Professional Documents

Culture Documents

Si 596 Red-En

Si 596 Red-En

Uploaded by

kabirisc0 ratings0% found this document useful (0 votes)

32 views3 pagesLoctite SI Red data sheet

Original Title

SI 596 RED-EN

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLoctite SI Red data sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

32 views3 pagesSi 596 Red-En

Si 596 Red-En

Uploaded by

kabiriscLoctite SI Red data sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

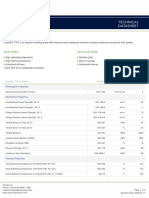

Technical Data Sheet

LOCTITE® SI 596 RED

Known as LOCTITE® Superflex® Red RTV Silicone or LOCTITE® 596

August-2014

PRODUCT DESCRIPTION TYPICAL CURING PERFORMANCE

LOCTITE® SI 596 RED provides the following product characteristics: LOCTITE® SI 596 RED cures on exposure to moisture in the

Technology Silicone air. The product dries tack free in 1 hour and fully cures in 24

Chemical Type Acetoxy silicone hours. Cure times will vary with temperature, humidity and

Appearance (uncured) Red homogeneous pasteLMS gap.

Components One component -

requires no mixing

Thixotropic Reduced migration TYPICAL PROPERTIES OF CURED MATERIAL

of liquid product after Cured for 7 days @ 25 °C / 50% RH

application to substrate Physical Properties:

Cure Room temperature vulcanizing (RTV) Shore Hardness, ISO 868, Durometer A ≥18LMS

Application Gasketing or Sealing Elongation, ISO 37, % ≥300LMS

Flexibility Enhances load bearing & shock Tensile Strength, ISO 37 N/mm² ≥1.5LMS

absorbing characteristics of the bond (psi) (≥217)

area.

Specific Application Gasket dressing

Specific Benefit Good temperature resistance. Cured for 14 days @ 25 °C

180° Peel Strength :

Aluminum N/mm ≥1.73LMS

®

LOCTITE SI 596 RED is used for gasketing and sealing (lb/in) (≥9.88)

Steel N/mm ≥1.73LMS

applications for both plant maintenance and small, medium, (lb/in) (≥9.88)

and large-sized OEM. It is specially formulated to meet the low

silicone volatiles requirements of the automotive industry for

315°C flange sealants. As a formed-in-place gasket/sealant,

LOCTITE® SI 596 RED has been designed to give outstanding

performance in typical automotive gasketing applications TYPICAL ENVIRONMENTAL RESISTANCE

including valve covers, rocker covers, oil pans, water pumps, Cured @ 25 °C / 50±5 % RH for 7 days, tested @ 25 °C, 3.2

end seals, intake manifolds, and rear axle housings. This mm thick film

product is also used as a sealant and adhesive for assembly Heat Aging

and repair of industrial furnaces, ovens, boilers, exhaust Aged at temperature indicated and tested @ 22 °C

stacks, high temperature ducting, and heating elements in Week(s) @ 204 °C

electrical appliances. This product is typically used in 1 2 4 8

applications up to 315 °C. Shore Hardness, ISO 868, Durometer A 29 28 25 22

Tensile Strength, ISO 527-3, N/mm² 2.0 2.2 2.3 1.9

Elongation, ISO 527-2, % 370 450 490 500

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C 1.05 Week(s) @ 260 °C

Extrusion Rate, g/min: 1 2 4 7

Pressure 0.62 MPa, time 15 seconds, temperature 25 °C: Shore Hardness, ISO 868, Durometer A 23 16 15 17

Semco Cartridge ≥250LMS Tensile Strength, ISO 527-3, N/mm² 1.3 0.7 0.4 0.3

Flash Point - See SDS Elongation, ISO 527-2, % 520 440 280 210

Odor Acetic Acid

Week(s) @ 316 °C

1 2 3

Shore Hardness, ISO 868, Durometer A 48 64 82

Tensile Strength, ISO 527-3, N/mm² 1.4 1.6 1.5

Elongation, ISO 527-2, % 175 70 25

TDS LOCTITE® SI 596 RED, August-2014

At 260°C, softening is due to reversion and will occur Conversions

regardless of how the sealant is cured. For flange sealing, this (°C x 1.8) + 32 = °F

softening is usually an attribute. kV/mm x 25.4 = V/mil

mm / 25.4 = inches

At 315°C, hardening is due to thermal rearrangement of the µm / 25.4 = mil

polymer and also oxidation. Oxidation is retarded when the N x 0.225 = lb

product is used as a flange sealant. N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi

GENERAL INFORMATION N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

This product is not recommended for use in pure oxygen

N·mm x 0.142 = oz·in

and/or oxygen rich systems and should not be selected as

mPa·s = cP

a sealant for chlorine or other strong oxidizing materials.

Note:

For safe handling information on this product, consult the The information provided in this Technical Data Sheet (TDS) including

Safety Data Sheet (SDS). the recommendations for use and application of the product are based

on our knowledge and experience of the product as at the date of this

Directions for use: TDS. The product can have a variety of different applications as well as

differing application and working conditions in your environment that

1. For best performance bond surfaces should be clean and are beyond our control. Henkel is, therefore, not liable for the suitability

free from grease. of our product for the production processes and conditions in respect

2. Full performance properties will develop over 24 hours. of which you use them, as well as the intended applications and

3. Moisture curing begins immediately after the product is results. We strongly recommend that you carry out your own prior trials

exposed to the atmosphere, therefore parts to be to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or

assembled should be mated within a few minutes after the

any other written or oral recommendation(s) regarding the concerned

product is dispensed. product is excluded, except if otherwise explicitly agreed and except in

4. Press or firmly clamp parts together. Do not slide parts relation to death or personal injury caused by our negligence and any

together. liability under any applicable mandatory product liability law.

5. Excess material can be easily wiped away with non-polar

In case products are delivered by Henkel Belgium NV, Henkel

solvents. Electronic Materials NV, Henkel Nederland BV, Henkel

6. Excess cured material can be removed with a knife or Technologies France SAS and Henkel France SA please

single edge razor blade. additionally note the following:

In case Henkel would be nevertheless held liable, on whatever legal

NOTE: Do not use LOCTITE® SI 596 RED for gasketing ground, Henkel’s liability will in no event exceed the amount of the

concerned delivery.

carburetors or fuel control devices where it will be in

constant contact with hydrocarbon fuels. Material will In case products are delivered by Henkel Colombiana, S.A.S. the

develop excessive swell and loss of mechanical following disclaimer is applicable:

The information provided in this Technical Data Sheet (TDS) including

properties. the recommendations for use and application of the product are based

on our knowledge and experience of the product as at the date of this

Loctite Material SpecificationLMS TDS. Henkel is, therefore, not liable for the suitability of our product for

LMS dated July-06, 2005. Test reports for each batch are the production processes and conditions in respect of which you use

available for the indicated properties. LMS test reports include them, as well as the intended applications and results. We strongly

selected QC test parameters considered appropriate to recommend that you carry out your own prior trials to confirm such

specifications for customer use. Additionally, comprehensive suitability of our product.

controls are in place to assure product quality and Any liability in respect of the information in the Technical Data Sheet or

consistency. Special customer specification requirements may any other written or oral recommendation(s) regarding the concerned

product is excluded, except if otherwise explicitly agreed and except in

be coordinated through Henkel Quality.

relation to death or personal injury caused by our negligence and any

Storage liability under any applicable mandatory product liability law.

Store product in the unopened container in a dry location. In case products are delivered by Henkel Corporation, Resin

Storage information may be indicated on the product container Technology Group, Inc., or Henkel Canada Corporation, the

labeling. following disclaimer is applicable:

Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or The data contained herein are furnished for information only and are

greater than 28 °C can adversely affect product properties. believed to be reliable. We cannot assume responsibility for the results

Material removed from containers may be contaminated during obtained by others over whose methods we have no control. It is the

use. Do not return product to the original container. Henkel user's responsibility to determine suitability for the user's purpose of

any production methods mentioned herein and to adopt such

Corporation cannot assume responsibility for product which

precautions as may be advisable for the protection of property and of

has been contaminated or stored under conditions other than persons against any hazards that may be involved in the handling and

those previously indicated. If additional information is required, use thereof. In light of the foregoing, Henkel Corporation specifically

please contact your local Technical Service Center or disclaims all warranties expressed or implied, including

Customer Service Representative. warranties of merchantability or fitness for a particular purpose,

arising from sale or use of Henkel Corporation’s products. Henkel

Corporation specifically disclaims any liability for consequential

or incidental damages of any kind, including lost profits. The

discussion herein of various processes or compositions is not to be

interpreted as representation that they are free from domination of

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE® SI 596 RED, August-2014

patents owned by others or as a license under any Henkel Corporation

patents that may cover such processes or compositions. We

recommend that each prospective user test his proposed application

before repetitive use, using this data as a guide. This product may be

covered by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document are

trademarks of Henkel Corporation in the U.S. and elsewhere. ®

denotes a trademark registered in the U.S. Patent and Trademark

Office.

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere. ® denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 1.3

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

You might also like

- Chemistry Project Class 12 - Variation of Conductance of Electrolytes With TemperatureDocument21 pagesChemistry Project Class 12 - Variation of Conductance of Electrolytes With TemperatureHimank Goel47% (15)

- Science Activity Sheet Quarter 4-MELC 1 Week 1 Gas LawsDocument12 pagesScience Activity Sheet Quarter 4-MELC 1 Week 1 Gas LawsKim Camposano73% (11)

- Principles of Food Preservation, Processing and PackagingDocument46 pagesPrinciples of Food Preservation, Processing and PackagingAshok Yadav100% (1)

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechNo ratings yet

- LOCTITE SI 5927 RED en - GLDocument2 pagesLOCTITE SI 5927 RED en - GLOmer IkhlasNo ratings yet

- Ea 3463 New-EnDocument2 pagesEa 3463 New-EnRonald Mario Quiroz SerrateNo ratings yet

- LOCTITE 315 en - GLDocument2 pagesLOCTITE 315 en - GLinigo.bretonNo ratings yet

- Loctite SI 5366™: Technical Data SheetDocument2 pagesLoctite SI 5366™: Technical Data SheetSanthosh Kumar RavichandranNo ratings yet

- 5570 WhiteDocument2 pages5570 WhitesasidharkanthetiNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Loctite Fixmaster Metal Magic Steel™: Technical Data SheetDocument3 pagesLoctite Fixmaster Metal Magic Steel™: Technical Data SheetHamzaNoumanNo ratings yet

- Top Coat Blue Pool Iso-Npg enDocument4 pagesTop Coat Blue Pool Iso-Npg enVICTOR MARCOSNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Loctitie Fix Master Ea 3463-Na-EnDocument3 pagesLoctitie Fix Master Ea 3463-Na-EnImran KhanNo ratings yet

- Si 5970-EnDocument4 pagesSi 5970-EnphairyNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- LOctite SI 5900Document3 pagesLOctite SI 5900Giovanni HernandezNo ratings yet

- Loctite Ea 3478 - Carga MetalicaDocument3 pagesLoctite Ea 3478 - Carga Metalicafrancisca ferrerNo ratings yet

- DION IMPACT 9102 SeriesDocument5 pagesDION IMPACT 9102 SeriesLENEEVERSONNo ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- 5660 enDocument3 pages5660 enסטניסלב טלשבסקיNo ratings yet

- Impeller STD Resin - Dion 9800 PDFDocument5 pagesImpeller STD Resin - Dion 9800 PDFWilmer AndresNo ratings yet

- LOCTITEDocument2 pagesLOCTITEHrNo ratings yet

- Loctite 3568 TDSDocument3 pagesLoctite 3568 TDSShareduwan SannosiNo ratings yet

- Carter XepDocument2 pagesCarter XepSami KahtaniNo ratings yet

- Ea 3463 enDocument3 pagesEa 3463 enasistengerenciasigsNo ratings yet

- 190017-EN - Explosive Charge BonderDocument2 pages190017-EN - Explosive Charge BonderdatkoloNo ratings yet

- Zalac 002Document4 pagesZalac 002Stevie Herman TDNo ratings yet

- Loctite SI 5970-EnDocument3 pagesLoctite SI 5970-EnAshishNo ratings yet

- Loctite SI 5900: Technical Data SheetDocument3 pagesLoctite SI 5900: Technical Data SheetSanthosh Kumar RavichandranNo ratings yet

- Loctite EA 907™: Technical Data SheetDocument2 pagesLoctite EA 907™: Technical Data Sheetuzzy2No ratings yet

- Sikaflex® Pro-3 Purform® - Material SubmittalDocument34 pagesSikaflex® Pro-3 Purform® - Material SubmittalEmad El ShaerNo ratings yet

- SureCav TDS July 2017Document2 pagesSureCav TDS July 2017عبدالوهاب الشيخيNo ratings yet

- Shell Irus DU 68 TDSDocument2 pagesShell Irus DU 68 TDSHEENA SHAIKHNo ratings yet

- Loctite 5699 - enDocument3 pagesLoctite 5699 - enRider OaklandNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Sikafloor®-263 SLDocument6 pagesSikafloor®-263 SLHalit Baris SertbakanNo ratings yet

- Technical Data Sheet: Perspex CCDocument2 pagesTechnical Data Sheet: Perspex CCResist IkatNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- LOCTITE SI 5910 en - GLDocument3 pagesLOCTITE SI 5910 en - GLChandra Budhi RizkyNo ratings yet

- Untitled GkrsbhinsergDocument3 pagesUntitled GkrsbhinsergMohitrajranikashyapNo ratings yet

- Loctite Stycast 2762: Technical Data SheetDocument3 pagesLoctite Stycast 2762: Technical Data SheetankitaNo ratings yet

- Si 5699-EnDocument3 pagesSi 5699-EnWahyu Riz AmblakadarrNo ratings yet

- SEMICOSIL 987 GR en 2021.09.17Document4 pagesSEMICOSIL 987 GR en 2021.09.17Carlos Enriquez ReyesNo ratings yet

- Loctite Hysol 891-60 TNDocument2 pagesLoctite Hysol 891-60 TNSebas TianNo ratings yet

- Polystyrene CRYSTAL 1160: DescriptionDocument2 pagesPolystyrene CRYSTAL 1160: DescriptionlyesNo ratings yet

- Shell Heat Transfer Oil S2X TDSDocument2 pagesShell Heat Transfer Oil S2X TDSrudiarto 07No ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Loctite MR 2000™: Technical Data SheetDocument3 pagesLoctite MR 2000™: Technical Data Sheetروشان فاطمة روشانNo ratings yet

- Loctite 384Document2 pagesLoctite 384A DamiánNo ratings yet

- Loctite 577™: Technical Data SheetDocument4 pagesLoctite 577™: Technical Data SheetCristian SerbovNo ratings yet

- Shell Thermia B PDFDocument2 pagesShell Thermia B PDFEduardo Dreifus100% (1)

- Ea E-214hp-EnDocument3 pagesEa E-214hp-EnHendi AfriyanNo ratings yet

- Sikaflex Pro-3Document5 pagesSikaflex Pro-3MCCIN L&WNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Loctite Ea 9395 Aero: Epoxy Paste AdhesiveDocument5 pagesLoctite Ea 9395 Aero: Epoxy Paste AdhesiveFernando GarzonNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- Eva - RenewsysDocument1 pageEva - RenewsysShashwata ChattopadhyayNo ratings yet

- TDS Loctite Nordbak Wearing - CompoundDocument3 pagesTDS Loctite Nordbak Wearing - CompoundSadamNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Loctite Nordbak Wear Resistant Putty: Product Description MixedDocument3 pagesLoctite Nordbak Wear Resistant Putty: Product Description MixedFurqan ShabbirNo ratings yet

- Injection Molding Resins Brochure May 2017Document2 pagesInjection Molding Resins Brochure May 2017Lucas Valentim MendesNo ratings yet

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocument1 pageNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191No ratings yet

- R P RP O501 E W P S: Ecommended RacticeDocument43 pagesR P RP O501 E W P S: Ecommended RacticepaulortsNo ratings yet

- TDS - TDS - 23660 - Solvalitt Midtherm Alu - Eng - USDocument5 pagesTDS - TDS - 23660 - Solvalitt Midtherm Alu - Eng - USพสธร สอนทองNo ratings yet

- NGF Series - Element Replacement ProcedureDocument2 pagesNGF Series - Element Replacement Proceduresakura_jNo ratings yet

- Is.2529.1983 MGODocument21 pagesIs.2529.1983 MGOPrashantha NandavarNo ratings yet

- Properly Processing A SST™ TubeDocument1 pageProperly Processing A SST™ TubeARIF AHAMMED P100% (1)

- BETE WL-metricDocument1 pageBETE WL-metriccpvwqthcghoNo ratings yet

- Hydrogen Spectral LinesDocument17 pagesHydrogen Spectral LinesarnoldNo ratings yet

- Complete Full Report - Project Design 2019 Sem IIDocument67 pagesComplete Full Report - Project Design 2019 Sem IIGua Hantu100% (1)

- Qualitative Analysis - 8Document12 pagesQualitative Analysis - 8rashidNo ratings yet

- Gas Booster Brochure R9Document12 pagesGas Booster Brochure R9mecamb100% (1)

- BIO111 Principles of Biology Course Outline 2022Document5 pagesBIO111 Principles of Biology Course Outline 2022Resego lentsweNo ratings yet

- 6.5 Literacy ANSDocument2 pages6.5 Literacy ANStholmesNo ratings yet

- FlamesDocument16 pagesFlamesAffan MaqsoodNo ratings yet

- D 2340 - 03Document2 pagesD 2340 - 03Sinisa Gale Gacic100% (1)

- General Chemistry 1 - W5 L5Document2 pagesGeneral Chemistry 1 - W5 L5Ray Harvey Capuno67% (3)

- Physics MCQs For Class 12 CH 11 Dual Nature of Matter and RadiationDocument7 pagesPhysics MCQs For Class 12 CH 11 Dual Nature of Matter and RadiationAkshith ReddyNo ratings yet

- Impact Test Ravi Agarwal 09003017 Group GDocument8 pagesImpact Test Ravi Agarwal 09003017 Group GRavi Agarwal100% (1)

- Page 1 of 17 Sacred Heart of Mary Girls' SchoolDocument17 pagesPage 1 of 17 Sacred Heart of Mary Girls' SchoolAngeleena ANTONo ratings yet

- Substances, Compounds & Mixtures: How Everything Is Put TogetherDocument16 pagesSubstances, Compounds & Mixtures: How Everything Is Put TogetherMaria Rissa HerbaNo ratings yet

- ASTM A335-A335M-05aDocument9 pagesASTM A335-A335M-05aNadhiraNo ratings yet

- Unfolding Disaster - A Study of Chemplast Sanmar's Toxic Contamination in Mettur, TamilnaduDocument33 pagesUnfolding Disaster - A Study of Chemplast Sanmar's Toxic Contamination in Mettur, TamilnadulpremkumarNo ratings yet

- Protegra RO enDocument2 pagesProtegra RO enAnonymous PgiWw85t9No ratings yet

- Solution To Improve The Dust Collection Process in A Sand Reclamation PlantDocument48 pagesSolution To Improve The Dust Collection Process in A Sand Reclamation Plantananda narayananNo ratings yet

- Citric Acid Cross LinkingDocument12 pagesCitric Acid Cross LinkingivanlaunamiNo ratings yet

- Thermal and Spectroscopic Investigation of Sol-Gel Derived Aluminosilicate Bioglass MatricesDocument5 pagesThermal and Spectroscopic Investigation of Sol-Gel Derived Aluminosilicate Bioglass MatricesAlina PopaNo ratings yet

- Hot Water Can Freeze Faster Than ColdDocument11 pagesHot Water Can Freeze Faster Than ColdAlberto Di LulloNo ratings yet