Professional Documents

Culture Documents

United States Patent (19) : Atkinson (45) Aug. 10, 1976

United States Patent (19) : Atkinson (45) Aug. 10, 1976

Uploaded by

zgregz0 ratings0% found this document useful (0 votes)

19 views9 pages1. This patent describes a system for determining and controlling the thickness profile of sheet materials during production. It uses multiple sensors to simultaneously measure thickness across the sheet and compares each measurement to the average, generating signals for any differences.

2. These signals can then be used to automatically correct thickness variations and reduce persistent unevenness across the sheet. Prior systems could only measure thickness at single points, making it difficult to obtain accurate control information quickly enough.

3. The described system provides improved monitoring and feedback control of the transverse thickness profile during manufacturing, allowing issues like tight or slack bands in rolled materials to be reduced. It is particularly useful for processes like calendaring or stretching where variations can be introduced or magnified.

Original Description:

Original Title

US3974248

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. This patent describes a system for determining and controlling the thickness profile of sheet materials during production. It uses multiple sensors to simultaneously measure thickness across the sheet and compares each measurement to the average, generating signals for any differences.

2. These signals can then be used to automatically correct thickness variations and reduce persistent unevenness across the sheet. Prior systems could only measure thickness at single points, making it difficult to obtain accurate control information quickly enough.

3. The described system provides improved monitoring and feedback control of the transverse thickness profile during manufacturing, allowing issues like tight or slack bands in rolled materials to be reduced. It is particularly useful for processes like calendaring or stretching where variations can be introduced or magnified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

19 views9 pagesUnited States Patent (19) : Atkinson (45) Aug. 10, 1976

United States Patent (19) : Atkinson (45) Aug. 10, 1976

Uploaded by

zgregz1. This patent describes a system for determining and controlling the thickness profile of sheet materials during production. It uses multiple sensors to simultaneously measure thickness across the sheet and compares each measurement to the average, generating signals for any differences.

2. These signals can then be used to automatically correct thickness variations and reduce persistent unevenness across the sheet. Prior systems could only measure thickness at single points, making it difficult to obtain accurate control information quickly enough.

3. The described system provides improved monitoring and feedback control of the transverse thickness profile during manufacturing, allowing issues like tight or slack bands in rolled materials to be reduced. It is particularly useful for processes like calendaring or stretching where variations can be introduced or magnified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 9

United States Patent (19) [11] 3,974,248

Atkinson (45) Aug. 10, 1976

54 PROFILE DETERMINING AND/OR 3,307,215 3/1967 Gerhard et al...................... 425/14

CONTROLLING SYSTEM 3,341,388 9/1967 Bunyea ................................. 264/40

?h 3,599,288 8/1971 Eakman................................ 264/40

(75) Inventor: Edward Browell Atkinson, Ipswich, 3,646,188 2/1972 Campbell.............................. 264/40

England

73 Assignee: Bakelite Xylonite Limited, London, Primary Examiner-Jan H. Silbaugh

England Attorney, Agent, or Firm-Brisebois & Kruger

22 Filed: Sept. 5, 1973

21) Appl. No.: 394,416 57 ABSTRACT

48 a A system for determining and/or controlling the pro

30 Foreign Application Priority Data file of a property of an article, in which sensing means

Sept. 8, 1972 United Kingdom............... 4.1858/72 simultaneously obtains a multiplicity of electrical

gauging signals, each signal being proportional to a

52 U.S. Cl.................................. 264/40.2; 73/159; property of the article in a particular region, the gaug

425/141; 425/162 ing signals are passed to electrical circuit means which

(51 int. C.’............................................ B29D 7700 detect any difference in magnitude between the sig

58) Field of Search.............. 264/40, 425/141, 135, nals from a given region and the average for all such

425/140, 162; 73/159; 250/559, 560 signals and deriving a functional signal for any such

difference.

(56) References Cited

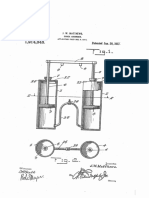

UNITED STATES PATENTS 7 Claims, 6 Drawing Figures

3,212,127 10/1965 Flook, Jr. et al................... 425/141

U.S. Patent Aug. 10, 1976 Sheet 1 of 2 3,974,248

U.S. Patent Aug. 10, 1976 Sheet 2 of 2 3,974,248

3,974,248

1. 2

along the length of the sheet in a regular or a random

PROFILE DETERMINING AND/OR ae.

CONTROLLING SYSTEM When the average thickness of the sheet at various

positions across the direction of production of the sheet

This invention relates to apparatus for determining 5 are determined, a persistent, nearly constant, profile

the profile of a characteristic or property of an article may be apparent due to some persistent influence such

and to a method employing such apparatus for control as the shape of the die gap or a transverse temperature

ling the profile of a characteristic or property of an distribution. When a film with a substantial persistent

article' or articles during production. transverse thickness profile is wound into a roll, tight or

The apparatus and method of the present invention 10 slack bands appear corresponding to persistently thick

have been found to be particularly useful in the deter or thin bands in the sheet or film. Such reels are un

mination and control of the thickness profile of sheet sightly and will generally be difficult to slit because of

materials to which, for the purpose of clarity only and film wandering or creasing. Also, such reels may cause

not for limiting the scope of the present invention, the film to become distorted with adverse effect on the

particular reference is made in the following descrip 5 flat-lying properties of the film.

tion. It is thus desirable to be able to measure the persis

Continuous sheets and films for example, of organic tent thickness variations across the width of a moving

thermoplastic materials, are manufactured by the use sheet material and, further, to apply corrective meas

of a variety of processes such as rolling, calendering, ures automatically in order to reduce the persistent

extrusion through slot-like extrusion dies and by extru 20 variations to a tolerable level. Conventional thickness

sion of tubes which may be subsequently enlarged in measuring and controlling apparatus gives difficulty in

diameter by a captive bubble technique before slitting coping with a situation, where both lengthwise and

into sheets. Sheets or films so produced may be subse transverse variations of thickness occur simultaneously

quently modified in thickness or physical properties by and where the persistent variations across its width only

lengthwise, transverse or biaxial stretching, or by 25 appear after the thickness at each point across the

shrinking and annealing. sheet has been averaged over a considerable length of

It is usually a desirable object of such processes to sheet. To gather sufficient information for control pur

produce a sheet or film of uniform thickness, or with a poses, a thickness gauge having a single measuring

distribution of thickness across its width which con head would need to be traversed many times across the

forms to a required profile. . . . 30 sheet. If the response time of the thickness measuring

The calendering process lends itself readily to the device was such that only relatively low scanning

production of sheet materials with a high degree of speeds could be used, then the time required to obtain

uniformity of thickness, the profile of which may be control information may be very long. The result of this

modified by mechanical adjustments of the calendering 35 would be that corrective action would take place slowly

rolls such as roll bending or skewing of the roll axes. or infrequently and so only relatively poor control

Fine adjustments may be made by grinding the rolls could be obtained.

themselves to a suitable profile. Accordingly, the present invention provides in par

Alternatively, processes in which the primary sheet ticular a system for determining, and also for control

material is formed by extrusion for example, and par ling, the persistent transverse thickness profile across a

ticularly when the primary sheet thickness is reduced 40 thermoplastic sheet material during its manufacture.

by stretching processes as is common in the production Other applications for the apparatus and for the

of packaging films and synthetic paper for example, are method hereinafter defined will be evident from the

likely to produce sheet or film which varies considera subsequent description to those skilled in industrial

bly in thickness from place to place along or across the processing, considered in conjunction with the accom

sheet. These variations may arise from changes in the 45 panying drawings in which: ..

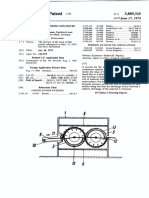

composition, molecular weight or state of plasticisation FIG. 1 is a schematic perspective view showing gaug

of the thermoplastic material, from fluctuations in the ing apparatus suitable for use in carrying out the pre

output of the extrusion machine or local variation in sent invention;

the temperature of the molten material or partly cooled 50 FIG. 2 is the circuit diagram of an electrical system

sheet. If the primary sheet produced by extrusion is for accepting gauging signals from the apparatus of

then subjected to stretching processes to thin the sheet FIG. 1 and deriving functional signals proportional to

or to produce a state of uniaxial or biaxial orientation, any differences between each individual gauging signal

further thickness changes may be produced, for exam and the average of all such signals;

ple if the sheet varies in temperature across the width at 55 FIG.3 shows one portion of the circuit of FIG. 2 on

the time of stretching, or thickness variations already an enlarged scale; ". .

present in the sheet may be magnified. It is therefore FIG. 4 is the circuit diagram of a display unit for

often impossible to ensure a uniform thickness distribu displaying a graphic indication of the thickness profile

tion across the sheet by a fixed adjustment of the extru of the sheet;

sion die gap for example, and desirable to control some FIG. 5 is a circuit diagram of an electrical integrator

significant variables of the process systematically by 60 suitable for use as a signal-conditioning device; and

automatic feed-back control from the observed thick FIG. 6 shows an arrangement in which the integrators

ness profile. illustrated in FIG. 5 are connected to an auxiliary cir

The variations in thickness may be distributed in a cuit.

complex pattern over a sheet produced by an extrusion According to one aspect of the present invention

process for example. The thickness profile at any stage 65 there is provided apparatus which comprises means to

of the process may not always be of the same shape, but obtain simultaneously a multiplicity of electrical gaug

may change in a periodic or a random manner. Like ing signals the magnitude of each being a substantially

wise, the average thickness across the sheet may vary linear function, over a working range, of a characteris

3,974,248

3 4

tic or property of an article in a respective region of the of using selenium barrier layer photo-voltaic cells, for

article, the slopes of the substantially linear functions example, as are preferred, to connect across each

having the same sign, means comprising an electrical photo-cell a resistor of low value, and which is prefer

circuit to accept the gauging signals obtained over the ably a variable resistor, such as Ry as described with

working range, detect any difference in magnitude reference to FIGS. 2 and 3. If variable resistors are used

occurring between each gauging signal and the average these may be used to adjust the outputs from the photo

of all the gauging signals and derive respective func cells such that for a desired reference profile the re

tional signals proportional to each difference such that spective gauging signals are all equal. Variable resistors

each functional signal may be correlated with the re O R may be used across other types of sensing devices of

spective region of the article. course, when used, to facilitate matching of the gauging

According to a second aspect of the present inven signals in the same way for a desired reference profile.

tion there is provided a method for controlling the When using photo-cells in the manner described above,

profile of a characteristic or property of an article optical filters with a peferential transmission for blue

being produced, which method employs the apparatus and green light, for example, may be placed between

of the invention and comprises positioning the means 15 the sheet and the photo-electric cells. If the concentra

such as to obtain simultaneously the multiplicity of tion of the light absorbing component in the material of

electrical gauging signals the magnitude of each being a the sheet is substantially uniform, for moderate

substantially linear function, over a desired working changes in the thickness of the sheet in the region of a

range, of the characteristic or property of the article in photo-cell the photo-electric current in that cell

a respective region of the article, the slopes of the 20 changes in a substantially linear manner with change in

substantially linear functions having the same sign, and thickness.

utilizing each functional signal derived to control a The means comprising an electrical circuit to accept

device for adjusting the characteristic or property of the gauging signals, detect any difference in magnitude

the article being produced in the respective region of occuring between each gauging signal and the average

the article such as to reduce any difference between the 25 of all the gauging signals and derive respective func

respective gauging signal and the average of all the tional signals proportional to each difference is prefer

gauging signals. ably an electrical circuit of the form illustrated in FIG.

The article may comprise any material, particularly 2 and which when receiving gauging signals from sele

any solid material, having any form. The invention has 30 nium barrier layer photo-voltaic cells, across which are

been found to be particularly applicable to articles connected resistors Ry, which are preferably variable

comprising sheets, films, tubes, and moulded articles resistors, as shown, and when incorporating a corre

and particularly where these are produced by continu sponding number of operational amplifiers, preferably

ous or repetitive processes. of the monolithic silicon integrated circuit type, may

The characteristic or property may be any character provide electrical signals of magnitude and polarity

istic or property such as for example, temperature, 35 which makes it particularly suitable for controlling

opacity, colour, specific gravity, electrical conductiv thickness profile display and adjusting devices. FIG. 3

ity, composition and thickness including coating thick shows one element of the circuit shown in FIG. 2 in

ness, but it will be appreciated that in the method of the cluding photo-voltaic cell P, a variable resistance Ry

present invention the characteristic or property should 40 and an operational amplifier A. In the circuit shown in

be such that it is capable of being influenced by practi FIG. 3, light, from a lamp, which is transmitted by a

cal means. The invention has been found to be particu translucent sheet material, for example, falls on the

larly applicable to the determination and/or control of sensitive area of the photo-voltaic cell P and causes th

the thickness profile of an article, especially when the photo-electric current to flow through the variable

article is a sheet or film. resistance Ry thus creating a difference in electrical

The means to obtain simultaneously a multiplicity of 45 potential between the common earth line and the non

electrical gauging signals may be a multiplicity of char inverting input terminal of the operational amplifier

acteristic or property sensing devices which may be marked with a + sign in the diagram. Provided the

suitably positioned in relation to the article. In the value of the resistance Ry is lower than a value which

method of the present invention when used to control depends upon the size of the photo-voltaic cell and the

the characteristic or property profile of an article being 50 mean light intensity falling on it, then the voltage across

produced along a direction, the sensing devices may be Ry, that is the gauging signal, is proportional to the

advantageously positioned in relation to one another in intensity of the light reaching the cell P, for example by

a direction transverse to the direction of production. transmission through a sheet material, and to the value

The sensing devices may be based upon, for example, 55 of the resistance Ry. Thus each similar resistance which

the principle of the absorption or scattering of radia is combined with the other photo-voltaic cells and am

tion, atomic particles, or electrons, the reflection of plifiers may be individually adjusted so that the change

micro-waves or the perturbation of electro-magnetic in voltage across the Ry caused by a change in light

fields by the material of the article. For example, one intensity may be set to a required value. It is obvious

array of thickness sensing devices which has been 60 that if the lamp used behind the sheet is not exactly of

found to be suitable for translucent pigmented sheet uniform intensity at all points across the sheet, it will be

materials and which will be referrred to hereinafter by necessary to adjust each resistance Ry so that if a sheet

way of exemplification only, consists of an electrical of uniform thickness and containing a uniform concen

fluorescent tube lamp placed behind the sheet material tration of light absorbing component along the line of

and spanning its width, and a number of photoelectric the lamp is interposed between the lamp and the photo

cells P placed in front of the sheet at intervals across it, 65 voltaic cells, the same voltage across Ry is obtained in

along the line of the lamp L as indicated in FIG. 1. In each case, that is to say the gauging signals are all

order to obtain a substantially linear response from the equivalent. The resistances R have the same value for

photo-cells it is normally necessary, such as in the case each amplifier and are typically about 1000). The

3,974,248

S 6

resistances R2 are each of a value which is a fixed multi sheet. A diagramatic representation of a display unit of

ple of the value of R, for example 20 or 100 times R. this kind is shown in FIG. 4, in which filter units con

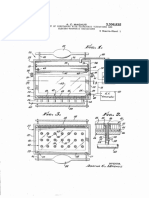

FIG. 2 shows how the elements as shown in FIG. 3 are sisting of resistors R and capacitors Cr are situated

interconnected by means of a common bus-bar D to 5

between the respective outputs O, to O, of the amplifi

which all the ends of the resistors R are connected. It ers and a multiplex switch device M.

will be seen that R and R, form potential dividing The multiplex switch device may be a monolithic

networks between the output of each amplifier and the silicon integrated circuit, the switching sequence being

common bus-bar, the mid-point being connected to the controlled by signals from a binary counter Q fed from

inverting input terminal marked with a negative sign. O

a multivibratr F. A saw-tooth waveform generator G is

The amplifiers are supplied from a dual constant volt also controlled by the binary counter so that its repeti

age Direct Current supply giving positive and negative tive period corresponds to a complete switching se

potentials symmetrical about earth, and conventional quence of the multiplex switch. The multiplex switch

zero adjusting controls, not shown in FIGS. 2 and 3, are connects the capacitors Cin turn to the vertical deflec

used to correct the balance of each amplifier so that the 15

tion amplifier input of the cathode ray oscilloscope T.

outputs O, O... O, which are the respective func The horizontal deflection of the electron beam of the

tional signals, are zero when the potential difference cathode ray oscilloscope is derived from the saw-tooth

between the two input terminals of each amplifier is generator G and is synchronised to the switching device

ZeO. so that at any time the horizontal coordinate of the light

When light shines on the photo-volatic cells and the: 20 spot on the screen corresponds to the position across

respective gauging signals comprising voltages E., E. . . the sheet of the photo-electric cell to which the switch

. E. generated across the resistors Ry, Ry, ... Ryi are ing device has connected the oscilloscope vertical am

produced, the action of the circuit is such that the plifier. By this means a magnified thickness profile in

bus-bar D takes up a potential Ec with respect to earth the form of a histogram may be displayed on the cath

potential which is the arithmetic mean of the separate 25 ode ray oscilloscope screen. If the "fly-back' trace of

gauging signal potentials E, E, ... E., and the outputs the oscilloscope is not blacked out and during the fly

O, O, ... O are given by the expression back period the switch unit connects the vertical ampli

fier to the common line D (also preferably through a

O =E +

low pass filter unit,) then the fly-back trace may be

30 used as a reference line for the average thickness, and

the position of the main trace above or below this line

If R is much smaller than R, the second expression on used to indicate positive or negative thickness devia

the right-hand side of the equation is large compared tions from the mean value. A complete switching cycle

with the first. Thus the outputs, that is to say the func should preferably take place in less than 0.04 seconds

tional signals, are substantially equal to the difference 35 toInavoid flickering of the trace.

addition, or as an alternative, to the above, the

between the individual values E of the potentials

across the resistors. Ry and the mean potential, ampli functional signals may be fed to, for example thickness

fied by a factor, adjusting devices. Because there will generally be a

time delay between the response of such devices and

Rt R2 40 changes in the sheet thickness reaching the point of

R. measurement, it is normally necessary to interpose

signal conditioning devices between the output of each

In FIG. 2, the polarity of the photo-voltaic cells is such amplifierA typical

and the corresponding thickness adjusting

that when illuminated, positive voltages, appear at the device.

be used when the

signal conditioning device which may

thickness adjusting device is an elec

inverting input terminals of the amplifiers. Thus an trical heater for example,

45

is an electrical integrator

increase in the local sheet thickness, by reducing the which may be a circuit such as that shown in FIG. 5.

light intensity at a photo-cell, causes the output voltage

of the associated amplifier to become negative with sponding integrator via a relay such as afed

Each functional signal is preferably to its corre

respect to the bus-bar D, and usually negative with 50 S operated by a Solenoid H. The integratorreed dry switch

shown in

respect to the earth line to a degree proportional to the FIG. 5 comprises a resistance R, connected to the in

difference of the sheet thickness at the photo-voltaic verting input of an operational amplifier U of very high

cell position from the average thickness.

With such a circuit, the output, that is to say the input (f.e.t.)

resistance such as a field effect transistor input

operational amplifier. The feed-back capacitor

functional signal, from each amplifier is distinct from 55 C is connected between the output terminal O, and the

the output of any of the other amplifiers and therefore inverting input. The rate of change of output voltage is

may be correlated directly with its associated sensing given by the approximate expression:

device, and corresponding region of the article. In such

an arrangement for example, the individual output

terminals of the amplifiers may be connected to a dis 60

dout --

dt

Vin

RC

play device which may give a graphic indication of the

persistent thickness profile of the sheet and may consist

of a series of electrical low pass filters, one connected where Vin is the potential difference between K and B

to each output, and a switching or multiplexing device of FIG. 5. B may be connected to the common bus-bar

which connects the output of each filter in turn to the of FIG. 2, or to an auxiliary circuit to be described

vertical deflection amplifier of the cathode ray oscillo 65 later. The dry reed switch S is normally held closed by

scope the sequence of the filter, output connections a current passing through the solenoid. Means may thus

being chosen to correspond to the order in which the be provided such that in the event of any interruption

associated photo-voltaic cells are disposed across the of the process or failure of the lamp for example, the

3,974,248

7 8

current through each solenoid is interrupted causing FIG. 2, comparing this potential with a pre-set potential

the switches S to open. Under these conditions the and using the difference between these potentials to

output voltages of the integrators remain unchanged activate a device to control the average thickness such

for long periods of time, until production is re-estab as a device to control the rotational speed of an ex

lished or the fault cleared. This feature avoids undue truder screw feeding plastic material to a sheeting die.

delay in re-establishing the appropriate control condi Although in sheet manufacture it is usually desirable

tions after the interruption of production. to achieve sheet with a uniform thickness across it,

If K in FIG. 5 is negative in potential with respect to there are situations in which a controlled but non

B, such as could occur if the article thickness at the uniform thickness profile is required This may be

corresponding photo-cell is greater than the average, O achived quite simply in the system described by adjust

Os will become progressively more positive in potential ing the variable resistances Ry according to a predeter

whereas if K is positive with respect to B (the sheet mined pattern. An increase in the value of Ry con

being thinner than average) O, will become progres nected to any one photo-cell would result in an in

sively more negative. crease in thickness of the sheet in the band covered by

If the outputs from the terminals O of the integrators 15 the photo-cell and its associated thickness adjusting

are fed to the control circuits of thickness adjusting device.

devices, which are such that a more positive voltage It may, in addition, be of advantage to control the

applied to the control circuit produces a decrease in average output potentials of the integrators without

the thickness of the final sheet in a band which is moni alteration of their relative values, for example to ensure

tored by the corresponding thickness sensing device, it that the thickness adjusting devices are operated over

will be obvious that the overall action of the system is the most effective part of their range of control. This

to correct the thickness at each band across the sheet may be accomplished by a circuit such as that shown in

towards the average thickness. FIG. 6 in which the integrators illustrated by FIG. 5 are

It will be appreciated that, the device for adjusting a connected to an auxiliary circuit.

characteristic or property of an article may take any 25 In the circuit of FIG. 6 the terminals B of the integra

appropriate form. Thickness adjusting devices may tors, instead of being connected to the bus-bar D, are

include, for example radiant heating elements which controlled at a potential determined by the difference

adjust the temperature distribution across a sheet at between the average output potential of the integrators

some point of its passage through a machine, or devices and a fixed reference potential derived from a potenti

which adjust the temperature or separation of portions ometer E. The amplifier W may be of the same type as

of an extrusion nozzle in which a primary sheet is the amplifiers A in FIGS. 2 and 3.

formed, controlled directly, or indirectly for example In order to obtain a smooth control action for the

via conventional control circuits if these are required. whole system which is free from hunting but is not

Devices of these kinds more often act by causing a sluggish in response, the control parameters of the

redistribution of the thickness of the sheet across its 35 system must be optimised in a manner which is well

width rather than by altering the thickness at each known to those skilled in the art.

point independently. Thus an increase in thickness in The values of R and C in FIG. 5 and particularly the

one band along the sheet caused by a local adjustment values of the product RX C must be chosen so that the

in sheet tenerature may be accompanied by a general speed of response of the thickness adjusting device

decrease in thickness elsewhere. 40 occasioned by a departure of the article thickness from

If, for example, the potential applied to each integra the mean value at any photo-voltaic cell position is of

tor was proportional to the difference between the an optimum value. The optimum speed of response will

output voltage of the corresponding photo-voltaic cell be lower if longer time delays occur between passage of

and a pre-set fixed reference potential, instead of being a portion of the sheet, for example, past the thickness

proportional to the difference between the photo-vol 45 adjusting devices and its arrival at the thickness mea

taic cell output and the average of the cell outputs, suring stations.

undesirable effects arise. If the fixed reference poten The following Examples are given to illustrate the

tial differs from the average photo-cell output which present invention but to in no way limit the scope

would be obtained when the thickess variations had thereof:

been reduced to low values, most of the integrators 50

EXAMPLE

would still be subjected to a finite input voltage of the

same polarity tending to make their outputs increase An apparatus as described and illustrated with refer

steadily to high values, or fall steadily to low values. ence to FIGS. 1 to 4 was constructed to include 13

Thus the thickness adjusting devices would be acti photo-voltaic cells P and their associated amplifiers A,

vated progressively until most of them reached the 55 A2 . . . As. The photo-voltaic cells were selenium bar

limits of their effective operating range, and thereafter rier layer cells each of sensitive area 15X 30 mm, and

effective control action would be lost. were enclosed in a light-tight box with apertures dis

An advantage of the method of the present invention posed such that light transmitted by a translucent sheet

lies in the fact that the control of the shape of the pro material from a day-light type, 40 Watt, 4 foot long

file of the characteristic or property across an article, 60 fluorescent lamp fell upon the sensitive area of each

for example, is separate from any control of the aver cell. Blue-green filters were placed immediately in

age of the characteristic or property of the article. The front of each photo-voltaic cell. The sensing photo

control of the shape of the thickness profile across a cells and the corresponding apertures were separated

sheet being produced by an extrusion process for exam at 3 inch intervals across the path of the sheet. The

ple, is separate from any control of the average thick 65 construction of the box and lamp housing was such as

ness of the sheet. The average thickness of such a sheet to reduce to small values any photo-current in any cell

for example, may be controlled by measurement of the caused by light other than that transmitted by the trans

potential which appears on the common bus-bar D of lucent sheet material immediately below that cell. The

3,974,248

: 10

amplifiers A. A... As were of type 709 monolithic ness of 4/1000 inch and consisting of high density poly

silicon operational amplifiers of an open loop power ethylene containing fillers and pigments such that its

gain of 90 decibels, each being balanced to less than average light transmission for green light was approxi

0.5 mV referred to the input circuit. R was 100,000) mately 11%, at a position beyond the exit of the ma

and R 10000 in each case. Ry, Ry, . . . Ry, were 5 chine and before the wind-up unit. The position of the

adjusted so that with a uniform 4/1000 inch sheet of a heaters was such that an element of the in-going sheet

translucent polyethylene film containing titanium diox material passing under a particular heater would subse

ide and of average diffuse light transmission for green quently pass between the lamp and the photo-voltaic

light of 11%, the potential difference across each was cell which actuated the control channel controlling the

the same and equal to 90-millivolts: The capacitors C 10 radiant heating power of that particular heater. The

in FIG. 4 were of 2. microfarads capacitance, and of distance between respective photo-voltaic cells and

high leakage resistance and the resistors R were their corresponding heaters was such that the time it

mounted in plug-in units enabling them to be changed would take for an element of sheet to pass between

readily. M was a solid state multiplex switch of type them was approximately 1 minute.

DG506 supplied by Siliconix. Ltd. F. was a multi-vibra 15 The biaxial stretching machine was started without

tor with an output frequency of 400 cycles per second. initially energising the radiantheaters and the stretched

G and T were conventional units as described with sheet material was found to vary persistently in thick

: reference to FIG. 4 and Q was a T.T.L. (Transistor - ness across the width, the maximum thickness devia

Transistor Logic) 4-Bit Binary Counter Type FJJ 211 20 tion being it 10% of the average thickness. When the

as supplied by Mullard Ltd. ' ' ..., , .. . heaters were energised in a pattern of intensities con

The apparatus was used to monitor thickness varia trolled by the apparatus described, the maximum thick

tions on a sheet material 48 inches wide during produc ness deviation was seen to diminish to it 2%% of the

tion by an extrusion operation, the sheet being of average thickness.

4/1000 inch average thickness and consisting of high The apparatus and method of the invention has been

density polyethylene containing fillers and pigments 25 described with particular reference to the determina

such that its average light transmission for green light tion and control of the thickness profile of a thermo

was approximately 11%. plastic sheet during continuous production and to the

A trace was formed on the oscilloscope screen which use of correspondingly suitable apparatus components

clearly indicated deviations of thickness across the but it will be obvious that the apparatus and method

sheet, when the resistors R were each of 1 Megohm 30 may be adapted and employed in many different ways

resistance, short period variations in thickness along to determine and control the profile of any characteris

and across the sheet were readily observed and these tic or property of an article. The apparatus for example

observations were of use in tracing the origin of the may be adpated to determine characteristic or property

transient thickness variations. When the resistors R. profiles such as the thickness profiles of the walls of

were replaced by resistors of 10 Megohm values, the 35 tubes, bottles and a variety of articles. Such use of the

short period variations were smoothed out and a persis apparatus of the invention may assist the manual con

tent profile of sheet thickness was observed, enabling trol of processes by which the profile is obtained. The

corrective actions to be taken to reduce the differences method of the invention may be adapted to control

in average thickness across the sheet. automatically a characteristic or property profile of any

EXAMPLE 2

40 article produced by a continuous or repetitive process,

and particularly a characteristic or property profile in a

The apparatus as described in Example 1 was modi direction transverse to the direction of production of

fied by the addition of a set of 13 integrators, each as such an article or articles. An example of a repetitive

illustrated in FIG.5 and in which C was a 2puF capaci process is the injection moulding of hollow articles

tor of leakage resistance greater than 20,000 Megohms 45 where a deviation of the thickness, for example, of an

and R was of 20 Megohms resistance. The fe.t. opera article wall from the average may be determined and

tional amplifier U was of type E78 as supplied by Com the appropriate automatic adjustment of the die com

puting Techniques Ltd. The integrators were con ponents effected before the next moulding operation

nected together in a circuit as described with reference takes place. Clearly, applications will not be limited to

to, and as illustrated in FIG. 6 in which the amplifier W 50 the plastics industry and the apparatus and method of

was of the same type as the amplifiers. A described in the invention may find applications in the paper, glass

Example 1. The free terminals of the resistors Rs were or steel industries for example.

connected respectively, via switches s, not shown in What is claimed is:

FIG. 6, to receive the functional signals O, O, ... Oua. 1. A method for controlling the profile of a charac

With the resistors R adjusted as described in Exam- 55 teristic of an article, which comprises the steps of mea

ple 1 and the switches S closed, the outputs O, O. . suring said characteristic by means of a plurality of

... O were used to adjust the outputs of conventional individual sensing means, simultaneously producing an

power control circuits which supplied electrical power individual electrical gauging signal for each sensing

respectively to 13 radiant heaters. The potentiometer E means determining the average of all said individual

was adjusted such that the total heating effect of the 60 signals, the magnitude of each individual signal being a

heaters at any time was approximately 30% of their substantially linear function at least over a working

total maximum rated value. range of the characteristic at a particular region of the

The heaters were disposed across a continuous plas article, the slopes of all the substantially linear func

tic sheet which was otherwise heated to an extensible tions having the same sign, detecting any difference in

condition prior to entering a continuous simultaneous 65 magnitude occurring between each individual signal

biaxial stretching machine. The photo-voltaic cells and and said average of all said signals, electrically deriving

the lamp of Example 1 were disposed on opposite sides directly from said difference a functional signal for any

of the stretched sheet, having a nominal average thick such difference which is correlated with the region of

3,974,248

1 12

the article from which it is derived and utilizing each 6. A method according to claim 1, wherein the article

functional signal to control a device for adjusting said is a sheet or film and the characteristic or property to

characteristic of at least one article subsequently pro be controlled is the thickness thereof.

duced in the same run of an article producing appara 7. Apparatus for controlling the profile of a charac

tus in any region for which a functional signal is pro teristic of an article, said apparatus comprising a plural

duced so as to reduce any difference between the gaug ity of individual sensing means for measuring said char

ing signal from that region and the average of all the acteristic, means for simultaneously producing an indi

gauging signals. vidual gauging signal for each sensing means, and

2. A method as claimed in claim 1 in which the article 10 means for determining the average of all said individual

is a sheet, film, tube or moulded article. signals, the magnitude of each individual signal being a

3. A method according to claim 1 wherein the electri substantially linear function, at least over a working

cal gauging signals are fed separately to the non-invert range, of said characteristic at a particular region of the

ing input terminals of separate operational amplifiers, article with the slopes of all the substantially linear

functions having the same sign, means for detecting any

the negative feed-back resistive divider circuits of said 15 difference in magnitude between each individual signal

amplifiers being connected to one point, such that the and said average of all said signals, means for electri

functional output signals from each amplifier are pro cally deriving directly from said difference a functional

portional to the difference between the magnitude of signal for any such difference which is correlated with

the gauging signal fed to each amplifier and the average the region of the article from which it is derived, and

magnitude of the signals fed to all of the amplifiers. 20 means for utilizing each functional signal to control a

4. A method according to claim 1, wherein the arti device for adjusting the characteristic of the article or

cles are produced by a continuous method or a repeti articles subsequently produced in the same run of an

tive method. article producing apparatus in any region of the article

5. A method according to claim 1, wherein the char for which a functional signal is produced so as to re

acteristic or property of the article is temperature, 25 duce any difference between the gauging signal from

opacity, colour, specific gravity, electrical conductiv that region and the average

k k k

ofckall skthe gauging signals.

ity, composition or thickness.

30

35

40

45

50

55

60

65

You might also like

- US5951926Document6 pagesUS5951926mohammedaz71657151No ratings yet

- United States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsDocument8 pagesUnited States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsUvxtalNo ratings yet

- Patente CortinaDocument16 pagesPatente CortinarublasterNo ratings yet

- Us 5607638Document7 pagesUs 5607638ramcivmngrNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- Tensioning StripsDocument11 pagesTensioning StripssuksesNo ratings yet

- US6926223Document5 pagesUS6926223José Roberto LazoNo ratings yet

- Us4046469a 1Document12 pagesUs4046469a 1yma warriorNo ratings yet

- Stereoloithography Patent-3D SystemsDocument16 pagesStereoloithography Patent-3D SystemsRaheel AhmedNo ratings yet

- Us 5864600Document21 pagesUs 5864600Hữu VănNo ratings yet

- United States Patent (19) : (45) Sept. 27, 1977Document4 pagesUnited States Patent (19) : (45) Sept. 27, 1977aless2056No ratings yet

- United States Patent 19: Harth, II Et Al. 11 Patent Number: 5,661,241 45 Date of Patent: Aug. 26, 1997Document16 pagesUnited States Patent 19: Harth, II Et Al. 11 Patent Number: 5,661,241 45 Date of Patent: Aug. 26, 1997TYO WIBOWONo ratings yet

- United States Patent (19) : (54) Coating Device For Coating OfaDocument10 pagesUnited States Patent (19) : (54) Coating Device For Coating OfaNiccolast Adnandito SaputraNo ratings yet

- United States PatentDocument8 pagesUnited States PatentGersonNo ratings yet

- United States Patent: (45) July 4, 1972Document4 pagesUnited States Patent: (45) July 4, 1972Lidya SimatupangNo ratings yet

- US4103849Document5 pagesUS4103849Zhu LeeNo ratings yet

- United States Patent (19) : Siegmund 11) 4,175,940Document4 pagesUnited States Patent (19) : Siegmund 11) 4,175,940markokocNo ratings yet

- United States Patent (19) : 11 Patent Number: 5,072,729 45 Date of Patent: Dec. 17, 1991Document11 pagesUnited States Patent (19) : 11 Patent Number: 5,072,729 45 Date of Patent: Dec. 17, 1991Bareethul KaderNo ratings yet

- US3921555Document6 pagesUS3921555Muhammad TalhaNo ratings yet

- Advanced Composite Tow-Steered ShellsDocument20 pagesAdvanced Composite Tow-Steered ShellsmihailmiNo ratings yet

- United States Patent (19) : Reilly Et Al. (45) Apr. 20, 1976Document6 pagesUnited States Patent (19) : Reilly Et Al. (45) Apr. 20, 1976Vaittianathan MahavapillaiNo ratings yet

- United States PatentDocument8 pagesUnited States PatentClaudinei MayerNo ratings yet

- Patente TrituradoraDocument11 pagesPatente TrituradoraDany ChimborazoNo ratings yet

- PCB Helical Resonator and FilterDocument7 pagesPCB Helical Resonator and FilterbaymanNo ratings yet

- US5678477 Sheller PatentDocument14 pagesUS5678477 Sheller PatentNiranjan PuduruNo ratings yet

- US5513743Document6 pagesUS5513743AdailsonNo ratings yet

- US6110313Document12 pagesUS6110313Sayyed Abdul QayyumNo ratings yet

- United States PatentDocument10 pagesUnited States PatentEric UzueliNo ratings yet

- Us 20040155650Document13 pagesUs 20040155650dfgsfgsre rete rtwNo ratings yet

- Patent DocumentDocument11 pagesPatent DocumentSaikat MondalNo ratings yet

- United States Patent (19) : Hansen Et AlDocument5 pagesUnited States Patent (19) : Hansen Et AlFernandoNo ratings yet

- United States Patent: Odell (451 Sept. 26, 1972Document12 pagesUnited States Patent: Odell (451 Sept. 26, 1972Thiago Souza da RosaNo ratings yet

- United States Patent (19) : (45) Date of Patent: Jun. 30, 1998Document8 pagesUnited States Patent (19) : (45) Date of Patent: Jun. 30, 1998mohadeseNo ratings yet

- US5121329Document15 pagesUS5121329AndersonNo ratings yet

- Unlted States Patent (19) (11) Patent Number: 4,533,308: Cloeren (45) Date of Patent: Aug. 6, 1985Document9 pagesUnlted States Patent (19) (11) Patent Number: 4,533,308: Cloeren (45) Date of Patent: Aug. 6, 1985Joe budarNo ratings yet

- Ada 482574Document67 pagesAda 482574hasantapNo ratings yet

- Windproof Umbrella Having An Improved Rib Linkage SystemDocument9 pagesWindproof Umbrella Having An Improved Rib Linkage SystemAyoub El kadaouiNo ratings yet

- Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsDocument6 pagesTensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsPablo AlcázarNo ratings yet

- United States Patent: Price (45) Date of Patent: Apr. 22, 2008Document11 pagesUnited States Patent: Price (45) Date of Patent: Apr. 22, 2008Aslam KhanNo ratings yet

- United States Patent (10) Patent No.: Us 6,628,382 B2: Robertson (45) Date of Patent: Sep. 30, 2003Document14 pagesUnited States Patent (10) Patent No.: Us 6,628,382 B2: Robertson (45) Date of Patent: Sep. 30, 2003LazScibdNo ratings yet

- Method For Making Schmidt Corrector LensesDocument7 pagesMethod For Making Schmidt Corrector LensesjorgeNo ratings yet

- United States Patent (191: Epperson, JRDocument6 pagesUnited States Patent (191: Epperson, JRAparnaNo ratings yet

- Adjustable Cutting JigDocument10 pagesAdjustable Cutting JigFakrul HakimieNo ratings yet

- United States Patent (19) : E73 Assignee: Softal Elektronik GMBH, HamburgDocument6 pagesUnited States Patent (19) : E73 Assignee: Softal Elektronik GMBH, Hamburgaless2056No ratings yet

- United States Patent (19) : (45) Date of Patent: " Apr. 4, 1989Document10 pagesUnited States Patent (19) : (45) Date of Patent: " Apr. 4, 1989Niki Wijaya SariNo ratings yet

- Static Electricity ArrestorDocument4 pagesStatic Electricity Arrestorramakrishna.goliNo ratings yet

- Us 4785300Document12 pagesUs 4785300MasoudNo ratings yet

- Vernier Caliper PatentDocument9 pagesVernier Caliper Patentmeinard angelesNo ratings yet

- United States Patent (19) : Jul. 5, 1977 (JP Japan .................................. 52-79532Document8 pagesUnited States Patent (19) : Jul. 5, 1977 (JP Japan .................................. 52-79532Andrew StarkNo ratings yet

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Document7 pagesUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348No ratings yet

- United States Patent (191: Reylek Et Al. (45) Date of Patent: Aug. 19, 1986Document8 pagesUnited States Patent (191: Reylek Et Al. (45) Date of Patent: Aug. 19, 1986fikrian kasaljiNo ratings yet

- US5455474Document16 pagesUS5455474naturist_medNo ratings yet

- United States Patent (19) 11 Patent Number: 4,863,538: Deckard 45 Date of Patent: Sep. 5, 1989Document12 pagesUnited States Patent (19) 11 Patent Number: 4,863,538: Deckard 45 Date of Patent: Sep. 5, 1989Yusuf Gürcan ŞahinNo ratings yet

- US3552631Document5 pagesUS3552631Mostafa AlakhliNo ratings yet

- Us6230368 PDFDocument9 pagesUs6230368 PDFSantoshNo ratings yet

- US3889325 Shrinking Non Woven Webs ArticleDocument6 pagesUS3889325 Shrinking Non Woven Webs ArticleValentin Velazquez RodriguezNo ratings yet

- Patente, Cuero RealDocument9 pagesPatente, Cuero RealAngélica SixtosNo ratings yet

- Tgcure BogettiDocument72 pagesTgcure BogettiDani DiosNo ratings yet

- US6379299Document15 pagesUS6379299BattleAppleNo ratings yet

- Next Generation Optical Wireless Communication Systems: A Systems ApproachFrom EverandNext Generation Optical Wireless Communication Systems: A Systems ApproachNo ratings yet

- 9/2A9A O O: Feb. 28, 1967 A. C. Magnus 3,306,835Document13 pages9/2A9A O O: Feb. 28, 1967 A. C. Magnus 3,306,835zgregzNo ratings yet

- United States Patent (19) : Filed: Feb. 14, 1972Document5 pagesUnited States Patent (19) : Filed: Feb. 14, 1972zgregzNo ratings yet

- Acetat: Methacyl AteDocument6 pagesAcetat: Methacyl AtezgregzNo ratings yet

- Ited States Patent: Inventor: Raymond G. Voss, Bartlesville, OklaDocument5 pagesIted States Patent: Inventor: Raymond G. Voss, Bartlesville, OklazgregzNo ratings yet

- 3,328,019 June 27, 1967: Filed Oct. 20, 1965Document3 pages3,328,019 June 27, 1967: Filed Oct. 20, 1965zgregzNo ratings yet

- United States Patent: Gray Et Al. (45) Mar. 7, 1972Document15 pagesUnited States Patent: Gray Et Al. (45) Mar. 7, 1972zgregzNo ratings yet

- Fig 2. A More: March 28, 1961 W. D. Edwards Eta, 2,977,146Document5 pagesFig 2. A More: March 28, 1961 W. D. Edwards Eta, 2,977,146zgregzNo ratings yet

- ??J.Wima: Patented JanDocument3 pages??J.Wima: Patented JanzgregzNo ratings yet

- United States Patent Office - Patented Jan. 19, 1965: Nomic Picture Is Quite Different From That Which Exists inDocument3 pagesUnited States Patent Office - Patented Jan. 19, 1965: Nomic Picture Is Quite Different From That Which Exists inzgregzNo ratings yet

- Buddy SystemDocument7 pagesBuddy SystemJahangir SiddikiNo ratings yet

- The Vivekanand School: Annual Exam Session: 2022-2023Document6 pagesThe Vivekanand School: Annual Exam Session: 2022-2023chaitanya goyalNo ratings yet

- Name of Customer - Name of Project - TE-112045 - WFC - Print - OutDocument1 pageName of Customer - Name of Project - TE-112045 - WFC - Print - OutJavier EspinosaNo ratings yet

- T6963C LCD Device Driver LinuxDocument10 pagesT6963C LCD Device Driver LinuxAnonymous NZrcrgNo ratings yet

- OtooDocument11 pagesOtooStefania DavidNo ratings yet

- Solucionario Ingenieria en Control Moderna OGATADocument240 pagesSolucionario Ingenieria en Control Moderna OGATAanandpj444471% (7)

- Community Forest 1Document20 pagesCommunity Forest 1Ananta ChaliseNo ratings yet

- Current Affairs QuizDocument3 pagesCurrent Affairs QuizJay KothariNo ratings yet

- Experiment No. 2: Aim: A) D Flip-Flop: Synchronous VHDL CodeDocument6 pagesExperiment No. 2: Aim: A) D Flip-Flop: Synchronous VHDL CodeRahul MishraNo ratings yet

- Employee Behaviour in Organization Under Work Moral: Project OnDocument26 pagesEmployee Behaviour in Organization Under Work Moral: Project OnDhanvanth ReddyNo ratings yet

- Crown Amplifiers Catalog PDFDocument68 pagesCrown Amplifiers Catalog PDFArjay DomisiwNo ratings yet

- ENGLISH - 2006 Read The Following Poem Carefully and Answer The Questions That Follow: (8 Marks) Forest FiresDocument6 pagesENGLISH - 2006 Read The Following Poem Carefully and Answer The Questions That Follow: (8 Marks) Forest FiresSanjay KumarNo ratings yet

- Implementation of Restructuring of The NcrpoDocument1 pageImplementation of Restructuring of The Ncrpojames antonioNo ratings yet

- Lab 1Document15 pagesLab 1Vic SeungNo ratings yet

- 3.3.2.3 Lab - Configuring Rapid PVST, PortFast, and BPDU GuardDocument9 pages3.3.2.3 Lab - Configuring Rapid PVST, PortFast, and BPDU Guardsebastian ruiz100% (1)

- Present Etac Dep Psis PDFDocument96 pagesPresent Etac Dep Psis PDFRobiahZakariaNo ratings yet

- Debug Tacacs CiscoDocument5 pagesDebug Tacacs CiscodeztrocxeNo ratings yet

- Effect of Work Environment On Organizational PerformanceDocument14 pagesEffect of Work Environment On Organizational PerformanceDr. Mahesh GopalNo ratings yet

- Lesson-2-Climate IiDocument30 pagesLesson-2-Climate IiErica NatividadNo ratings yet

- Analyzing Factual Report Text "ROSE"Document9 pagesAnalyzing Factual Report Text "ROSE"Muhammad Taufiq GunawanNo ratings yet

- Technical Paper (Al Sharq Tower)Document17 pagesTechnical Paper (Al Sharq Tower)ကိုနေဝင်းNo ratings yet

- National Youth Service CorpsDocument2 pagesNational Youth Service CorpsSeunAjiniranNo ratings yet

- Class 12 CS ProjectDocument27 pagesClass 12 CS ProjectKs100% (3)

- Structural Analysis of Complex Networks 2011Document501 pagesStructural Analysis of Complex Networks 2011kemalihsan_17959No ratings yet

- Infosys: Transition at The Top: Management CaseDocument15 pagesInfosys: Transition at The Top: Management CaseVKNo ratings yet

- Değişim Sınavı 2020Document29 pagesDeğişim Sınavı 2020Mustafa CinNo ratings yet

- SADP User Manual (V2.0)Document10 pagesSADP User Manual (V2.0)tehixazNo ratings yet

- Aerospace Engg.Document75 pagesAerospace Engg.Omkar KadamNo ratings yet

- Niir Mumbai Companies Directory Database XLSX Excel Format 5th EditionDocument2 pagesNiir Mumbai Companies Directory Database XLSX Excel Format 5th Editionphone25hire phone25hireNo ratings yet

- City Gas DistributionDocument22 pagesCity Gas DistributionMohit Pandey100% (1)