Professional Documents

Culture Documents

HH 160 MO - Brochure

HH 160 MO - Brochure

Uploaded by

Centrifugal SeparatorCopyright:

Available Formats

You might also like

- FQC-950M-BF - Installation, Operation & Maintenance Manual - 2015Document96 pagesFQC-950M-BF - Installation, Operation & Maintenance Manual - 2015Centrifugal SeparatorNo ratings yet

- Model Hh219Document54 pagesModel Hh219helbertortiz100% (1)

- PSS 3.2-780 - Parts List - 2016Document10 pagesPSS 3.2-780 - Parts List - 2016Centrifugal SeparatorNo ratings yet

- Oil FlushDocument7 pagesOil FlushDaniel JurcichNo ratings yet

- Palm Oil RefiningDocument10 pagesPalm Oil Refiningharrison_sNo ratings yet

- Steam Turbine Lube Oil and Control Oil SystemDocument23 pagesSteam Turbine Lube Oil and Control Oil SystemMoinuddin Mohammed100% (3)

- Turbine Lub Oil SystemDocument25 pagesTurbine Lub Oil Systemrishinric90% (10)

- New American Paintings - December-January, 2019Document180 pagesNew American Paintings - December-January, 2019Fabio Nagual100% (2)

- Heat Integration AssignmentDocument8 pagesHeat Integration AssignmentMian Kamran AliNo ratings yet

- HH 360 BD Product LeafletDocument2 pagesHH 360 BD Product LeaflethelbertortizNo ratings yet

- HH 219 BD - BrochureDocument2 pagesHH 219 BD - BrochureCentrifugal SeparatorNo ratings yet

- HH 219 MO - BrochureDocument2 pagesHH 219 MO - BrochureCentrifugal SeparatorNo ratings yet

- HH 845 - BrochureDocument2 pagesHH 845 - BrochureCentrifugal SeparatorNo ratings yet

- HH 1200 - BrochureDocument2 pagesHH 1200 - BrochureCentrifugal SeparatorNo ratings yet

- Hpu 0-3-MDocument2 pagesHpu 0-3-MlearningzabatNo ratings yet

- Recommended Operating Conditions - Presentation (Final)Document50 pagesRecommended Operating Conditions - Presentation (Final)Abdul WasiqNo ratings yet

- HH 219 - Maintenance, Operation and Parts ManualDocument54 pagesHH 219 - Maintenance, Operation and Parts ManualCentrifugal Separator100% (1)

- Cathead Parts BrochureDocument8 pagesCathead Parts BrochureJuan LorenzoNo ratings yet

- Steam Sterilizer 10TPH Palm Oil Production Line 2020-03Document9 pagesSteam Sterilizer 10TPH Palm Oil Production Line 2020-03Souleïman CisséNo ratings yet

- Automated Tube Honing Machine BrochureDocument3 pagesAutomated Tube Honing Machine BrochurePanami AryaNo ratings yet

- Des AlterDocument5 pagesDes Altersagarchawla13No ratings yet

- Lube Oil System PDFDocument18 pagesLube Oil System PDFHuỳnh Phan Ngọc100% (1)

- HH 1456 - BrochureDocument2 pagesHH 1456 - BrochureCentrifugal SeparatorNo ratings yet

- Pen-88 HT™ High-Temperature Surfactant: StimulationDocument2 pagesPen-88 HT™ High-Temperature Surfactant: StimulationJavier Lora BarbaNo ratings yet

- System Description - 01810640Document16 pagesSystem Description - 01810640dannyNo ratings yet

- Seal Oil SystemDocument40 pagesSeal Oil Systemsameer betalNo ratings yet

- PurifiersDocument8 pagesPurifiersEzy WaqaNo ratings yet

- ETI AutoLube-Presentation - ARDocument29 pagesETI AutoLube-Presentation - ARAbdul BasitNo ratings yet

- Roxen LubricatorDocument12 pagesRoxen Lubricatorcengiz kutukcuNo ratings yet

- PULVERISER LUBE OIL SYSTEM OPERATING PROCEDURE REV 00 - WBPDCL SAGARDIGHI 2x500MW - Rev00 - ApprovedDocument4 pagesPULVERISER LUBE OIL SYSTEM OPERATING PROCEDURE REV 00 - WBPDCL SAGARDIGHI 2x500MW - Rev00 - ApprovedSourav SahaNo ratings yet

- W-1250-Ast-E SpecsheetsDocument2 pagesW-1250-Ast-E Specsheetsapi-261294473No ratings yet

- Weh Maritime EduDocument5 pagesWeh Maritime EduErick PachasNo ratings yet

- STX Man B&W 5l2330h Auxiliary Engine Manual p.3Document479 pagesSTX Man B&W 5l2330h Auxiliary Engine Manual p.3vlasovalexander2404No ratings yet

- ПурификаторDocument10 pagesПурификаторmomoyomotaNo ratings yet

- Role of Hydrogen in GeneratorDocument33 pagesRole of Hydrogen in GeneratorVasudev Agrawal100% (1)

- Elementos de Desgaste 160hDocument6 pagesElementos de Desgaste 160hAnonymous F2Q7hAtscNo ratings yet

- Oil Flushing Procedures For Steam Turbine & Generator Sets 1Document8 pagesOil Flushing Procedures For Steam Turbine & Generator Sets 1atul singhNo ratings yet

- Lub Oil Sys ManualDocument17 pagesLub Oil Sys Manualniranjan.malla4No ratings yet

- Lurgi Deodorizing PDFDocument6 pagesLurgi Deodorizing PDFAnonymous 6Nt20xKNo ratings yet

- Fail Free Commissioning-Steam Turbine Hydraulic SystemDocument36 pagesFail Free Commissioning-Steam Turbine Hydraulic SystemPrabhudhasanNo ratings yet

- Biofuel Vacuum PumpDocument4 pagesBiofuel Vacuum Pumpkla_alkNo ratings yet

- Ghee Mill AllDocument36 pagesGhee Mill AllNuman TariqNo ratings yet

- High-Capacity Self-Cleaning Centrifugal Separator For Fuel OilsDocument2 pagesHigh-Capacity Self-Cleaning Centrifugal Separator For Fuel Oilsامير الموسويNo ratings yet

- Pack RYTDocument41 pagesPack RYTGonzalo Alonso QuintanaNo ratings yet

- DPA - 240 User'S Manual: Diesel Parts of AmericaDocument54 pagesDPA - 240 User'S Manual: Diesel Parts of AmericaEdinson Ariel Chavarro QuinteroNo ratings yet

- Alfa Laval Brew 301Document4 pagesAlfa Laval Brew 301Andor MolitoriszNo ratings yet

- B01 Crude Oil Treatment, Rev 4-2014 PDFDocument2 pagesB01 Crude Oil Treatment, Rev 4-2014 PDFNihad S ZainNo ratings yet

- By Rajesh Adhate J.E Manikdoh H.P.SDocument38 pagesBy Rajesh Adhate J.E Manikdoh H.P.SAhemadNo ratings yet

- Hydraulic Fluid Changeover Procedure: Marine Lubricants Information Bulletin 16Document3 pagesHydraulic Fluid Changeover Procedure: Marine Lubricants Information Bulletin 16AymanSayedElantableeNo ratings yet

- Project Finance - Management Input V 5.2Document25 pagesProject Finance - Management Input V 5.2gaurav gargNo ratings yet

- Unidad de Potencia Hidraulica Hycon HPP13 FlexDocument9 pagesUnidad de Potencia Hidraulica Hycon HPP13 FlexJorge Diaz Nestor MonsalveNo ratings yet

- Engines 19 Gas Turbine Lubrication PDFDocument31 pagesEngines 19 Gas Turbine Lubrication PDFCemalettin öztoprakNo ratings yet

- Alfa Laval MAB 104B 1424 Solids Retaining Centrifuge PDFDocument2 pagesAlfa Laval MAB 104B 1424 Solids Retaining Centrifuge PDFzzapiecheNo ratings yet

- Catalogo Hidrolavadora HotsyDocument226 pagesCatalogo Hidrolavadora HotsyWuillians GuzmanNo ratings yet

- Soxtec 2050 Auto Fat Extraction System: Features and BenefitsDocument2 pagesSoxtec 2050 Auto Fat Extraction System: Features and Benefitsosklav50% (2)

- What Are Purifiers and Why To Use Them On Ship: Centripetal ForceDocument16 pagesWhat Are Purifiers and Why To Use Them On Ship: Centripetal ForceFe CaprichoNo ratings yet

- CH Bearing CatalogDocument21 pagesCH Bearing CatalogScott TorgussonNo ratings yet

- Vt2222 EnglischDocument4 pagesVt2222 Englischericchel850712No ratings yet

- Emmie2 - EFU00047ENDocument2 pagesEmmie2 - EFU00047ENSyahrul AbidinNo ratings yet

- Broschyr COT Eng May 2020Document8 pagesBroschyr COT Eng May 2020Marek JeznachNo ratings yet

- Lubication Oil SystemDocument3 pagesLubication Oil SystemAustin UdofiaNo ratings yet

- 6bta f1Document6 pages6bta f1Salatiel SanchezNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- PSS 5.2-520 V4A - Parts List - 2020Document9 pagesPSS 5.2-520 V4A - Parts List - 2020Centrifugal SeparatorNo ratings yet

- FQ-FC3000 - Installation, Operation & Maintenance Manual - 2015Document58 pagesFQ-FC3000 - Installation, Operation & Maintenance Manual - 2015Centrifugal Separator100% (1)

- Separator PSS - BrochureDocument2 pagesSeparator PSS - BrochureCentrifugal SeparatorNo ratings yet

- Separator Green Bedding - BrochureDocument2 pagesSeparator Green Bedding - BrochureCentrifugal SeparatorNo ratings yet

- PSS 5.2-780 V4A - Parts List - 2020Document9 pagesPSS 5.2-780 V4A - Parts List - 2020Centrifugal SeparatorNo ratings yet

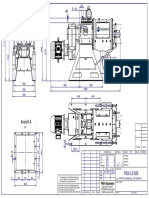

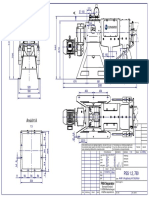

- PSS 5.2 - 780 - 5,5kW - DrawingDocument1 pagePSS 5.2 - 780 - 5,5kW - DrawingCentrifugal SeparatorNo ratings yet

- PSS 5.2-1040 V4A - Parts List - 2020Document9 pagesPSS 5.2-1040 V4A - Parts List - 2020Centrifugal SeparatorNo ratings yet

- PSS 3.2-1040 - Parts List - 2017Document10 pagesPSS 3.2-1040 - Parts List - 2017Centrifugal SeparatorNo ratings yet

- PSS 3.2-520 - Parts List - 2016Document10 pagesPSS 3.2-520 - Parts List - 2016Centrifugal SeparatorNo ratings yet

- PSS 3.2 - 520 - 5,5kW - DrawingDocument1 pagePSS 3.2 - 520 - 5,5kW - DrawingCentrifugal SeparatorNo ratings yet

- PSS 1.2-520 - Parts List - 2016Document9 pagesPSS 1.2-520 - Parts List - 2016Centrifugal SeparatorNo ratings yet

- PSS 1.2 - 3.2 - 3.3 - 5.2 - Operating Manual - Vol. 1 - 2019Document43 pagesPSS 1.2 - 3.2 - 3.3 - 5.2 - Operating Manual - Vol. 1 - 2019Centrifugal SeparatorNo ratings yet

- PSS 1.2 - Manual - 2009Document45 pagesPSS 1.2 - Manual - 2009Centrifugal SeparatorNo ratings yet

- Motor and Gear G500 S8000 4kW LL, 5,5kW LL, 11kW and 11kW LL - Parts List - 2020Document1 pageMotor and Gear G500 S8000 4kW LL, 5,5kW LL, 11kW and 11kW LL - Parts List - 2020Centrifugal SeparatorNo ratings yet

- Gears - Parts List - 2016Document14 pagesGears - Parts List - 2016Centrifugal SeparatorNo ratings yet

- PSS 1.2 - 780 - 4kW - DrawingDocument1 pagePSS 1.2 - 780 - 4kW - DrawingCentrifugal SeparatorNo ratings yet

- PSS - 3.3 - 780 - 7,5kW Green Bedding - DrawingDocument1 pagePSS - 3.3 - 780 - 7,5kW Green Bedding - DrawingCentrifugal SeparatorNo ratings yet

- PSS 1.2-780 - Parts List - 2017Document10 pagesPSS 1.2-780 - Parts List - 2017Centrifugal SeparatorNo ratings yet

- PSS 1.1-300 - Operating Manual - Vol. 2 - 2019Document41 pagesPSS 1.1-300 - Operating Manual - Vol. 2 - 2019Centrifugal SeparatorNo ratings yet

- Green Bedding Separator FAN - Parts List - 2017Document9 pagesGreen Bedding Separator FAN - Parts List - 2017Centrifugal SeparatorNo ratings yet

- Quality Low-Speed Decanter Centrifuges - 2018 - BrochureDocument2 pagesQuality Low-Speed Decanter Centrifuges - 2018 - BrochureCentrifugal SeparatorNo ratings yet

- Motor and Gear G500 S3100 5,5kW, 7,5kW - Parts List - 2020Document1 pageMotor and Gear G500 S3100 5,5kW, 7,5kW - Parts List - 2020Centrifugal SeparatorNo ratings yet

- Motor and Gear 3kW, 4kW - Parts List - 2020Document1 pageMotor and Gear 3kW, 4kW - Parts List - 2020Centrifugal SeparatorNo ratings yet

- Decanter Centrifuges - 2019 - BrochureDocument48 pagesDecanter Centrifuges - 2019 - BrochureCentrifugal SeparatorNo ratings yet

- ESS-2272HD - 2019 - BrochureDocument2 pagesESS-2272HD - 2019 - BrochureCentrifugal SeparatorNo ratings yet

- Centrifuge Solutions - 2021 - BrochureDocument12 pagesCentrifuge Solutions - 2021 - BrochureCentrifugal SeparatorNo ratings yet

- ESS-1450HD2 - 2020 - BrochureDocument4 pagesESS-1450HD2 - 2020 - BrochureCentrifugal SeparatorNo ratings yet

- Common Challenges Relative To The Use of Decanter Centrifuges For Barite Recovery in The Oil & Gas Industry - BrochureDocument13 pagesCommon Challenges Relative To The Use of Decanter Centrifuges For Barite Recovery in The Oil & Gas Industry - BrochureCentrifugal SeparatorNo ratings yet

- Part 4 Crop Protection Q ADocument54 pagesPart 4 Crop Protection Q AEleven HopperNo ratings yet

- Lubrication SystemDocument43 pagesLubrication Systemkebaman1986No ratings yet

- Purgador Parker v200Document15 pagesPurgador Parker v200David Fabian Rodriguez AlvarezNo ratings yet

- Steam Tracing SpecificationDocument14 pagesSteam Tracing SpecificationPankaj SahuNo ratings yet

- The Legend of Lake TobaDocument2 pagesThe Legend of Lake Tobamesin cuci15No ratings yet

- TeamCare DentalDocument8 pagesTeamCare DentalHector FloydNo ratings yet

- Grid ACS L2 Mobile Substations 0311 2016 03 enDocument12 pagesGrid ACS L2 Mobile Substations 0311 2016 03 enJose ValdiviesoNo ratings yet

- Carrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetDocument16 pagesCarrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetQazertNo ratings yet

- Aviation Indutry in IndiaDocument20 pagesAviation Indutry in IndiayuktimNo ratings yet

- RB Cba Executive Summary 0405Document24 pagesRB Cba Executive Summary 0405pepegrillo891No ratings yet

- Comprehensive Operations Planning Directive (COPD) IntroductionDocument4 pagesComprehensive Operations Planning Directive (COPD) Introductionstlpts75100% (1)

- Civil Air Patrol News - Mar 2007Document60 pagesCivil Air Patrol News - Mar 2007CAP History LibraryNo ratings yet

- We Are Young Chords-FunDocument11 pagesWe Are Young Chords-FunDimas NaufalNo ratings yet

- STS1 1Document42 pagesSTS1 1Peter Paul Rebucan PerudaNo ratings yet

- Electricity Worksheet Physics GcseDocument5 pagesElectricity Worksheet Physics Gcsetun1123tNo ratings yet

- 5s Audit Checklist and Performance Measurement SystemDocument31 pages5s Audit Checklist and Performance Measurement Systemkhurram khanNo ratings yet

- LeeBoy Tack Tank Manual 8 21 06 PDFDocument40 pagesLeeBoy Tack Tank Manual 8 21 06 PDFLuis Miguel Mamani CastroNo ratings yet

- Factores de Virulencia Del Streptococcus PneumoniaeDocument7 pagesFactores de Virulencia Del Streptococcus PneumoniaeFranklin ArandaNo ratings yet

- Indian ArchitectsDocument14 pagesIndian ArchitectsNabeel KTNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- REC EQ ChartDocument2 pagesREC EQ ChartAntonio F.M. PalloneNo ratings yet

- Chapter-3 - Pie ChartsDocument6 pagesChapter-3 - Pie Chartsvishesh bhatiaNo ratings yet

- wph11 01 Rms 20230817Document17 pageswph11 01 Rms 20230817Nirmani RodrigoNo ratings yet

- Full Metal Crown ConstructionDocument48 pagesFull Metal Crown ConstructionAnonymous k8rDEsJsU1100% (1)

- Biological Disaster: InformationDocument4 pagesBiological Disaster: InformationBarani DharanNo ratings yet

- Product CatalogDocument30 pagesProduct CatalogVeri Ambar SariNo ratings yet

- LabVentMgmt RPDocument100 pagesLabVentMgmt RPGanesh.MahendraNo ratings yet

- PE PipesDocument28 pagesPE Pipesmanar rafikNo ratings yet

HH 160 MO - Brochure

HH 160 MO - Brochure

Uploaded by

Centrifugal SeparatorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HH 160 MO - Brochure

HH 160 MO - Brochure

Uploaded by

Centrifugal SeparatorCopyright:

Available Formats

Hutchison Hayes Separation Inc.

HH 160 MO

The HH 160 centrifuge is a oil cleaning system with a

low installation cost. It is a small and compact system

with well proven components.

Application

The HH 160 system is specifically designed for

purification or clarification of mineral oils found in the

marine and power industries.

• Lubricating oils.

• Distillate and light diesel oils (MDO).

Working principle:

Separation takes place in a solids-retaining, also

known as a solid bowl that can be arranged for

purification or clarification (optional). In both cases the

dirty oil is fed in to the separator by a build-on feed

pump through the oil inlet and is separated by

centrifugal force into its various phases. The heaviest phase, sludge, is forced to and deposited

at the periphery of the bowl. Separated sludge is collected in the space at the periphery of the

bowl and must be removed periodically by hand. The clean oil is continuously discharged

through a built-on pump.

Water leaves the bowl via an open outlet. When operated in purifier mode, a gravity disc must

be fitted to obtain the correct interface position (the boundary between the separated oil and the

water seal) in the separator bowl. In the optional clarifier mode, a clarifier disc is fitted instead of

a gravity disc.

A water seal alarm is available as optional equipment to monitor the

pressure in the clean oil outlet. The control unit will shut off the oil

feed to the separator in case a pressure drop is detected and give an

audible and/or visible alarm.

Installation

The HH 160 separation system is designed for installation as a

complete system. The layout schematic shows a typical installation

of an HH 160 separator. Dirty oil is supplied by the feed pump from

the oil tank to the separator bowl for continuous cleaning. After

separation, the cleaned oil is discharged by a built-on pump.

Options

A complete system includes an optional water seal alarm, starter, heater, valves, piping and

other equipment.

Hutchison Hayes Separation Inc www.hutchisonhayes.com

3520 East Sam Houston beltway N. P.O.Box 2965

Houston, Texas 77015, USA Houston, Texas 77252, USA

Phone 713 455 9600 Fax 713 455 7753

Hutchison Hayes Separation Inc.

TECHNICAL DATA SHEET

MODEL HH-160 MO

MAXIMUM RATED CAPACITY 344 GPH SPEED

Minimum temperature 30°F The maximum speed of the spindle must not be

exceeded.

Maximum temperature 212°F Drive motor 1750 RPM

Recommended throughput: Bowl Spindle 8600 RPM

Distillate 304 GPH Run up time 2 minutes

Viscosity 1.5 - 5.5 cSt/40°C (104°F) Run down time 3 minutes

Marine Diesel (MDO 2) 238 GPH

Viscosity 14 cSt/40°C (104°F) Materials

Diesel Engine Lube oil Frame: cast iron (epoxy enamel)

Cross head 105 GPH Covers: cast aluminum

Trunk 80 GPH

Steam Turbine Lube oil 212 GPH Bowl Components

Viscosity 32-46 cSt/40°C (104°F) Bowl body, hood, disc stack: stainless steel

Distributor, top disc: bronze

Suction lift to pump 12 Feet, WC

Delivery head pump 45 Feet, WC

Shipping Data

Sludge Holding Space .15 Gallon Unit is shipped with all necessary bowl insertion

tools,

Drive Motor 1.2 HP mounting isolators, built-on feed pump and motor.

Gear Case Oil 1 Quart

Net weight 155 Lbs

Operating Water for Sealing Gross weight 221 Lbs

Max chloride content 60 PPM Volume 10.5 Cu. Ft.

Hutchison Hayes Separation Inc www.hutchisonhayes.com

3520 East Sam Houston beltway N. P.O.Box 2965

Houston, Texas 77015, USA Houston, Texas 77252, USA

Phone 713 455 9600 Fax 713 455 7753

You might also like

- FQC-950M-BF - Installation, Operation & Maintenance Manual - 2015Document96 pagesFQC-950M-BF - Installation, Operation & Maintenance Manual - 2015Centrifugal SeparatorNo ratings yet

- Model Hh219Document54 pagesModel Hh219helbertortiz100% (1)

- PSS 3.2-780 - Parts List - 2016Document10 pagesPSS 3.2-780 - Parts List - 2016Centrifugal SeparatorNo ratings yet

- Oil FlushDocument7 pagesOil FlushDaniel JurcichNo ratings yet

- Palm Oil RefiningDocument10 pagesPalm Oil Refiningharrison_sNo ratings yet

- Steam Turbine Lube Oil and Control Oil SystemDocument23 pagesSteam Turbine Lube Oil and Control Oil SystemMoinuddin Mohammed100% (3)

- Turbine Lub Oil SystemDocument25 pagesTurbine Lub Oil Systemrishinric90% (10)

- New American Paintings - December-January, 2019Document180 pagesNew American Paintings - December-January, 2019Fabio Nagual100% (2)

- Heat Integration AssignmentDocument8 pagesHeat Integration AssignmentMian Kamran AliNo ratings yet

- HH 360 BD Product LeafletDocument2 pagesHH 360 BD Product LeaflethelbertortizNo ratings yet

- HH 219 BD - BrochureDocument2 pagesHH 219 BD - BrochureCentrifugal SeparatorNo ratings yet

- HH 219 MO - BrochureDocument2 pagesHH 219 MO - BrochureCentrifugal SeparatorNo ratings yet

- HH 845 - BrochureDocument2 pagesHH 845 - BrochureCentrifugal SeparatorNo ratings yet

- HH 1200 - BrochureDocument2 pagesHH 1200 - BrochureCentrifugal SeparatorNo ratings yet

- Hpu 0-3-MDocument2 pagesHpu 0-3-MlearningzabatNo ratings yet

- Recommended Operating Conditions - Presentation (Final)Document50 pagesRecommended Operating Conditions - Presentation (Final)Abdul WasiqNo ratings yet

- HH 219 - Maintenance, Operation and Parts ManualDocument54 pagesHH 219 - Maintenance, Operation and Parts ManualCentrifugal Separator100% (1)

- Cathead Parts BrochureDocument8 pagesCathead Parts BrochureJuan LorenzoNo ratings yet

- Steam Sterilizer 10TPH Palm Oil Production Line 2020-03Document9 pagesSteam Sterilizer 10TPH Palm Oil Production Line 2020-03Souleïman CisséNo ratings yet

- Automated Tube Honing Machine BrochureDocument3 pagesAutomated Tube Honing Machine BrochurePanami AryaNo ratings yet

- Des AlterDocument5 pagesDes Altersagarchawla13No ratings yet

- Lube Oil System PDFDocument18 pagesLube Oil System PDFHuỳnh Phan Ngọc100% (1)

- HH 1456 - BrochureDocument2 pagesHH 1456 - BrochureCentrifugal SeparatorNo ratings yet

- Pen-88 HT™ High-Temperature Surfactant: StimulationDocument2 pagesPen-88 HT™ High-Temperature Surfactant: StimulationJavier Lora BarbaNo ratings yet

- System Description - 01810640Document16 pagesSystem Description - 01810640dannyNo ratings yet

- Seal Oil SystemDocument40 pagesSeal Oil Systemsameer betalNo ratings yet

- PurifiersDocument8 pagesPurifiersEzy WaqaNo ratings yet

- ETI AutoLube-Presentation - ARDocument29 pagesETI AutoLube-Presentation - ARAbdul BasitNo ratings yet

- Roxen LubricatorDocument12 pagesRoxen Lubricatorcengiz kutukcuNo ratings yet

- PULVERISER LUBE OIL SYSTEM OPERATING PROCEDURE REV 00 - WBPDCL SAGARDIGHI 2x500MW - Rev00 - ApprovedDocument4 pagesPULVERISER LUBE OIL SYSTEM OPERATING PROCEDURE REV 00 - WBPDCL SAGARDIGHI 2x500MW - Rev00 - ApprovedSourav SahaNo ratings yet

- W-1250-Ast-E SpecsheetsDocument2 pagesW-1250-Ast-E Specsheetsapi-261294473No ratings yet

- Weh Maritime EduDocument5 pagesWeh Maritime EduErick PachasNo ratings yet

- STX Man B&W 5l2330h Auxiliary Engine Manual p.3Document479 pagesSTX Man B&W 5l2330h Auxiliary Engine Manual p.3vlasovalexander2404No ratings yet

- ПурификаторDocument10 pagesПурификаторmomoyomotaNo ratings yet

- Role of Hydrogen in GeneratorDocument33 pagesRole of Hydrogen in GeneratorVasudev Agrawal100% (1)

- Elementos de Desgaste 160hDocument6 pagesElementos de Desgaste 160hAnonymous F2Q7hAtscNo ratings yet

- Oil Flushing Procedures For Steam Turbine & Generator Sets 1Document8 pagesOil Flushing Procedures For Steam Turbine & Generator Sets 1atul singhNo ratings yet

- Lub Oil Sys ManualDocument17 pagesLub Oil Sys Manualniranjan.malla4No ratings yet

- Lurgi Deodorizing PDFDocument6 pagesLurgi Deodorizing PDFAnonymous 6Nt20xKNo ratings yet

- Fail Free Commissioning-Steam Turbine Hydraulic SystemDocument36 pagesFail Free Commissioning-Steam Turbine Hydraulic SystemPrabhudhasanNo ratings yet

- Biofuel Vacuum PumpDocument4 pagesBiofuel Vacuum Pumpkla_alkNo ratings yet

- Ghee Mill AllDocument36 pagesGhee Mill AllNuman TariqNo ratings yet

- High-Capacity Self-Cleaning Centrifugal Separator For Fuel OilsDocument2 pagesHigh-Capacity Self-Cleaning Centrifugal Separator For Fuel Oilsامير الموسويNo ratings yet

- Pack RYTDocument41 pagesPack RYTGonzalo Alonso QuintanaNo ratings yet

- DPA - 240 User'S Manual: Diesel Parts of AmericaDocument54 pagesDPA - 240 User'S Manual: Diesel Parts of AmericaEdinson Ariel Chavarro QuinteroNo ratings yet

- Alfa Laval Brew 301Document4 pagesAlfa Laval Brew 301Andor MolitoriszNo ratings yet

- B01 Crude Oil Treatment, Rev 4-2014 PDFDocument2 pagesB01 Crude Oil Treatment, Rev 4-2014 PDFNihad S ZainNo ratings yet

- By Rajesh Adhate J.E Manikdoh H.P.SDocument38 pagesBy Rajesh Adhate J.E Manikdoh H.P.SAhemadNo ratings yet

- Hydraulic Fluid Changeover Procedure: Marine Lubricants Information Bulletin 16Document3 pagesHydraulic Fluid Changeover Procedure: Marine Lubricants Information Bulletin 16AymanSayedElantableeNo ratings yet

- Project Finance - Management Input V 5.2Document25 pagesProject Finance - Management Input V 5.2gaurav gargNo ratings yet

- Unidad de Potencia Hidraulica Hycon HPP13 FlexDocument9 pagesUnidad de Potencia Hidraulica Hycon HPP13 FlexJorge Diaz Nestor MonsalveNo ratings yet

- Engines 19 Gas Turbine Lubrication PDFDocument31 pagesEngines 19 Gas Turbine Lubrication PDFCemalettin öztoprakNo ratings yet

- Alfa Laval MAB 104B 1424 Solids Retaining Centrifuge PDFDocument2 pagesAlfa Laval MAB 104B 1424 Solids Retaining Centrifuge PDFzzapiecheNo ratings yet

- Catalogo Hidrolavadora HotsyDocument226 pagesCatalogo Hidrolavadora HotsyWuillians GuzmanNo ratings yet

- Soxtec 2050 Auto Fat Extraction System: Features and BenefitsDocument2 pagesSoxtec 2050 Auto Fat Extraction System: Features and Benefitsosklav50% (2)

- What Are Purifiers and Why To Use Them On Ship: Centripetal ForceDocument16 pagesWhat Are Purifiers and Why To Use Them On Ship: Centripetal ForceFe CaprichoNo ratings yet

- CH Bearing CatalogDocument21 pagesCH Bearing CatalogScott TorgussonNo ratings yet

- Vt2222 EnglischDocument4 pagesVt2222 Englischericchel850712No ratings yet

- Emmie2 - EFU00047ENDocument2 pagesEmmie2 - EFU00047ENSyahrul AbidinNo ratings yet

- Broschyr COT Eng May 2020Document8 pagesBroschyr COT Eng May 2020Marek JeznachNo ratings yet

- Lubication Oil SystemDocument3 pagesLubication Oil SystemAustin UdofiaNo ratings yet

- 6bta f1Document6 pages6bta f1Salatiel SanchezNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- PSS 5.2-520 V4A - Parts List - 2020Document9 pagesPSS 5.2-520 V4A - Parts List - 2020Centrifugal SeparatorNo ratings yet

- FQ-FC3000 - Installation, Operation & Maintenance Manual - 2015Document58 pagesFQ-FC3000 - Installation, Operation & Maintenance Manual - 2015Centrifugal Separator100% (1)

- Separator PSS - BrochureDocument2 pagesSeparator PSS - BrochureCentrifugal SeparatorNo ratings yet

- Separator Green Bedding - BrochureDocument2 pagesSeparator Green Bedding - BrochureCentrifugal SeparatorNo ratings yet

- PSS 5.2-780 V4A - Parts List - 2020Document9 pagesPSS 5.2-780 V4A - Parts List - 2020Centrifugal SeparatorNo ratings yet

- PSS 5.2 - 780 - 5,5kW - DrawingDocument1 pagePSS 5.2 - 780 - 5,5kW - DrawingCentrifugal SeparatorNo ratings yet

- PSS 5.2-1040 V4A - Parts List - 2020Document9 pagesPSS 5.2-1040 V4A - Parts List - 2020Centrifugal SeparatorNo ratings yet

- PSS 3.2-1040 - Parts List - 2017Document10 pagesPSS 3.2-1040 - Parts List - 2017Centrifugal SeparatorNo ratings yet

- PSS 3.2-520 - Parts List - 2016Document10 pagesPSS 3.2-520 - Parts List - 2016Centrifugal SeparatorNo ratings yet

- PSS 3.2 - 520 - 5,5kW - DrawingDocument1 pagePSS 3.2 - 520 - 5,5kW - DrawingCentrifugal SeparatorNo ratings yet

- PSS 1.2-520 - Parts List - 2016Document9 pagesPSS 1.2-520 - Parts List - 2016Centrifugal SeparatorNo ratings yet

- PSS 1.2 - 3.2 - 3.3 - 5.2 - Operating Manual - Vol. 1 - 2019Document43 pagesPSS 1.2 - 3.2 - 3.3 - 5.2 - Operating Manual - Vol. 1 - 2019Centrifugal SeparatorNo ratings yet

- PSS 1.2 - Manual - 2009Document45 pagesPSS 1.2 - Manual - 2009Centrifugal SeparatorNo ratings yet

- Motor and Gear G500 S8000 4kW LL, 5,5kW LL, 11kW and 11kW LL - Parts List - 2020Document1 pageMotor and Gear G500 S8000 4kW LL, 5,5kW LL, 11kW and 11kW LL - Parts List - 2020Centrifugal SeparatorNo ratings yet

- Gears - Parts List - 2016Document14 pagesGears - Parts List - 2016Centrifugal SeparatorNo ratings yet

- PSS 1.2 - 780 - 4kW - DrawingDocument1 pagePSS 1.2 - 780 - 4kW - DrawingCentrifugal SeparatorNo ratings yet

- PSS - 3.3 - 780 - 7,5kW Green Bedding - DrawingDocument1 pagePSS - 3.3 - 780 - 7,5kW Green Bedding - DrawingCentrifugal SeparatorNo ratings yet

- PSS 1.2-780 - Parts List - 2017Document10 pagesPSS 1.2-780 - Parts List - 2017Centrifugal SeparatorNo ratings yet

- PSS 1.1-300 - Operating Manual - Vol. 2 - 2019Document41 pagesPSS 1.1-300 - Operating Manual - Vol. 2 - 2019Centrifugal SeparatorNo ratings yet

- Green Bedding Separator FAN - Parts List - 2017Document9 pagesGreen Bedding Separator FAN - Parts List - 2017Centrifugal SeparatorNo ratings yet

- Quality Low-Speed Decanter Centrifuges - 2018 - BrochureDocument2 pagesQuality Low-Speed Decanter Centrifuges - 2018 - BrochureCentrifugal SeparatorNo ratings yet

- Motor and Gear G500 S3100 5,5kW, 7,5kW - Parts List - 2020Document1 pageMotor and Gear G500 S3100 5,5kW, 7,5kW - Parts List - 2020Centrifugal SeparatorNo ratings yet

- Motor and Gear 3kW, 4kW - Parts List - 2020Document1 pageMotor and Gear 3kW, 4kW - Parts List - 2020Centrifugal SeparatorNo ratings yet

- Decanter Centrifuges - 2019 - BrochureDocument48 pagesDecanter Centrifuges - 2019 - BrochureCentrifugal SeparatorNo ratings yet

- ESS-2272HD - 2019 - BrochureDocument2 pagesESS-2272HD - 2019 - BrochureCentrifugal SeparatorNo ratings yet

- Centrifuge Solutions - 2021 - BrochureDocument12 pagesCentrifuge Solutions - 2021 - BrochureCentrifugal SeparatorNo ratings yet

- ESS-1450HD2 - 2020 - BrochureDocument4 pagesESS-1450HD2 - 2020 - BrochureCentrifugal SeparatorNo ratings yet

- Common Challenges Relative To The Use of Decanter Centrifuges For Barite Recovery in The Oil & Gas Industry - BrochureDocument13 pagesCommon Challenges Relative To The Use of Decanter Centrifuges For Barite Recovery in The Oil & Gas Industry - BrochureCentrifugal SeparatorNo ratings yet

- Part 4 Crop Protection Q ADocument54 pagesPart 4 Crop Protection Q AEleven HopperNo ratings yet

- Lubrication SystemDocument43 pagesLubrication Systemkebaman1986No ratings yet

- Purgador Parker v200Document15 pagesPurgador Parker v200David Fabian Rodriguez AlvarezNo ratings yet

- Steam Tracing SpecificationDocument14 pagesSteam Tracing SpecificationPankaj SahuNo ratings yet

- The Legend of Lake TobaDocument2 pagesThe Legend of Lake Tobamesin cuci15No ratings yet

- TeamCare DentalDocument8 pagesTeamCare DentalHector FloydNo ratings yet

- Grid ACS L2 Mobile Substations 0311 2016 03 enDocument12 pagesGrid ACS L2 Mobile Substations 0311 2016 03 enJose ValdiviesoNo ratings yet

- Carrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetDocument16 pagesCarrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetQazertNo ratings yet

- Aviation Indutry in IndiaDocument20 pagesAviation Indutry in IndiayuktimNo ratings yet

- RB Cba Executive Summary 0405Document24 pagesRB Cba Executive Summary 0405pepegrillo891No ratings yet

- Comprehensive Operations Planning Directive (COPD) IntroductionDocument4 pagesComprehensive Operations Planning Directive (COPD) Introductionstlpts75100% (1)

- Civil Air Patrol News - Mar 2007Document60 pagesCivil Air Patrol News - Mar 2007CAP History LibraryNo ratings yet

- We Are Young Chords-FunDocument11 pagesWe Are Young Chords-FunDimas NaufalNo ratings yet

- STS1 1Document42 pagesSTS1 1Peter Paul Rebucan PerudaNo ratings yet

- Electricity Worksheet Physics GcseDocument5 pagesElectricity Worksheet Physics Gcsetun1123tNo ratings yet

- 5s Audit Checklist and Performance Measurement SystemDocument31 pages5s Audit Checklist and Performance Measurement Systemkhurram khanNo ratings yet

- LeeBoy Tack Tank Manual 8 21 06 PDFDocument40 pagesLeeBoy Tack Tank Manual 8 21 06 PDFLuis Miguel Mamani CastroNo ratings yet

- Factores de Virulencia Del Streptococcus PneumoniaeDocument7 pagesFactores de Virulencia Del Streptococcus PneumoniaeFranklin ArandaNo ratings yet

- Indian ArchitectsDocument14 pagesIndian ArchitectsNabeel KTNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- REC EQ ChartDocument2 pagesREC EQ ChartAntonio F.M. PalloneNo ratings yet

- Chapter-3 - Pie ChartsDocument6 pagesChapter-3 - Pie Chartsvishesh bhatiaNo ratings yet

- wph11 01 Rms 20230817Document17 pageswph11 01 Rms 20230817Nirmani RodrigoNo ratings yet

- Full Metal Crown ConstructionDocument48 pagesFull Metal Crown ConstructionAnonymous k8rDEsJsU1100% (1)

- Biological Disaster: InformationDocument4 pagesBiological Disaster: InformationBarani DharanNo ratings yet

- Product CatalogDocument30 pagesProduct CatalogVeri Ambar SariNo ratings yet

- LabVentMgmt RPDocument100 pagesLabVentMgmt RPGanesh.MahendraNo ratings yet

- PE PipesDocument28 pagesPE Pipesmanar rafikNo ratings yet