Professional Documents

Culture Documents

Ielts Diagram Task 1 Writing

Ielts Diagram Task 1 Writing

Uploaded by

Gúm Mì Haribô0 ratings0% found this document useful (0 votes)

159 views1 pageThe 11-stage process of producing steel rod begins with obtaining raw materials like iron ore, yellow ore, and carbon. The materials are melted at 1300-1500 degrees Celsius and refined before being poured into ingots and cooled in a reservoir at 60-100 degrees Celsius to form strands. The strands are rolled into shape, heated, measured, cut to size, and given an ID before a final inspection makes the rods ready for use.

Original Description:

Original Title

ielts diagram task 1 writing

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe 11-stage process of producing steel rod begins with obtaining raw materials like iron ore, yellow ore, and carbon. The materials are melted at 1300-1500 degrees Celsius and refined before being poured into ingots and cooled in a reservoir at 60-100 degrees Celsius to form strands. The strands are rolled into shape, heated, measured, cut to size, and given an ID before a final inspection makes the rods ready for use.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

159 views1 pageIelts Diagram Task 1 Writing

Ielts Diagram Task 1 Writing

Uploaded by

Gúm Mì HaribôThe 11-stage process of producing steel rod begins with obtaining raw materials like iron ore, yellow ore, and carbon. The materials are melted at 1300-1500 degrees Celsius and refined before being poured into ingots and cooled in a reservoir at 60-100 degrees Celsius to form strands. The strands are rolled into shape, heated, measured, cut to size, and given an ID before a final inspection makes the rods ready for use.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

The diagram describes the stages involved in the production of steel rod.

Overall, the process consists of 11

stages, starting with collecting raw materials and ending with the product’s inspection.

The production starts with obtaining pure iron ore, yellow ore and carbon for raw materials. After that, they

are put in melting slit with the optimal temperature of 1300 – 1500 degrees celcius. The melted mass is then

transferred to a smelting cabin to undergo refinement. Next, the candescent metal is poured into the ingots.

At the next stage, people connected the ingots to a cooling reservoir at temperature from 60 to 100 degrees

celcius. The metal passes through the nozzles and molds into strands while cooling down. Following this,

the metal strands are gone through rollers to form their shape. After that, the completed strands are

transferred to the heating machine. Having been heated, the metal undergo surface check by delivering

them to measuring automation.

Then, the metal strands are sized by the cutter and received ID standing. In the final stage, the metal rods

undergo inspection and get ready for use.

You might also like

- Open Hearth FurnaceDocument19 pagesOpen Hearth Furnacemanikandan50% (2)

- Hydraulics in Vizag Steel PlantDocument54 pagesHydraulics in Vizag Steel Plant9700352181100% (2)

- Menu-WPS OfficeDocument2 pagesMenu-WPS Officereshmahusna8No ratings yet

- Engineering Chemistry Assignment # 3: Submitted To: Submitted By: Registration #: Department: SectionDocument3 pagesEngineering Chemistry Assignment # 3: Submitted To: Submitted By: Registration #: Department: SectionWamiq SohailNo ratings yet

- 6 - 6 - 21 IELTSUp Sample DiagramDocument2 pages6 - 6 - 21 IELTSUp Sample Diagramthe pioneerNo ratings yet

- Prepared By:-Sumant Sahu Metallurgy 3203808302Document21 pagesPrepared By:-Sumant Sahu Metallurgy 3203808302Rahul PandeyNo ratings yet

- Report TrainingDocument15 pagesReport TrainingGaurav AkotkarNo ratings yet

- Friction Stir Welding: Figure 1 WheelsDocument16 pagesFriction Stir Welding: Figure 1 WheelsMashooq JainNo ratings yet

- 114 - CS - 114-SMS-Minimizimg of IRUT Hood Jams in TP-bayDocument14 pages114 - CS - 114-SMS-Minimizimg of IRUT Hood Jams in TP-bayVivekanand DathivalasaNo ratings yet

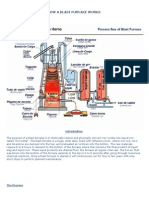

- How A Blast Furnace WorksDocument7 pagesHow A Blast Furnace WorksprasenjitsayantanNo ratings yet

- Sample2Procedure PDFDocument2 pagesSample2Procedure PDFWill KurlinkusNo ratings yet

- Jimenez (Making Steel)Document19 pagesJimenez (Making Steel)NATSOKO XPNo ratings yet

- Convert The Following Flow Chart Into A Paragraph of About 150 WordsDocument10 pagesConvert The Following Flow Chart Into A Paragraph of About 150 WordsShraboni SinhaNo ratings yet

- Iron RecyclingDocument9 pagesIron RecyclingYousef SailiniNo ratings yet

- Proceso Bof en InglesDocument25 pagesProceso Bof en InglesMossstazzzaNo ratings yet

- Blast Furnace - Material TeknikDocument8 pagesBlast Furnace - Material TeknikDaniel Parsaoran Hamonangan SinagaNo ratings yet

- Learning Center. SailDocument5 pagesLearning Center. SailpdiconpNo ratings yet

- How A Blast Furnace WorksDocument6 pagesHow A Blast Furnace Worksvikrantsingh2908No ratings yet

- Blast Furnace Water Recirculation SystemDocument19 pagesBlast Furnace Water Recirculation SystemDaniel Seixas Breda100% (1)

- Unit 1 Metals and Melting Practices: StructureDocument45 pagesUnit 1 Metals and Melting Practices: StructureTapas BanerjeeNo ratings yet

- Steel Making: Basic Oxygen ProcessDocument1 pageSteel Making: Basic Oxygen ProcessPablo GomesNo ratings yet

- E Mat: Engineering MaterialsDocument135 pagesE Mat: Engineering MaterialsStevenson CacNo ratings yet

- Roll No 33Document39 pagesRoll No 33Rahul PandeyNo ratings yet

- OF Manufacturing Sciences 104: Melting Practices and FurnacesDocument14 pagesOF Manufacturing Sciences 104: Melting Practices and FurnacesnikhilzzNo ratings yet

- Ibrahim TrainingDocument7 pagesIbrahim Trainingahmedameer20189No ratings yet

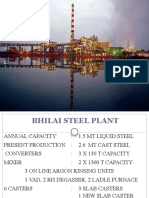

- BSPDocument50 pagesBSPRahul PandeyNo ratings yet

- Sms ProcessDocument7 pagesSms ProcessAnonymous p4GdtQpNo ratings yet

- Lecture 03 - Ferrous Metal & AlloysDocument42 pagesLecture 03 - Ferrous Metal & AlloysJuffrizal KarjantoNo ratings yet

- Oxygen Lance TechnologyDocument15 pagesOxygen Lance TechnologyEduardo Daniel Ortiz TorresNo ratings yet

- The Blast FurnaceDocument6 pagesThe Blast FurnaceJayanta MondalNo ratings yet

- ProjectDocument34 pagesProjectfaisalmir27100% (1)

- Iron Metallurgy by Nwaogbe JohnDocument26 pagesIron Metallurgy by Nwaogbe JohnDavid UdohNo ratings yet

- Ductie PipeDocument16 pagesDuctie PipeGond AbhishekNo ratings yet

- Billets ProcessDocument5 pagesBillets ProcessWewey NuestroNo ratings yet

- UNITED STATES STEEL CORPORATION MODERN STEEL MAKING PROMOTIONAL FILM MD86474 Many Many Things Are Vital To While WeDocument3 pagesUNITED STATES STEEL CORPORATION MODERN STEEL MAKING PROMOTIONAL FILM MD86474 Many Many Things Are Vital To While WeAstro EspejosNo ratings yet

- Blast FurnaceDocument3 pagesBlast FurnaceNarendra Singh ShekhawatNo ratings yet

- Hot Chamber Die Casting MachineDocument3 pagesHot Chamber Die Casting MachineAnand BossNo ratings yet

- Big Picture A - in A Nutshell ActivityDocument2 pagesBig Picture A - in A Nutshell ActivityJohndell H CastrodesNo ratings yet

- Types of Furnaces Used in CastingDocument29 pagesTypes of Furnaces Used in CastingMurali100% (1)

- PPR Model For The Production SystemDocument5 pagesPPR Model For The Production Systemdeepak devassiaNo ratings yet

- FinincialDocument10 pagesFinincialtesfaye mitikuNo ratings yet

- Continuous Casting and Mould Level ControlDocument15 pagesContinuous Casting and Mould Level ControlmehdihaNo ratings yet

- 3 Materila ScienceDocument34 pages3 Materila ScienceAlfred KuwodzaNo ratings yet

- Billet Making ProcessDocument5 pagesBillet Making Processrameshrangachari2008No ratings yet

- Apple Industries LTD - Anantapur Dist Exe Sum EngDocument8 pagesApple Industries LTD - Anantapur Dist Exe Sum EngRashmi PatelNo ratings yet

- Primary Steel MakingDocument56 pagesPrimary Steel MakingnitinrnnnNo ratings yet

- Ld#2 OverviewDocument7 pagesLd#2 Overviewsatish_trivedi100% (1)

- Steel Making Using Open Hearth Furnace-1Document9 pagesSteel Making Using Open Hearth Furnace-1victorymusa45No ratings yet

- Steel ManufacturingDocument23 pagesSteel ManufacturingIsrael HailuNo ratings yet

- Writing Task 1 ProcessDocument15 pagesWriting Task 1 Processneha sharmaNo ratings yet

- How's Steel Manufactured?: Raw Materials For IronmakingDocument6 pagesHow's Steel Manufactured?: Raw Materials For Ironmakingamitkhanna71No ratings yet

- Cement Manufacturing ProcessDocument2 pagesCement Manufacturing ProcessMorning Kalal0% (1)

- Die Casting Is A Manufacturing Process That Can Produce Geometrically Complex Metal Parts Through The Use of Reusable MoldsDocument13 pagesDie Casting Is A Manufacturing Process That Can Produce Geometrically Complex Metal Parts Through The Use of Reusable MoldsSanjay MukalaNo ratings yet

- 3.3. MetalsDocument7 pages3.3. MetalsVinothKumarVinothNo ratings yet

- Steel Industry Fact SheetDocument4 pagesSteel Industry Fact SheetYbonnie Mae T. LAPINIGNo ratings yet

- Tsubaki Steel Mill ChainsDocument10 pagesTsubaki Steel Mill ChainsSandip GhoshNo ratings yet

- Lecture-4-Intro. To Melting Furnaces-Lecture NotesDocument43 pagesLecture-4-Intro. To Melting Furnaces-Lecture NotesManchi MaheetNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Mensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeFrom EverandMensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeNo ratings yet

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet