBohlerjupiter zNo ratings yet

- High Speed Steel Round BarDocument4 pagesHigh Speed Steel Round BarMANJEET KUMARNo ratings yet

- LEFON Saw Blade CatalogDocument3 pagesLEFON Saw Blade Catalogoleu67No ratings yet

- Wear and RepairDocument12 pagesWear and RepairmtonellyNo ratings yet

- Strong: StuffDocument9 pagesStrong: StuffAnonymous FO2ABXXNo ratings yet

- Stud Welding A First LookDocument16 pagesStud Welding A First Lookspalaniandavar07No ratings yet

- DS Wear Creusabro Superten 2020 1Document3 pagesDS Wear Creusabro Superten 2020 1Erdinc BayatNo ratings yet

- SERVOTECNICA-SRH SlipRingsDocument4 pagesSERVOTECNICA-SRH SlipRingsTenday Agus Setya WibawaNo ratings yet

- Ball Bearings For Conveyor RollersDocument3 pagesBall Bearings For Conveyor RollersMehran KhNo ratings yet

- BurrDocument9 pagesBurrOmsri VinashaNo ratings yet

- Scotchman Cold Saw Blade BasicsDocument9 pagesScotchman Cold Saw Blade BasicsrjsnelsonjrNo ratings yet

- EN Wiha Bolt CuttersDocument1 pageEN Wiha Bolt CuttersSzilvia Gazdag-RozsNo ratings yet

- Bonded Abrasives CataloguesDocument10 pagesBonded Abrasives CataloguesValeriia HnutovaNo ratings yet

- Synergy CatalogueDocument8 pagesSynergy CatalogueTino JuNo ratings yet

- StdrillserratedDocument2 pagesStdrillserratedSaul AguilarNo ratings yet

- Master Tungsten Carbide Rotary Burrs PDFDocument12 pagesMaster Tungsten Carbide Rotary Burrs PDFFred AksoNo ratings yet

- Crusher Crusher Crusher Crusher Hammer Hammer Hammer Hammer Detail Detail Detail Detail Information Information Information InformationDocument9 pagesCrusher Crusher Crusher Crusher Hammer Hammer Hammer Hammer Detail Detail Detail Detail Information Information Information InformationAlbin Moniago SimanjuntakNo ratings yet

- Bearing Lock Nuts Brochure 20200515Document8 pagesBearing Lock Nuts Brochure 20200515Bayu SutiaraNo ratings yet

- Miranda PLDocument48 pagesMiranda PLGOYMA IMPEXNo ratings yet

- Campaign: Solid Carbide End MillsDocument8 pagesCampaign: Solid Carbide End Mills2dex1adwief2m1a6No ratings yet

- 008 Alloy Tool SteelDocument66 pages008 Alloy Tool SteelJose A DominguezNo ratings yet

- Consumables Catalogue PDFDocument68 pagesConsumables Catalogue PDFGunasekaran paramasamyNo ratings yet

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKNo ratings yet

- Prepared By: Parth Shah Dharamjeet Jadeja Sanjay Parmar Purav VyasDocument26 pagesPrepared By: Parth Shah Dharamjeet Jadeja Sanjay Parmar Purav VyasNordiana IdrisNo ratings yet

- Stainless Steel Flexible Conduit:: Type SL and UI CapDocument2 pagesStainless Steel Flexible Conduit:: Type SL and UI CapStone123456789No ratings yet

- Ryan Product ListDocument9 pagesRyan Product ListjoshNo ratings yet

- Stainless Steel 420 Material Chemical CompositionDocument3 pagesStainless Steel 420 Material Chemical Compositionr arumugamNo ratings yet

- Recommendations For Cutting Speeds N and Feeds F MM: Tool ØDocument9 pagesRecommendations For Cutting Speeds N and Feeds F MM: Tool ØLeonardo PachecoNo ratings yet

- Diamond WireDocument6 pagesDiamond Wirereworksystems1No ratings yet

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderFrom EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderNo ratings yet

- Air FilterDocument2 pagesAir FilteruripssgmailNo ratings yet

- Sutorbilt Air Power UnitsDocument1 pageSutorbilt Air Power UnitsuripssgmailNo ratings yet

- Duroflow Air Power UnitsDocument1 pageDuroflow Air Power UnitsuripssgmailNo ratings yet

- R700C Sawbench Feb 2008 Operator & Parts Manual OptDocument14 pagesR700C Sawbench Feb 2008 Operator & Parts Manual OpturipssgmailNo ratings yet

- Kice PD Air Power UnitsDocument1 pageKice PD Air Power UnitsuripssgmailNo ratings yet

- FC Performance ChartDocument11 pagesFC Performance CharturipssgmailNo ratings yet

- MCO05000 - Platinum Series 10 - 5 Function Combination Machine W - Spiral Cutters13 03 2015Document51 pagesMCO05000 - Platinum Series 10 - 5 Function Combination Machine W - Spiral Cutters13 03 2015uripssgmailNo ratings yet

- Mixer MotorsDocument1 pageMixer MotorsuripssgmailNo ratings yet

- Wravor Catalog enDocument28 pagesWravor Catalog enuripssgmailNo ratings yet

- Mixing Air Motor LZL 03-05 - tcm509-1188338Document4 pagesMixing Air Motor LZL 03-05 - tcm509-1188338uripssgmailNo ratings yet

- DUNLOPDocument51 pagesDUNLOPuripssgmailNo ratings yet

- Specify Your LZL To Match Your Mounting NeedsDocument1 pageSpecify Your LZL To Match Your Mounting NeedsuripssgmailNo ratings yet

- Airmotor Catalogue2010 EN 0922 - tcm509-1188313Document76 pagesAirmotor Catalogue2010 EN 0922 - tcm509-1188313uripssgmailNo ratings yet

- Ie300 ManualDocument14 pagesIe300 ManualuripssgmailNo ratings yet

- Kayttoohje - SSG600 A DCDocument34 pagesKayttoohje - SSG600 A DCuripssgmailNo ratings yet

- Manufacturing Quality Control Checklist - SafetyCultureDocument10 pagesManufacturing Quality Control Checklist - SafetyCultureuripssgmailNo ratings yet

- FAT ReferenceDocument12 pagesFAT ReferenceuripssgmailNo ratings yet

- Different Types of AugerDocument3 pagesDifferent Types of AugeruripssgmailNo ratings yet

- 12 Machinery Catalog 10Document50 pages12 Machinery Catalog 10uripssgmailNo ratings yet

- Manual Eagle 5-2017 EN - 0Document29 pagesManual Eagle 5-2017 EN - 0uripssgmailNo ratings yet

- Safety of Woodworking Machines - Circular Sawing MachinesDocument110 pagesSafety of Woodworking Machines - Circular Sawing MachinesuripssgmailNo ratings yet

- Cut 315 ManualDocument24 pagesCut 315 ManualuripssgmailNo ratings yet

- 2014-10-07 Produkt Katalog PG B en LRDocument25 pages2014-10-07 Produkt Katalog PG B en LRuripssgmailNo ratings yet

- Screw Conveyor Components and DesignDocument10 pagesScrew Conveyor Components and DesignuripssgmailNo ratings yet

- Screw Conveyor Components and DesignDocument3 pagesScrew Conveyor Components and DesignuripssgmailNo ratings yet

- Crane SafetyDocument3 pagesCrane SafetyuripssgmailNo ratings yet

- Manufacturing Facility Daily Checklist - SafetyCultureDocument20 pagesManufacturing Facility Daily Checklist - SafetyCultureuripssgmailNo ratings yet

- Technical Clarification MeetingDocument1 pageTechnical Clarification MeetinguripssgmailNo ratings yet

- Gaining An Edge: A Shrink-Wrap Machine Manufacturer Finally Finds A Deburring and Buffing Machine That Meets Its NeedsDocument5 pagesGaining An Edge: A Shrink-Wrap Machine Manufacturer Finally Finds A Deburring and Buffing Machine That Meets Its NeedsuripssgmailNo ratings yet

- Factory Acceptance Template Checklist - SafetyCultureDocument14 pagesFactory Acceptance Template Checklist - SafetyCultureuripssgmailNo ratings yet

- Halfen Castin Channel FixingsDocument40 pagesHalfen Castin Channel Fixingspodrow100% (1)

- Case Study - Knockout DrumDocument2 pagesCase Study - Knockout DrumAshfaq AnwerNo ratings yet

- Tunneling and Geotechnical SystemsDocument12 pagesTunneling and Geotechnical SystemsHakan_KURUNo ratings yet

- BaerFix en 2019Document24 pagesBaerFix en 2019Triantafyllos MalakisNo ratings yet

- Performance of Copper Slag As Replacement of Fine Aggregate With Different GradesDocument5 pagesPerformance of Copper Slag As Replacement of Fine Aggregate With Different Gradesemraan KhanNo ratings yet

- Sriram Centre, Vernacular Architecture - CoaDocument13 pagesSriram Centre, Vernacular Architecture - CoaVarunNo ratings yet

- Danav Buildcon (Main Sheet)Document91 pagesDanav Buildcon (Main Sheet)Rizwana PatelNo ratings yet

- Mac Alloy Bars Method StatementDocument13 pagesMac Alloy Bars Method StatementGouse. ShaikNo ratings yet

- Trays and Packing Random & Structured PDFDocument9 pagesTrays and Packing Random & Structured PDFAsifNo ratings yet

- Ancillary Products: DualproofDocument24 pagesAncillary Products: DualproofNightly OwlNo ratings yet

- Strip Foudation ExcavationsDocument8 pagesStrip Foudation ExcavationsImperial OneNo ratings yet

- BS1199 1976Document13 pagesBS1199 1976FuziahsabtuNo ratings yet

- Vicat Apparatus PrimoDocument10 pagesVicat Apparatus PrimoMoreno, Leanne B.No ratings yet

- Concreto Construccion CivilDocument4 pagesConcreto Construccion CivilMarcela Campos100% (1)

- EN8 Carbon Steel: Form of SupplyDocument3 pagesEN8 Carbon Steel: Form of SupplyExcel Hydro Pneumatics (INDIA) EHPINo ratings yet

- Effect of Using Saturated Lime Water in The Production of Concrete Using Pozzolanic Cement Cem II B-PDocument18 pagesEffect of Using Saturated Lime Water in The Production of Concrete Using Pozzolanic Cement Cem II B-PKellymax olakitarNo ratings yet

- SANITARYDocument8 pagesSANITARYpat.No ratings yet

- Mrs Akhila Vimal Rev 1mar 23Document3 pagesMrs Akhila Vimal Rev 1mar 23karthik karikalvalavanNo ratings yet

- 10-Tmss-07-Substation Grounding Materials-R0Document17 pages10-Tmss-07-Substation Grounding Materials-R0m3een100% (1)

- COATING - List of International Coating-StandardsDocument8 pagesCOATING - List of International Coating-StandardsEdison Walit100% (1)

- ASTER 24QF - Data Sheet: StructureDocument1 pageASTER 24QF - Data Sheet: Structureroberto riveraNo ratings yet

- Price: Public Works DepartmentDocument2 pagesPrice: Public Works DepartmentJojy SebastianNo ratings yet

- Data Sheets Optiseal Wafer Lugged Keystone en en 5445860Document9 pagesData Sheets Optiseal Wafer Lugged Keystone en en 5445860oukassou.mohamed10No ratings yet

- Magnet 40x15x8Document1 pageMagnet 40x15x8George PaulNo ratings yet

- Fosroc Conbextra TS: Non Shrink Cementitious Aggregate Filled GroutDocument2 pagesFosroc Conbextra TS: Non Shrink Cementitious Aggregate Filled Grouthameed6101986No ratings yet

- Astm A276 A276m 17Document4 pagesAstm A276 A276m 17serinacui19880818No ratings yet

- Gutter DetailDocument1 pageGutter DetailarkikuNo ratings yet

- Mating Flanges: ST Issue 2Document2 pagesMating Flanges: ST Issue 2Nugrawan SatriaNo ratings yet

- Weld Australia Guidance Note TGN SG03 AS NZS 2980 A Summary of Changes PDFDocument14 pagesWeld Australia Guidance Note TGN SG03 AS NZS 2980 A Summary of Changes PDFRodolfoMarínNo ratings yet