Professional Documents

Culture Documents

Alloy Steel Socket Shoulder Screws

Alloy Steel Socket Shoulder Screws

Uploaded by

ShreenidhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alloy Steel Socket Shoulder Screws

Alloy Steel Socket Shoulder Screws

Uploaded by

ShreenidhiCopyright:

Available Formats

Sockets Alloy

Socket Shoulder Screws Steel

H

T ‡

L±.005

A SEE DETAIL Y SEE DETAIL Z

J E

K D D1

G

C

‡Length of a socket shoulder screw is measured from the underhead bearing surface to the plane of the shoulder at the threaded end.

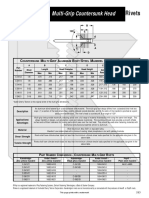

SOCKET HEAD SHOULDER SCREWS - ALLOY STEEL ASME B18.3-1988

D A H C J T M R K F

Chamfer Hex Fillet Head Shoulder Shoulder

Nominal Shoulder Head Key

Head Height or Socket Transition Fillet Neck Neck

Size Diameter Diameter Engagement

Radius Size Diameter Radius Diameter Width

Max Min Max Min Max Min Min Nom Min Max Min Min Max

1/4 0.2480 0.2460 0.375 0.357 0.188 0.177 0.020 1/8 0.094 0.276 0.009 0.227 0.093

5/16 0.3105 0.3085 0.438 0.419 0.219 0.209 0.026 5/32 0.117 0.345 0.012 0.289 0.093

3/8 0.3730 0.3710 0.562 0.543 0.250 0.240 0.031 3/16 0.141 0.413 0.015 0.352 0.093

1/2 0.4980 0.4960 0.750 0.729 0.312 0.302 0.040 1/4 0.188 0.550 0.020 0.477 0.093

5/8 0.6230 0.6210 0.875 0.853 0.375 0.365 0.050 5/16 0.234 0.687 0.024 0.602 0.093

3/4 0.7480 0.7460 1.000 0.977 0.500 0.490 0.069 3/8 0.281 0.826 0.030 0.727 0.093

A hex socket head screw with an enlarged, unthreaded, cylindrical shoulder under the head, the diameter of which serves as the

Description basis for the derivation of the nominal size.

Applications/ For rotation or sliding applications, such as pulley shafts, in punch and die work, or for use as a bearing pin. Shoulder screws are

Advantages also referred to as "stripper bolts".

Shoulder screws shall be made fabricated from an alloy steel having one or more of the following elements: chromium, nickel,

Material molybdenum or vanadium, in sufficient quantity to assure the hardness specified below.

Shoulder screws shall be heat-treated by oil quenching from above the transformation temperature and then tempered at a

Heat Treatment temperature not lower than 650°F.

Hardness Rockwell C32 - 43

Tensile Strength 140,000 psi. minimum (material only)

Yield Strength 120,000 psi. minimum (material only)

Elongation 15% minimum (applies to all machined specimens of length at least 4D where D equals the nominal diameter of the screw)

Reduction of Area 45% minimum (applies to all machined specimens)

Plating Shoulder screws are usually supplied with a plain finish.

Alloy Sockets

Socket Shoulder Screws

Steel

I

F

M N

R

THIS DIA NOT TO

EXCEED MAJOR

DIA OF THREAD

ENLARGED DETAIL Y ENLARGED DETAIL Z

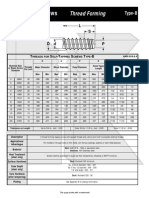

ASME B18.3-1998,

SOCKET HEAD SHOULDER SCREWS - ALLOY STEEL (CONTINUED) Blue Devil®

Thread Single Shear

D1 G I N E Section Strength (Lbs)

Tensile Seating

Nominal Threads Thread Neck Thread Neck Thread Strength Thread

Nominal Shoulder Torque

Size Per Inch Diameter Thread Fillet Length (Lbs) Neck

Thread (Inch Lbs)

Neck

Size

Width

Max Min Max Min Basic Min Min Min

1/4 10 24 0.142 0.133 0.083 0.023 0.017 0.375 2,540 4,515 1,250 50

5/16 1/4 20 0.193 0.182 0.100 0.028 0.022 0.438 4,610 7,100 2,340 125

3/8 5/16 18 0.249 0.237 0.111 0.031 0.025 0.500 7,600 10,280 3,970 265

1/2 3/8 16 0.304 0.291 0.125 0.035 0.029 0.625 11,240 18,350 5,985 470

5/8 1/2 13 0.414 0.397 0.154 0.042 0.036 0.750 20,570 28,785 11,140 1,150

3/4 5/8 11 0.521 0.502 0.182 0.051 0.045 0.875 32,770 41,515 17,800 2,000

Nominal Screw Sizes

Tolerance on Thread Length Up to 3/8 in., Inclusive Over 3/8 in.

-0.020 -0.030

You might also like

- Capitolo1 - VORON 2.4r2Document18 pagesCapitolo1 - VORON 2.4r2Ivica VuknićNo ratings yet

- 1C 130H 4 27 1 Flight ControlsDocument262 pages1C 130H 4 27 1 Flight ControlsMohamed Hassan100% (1)

- Honing Machine Type S and S2: Instruction ManualDocument60 pagesHoning Machine Type S and S2: Instruction ManualSpider 022No ratings yet

- MS22045 - 00E 12V 16V 2000 M84 M94 Instructions For Exchange of AssembliesDocument298 pagesMS22045 - 00E 12V 16V 2000 M84 M94 Instructions For Exchange of Assembliesmar100% (16)

- Ifi 115Document1 pageIfi 115Vinay PawarNo ratings yet

- Asme B18.2.1 PDFDocument37 pagesAsme B18.2.1 PDFJUAN C100% (1)

- Steel Bush Knuckle Chain Renold JeffreyDocument7 pagesSteel Bush Knuckle Chain Renold JeffreyJesus SansjNo ratings yet

- Rivets Multi Grip CountersunkDocument1 pageRivets Multi Grip CountersunkIsrael OluwagbemiNo ratings yet

- Screw, ISO 7380, Six Lobe, Metic, TorxDocument1 pageScrew, ISO 7380, Six Lobe, Metic, TorxDerekNo ratings yet

- Bolt A325 A490 PDFDocument2 pagesBolt A325 A490 PDFmostapha soubraNo ratings yet

- Ms Blind Bolts: Alloy Steel and A-286 StainlessDocument19 pagesMs Blind Bolts: Alloy Steel and A-286 StainlessJuan Fernando Quintero BalcazarNo ratings yet

- ASME B18.9 TabDocument2 pagesASME B18.9 TabmarceloNo ratings yet

- #3 Domed Head Plow Bolt: Earnest Technical BulletinDocument3 pages#3 Domed Head Plow Bolt: Earnest Technical BulletinNarvaxisNo ratings yet

- Type 6: Elastomer Bellows SealDocument4 pagesType 6: Elastomer Bellows SealTommy Tran NguyenNo ratings yet

- CapScrewgr5 8Document2 pagesCapScrewgr5 8cucho31No ratings yet

- Plow BoltsDocument7 pagesPlow BoltsNarvaxisNo ratings yet

- Guardian CouplingDocument8 pagesGuardian CouplingericallNo ratings yet

- Acoplamento JBDocument8 pagesAcoplamento JBjbernardoNo ratings yet

- StdrillserratedDocument2 pagesStdrillserratedSaul AguilarNo ratings yet

- Elastomer Bellows Seal: Performance Capabilities Product DescriptionDocument4 pagesElastomer Bellows Seal: Performance Capabilities Product DescriptionKaarthicNatarajanNo ratings yet

- Sttype BDocument1 pageSttype BSean YangNo ratings yet

- Self Tapping ScrewsDocument1 pageSelf Tapping ScrewsGulfstream Data, IncNo ratings yet

- B.S. 3293 FlangesDocument8 pagesB.S. 3293 FlangesTiến ĐìnhNo ratings yet

- FL Flywheel Coupling/ Guardex Type FLD Pulley Coupling: Altra Industrial MotionDocument8 pagesFL Flywheel Coupling/ Guardex Type FLD Pulley Coupling: Altra Industrial MotionKalai SelvanNo ratings yet

- Lista de MaterialesDocument39 pagesLista de MaterialesCristian Ookami CcenchoNo ratings yet

- Countersunk Head Cap ScrewsDocument2 pagesCountersunk Head Cap ScrewsmuathNo ratings yet

- North American Cable Glands/ConnectorsDocument1 pageNorth American Cable Glands/ConnectorsrhomadonaNo ratings yet

- Oval Head Semi Tubular RivetsDocument1 pageOval Head Semi Tubular RivetstrandangbkNo ratings yet

- SocketspipeflushDocument1 pageSocketspipeflushLuís Felipe GuimaraesNo ratings yet

- Bray Mccannalok-Navy 3252019Document8 pagesBray Mccannalok-Navy 3252019oscar-hortaNo ratings yet

- Dimensions Mechanical & Performance RequirementsDocument7 pagesDimensions Mechanical & Performance RequirementsLorena PessanhaNo ratings yet

- Globe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"Document4 pagesGlobe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"dmitosNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- SocketspipedryDocument1 pageSocketspipedryLuís Felipe GuimaraesNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- CT WKM Ball Dynaseal 310Document1 pageCT WKM Ball Dynaseal 310JonathanNo ratings yet

- Armstrong Isolation ValveDocument4 pagesArmstrong Isolation ValveAnggaNo ratings yet

- Del West: Ready-to-Ship ComponentsDocument12 pagesDel West: Ready-to-Ship ComponentsADNo ratings yet

- FLO DS 0006 Wafer Butterfly ValvesDocument4 pagesFLO DS 0006 Wafer Butterfly ValvesShubhajit ChakrabortyNo ratings yet

- 5 - MSSDocument5 pages5 - MSSANDERSON NERESNo ratings yet

- FT Valvula Acero 300 LBS Crane 33xu.fDocument1 pageFT Valvula Acero 300 LBS Crane 33xu.fFernando CarreñoNo ratings yet

- Pernos Cat PDFDocument72 pagesPernos Cat PDFTania VélezNo ratings yet

- 423-U SlotMill SeriesDocument28 pages423-U SlotMill Seriespapa bianNo ratings yet

- Series 25 DelTorq Heavy Duty ActuatorDocument2 pagesSeries 25 DelTorq Heavy Duty ActuatorProcess Controls & ServicesNo ratings yet

- Sttype ABDocument1 pageSttype ABSean YangNo ratings yet

- B 16 36 Orifice Flange Chart Front MMDocument1 pageB 16 36 Orifice Flange Chart Front MMJessica Paola Contreras AlmanzaNo ratings yet

- Studb7 PDFDocument1 pageStudb7 PDFIvo KovachevNo ratings yet

- ASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-18-19Document2 pagesASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-18-19Andres SilveyraNo ratings yet

- 2010-Catalog Rivet PDFDocument68 pages2010-Catalog Rivet PDFviettri31No ratings yet

- Copper Nickel Catalog Comp ECRDocument78 pagesCopper Nickel Catalog Comp ECRstevenNo ratings yet

- Rotary Joint: SeriesDocument19 pagesRotary Joint: SeriesSUBHAMOY BASUNo ratings yet

- Bronze&Brass 36Document1 pageBronze&Brass 36jexz BRONXKIDZNo ratings yet

- TSeries CouplingDocument6 pagesTSeries Couplingcarlos sotoNo ratings yet

- Profile Products Associates Exhibitions Enquiry Contact UsDocument1 pageProfile Products Associates Exhibitions Enquiry Contact UsENGR 414No ratings yet

- Sdi 111-1Document23 pagesSdi 111-1SameerSaleemNo ratings yet

- Catalog f8 11 01Document1 pageCatalog f8 11 01ArunNo ratings yet

- Thermocouple With Flange Thermowell Tapered & Adjustable Compensation FittingDocument1 pageThermocouple With Flange Thermowell Tapered & Adjustable Compensation Fittingmohan babuNo ratings yet

- Valv. Comp. Ansi 150 Crane Fig. 47xuDocument2 pagesValv. Comp. Ansi 150 Crane Fig. 47xujulio sanchez camonesNo ratings yet

- 150 RacDocument1 page150 RacM Umar ChatthaNo ratings yet

- Turnbuckle AssembliesDocument4 pagesTurnbuckle AssembliesarbiNo ratings yet

- Sdi 111Document23 pagesSdi 111TheOne YasirNo ratings yet

- Saltus Sockets & Bits Catalogue 2019Document144 pagesSaltus Sockets & Bits Catalogue 2019FlorinNo ratings yet

- Practical Blacksmithing Vol. IV: A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright" and Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex ForgingsFrom EverandPractical Blacksmithing Vol. IV: A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright" and Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex ForgingsRating: 5 out of 5 stars5/5 (1)

- 10 Emerging Technologies: 1. Design ThinkingDocument4 pages10 Emerging Technologies: 1. Design ThinkingShreenidhiNo ratings yet

- Chapter6 Mechanical HandoutsDocument15 pagesChapter6 Mechanical HandoutsShreenidhiNo ratings yet

- Module 3Document51 pagesModule 3ShreenidhiNo ratings yet

- Modification of BB1 Pump Vibration To Meet API-610Document18 pagesModification of BB1 Pump Vibration To Meet API-610Shreenidhi100% (1)

- Full Stroke Time & Stroke End Velocity: Air Cylinders' Drive SystemDocument16 pagesFull Stroke Time & Stroke End Velocity: Air Cylinders' Drive SystemShreenidhiNo ratings yet

- Module 6 Lesson 1Document15 pagesModule 6 Lesson 1ShreenidhiNo ratings yet

- Emerson-Valve Sizing Calculations (Traditional Method)Document21 pagesEmerson-Valve Sizing Calculations (Traditional Method)iqtorresNo ratings yet

- Designing and Analysis of Lifting Eye Bolt For Various GeometryDocument8 pagesDesigning and Analysis of Lifting Eye Bolt For Various GeometryShreenidhiNo ratings yet

- Designing and Analysis of Lifting Eye Bolt For Various GeometryDocument8 pagesDesigning and Analysis of Lifting Eye Bolt For Various GeometryShreenidhiNo ratings yet

- Design of Machine Elements: Nivish GeorgeDocument51 pagesDesign of Machine Elements: Nivish GeorgeShreenidhiNo ratings yet

- Module 6 Lesson 1Document15 pagesModule 6 Lesson 1ShreenidhiNo ratings yet

- Module 3Document51 pagesModule 3ShreenidhiNo ratings yet

- Designing and Analysis of Lifting Eye Bolt For Various GeometryDocument8 pagesDesigning and Analysis of Lifting Eye Bolt For Various GeometryShreenidhiNo ratings yet

- Stainless Lifting Bolts - Male: MetricDocument3 pagesStainless Lifting Bolts - Male: MetricShreenidhiNo ratings yet

- Design of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaDocument5 pagesDesign of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaShreenidhiNo ratings yet

- VPL Profile HPDocument2 pagesVPL Profile HPVivek AgarwalNo ratings yet

- PanelGrip - Glass Railing SystemDocument4 pagesPanelGrip - Glass Railing SystemSarinNo ratings yet

- Asme B 18.2.2Document41 pagesAsme B 18.2.2Luis Montoya100% (1)

- E 80150 enDocument24 pagesE 80150 enmlachenal5237No ratings yet

- Lab File - Work RestDocument5 pagesLab File - Work RestSiddharthNo ratings yet

- Starter PackDocument156 pagesStarter PacksudhakarmnNo ratings yet

- Chattanooga - Group - TX-7 - Mobile - Traction IngDocument20 pagesChattanooga - Group - TX-7 - Mobile - Traction Ingandres05262No ratings yet

- EXHAUST ADAPTER (90 HP Up To SN 029194, 115 HP Up To SN 032266)Document8 pagesEXHAUST ADAPTER (90 HP Up To SN 029194, 115 HP Up To SN 032266)Yamahauki SusukiNo ratings yet

- Trimmer OP Manual UT20044BDocument22 pagesTrimmer OP Manual UT20044Bt38esupNo ratings yet

- PARTTTDocument10 pagesPARTTTOmar BermúdezNo ratings yet

- Janome Four DBL Sewing Machine Service ManualDocument29 pagesJanome Four DBL Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Liste Pats ListDocument21 pagesListe Pats ListBARIŞNo ratings yet

- MECH 313 Engineering Drawing & Design: Lectures 12 and 13Document66 pagesMECH 313 Engineering Drawing & Design: Lectures 12 and 13RUBY_05No ratings yet

- Coupling Manual PDFDocument23 pagesCoupling Manual PDFSatNo ratings yet

- Metric Screw Threads: Nissan Engineering StandardDocument90 pagesMetric Screw Threads: Nissan Engineering StandardBea RiveraNo ratings yet

- Formwork and Shoring: Product GuideDocument61 pagesFormwork and Shoring: Product Guidejakeer7No ratings yet

- Technical Specifications 11kvDocument106 pagesTechnical Specifications 11kvprasanthvenkatesh60% (5)

- Bottom Up Manual - System 336 - Metro IstanbulDocument4 pagesBottom Up Manual - System 336 - Metro IstanbulhalityuecelNo ratings yet

- GD&T WorkbookDocument96 pagesGD&T WorkbookramasandyaNo ratings yet

- DH 103 Hornet - A Building Guide: Fliteskin ProductsDocument76 pagesDH 103 Hornet - A Building Guide: Fliteskin ProductsBobNo ratings yet

- Steel - Technical Specification For Structural Steel WorksDocument26 pagesSteel - Technical Specification For Structural Steel WorksGnabBang100% (3)

- FSV35 Installation Manual B1Document66 pagesFSV35 Installation Manual B1Miguel PerezNo ratings yet

- Erection and Painting of Steel StructureDocument11 pagesErection and Painting of Steel StructureomarcadNo ratings yet

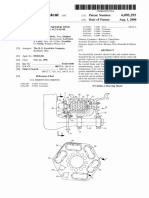

- Aircraft Brake and Method With Electromechanical Actuator ModulesDocument8 pagesAircraft Brake and Method With Electromechanical Actuator ModulesHassanNo ratings yet

- Connection: EN 1993-1-8 DefinitionsDocument49 pagesConnection: EN 1993-1-8 DefinitionsZeiwa Rex100% (1)

- Investigation and Repair of Heat Exchanger FlangeDocument12 pagesInvestigation and Repair of Heat Exchanger Flange최승원No ratings yet