Professional Documents

Culture Documents

ASME 830.4c 4994

ASME 830.4c 4994

Uploaded by

Alaeddine AbidCopyright:

Available Formats

You might also like

- IEC 15415-2006 EenDocument61 pagesIEC 15415-2006 EenAlaeddine AbidNo ratings yet

- Asme-B18.10 (2006)Document18 pagesAsme-B18.10 (2006)Sergio Rodriguez CamberosNo ratings yet

- A90.1 Safety Standard For Belt ManliftDocument36 pagesA90.1 Safety Standard For Belt ManliftYadi KusmayadiNo ratings yet

- Asme B20.1 2006Document26 pagesAsme B20.1 2006Diar Azzis SNo ratings yet

- Ultrasonic Welding of Lithium-Ion Batteries: Enter asset subtitleFrom EverandUltrasonic Welding of Lithium-Ion Batteries: Enter asset subtitleNo ratings yet

- Asme B30.26 Rigging HardwareDocument54 pagesAsme B30.26 Rigging HardwareRonald RegentNo ratings yet

- Asme B107.2-2002Document29 pagesAsme B107.2-2002noahb110No ratings yet

- Asme Y14 24 1999Document82 pagesAsme Y14 24 1999Gilberto FloresNo ratings yet

- Asme B18.21.1-1999Document27 pagesAsme B18.21.1-1999Edwin MariacaNo ratings yet

- Asme b73.1 PDFDocument48 pagesAsme b73.1 PDFGerencia Rigar Colombia SAS100% (3)

- Asme 36.19Document18 pagesAsme 36.19shakeelahmadjsr100% (3)

- ASME Y14.36M (1996) - Surface Texture Symbols PDFDocument14 pagesASME Y14.36M (1996) - Surface Texture Symbols PDFMiguelNo ratings yet

- Transmisi - ZF 16s150Document11 pagesTransmisi - ZF 16s150rezandriansyah100% (2)

- Asme B30.8C-1998Document10 pagesAsme B30.8C-1998Alaeddine AbidNo ratings yet

- Asme B16.36-2006Document30 pagesAsme B16.36-2006ChipNo ratings yet

- ASME B19.3b-1995 Addenda: Asme Safety Standard For Compressors For Process IndustriesDocument13 pagesASME B19.3b-1995 Addenda: Asme Safety Standard For Compressors For Process Industriesvijay pawarNo ratings yet

- Asme B16.28Document20 pagesAsme B16.28Nguyen Anh Tung100% (1)

- ASME QHO-1-2004Document20 pagesASME QHO-1-2004SharonNo ratings yet

- ASME B16.4 (1998) Gray Iron Threaded Fittings, Class 125 and 250Document19 pagesASME B16.4 (1998) Gray Iron Threaded Fittings, Class 125 and 250Mahmoud HekalNo ratings yet

- Asme Addenda: ASME 819.3-1991 Safety Standard For Compressors For Process IndustriesDocument15 pagesAsme Addenda: ASME 819.3-1991 Safety Standard For Compressors For Process Industriesvijay pawarNo ratings yet

- Asme B36.19M-2004Document14 pagesAsme B36.19M-2004JorgeNo ratings yet

- Hooks: ASME B30.10-2005Document26 pagesHooks: ASME B30.10-2005Carlos Aparicio100% (1)

- ASME B16.28 Wrought Steel Buttwelding Short Radius Elbows and Returns 1994Document20 pagesASME B16.28 Wrought Steel Buttwelding Short Radius Elbows and Returns 1994Luis OrtizNo ratings yet

- ASME B29.6m-1993Document53 pagesASME B29.6m-1993parashu104No ratings yet

- ASME A112.4.1-1993 - Water Heater Relief Valve Drain TubesDocument10 pagesASME A112.4.1-1993 - Water Heater Relief Valve Drain TubesFaisal EbrahimNo ratings yet

- ASME B30.3 (96) Torre Gruas de Construccion PDFDocument50 pagesASME B30.3 (96) Torre Gruas de Construccion PDFJhon Fabio ParraNo ratings yet

- BTH PDFDocument62 pagesBTH PDFsuranga100% (2)

- Asme B30.21-1999Document45 pagesAsme B30.21-1999oscarNo ratings yet

- Asme B I Addenda: To Asme Metallic Gaskets For Pipe Flanges Ring-Joint, Spiral-Wound, and JacketedDocument51 pagesAsme B I Addenda: To Asme Metallic Gaskets For Pipe Flanges Ring-Joint, Spiral-Wound, and JacketedTimilehin OladiranNo ratings yet

- Asme B30.3-1996-Grúas TorreDocument50 pagesAsme B30.3-1996-Grúas TorrejohnNo ratings yet

- Acme Screw Threads PDFDocument128 pagesAcme Screw Threads PDFJohan Medina Tovar100% (1)

- ASME A17.lC-I999Document26 pagesASME A17.lC-I999Alaeddine AbidNo ratings yet

- Asme B16.21-2005 PDFDocument22 pagesAsme B16.21-2005 PDFAhmed BaroukNo ratings yet

- Asme B30.18C-1997Document6 pagesAsme B30.18C-1997Alaeddine AbidNo ratings yet

- b16 14-1991 PDFDocument17 pagesb16 14-1991 PDFkarthimeenaNo ratings yet

- Asme B107.16M-1998Document20 pagesAsme B107.16M-1998thorek24No ratings yet

- Asme B18.2.4.6MDocument16 pagesAsme B18.2.4.6Mmanuneedhi100% (1)

- Asme B16.1Document41 pagesAsme B16.1Yhon Bastidas100% (2)

- ASME B1.20.5 Rosca NPTDocument63 pagesASME B1.20.5 Rosca NPTdopcncNo ratings yet

- B30.19-2005 CablewaysDocument36 pagesB30.19-2005 CablewaysMuhammadr Isa50% (2)

- Scheme For The Identification of Piping Systems: ASME A13.1-2007Document10 pagesScheme For The Identification of Piping Systems: ASME A13.1-2007roberto cNo ratings yet

- ASME B3022-2005 Articulating Boom Cranes - 221206 - 123014Document42 pagesASME B3022-2005 Articulating Boom Cranes - 221206 - 123014jesus rosas100% (1)

- ASME A112.6.3 2001 Floor and Trench DrainsDocument18 pagesASME A112.6.3 2001 Floor and Trench DrainsLuckyNo ratings yet

- ASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFDocument89 pagesASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFFabiano Lebkuchen100% (2)

- ASME B18.31.3-2009 - Threaded Rods - Inch SeriesDocument14 pagesASME B18.31.3-2009 - Threaded Rods - Inch SeriesSandeep Kumar Jaiswal100% (1)

- Asme B107.5M-2002Document22 pagesAsme B107.5M-2002noahb110No ratings yet

- Asme B16.48Document50 pagesAsme B16.48Ruben Dario DeaquizNo ratings yet

- ASME B16.48 Juntas CiegasDocument54 pagesASME B16.48 Juntas CiegasVictor TorresNo ratings yet

- Asme B18.2.3.3MDocument18 pagesAsme B18.2.3.3MPham Nhat50% (2)

- ASME B18.24a-2006 - Addenda of Part IdentifyDocument60 pagesASME B18.24a-2006 - Addenda of Part IdentifyThái Đạo Phạm LêNo ratings yet

- ASME B89 7 3 1 2001 Guidelines For Decision Rules Considering Measurement Uncertainty in Determining Conformance To Specifications PDFDocument24 pagesASME B89 7 3 1 2001 Guidelines For Decision Rules Considering Measurement Uncertainty in Determining Conformance To Specifications PDFprabhakaranme0% (1)

- ASME B18.24a-2006Document60 pagesASME B18.24a-2006Iliya100% (1)

- ASME B18.8.1-1994 Clevis Pins and Cotter Pins (Inch Series)Document20 pagesASME B18.8.1-1994 Clevis Pins and Cotter Pins (Inch Series)Vishal UpadhyeNo ratings yet

- ASME B30.26 - 04 Rigging HardwareDocument38 pagesASME B30.26 - 04 Rigging Hardwarejuan ninaNo ratings yet

- Asme-B18.9 (2007)Document22 pagesAsme-B18.9 (2007)Sergio Rodriguez CamberosNo ratings yet

- Asme B16.5 - 2003Document234 pagesAsme B16.5 - 2003JÚNIOR JR100% (1)

- Asme-B18 2 6mDocument21 pagesAsme-B18 2 6mthanh_121No ratings yet

- Asme B16.50 - 2001Document25 pagesAsme B16.50 - 2001phani u4meNo ratings yet

- ASME B16.34a-1998Document190 pagesASME B16.34a-1998jojeecaresNo ratings yet

- Bioceramics: Materials and Applications V: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandBioceramics: Materials and Applications V: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Veeraraghavan SundarNo ratings yet

- Synthesis, Properties, and Crystal Chemistry of Perovskite-Based Materials: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandSynthesis, Properties, and Crystal Chemistry of Perovskite-Based Materials: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Winnie Wong-NgNo ratings yet

- 1 Flare Net IntroductionDocument13 pages1 Flare Net IntroductionAlaeddine AbidNo ratings yet

- 2 Flare Net Introduction WorkshopDocument11 pages2 Flare Net Introduction WorkshopAlaeddine AbidNo ratings yet

- IEC 14598 2 2003 EenDocument21 pagesIEC 14598 2 2003 EenAlaeddine AbidNo ratings yet

- 4-Network Design WorkshopDocument27 pages4-Network Design WorkshopAlaeddine AbidNo ratings yet

- Uniiso Iec13818-10-2000 EenDocument147 pagesUniiso Iec13818-10-2000 EenAlaeddine AbidNo ratings yet

- 3 Network DesignDocument14 pages3 Network DesignAlaeddine AbidNo ratings yet

- IEC 17020-2005 EitDocument23 pagesIEC 17020-2005 EitAlaeddine AbidNo ratings yet

- Uni8719-1985 EitDocument3 pagesUni8719-1985 EitAlaeddine AbidNo ratings yet

- IEC 2022-2003 EenDocument61 pagesIEC 2022-2003 EenAlaeddine AbidNo ratings yet

- IEC 7811!4!1998 EenDocument13 pagesIEC 7811!4!1998 EenAlaeddine AbidNo ratings yet

- Unien12464 1Document43 pagesUnien12464 1Alaeddine AbidNo ratings yet

- IEC 17040-2005 EeiDocument39 pagesIEC 17040-2005 EeiAlaeddine AbidNo ratings yet

- IEC 10994-1995 EenDocument51 pagesIEC 10994-1995 EenAlaeddine AbidNo ratings yet

- IEC 17040-2005 EenDocument25 pagesIEC 17040-2005 EenAlaeddine AbidNo ratings yet

- IEC 7498!4!1993 EenDocument15 pagesIEC 7498!4!1993 EenAlaeddine AbidNo ratings yet

- IEC 17024-2004 EitDocument21 pagesIEC 17024-2004 EitAlaeddine AbidNo ratings yet

- IEC 7811!3!1998 EenDocument13 pagesIEC 7811!3!1998 EenAlaeddine AbidNo ratings yet

- IEC 17000-2005 EitDocument23 pagesIEC 17000-2005 EitAlaeddine AbidNo ratings yet

- Unien13201 3 2004 - EitDocument37 pagesUnien13201 3 2004 - EitAlaeddine AbidNo ratings yet

- IEC 17050 2 2005 EenDocument13 pagesIEC 17050 2 2005 EenAlaeddine AbidNo ratings yet

- Iec60512 1 4 (Ed1.0) BDocument23 pagesIec60512 1 4 (Ed1.0) BAlaeddine AbidNo ratings yet

- IEC 7811!5!1998 EenDocument13 pagesIEC 7811!5!1998 EenAlaeddine AbidNo ratings yet

- IEC 17050 2 2005 EeiDocument13 pagesIEC 17050 2 2005 EeiAlaeddine AbidNo ratings yet

- IEC 17050 1 2005 EeiDocument21 pagesIEC 17050 1 2005 EeiAlaeddine AbidNo ratings yet

- IEC 15419-2003 EenDocument41 pagesIEC 15419-2003 EenAlaeddine AbidNo ratings yet

- Iec7811!2!1998 EenDocument23 pagesIec7811!2!1998 EenAlaeddine AbidNo ratings yet

- IEC 17030-2006 EitDocument11 pagesIEC 17030-2006 EitAlaeddine AbidNo ratings yet

- IEC 15421-2003 EenDocument21 pagesIEC 15421-2003 EenAlaeddine AbidNo ratings yet

- Iec60896-21 (Ed1 0) BDocument89 pagesIec60896-21 (Ed1 0) BAlaeddine AbidNo ratings yet

- Revised AOCDocument2 pagesRevised AOCRHPS ProcurementNo ratings yet

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Power Generation SystemDocument72 pagesPower Generation SystemAbshir Mohamed HajjiNo ratings yet

- Introduction To Automobile EngineeringDocument14 pagesIntroduction To Automobile EngineeringdoomraNo ratings yet

- Artika Series: Cryogenic Submerged Pumps For Marine ApplicationsDocument2 pagesArtika Series: Cryogenic Submerged Pumps For Marine ApplicationsCami CamilongaNo ratings yet

- Hydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitDocument2 pagesHydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitMarcelino Huamani100% (1)

- TDBFP Manul PDFDocument266 pagesTDBFP Manul PDFsantosh100% (1)

- Nation Parts Guide PG 29Document1 pageNation Parts Guide PG 29ramsi17No ratings yet

- Nef Engine Nef Engine Nef Engine Nef Engine: Backhoe Loaders B90 - B100 - B110 - B115 (Tier 3)Document77 pagesNef Engine Nef Engine Nef Engine Nef Engine: Backhoe Loaders B90 - B100 - B110 - B115 (Tier 3)Oscarito VázquezNo ratings yet

- L2e 61sdh MitsubishiDocument127 pagesL2e 61sdh MitsubishiNUVE KARENTALNo ratings yet

- Effects:: A B A B B A B BDocument23 pagesEffects:: A B A B B A B BSenthil kumar BalakrishnanNo ratings yet

- User'S Manual: Pneumatic Positioner YT-1200 SeriesDocument22 pagesUser'S Manual: Pneumatic Positioner YT-1200 SeriescesarNo ratings yet

- Erection and Commissioning Works of The E/M Equipment: Guangdong Yuantian Engineering CompanyDocument103 pagesErection and Commissioning Works of The E/M Equipment: Guangdong Yuantian Engineering Companyxiaowei tuNo ratings yet

- Parker Pneumatic Robust Air Motor - P1V-M: PDE2600PNUKDocument5 pagesParker Pneumatic Robust Air Motor - P1V-M: PDE2600PNUKZoran JankovNo ratings yet

- Instruction Manual Zoje ZJ953-13H-ED2 PDFDocument19 pagesInstruction Manual Zoje ZJ953-13H-ED2 PDFMaskusyani0% (1)

- 950F Prueba y Ajuste Transmision Sistema ElectricoDocument38 pages950F Prueba y Ajuste Transmision Sistema Electricoale aleNo ratings yet

- Emission and Electrical Diagnosis (With Tech 2) : Workshop ManualDocument78 pagesEmission and Electrical Diagnosis (With Tech 2) : Workshop ManualAndres Miguel Cevallos Garcia100% (2)

- EST 8.6.0.0 Update 2Document3 pagesEST 8.6.0.0 Update 2gnomekdeNo ratings yet

- ALGB142Document44 pagesALGB142MahaManthra100% (1)

- Clutch SystemDocument32 pagesClutch SystemZerara KamelNo ratings yet

- GR-1600XL-3-2 LNG en Na S 2211Document20 pagesGR-1600XL-3-2 LNG en Na S 2211MauroNo ratings yet

- Parts Breakdown: Technical ServiceDocument3 pagesParts Breakdown: Technical ServicecafubodoNo ratings yet

- ZX300 6Document28 pagesZX300 6Bilal VURALNo ratings yet

- Manual Flowpacks Ensamble InstitucionalDocument32 pagesManual Flowpacks Ensamble InstitucionalhaynerNo ratings yet

- Sri Venkateswara College of Engg& Tech: Department of Mechanical EngineeringDocument8 pagesSri Venkateswara College of Engg& Tech: Department of Mechanical EngineeringLakshmi SinghNo ratings yet

- Treinamento - de lg936 - Eng - Rev1 - 2010Document146 pagesTreinamento - de lg936 - Eng - Rev1 - 2010Johan Mauricio Romero ChitivaNo ratings yet

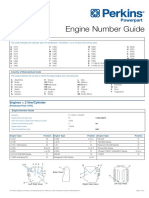

- Perkins Engine Number DataDocument3 pagesPerkins Engine Number Dataa100% (2)

- Mechanical Engineering-Compressors, Gas Turbines and Jet Engines Important MCQDocument28 pagesMechanical Engineering-Compressors, Gas Turbines and Jet Engines Important MCQavantgarde bwoyNo ratings yet

- Product Manual: Lifts Gearless InstallationDocument25 pagesProduct Manual: Lifts Gearless InstallationSatis100% (2)

ASME 830.4c 4994

ASME 830.4c 4994

Uploaded by

Alaeddine AbidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME 830.4c 4994

ASME 830.4c 4994

Uploaded by

Alaeddine AbidCopyright:

Available Formats

~ ~~~~

ASME B 3 0 - 4 C 9 4 0759670 0543626 698 M

AN AMERICAN NATIONAL STANDARD

SAFETY STANDARD FOR CABLEWAYS, CRANES, DERRICKS,

HOISTS, HOOKS, JACKS, AND SLINGS

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

ASME 8 3 0 . 4 ~ 4 9 9 4

ADDENDA

to

ASME B30.4-1990

PORTAL, TOWER, AND

PEDESTAL CRANES

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

United Engineering Center O O New York, N.Y. 10017

Copyright ASME International ',

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

ASME B30.4C 94 = 0759670 0543627 524

Date of Issuance: October 7, 1994

ASME is the registered trademark of The American Society of Mechanical Engineers.

This code or standard was developed under procedures accredited as meeting the criteria for

American National Standards. The Consensus Committee that approved the code or standard

was balanced to assure that individuals from competent and concerned interests have had an

opportunity to participate. The proposed code or standard was made available for public review

and comment which provides an opportunity for additional public input from industry, academia,

regulatory agencies, and the public-at-large.

ASME does not "approve," "rate," or "endorse" any item, construction, proprietary device, or

activity.

ASME does not take any position with respect to the validity of any patent rights asserted in

connection with any items mentioned in this document, and does not undertake to insure anyone

utilizing a standard against liability for infringement of any applicable Letters Patent, nor assume

any such liability. Users of a code or standard are expressly advised that determination of the

validity of any such patent rights, and the risk of infringement of such rights, is entirely their own

responsibility.

Participation by federal agency representativek) or person(s) affiliated with industry is not to

be interpreted as government or industry endorsement of this code or standard.

ASME accepts responsibility for only those interpretations issued in accordance with governing

ASME procedures and policies which preclude the issuance of interpretations by individual

volunteers.

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

No part of this document may be reproduced in any form,

in an electronic retrieval system or otherwise,

without the prior written permission of the publisher.

Copyright O 1994 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in U.S.A.

Copyright ASME International

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

ASME 830.4~-1994

Following approval by the ASME B30 Committee and ASME, and after public review,

ASME B30.4~-1994 was approved by the American National Standards Institute on August 1, 1994.

Addenda to the 1990 edition of ASME B30.4 are issued in the form of replacement pages. Revisions,

additions, and deletions are incorporated directly into the affected pages. It is advisable, however,

that this page, the Addenda title and copyright pages, and all replaced pages be retained for

reference.

SUMMARY OF CHANGES

This is the third Addenda to be published to ASME B30.4-1990.Previous Addenda were published

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

in 1991 and 1993.

Replace or insert the pages listed. Changes given below are identified on the pages by a margin

note, (c), placed next to the affected area. Previous Addenda changes are indicated by (a) and (b).

The pages not listed are the reverse sides of the listed pages and contain no changes.

Page Location Change

9 4-0.2.2 Definition of boom revised

10,11 4-0.3 References updated

32 4-3.2.2(b)(5) ANSI reference updated

Copyright ASME International

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

ASME B 3 0 . 4 C 9 4 = 0 7 5 9 6 7 0 0543b29 3T7 =

PORTAL, TOWER, AND PEDESTAL CRANES ASME 830.4~-1994

bogie - an assembly of two or more axles arranged to in-service - the condition of a crane ready for or en-

permit both vertical wheel displacement and an equal- gaged in work; an operator is at the controls

ization of loading on the wheels jib - an extension attached to the boom point to pro-

boom - a member used for supporting the hoisting tac- vide added boom length for lifting specified loads. The

kle, hinged to a fixed or rotating structure or to a mast, jib may be in line with the boom or offset to various

with its outer end supported by ropes, chains, rods, or angles.

a hydraulic cylinder load block, lower - the assembly of hook or shackle,

boom point - the outward end of the load-bearing boom swivel, sheaves, pins, and frame suspended by the

hoisting rope

brake - a device, other than a motor, used for retarding load block, upper - the assembly of sheaves, pins, and (b)

or stopping motion by friction or power means frame suspended from the boom or mounted in the load

braking means - a method or device for retarding or trolley

stopping motion load hoist - a hoist drum and rope reeving system used

buffer - an energy absorbing device for reducing im- for hoisting and lowering loads

pact when a moving crane reaches the end of its per- ib)

mitted travel load, working - the external load applied to the crane (b)

including the weight of load attaching equipment such

cab- a housing provided for the operator and contain-

as load blocks, ropes, shackles, and slings

ing the crane controls

(bl

clutch - a means for engagement or disengagement of out-ofservice - the condition of a crane when un-

power loaded, without power and with the controls unattended,

counterweight - weight used to supplement the weight and prepared to endure winds above the in-service level

of the machine in providing stability for lifting working parking track - for rail mounted cranes, a section of

loads; it swings with the crane track supported so that it is capable of sustaining storm

crane, standby - a crane which is not in regular service induced bogie loads; it is provided with storm anchor-

but that is used occasionally or intermittently as required ages when required

pawl (dog) - a device for positively holding a member

designated - selected or assigned by the employer or

against motion in one or more directions

the employer’s representative as being competent to

perform specific duties pedestal - a fixed raised crane base or foundation that

may be solid, enclosed, or framed, but without a portal

ùrum - the cylindrical member around which a rope is opening

wound and through which power is transmitted to the permanent installation - a crane installation intended

ropes to last the working life of the crane or for a period of

dynamic loading - loads introduced into the machine five years or more before dismantling and reerection

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

or its components by forces in motion pitch diameter - the diameter of a sheave or rope drum

flange point - the point of contact between the rope measured at the center line of the rope

and drum flange where the rope changes layers on a qualified person - a person who, by possession of a

rope drum recognized degree or certificate of professional stand-

ing, or who, by extensive knowledge, training, and ex-

gage, track - the horizontal distance between the center perience, has successfully demonstrated the ability to

lines of the two rails measured perpendicular to the solve or resolve problems relating to the subject matter

direction of travel and work

gantry - a movable structural frame consisting of col- radius (load) - the horizontal distance from a projec- (b)

umns and bracing capable of supporting a crane with tion of the axis of rotation to the base of the crane tower,

its working and dynamic loads gantry, or pedestal, before loading, to the center of ver-

high strength (traction) bolts - high strength tensile bolts tical hoist line or tackle with load applied

used in the assembly of crane components. The bolts rail clamp - a device for fastening a traveling crane to

are installed in tension, by torquing or other means, its rails to limit wind induced travel

at a level greater than that produced by in- or out-of- remote control station - a location, not on the crane,

service loads for the purpose of reducing the likelihood from which the operator can control all the crane move-

of bolt fatigue failure. ments

Copyright ASME International

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

ASME B30.4C 94 U 07.57670 0543b30 O17

ASME 830.4~-1994 PORTAL, TOWER, AND PEDESTAL CRANES

rope - refers to wire rope unless otherwise specified two-blocking - the condition when the lower load block

rotation-resistant rope - a wire rope consisting of an or hook assembly comes in contact with the upper load

inner layer of strand laid in one direction covered by a block

layer of strand laid in the opposite direction. This has unartended - a condition in which the operator of a

the effect of counteracting torque by reducing the ten- crane is not at the operating controls

dency of the finished rope to rotate. weathervaning - wind induced swinging of a crane,

service, light - service that involves irregular opera- when out of service, so as to expose minimal surface

tion with loads generally about one-half or less of the area to the wind

rated load wind velocity device - a device, such as an anemome-

servicr, normal - that service which involves operat- ter. that has a readout giving wind speeds

ing at less than 8 5 % rated load and not more than I O lift

cycles per hour except for isolated instances

service, heavy - that service which involves operating Section 4-0.3 - References (b)

at 8 5 % to 100% of rated load or in excess of 10 lift (cl

Within the text, reference is made to the following

cycles per hour as a regular specified procedure publications, copies of which may be obtained from the

service life - the time, expressed as the sum of the pe- publishers as indicated.

riods of operation, over which a stressed component can

function without undue risk of failure when the crane is ANSI A1264.1-1989, Safety Requirements for Work-

place Floor and Wall Openings, Stairs, and Railing

operated in accordance with the manufacturer's instruc-

Systems

tions under either light, normal, or heavy service

ANSUASCE 7-88-90, American Society of Civil Engi-

shall - indicates that the rule is mandatory and must be

neers Minimum Design Loads for Buildings and Other

followed

Structures

shoufd - indicates that the rule is a recommendation, ANSI 226.1-1983, Safety Code for Safety Glazing Ma-

the advisability of which depends on the facts in each terials for Glazing Motor Vehicles Operating on Land

situation Highways

standing rope Ipendunr) - a supporting rope that main- Publisher: American National Standards

tains a constant distance between the points of attach- Institue, Inc.

ment to the components connected by the rope 11 West 42nd Street, 13th FI.

structural competence - the ability of the machine and New York, New York 10036

its components to withstand the stresses imposed by ap-

ANSI A14.3-1992, Safety Requirements for Ladders -

plied rated loads

Fixed'

swing (slew) - rotation of the superstructure for move- Publisher: American Society of Safety

ment of loads in a horizontal direction about the axis of Engineers

rotation 1800 East Oakton Street

switch, limit - a device that is actuated by the motion Des Plaines, Illinois 60018-2187

of a part of a power-driven machine or equipment to

alter or disconnect the electric, hydraulic, or pneumatic ASME B30.3-1990, Hammerhead Tower Cranes'

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

circuit associated with the machine or equipment ASME B30.10-1993, Hooks'

ton (short) - 2000 pounds Publisher: The American Society of Mechanical

tower - a structural frame consisting of columns and Engineers

bracing capable of supporting a superstructure with its United Engineering Center

working and dynamic loads 345 East 47th Street

New York, NY 10017

traction (high strength) bolts - see high strength bolts

trolley, load - the device that travels along the hori- ASME Order Department

zontal boom of a hammerhead crane and contains the 22 Law Drive

upper load block Fairfield, NJ 07007-2300

truck, travel - the assembly that includes a pivot,

frame, axle(s), and wheel(s) on which a crane rides on 'May also be obtained from American National Standards Institute, (b)

rails; also, see bogie Inc., 11 West 42nd Street, New York, NY 10036.

10

Copyright ASME International

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

PORTAL, TOWER, AND PEDESTAL CRANES ASME B30.4C-1994

ANSI/SAE 5185 - JUN 81 Access Systems for Off-

Road Machines'

Publisher: Society of Automotive Engineers, Inc.

400 Commonwealth Drive

Warrendale, Pennsylvania 15096

AIS1 Wire Rope Users Manual, 2nd Edition

Publisher: American Iron and Steel Institute

1333 15th St., N.W.

Washington, DC 20005

ANSI/NEMA ICS3-1983, Part ICs 3-443, Industrial

Systems'

Publisher: National Electric Manufacturers

Association

2101 L St., N.W.

Washington, DC 20037

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

ANSI/NFPA 70-1987, National Electrical Code'

Publisher: National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

ANSI/AWS D14.3-82, Specification for Welding Earth-

moving and Construction Equipment'

Publisher: American Welding Society

550 N.W. LeJeune Road

Miami, Florida 33135

Copyright ASME International

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

ASME B 3 0 - 4 C q Y 0757670 0543632 971 m

PORTAL, TOWER, AND PEDESTAL CRANES ASME 830.4~-1994

(b) multiple part lines shall not be twisted around time frame. The statement, after being approved by the

each other; authorizer, shall be retained.

(c) the hook shall be brought over the load in (2) For each instance of personnel lifting, the per-

such a manner as to minimize swinging; son responsible for the task shall determine that each of

(d) if there is a slack rope condition, it shall be the following requirements in paras. (3) through (20)

determined that the rope is seated on the drum and in below has been met.

the sheaves, as the slack is removed; (3)When used for lifting personnel, the crane shall

(e) the effect of wind on the load and on the be inspected daily in accordance with the requirements

crane; of paras. 4-2.1.3 and 4-2.4.2(a).

íbl (f) the load is free to be lifted; it is not caught (4) The lifting and supporting shall be made under

on, nor attached to, other objects. controlled conditions and under the direction of an ap-

(3) During lifting, care shall be taken that: pointed signalperson.

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

(u) there is no sudden acceleration or decelera- (5) A planning meeting attended by the crane op-

tion of the moving load; erator, signalperson, person(s) to be lifted and sup-

(b) the load does not contact any obstructions. ported, and the supervisor responsible for the task shall

(4) Side loading of booms shall be limited to freely be held to review procedures to be followed, including

suspended loads. Cranes should not be used for drag- procedures for entering and leaving the personnel plat-

ging loads. form or basket, and to identify the location(s) persons

(5) The operator should avoid carrying loads over will enter and leave.

people. (6) The operator and signalperson shall conduct a

(6) The operator shall test the brakes each time a test lift with the empty platform or basket.

load approaching the rated load is handled by lifting it (7) Communication between the crane operator,

a few inches and applying the brakes. signalperson, and person(s) being lifted shall be main-

(7) The load shall not be lowered below the point tained.

where less than two full wraps of rope remain on the (8) When hook supported platforms are lifted, a

drum. two-block damage prevention feature shall be provided

(8) When swinging the boom, demcking load, or on telescopic boom cranes and a warning device shall

traveling the crane, sudden starts and stops shall be be provided on lattice boom cranes.

avoided. Swing and travel speeds shall be such that the (9) The crane shall be operated so that lowering

load does not swing out beyond the radius at which it motion will be power-controlled lowering (no free-fall).

can be controlled. A tag or restraint line shall be used (10) When welding is done by personnel from the

when swinging of the load is hazardous. platform or basket, the electrode holders shall be pro-

(9) Consideration should be given to the effects of tected from contact with metal components of the plat-

wind on loads with large sail area. form or basket.

(11) Personnel being lifted or supported shall wear

(bl 4-3.2.2 Personnel Lifting. This Volume recog- safety belts with lanyards attached to designated anchor

nizes that portal, tower, and pedestal cranes are de- point(s).

signed and intended for handling materials. They do not (12) The operator shall remain at the controls when

meet personnel lifting or elevator requirements. There- the platform is occupied.

fore, no crane function shall be performed while a per- (13) Movement of the work platform carrying per-

son is on the hook, load, manlift platform, boom, or sonnel shall be done in a slow, controlled, cautious

other personnel lifting device attached to the crane load manner with no sudden movements of the crane or work

line or boom, unless each of the specific, special, fol- platform. The lifting or lowering speed shall not exceed

lowing requirements are met. 100 ft/min (0.51 m/s).

(u) The following special procedures shall be fol- (14) The personnel being lifted or positioned shall

lowed when personnel are to be lifted. remain in continuous sight or in communication with the

(1) The person specifically responsible for the operator or signalperson.

overall work function to be performed shall determine (15) The total weight of the lifted load (including

that there is no practical alternate way to perform the personnel) shall not exceed 50% of the crane rating un-

needed work or gain access to the area and he shall au- der the planned conditions of use.

thorize its usage. The person responsible for the task (16) Suspended personnel platforms shall be used

shall issue a statement describing the operation and its only for personnel, their tools, and sufficient materials

Copyright ASME International

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

ASME B30.4C 9'4 = 0759670 0543b33 828

ASME B30.4c-1994 PORTAL, TOWER, AND PEDESTAL CRANES

to do their work. They shall not be used for transporting (IS) All welding shall be performed by a certified

bulk materials. welder.

(17) Personnel shall keep all parts of the body in-

side the suspended platform during raising, lowering,

and positioning to avoid pinch points. Personnel shall Section 4-3.3 - Signals

not stand on or work from the top rail, midrail, or toe-

4-3.3.1 Standard Signals. Standard signals to the

board of the suspended platform.

operator shall be in accordance with the standards pre-

(18)If the platform cannot be landed, it should be

scribed in para. 4-3.3.2, unless voice communication

tied to the structure before personnel get off or on.

equipment (telephone, radio, or equivalent) is utilized.

(19) Work platforms should not be used in winds

Signals shall be discernible or audible at all times. No

in excess of 15 mph (25 kmlh), electric storms, snow,

crane motion shall be made unless signals are clearly

ice, sleet, or other adverse weather conditions which

understood.

could affect the safety of personnel.

(20) After positioning of the work platform, all 4-3.3.2 Hand Signals. Hand signals shall be in ac-

brakes and locks on the lift crane shall be set before cordance with Fig. 7 and shall be posted at the work

personnel perform any work. site.

(b) A platform which is designed and constructed in

4-3.3.3 Special Signals. For operations not cov-

accordance with the following shall be used.

ered by para. 4-3.3.2, or for special conditions that oc-

(Z) The platform shall be designed by a qualified

--``,``,,,,,,``,,,,``,,,,`,,-`-`,,`,,`,`,,`---

cur from time to time, additions to or modifications of

person.

the standard signals may be required. In such cases,

(2) The platform shall be limited to a capacity of 6

these special signals shall be agreed upon in advance by

persons.

the operator and the signalperson and should not be in

(3) The platform and attaching devices shall have

conflict with standard signals.

a minimum design factor of 5.

(4) The platform shall have a plate specifying the 4-3.3.4 Instructions to the Operator. If it is de-

weight of the empty platform and the maximum number sired to give instmctions to the operator, other than those

of persons and weight for which the platform is rated. provided by the established signal system, crane mo-

(cl (5) The platform shall have standard railing as de- tions shall be stopped.

fined in ANSI A1264.1.

(6) A grab rail shall be provided inside the sus-

pended work platform to minimize hand exposure. Section 4-3.4 - Miscellaneous

(7)The sides of the platform shall be enclosed from 4-3.4.1 Rail Clamps. Rail clamps, if used, should

floor to midrail.

have slack between the point of attachment to the rail

(8) If access doors are installed, they shall open

and the end fastened to the crane. Rail clamps shall not

only to the interior of the platform. Access doors shall

be used as a means of restraining tipping of a crane.

be equipped with a device to restrain the door from in-

advertent opening. 4-3.4.2 Operating Near Electric Power Lines

(9) The platform shall have overhead protection (a) Cranes shall be operated so that no part of the

when there is an overhead hazard. crane or load enters into the Danger Zone shown in Fig.

(Z0) The platform shall be easily identifiable by 8.

high visibility color or marking. (1) Exceptions

( I I ) The platform shall be attached by means such (a) The Danger Zone may be entered if the elec-

as, but not limited to, a shackle, hook (latched or trical distribution and transmission lines have been de-

moused), or wedge and socket attachment. A wedge and energized and visibly grounded at the point of work or

socket attachment shall have a clip on the free end of (b) The Danger Zone may be entered if insulat-

the load line (see Fig. 5 ) . ing barriers (not a part of nor attachment to the crane)

(12) The suspension system shall minimize incli- have been erected to prevent physical contact with the

nation of the platform due to the movement of personnel lines.

on the platform. (2) For lines rated 50 kV or below, minimum clear-

(13) All rough edges shall be ground smooth. ance between the lines and any part of the crane or load

(14) All welds shall be inspected by a qualified per- (including handling appendages) shall be 10 ft (3 m).

son. For higher voltages, see Table 1.

32

Copyright ASME International

Provided by IHS under license with ASME Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 02/28/2007 02:26:56 MST

You might also like

- IEC 15415-2006 EenDocument61 pagesIEC 15415-2006 EenAlaeddine AbidNo ratings yet

- Asme-B18.10 (2006)Document18 pagesAsme-B18.10 (2006)Sergio Rodriguez CamberosNo ratings yet

- A90.1 Safety Standard For Belt ManliftDocument36 pagesA90.1 Safety Standard For Belt ManliftYadi KusmayadiNo ratings yet

- Asme B20.1 2006Document26 pagesAsme B20.1 2006Diar Azzis SNo ratings yet

- Ultrasonic Welding of Lithium-Ion Batteries: Enter asset subtitleFrom EverandUltrasonic Welding of Lithium-Ion Batteries: Enter asset subtitleNo ratings yet

- Asme B30.26 Rigging HardwareDocument54 pagesAsme B30.26 Rigging HardwareRonald RegentNo ratings yet

- Asme B107.2-2002Document29 pagesAsme B107.2-2002noahb110No ratings yet

- Asme Y14 24 1999Document82 pagesAsme Y14 24 1999Gilberto FloresNo ratings yet

- Asme B18.21.1-1999Document27 pagesAsme B18.21.1-1999Edwin MariacaNo ratings yet

- Asme b73.1 PDFDocument48 pagesAsme b73.1 PDFGerencia Rigar Colombia SAS100% (3)

- Asme 36.19Document18 pagesAsme 36.19shakeelahmadjsr100% (3)

- ASME Y14.36M (1996) - Surface Texture Symbols PDFDocument14 pagesASME Y14.36M (1996) - Surface Texture Symbols PDFMiguelNo ratings yet

- Transmisi - ZF 16s150Document11 pagesTransmisi - ZF 16s150rezandriansyah100% (2)

- Asme B30.8C-1998Document10 pagesAsme B30.8C-1998Alaeddine AbidNo ratings yet

- Asme B16.36-2006Document30 pagesAsme B16.36-2006ChipNo ratings yet

- ASME B19.3b-1995 Addenda: Asme Safety Standard For Compressors For Process IndustriesDocument13 pagesASME B19.3b-1995 Addenda: Asme Safety Standard For Compressors For Process Industriesvijay pawarNo ratings yet

- Asme B16.28Document20 pagesAsme B16.28Nguyen Anh Tung100% (1)

- ASME QHO-1-2004Document20 pagesASME QHO-1-2004SharonNo ratings yet

- ASME B16.4 (1998) Gray Iron Threaded Fittings, Class 125 and 250Document19 pagesASME B16.4 (1998) Gray Iron Threaded Fittings, Class 125 and 250Mahmoud HekalNo ratings yet

- Asme Addenda: ASME 819.3-1991 Safety Standard For Compressors For Process IndustriesDocument15 pagesAsme Addenda: ASME 819.3-1991 Safety Standard For Compressors For Process Industriesvijay pawarNo ratings yet

- Asme B36.19M-2004Document14 pagesAsme B36.19M-2004JorgeNo ratings yet

- Hooks: ASME B30.10-2005Document26 pagesHooks: ASME B30.10-2005Carlos Aparicio100% (1)

- ASME B16.28 Wrought Steel Buttwelding Short Radius Elbows and Returns 1994Document20 pagesASME B16.28 Wrought Steel Buttwelding Short Radius Elbows and Returns 1994Luis OrtizNo ratings yet

- ASME B29.6m-1993Document53 pagesASME B29.6m-1993parashu104No ratings yet

- ASME A112.4.1-1993 - Water Heater Relief Valve Drain TubesDocument10 pagesASME A112.4.1-1993 - Water Heater Relief Valve Drain TubesFaisal EbrahimNo ratings yet

- ASME B30.3 (96) Torre Gruas de Construccion PDFDocument50 pagesASME B30.3 (96) Torre Gruas de Construccion PDFJhon Fabio ParraNo ratings yet

- BTH PDFDocument62 pagesBTH PDFsuranga100% (2)

- Asme B30.21-1999Document45 pagesAsme B30.21-1999oscarNo ratings yet

- Asme B I Addenda: To Asme Metallic Gaskets For Pipe Flanges Ring-Joint, Spiral-Wound, and JacketedDocument51 pagesAsme B I Addenda: To Asme Metallic Gaskets For Pipe Flanges Ring-Joint, Spiral-Wound, and JacketedTimilehin OladiranNo ratings yet

- Asme B30.3-1996-Grúas TorreDocument50 pagesAsme B30.3-1996-Grúas TorrejohnNo ratings yet

- Acme Screw Threads PDFDocument128 pagesAcme Screw Threads PDFJohan Medina Tovar100% (1)

- ASME A17.lC-I999Document26 pagesASME A17.lC-I999Alaeddine AbidNo ratings yet

- Asme B16.21-2005 PDFDocument22 pagesAsme B16.21-2005 PDFAhmed BaroukNo ratings yet

- Asme B30.18C-1997Document6 pagesAsme B30.18C-1997Alaeddine AbidNo ratings yet

- b16 14-1991 PDFDocument17 pagesb16 14-1991 PDFkarthimeenaNo ratings yet

- Asme B107.16M-1998Document20 pagesAsme B107.16M-1998thorek24No ratings yet

- Asme B18.2.4.6MDocument16 pagesAsme B18.2.4.6Mmanuneedhi100% (1)

- Asme B16.1Document41 pagesAsme B16.1Yhon Bastidas100% (2)

- ASME B1.20.5 Rosca NPTDocument63 pagesASME B1.20.5 Rosca NPTdopcncNo ratings yet

- B30.19-2005 CablewaysDocument36 pagesB30.19-2005 CablewaysMuhammadr Isa50% (2)

- Scheme For The Identification of Piping Systems: ASME A13.1-2007Document10 pagesScheme For The Identification of Piping Systems: ASME A13.1-2007roberto cNo ratings yet

- ASME B3022-2005 Articulating Boom Cranes - 221206 - 123014Document42 pagesASME B3022-2005 Articulating Boom Cranes - 221206 - 123014jesus rosas100% (1)

- ASME A112.6.3 2001 Floor and Trench DrainsDocument18 pagesASME A112.6.3 2001 Floor and Trench DrainsLuckyNo ratings yet

- ASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFDocument89 pagesASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFFabiano Lebkuchen100% (2)

- ASME B18.31.3-2009 - Threaded Rods - Inch SeriesDocument14 pagesASME B18.31.3-2009 - Threaded Rods - Inch SeriesSandeep Kumar Jaiswal100% (1)

- Asme B107.5M-2002Document22 pagesAsme B107.5M-2002noahb110No ratings yet

- Asme B16.48Document50 pagesAsme B16.48Ruben Dario DeaquizNo ratings yet

- ASME B16.48 Juntas CiegasDocument54 pagesASME B16.48 Juntas CiegasVictor TorresNo ratings yet

- Asme B18.2.3.3MDocument18 pagesAsme B18.2.3.3MPham Nhat50% (2)

- ASME B18.24a-2006 - Addenda of Part IdentifyDocument60 pagesASME B18.24a-2006 - Addenda of Part IdentifyThái Đạo Phạm LêNo ratings yet

- ASME B89 7 3 1 2001 Guidelines For Decision Rules Considering Measurement Uncertainty in Determining Conformance To Specifications PDFDocument24 pagesASME B89 7 3 1 2001 Guidelines For Decision Rules Considering Measurement Uncertainty in Determining Conformance To Specifications PDFprabhakaranme0% (1)

- ASME B18.24a-2006Document60 pagesASME B18.24a-2006Iliya100% (1)

- ASME B18.8.1-1994 Clevis Pins and Cotter Pins (Inch Series)Document20 pagesASME B18.8.1-1994 Clevis Pins and Cotter Pins (Inch Series)Vishal UpadhyeNo ratings yet

- ASME B30.26 - 04 Rigging HardwareDocument38 pagesASME B30.26 - 04 Rigging Hardwarejuan ninaNo ratings yet

- Asme-B18.9 (2007)Document22 pagesAsme-B18.9 (2007)Sergio Rodriguez CamberosNo ratings yet

- Asme B16.5 - 2003Document234 pagesAsme B16.5 - 2003JÚNIOR JR100% (1)

- Asme-B18 2 6mDocument21 pagesAsme-B18 2 6mthanh_121No ratings yet

- Asme B16.50 - 2001Document25 pagesAsme B16.50 - 2001phani u4meNo ratings yet

- ASME B16.34a-1998Document190 pagesASME B16.34a-1998jojeecaresNo ratings yet

- Bioceramics: Materials and Applications V: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandBioceramics: Materials and Applications V: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Veeraraghavan SundarNo ratings yet

- Synthesis, Properties, and Crystal Chemistry of Perovskite-Based Materials: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandSynthesis, Properties, and Crystal Chemistry of Perovskite-Based Materials: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Winnie Wong-NgNo ratings yet

- 1 Flare Net IntroductionDocument13 pages1 Flare Net IntroductionAlaeddine AbidNo ratings yet

- 2 Flare Net Introduction WorkshopDocument11 pages2 Flare Net Introduction WorkshopAlaeddine AbidNo ratings yet

- IEC 14598 2 2003 EenDocument21 pagesIEC 14598 2 2003 EenAlaeddine AbidNo ratings yet

- 4-Network Design WorkshopDocument27 pages4-Network Design WorkshopAlaeddine AbidNo ratings yet

- Uniiso Iec13818-10-2000 EenDocument147 pagesUniiso Iec13818-10-2000 EenAlaeddine AbidNo ratings yet

- 3 Network DesignDocument14 pages3 Network DesignAlaeddine AbidNo ratings yet

- IEC 17020-2005 EitDocument23 pagesIEC 17020-2005 EitAlaeddine AbidNo ratings yet

- Uni8719-1985 EitDocument3 pagesUni8719-1985 EitAlaeddine AbidNo ratings yet

- IEC 2022-2003 EenDocument61 pagesIEC 2022-2003 EenAlaeddine AbidNo ratings yet

- IEC 7811!4!1998 EenDocument13 pagesIEC 7811!4!1998 EenAlaeddine AbidNo ratings yet

- Unien12464 1Document43 pagesUnien12464 1Alaeddine AbidNo ratings yet

- IEC 17040-2005 EeiDocument39 pagesIEC 17040-2005 EeiAlaeddine AbidNo ratings yet

- IEC 10994-1995 EenDocument51 pagesIEC 10994-1995 EenAlaeddine AbidNo ratings yet

- IEC 17040-2005 EenDocument25 pagesIEC 17040-2005 EenAlaeddine AbidNo ratings yet

- IEC 7498!4!1993 EenDocument15 pagesIEC 7498!4!1993 EenAlaeddine AbidNo ratings yet

- IEC 17024-2004 EitDocument21 pagesIEC 17024-2004 EitAlaeddine AbidNo ratings yet

- IEC 7811!3!1998 EenDocument13 pagesIEC 7811!3!1998 EenAlaeddine AbidNo ratings yet

- IEC 17000-2005 EitDocument23 pagesIEC 17000-2005 EitAlaeddine AbidNo ratings yet

- Unien13201 3 2004 - EitDocument37 pagesUnien13201 3 2004 - EitAlaeddine AbidNo ratings yet

- IEC 17050 2 2005 EenDocument13 pagesIEC 17050 2 2005 EenAlaeddine AbidNo ratings yet

- Iec60512 1 4 (Ed1.0) BDocument23 pagesIec60512 1 4 (Ed1.0) BAlaeddine AbidNo ratings yet

- IEC 7811!5!1998 EenDocument13 pagesIEC 7811!5!1998 EenAlaeddine AbidNo ratings yet

- IEC 17050 2 2005 EeiDocument13 pagesIEC 17050 2 2005 EeiAlaeddine AbidNo ratings yet

- IEC 17050 1 2005 EeiDocument21 pagesIEC 17050 1 2005 EeiAlaeddine AbidNo ratings yet

- IEC 15419-2003 EenDocument41 pagesIEC 15419-2003 EenAlaeddine AbidNo ratings yet

- Iec7811!2!1998 EenDocument23 pagesIec7811!2!1998 EenAlaeddine AbidNo ratings yet

- IEC 17030-2006 EitDocument11 pagesIEC 17030-2006 EitAlaeddine AbidNo ratings yet

- IEC 15421-2003 EenDocument21 pagesIEC 15421-2003 EenAlaeddine AbidNo ratings yet

- Iec60896-21 (Ed1 0) BDocument89 pagesIec60896-21 (Ed1 0) BAlaeddine AbidNo ratings yet

- Revised AOCDocument2 pagesRevised AOCRHPS ProcurementNo ratings yet

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Power Generation SystemDocument72 pagesPower Generation SystemAbshir Mohamed HajjiNo ratings yet

- Introduction To Automobile EngineeringDocument14 pagesIntroduction To Automobile EngineeringdoomraNo ratings yet

- Artika Series: Cryogenic Submerged Pumps For Marine ApplicationsDocument2 pagesArtika Series: Cryogenic Submerged Pumps For Marine ApplicationsCami CamilongaNo ratings yet

- Hydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitDocument2 pagesHydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitMarcelino Huamani100% (1)

- TDBFP Manul PDFDocument266 pagesTDBFP Manul PDFsantosh100% (1)

- Nation Parts Guide PG 29Document1 pageNation Parts Guide PG 29ramsi17No ratings yet

- Nef Engine Nef Engine Nef Engine Nef Engine: Backhoe Loaders B90 - B100 - B110 - B115 (Tier 3)Document77 pagesNef Engine Nef Engine Nef Engine Nef Engine: Backhoe Loaders B90 - B100 - B110 - B115 (Tier 3)Oscarito VázquezNo ratings yet

- L2e 61sdh MitsubishiDocument127 pagesL2e 61sdh MitsubishiNUVE KARENTALNo ratings yet

- Effects:: A B A B B A B BDocument23 pagesEffects:: A B A B B A B BSenthil kumar BalakrishnanNo ratings yet

- User'S Manual: Pneumatic Positioner YT-1200 SeriesDocument22 pagesUser'S Manual: Pneumatic Positioner YT-1200 SeriescesarNo ratings yet

- Erection and Commissioning Works of The E/M Equipment: Guangdong Yuantian Engineering CompanyDocument103 pagesErection and Commissioning Works of The E/M Equipment: Guangdong Yuantian Engineering Companyxiaowei tuNo ratings yet

- Parker Pneumatic Robust Air Motor - P1V-M: PDE2600PNUKDocument5 pagesParker Pneumatic Robust Air Motor - P1V-M: PDE2600PNUKZoran JankovNo ratings yet

- Instruction Manual Zoje ZJ953-13H-ED2 PDFDocument19 pagesInstruction Manual Zoje ZJ953-13H-ED2 PDFMaskusyani0% (1)

- 950F Prueba y Ajuste Transmision Sistema ElectricoDocument38 pages950F Prueba y Ajuste Transmision Sistema Electricoale aleNo ratings yet

- Emission and Electrical Diagnosis (With Tech 2) : Workshop ManualDocument78 pagesEmission and Electrical Diagnosis (With Tech 2) : Workshop ManualAndres Miguel Cevallos Garcia100% (2)

- EST 8.6.0.0 Update 2Document3 pagesEST 8.6.0.0 Update 2gnomekdeNo ratings yet

- ALGB142Document44 pagesALGB142MahaManthra100% (1)

- Clutch SystemDocument32 pagesClutch SystemZerara KamelNo ratings yet

- GR-1600XL-3-2 LNG en Na S 2211Document20 pagesGR-1600XL-3-2 LNG en Na S 2211MauroNo ratings yet

- Parts Breakdown: Technical ServiceDocument3 pagesParts Breakdown: Technical ServicecafubodoNo ratings yet

- ZX300 6Document28 pagesZX300 6Bilal VURALNo ratings yet

- Manual Flowpacks Ensamble InstitucionalDocument32 pagesManual Flowpacks Ensamble InstitucionalhaynerNo ratings yet

- Sri Venkateswara College of Engg& Tech: Department of Mechanical EngineeringDocument8 pagesSri Venkateswara College of Engg& Tech: Department of Mechanical EngineeringLakshmi SinghNo ratings yet

- Treinamento - de lg936 - Eng - Rev1 - 2010Document146 pagesTreinamento - de lg936 - Eng - Rev1 - 2010Johan Mauricio Romero ChitivaNo ratings yet

- Perkins Engine Number DataDocument3 pagesPerkins Engine Number Dataa100% (2)

- Mechanical Engineering-Compressors, Gas Turbines and Jet Engines Important MCQDocument28 pagesMechanical Engineering-Compressors, Gas Turbines and Jet Engines Important MCQavantgarde bwoyNo ratings yet

- Product Manual: Lifts Gearless InstallationDocument25 pagesProduct Manual: Lifts Gearless InstallationSatis100% (2)