Professional Documents

Culture Documents

Trimming Nox From Furnaces - Rev3

Trimming Nox From Furnaces - Rev3

Uploaded by

Deepika UmlaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trimming Nox From Furnaces - Rev3

Trimming Nox From Furnaces - Rev3

Uploaded by

Deepika UmlaniCopyright:

Available Formats

Originally appeared in: CHEMICAL ENGINEERING November 1992 Issue, pgs 122-128. Reprinted with publisher’s permission.

TRIMMING NOx FROM FURNACES

Ashutosh Garg,

Furnace Improvements

Each passing year seems to bring about standards. Under SCAQMD’s standard,

increasingly stringent pollutant-emission furnaces with capacities of less than 40

Emissions-control

laws governing combustion equipment. In million Btu/h must release less than 40 technologies need

the future, one can expect even-stricter ppm of NOx by September 1991. For

emissions limits to be imposed on the furnaces larger than 40 million Btu/h, the not limit a fired

chemical process industries (CPI). limit is less than 25 ppm by December

As regulations tighten, the necessity to 1995 (NOx emissions from 36 % of the heater’s perform-

consider environmental concerns in the units greater than 40 million Btu/h must be

operation of furnaces is also mounting. Of cut down to 25 ppm by September, 1992). ance

the various environmental laws now Finding the means for limiting NOx

affecting the CPI, laws covering nitrogen from fired heaters has become a major

oxides (NOx) are among the most thrust of many sectors in the CPI. The

sweeping. utility industry – the first industrial sector

For example, in the U.S., the South in the U.S. to be affected by NO x controls

FIGURE 1. CPI furnaces, available in

Coast Air Quality Management District, or – has been the spawning ground for many

SCAQMD, which covers the Los Angeles of the new technologies now being used to box or cylindrical designs, can be fitted

basin, already has one of the strictest stem NOx from CPI furnaces. Other with a number of coil configurations.

Furnace Improvements Services

www.heatflux.com 1

Trimming NOx from Furnaces

sectors that have also been strongly convection section consists of bare and while the conversion of chemically bound

affected by NOx standards are petroleum extended-surface tubes to recover heat nitrogen in the fuel produces “fuel NOx”.

refining and petrochemicals. from the flue gases before they exit from For natural-gas and light-distillate-oil

The stricter NOx limits means that it is the stack. Figure 1 shows the typical heater firing, nearly all NOx emissions result

increasingly important to understand both types used in the CPI. from thermal fixation. With residual fuel

the capabilities of these new emission- The pollutants generated by burning oil, the contribution from fuel-bound

control technologies, and how they affect a fuel fall into three primary categories: nitrogen can be significant and, in certain

fired heater’s overall performance, carbon monoxide, unburned hydrocarbons, cases, predominant. This is because the

reliability and operating flexibility. This is and partially oxidized organic materials nitrogen content in residual fuel oil can be

especially significant when retrofitting and soot that result from incomplete as high as 0.3% N2, and conversion to

combustion equipment with new emission combustion; sulfur oxides and ash directly NOx may be 50-60%.

controls. attributable to fuel composition; and The formation rate of thermal NOx is

nitrogen oxides formed at firebox dependent on the reaction temperature, the

The NO x Dilemma temperatures by the reaction of the oxygen local stoichiometry, and the residence

Vertical heaters used in the CPI fall and nitrogen present in the air and fuel. time. The fuel-NOx formation mechanism

broadly into two categories: cylindrical Incomplete combustion products can is more complex, depending upon fuel

and box heaters. In both types, the tubes usually be held to tolerable minimums by pyrolysis and subsequent reaction between

are laid out on the walls of the radiant the proper operation of modern burner many intermediate nitrogenous species and

section. equipment, while sulfur oxide and ash the oxidant species.

In cylindrical heaters, the tubes are emissions can be cut by using the right The rates for formation of both

installed vertically, while in box heaters, fuel. However, nitrogen oxide thermal NOx and fuel NO x are kinetically

the tubes are arranged horizontally. In both concentrations are primarily functions of or aerodynamically limited, with the

designs, the burners are installed on the fuel composition, burner design and amount of NOx formed being much less

floor, and fire vertically upwards. firebox temperature, and so have to be than the equilibrium value. The rate of

Most of the burners employ a natural- controlled by choosing the right operating formation of NOx is dominated by

draft design, in which the stack provides conditions. combustion conditions and can be

the draft for drawing air into the furnace There are several ways that NOx is suppressed by modifying the combustion

for combustion. Newer units are equipped formed in a furnace. Thermal fixation of process. Both thermal and fuel NOx are

with forced-draft firing systems and air atmospheric nitrogen and oxygen in the promoted by rapid mixing of oxygen with

preheaters to improve fuel efficiency. The combustion air produces “thermal NOx” the fuel. Thermal NOx is greatly increased

Furnace Improvements Services

www.heatflux.com 2

Trimming NOx from Furnaces

Modifying combustion conditions to

inhibit the mechanisms for formation of

NOx

FIGURE 2. Actual Lowering NO x generated during

measurements (in combustion by either catalytic or non-

ppm) of nitrogen catalytic reduction.

oxides in fluegases The NOx-control processes discussed

can be converted below utilize one or a combination of the

to the more com- above techniques.

mon way of repre-

senting emissions, Flue gas recirculation (FGR) extracts a

in lb NOx (as NO2)/ portion of the flue gas from the stack and

million Btu of returns it to the furnace along with

gross heat re- combustion air (Figure 3). This lowers

leased the peak flame temperature, and cuts

thermal-NOx formation. The addition of

fluegas also reduces the oxygen available

to react with the nitrogen. A comparison

of the two heat duties for a furnace with

and without – flue gas recirculation is

shown in the table.

Increasing the recirculation rate

generally corresponds to a decrease in

thermal NOx, but flame instability and a

decrease in the net thermal output limits

the recirculation rate. Recirculation rates

for gas-fired units are limited to about

15% to 25%, resulting in maximum

thermal-NOx reductions on the order of

50%. It is useful where low nitrogen

fuels, such as natural gas, are used.

Recirculating flue gas temperature should

by long residence time at high For quick NOx level estimations, the not be more than 600oF.

temperature. following DSCF – dry volume of flue-gas Flue gas recirculation has been

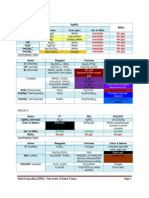

Emission limits are usually specified in standard cubic feet/ million Btu at 3% mostly applied to forced-draft burners.

in terms of pounds of NOx per million O2 concentration – values are Installation requires additional duct work,

Btu of gross heat released, or pounds per recommended: a flue gas recirculation fan, a flow control

hour. NOx concentrations, however, are damper, special burners and combustion

measured in terms of ppm (volume) Natural Gas 10,127 control instrumentation (such as

basis. Since operating conditions vary Propane 10,127 continuous oxygen and carbon monoxide

among various furnaces, the NOx Butane 10,127 analyzers in the stack). If the heat content

measurements are converted to standard Fuel Oil 10,684 of the fuel is highly variable, a flame

conditions at 3% oxygen. safeguard system is required to monitor

By calculating the dry combustion Post Combustion NOx Treatment the flames continuously. The technique is

production per million Btu and the heat The concentration of NOx in combustion suitable for heaters with a few burners,

release rate, R, it is possible to convert flue gases can be cut by: such as vertical, cylindrical heaters.

from ppm to lb/million Btu or lb/h. NOx Flue gas recirculation

emission calculations are made on the does not affect the overall

basis of NO2 (molecular weight of 46), efficiency of fired heaters

although NO2 is only 10-15% of the total if the temperature of

NOx. fluegas leaving the

convection zone is the

ppm vol. (at 3% O2) = ppm vol. same as that of the flue gas

measured x (21-3)/21 - % O2) being recirculated.

However, the split of

where, % O2 = vol. % O2, dry basis radiant heat and

convection heat duty will

NOx, in lb/million Btu = (ppm NOx) x change, since the

(DSCF/ million Btu) x 46/ (1,000,000 x TABLE. Fluegas recirculation changes the split recirculating flue gas acts

379.3) of convection -and radiant - heat duties. as a diluent, reducing the

Furnace Improvements Services

www.heatflux.com 3

Trimming NOx from Furnaces

uptake of heat in the radiant section and deactivation. However, this can be reduces NOx to N2 and H2O. Ammonia is

increasing it in the convection section. avoided if care is taken during the design injected into the upper part of combustion

stage. For example, if SO 2 is present in chamber or into a thermally favorable

Selective catalytic reduction (SCR) the flue gas, then a minimum temperature location downstream. The various

involves injecting ammonia into the flue of 608oF is recommended for SCR reactions are:

gas upstream of a catalyst bed. The operation. A catalyst’s life depends on its

chemical reaction involved is: type, the application and other factors, 6NO + 4NH 3 5N2 + 6H2O

with numbers of three to six years being

O2 + 4NO + 4NH3 4N2 + 6H2O reported in oil and gas applications.

SCR systems have the highest 6NO2 + 8NH 3 7N2 + 12H2O

NOx and NH3 combine on the catalyst’s installation costs and requires the greatest

surface, forming an ammonium salt amount of space of all NOx-control

intermediate that subsequently methods. They can be easily retrofitted in Recently, a urea-based regent is

decomposes to produce elemental fired heaters with air-preheating systems, increasingly being used in place of NH3

nitrogen and water. The catalyst lowers since all this involves is re-rating of the because it is safer and easier to handle.

the activation energy of the NOx fan and re-routing the duct to the air Urea decomposes into NH3 and carbon

decomposition reaction, thereby enabling preheater via an SCR unit. The left dioxide inside the firebox.

use of this technology at lower flue gas portion of Figure 3 shows a typical SCR The flue gas temperature is critical to

temperatures. The optimum temperature unit retrofitted in a furnace with an air the successful reduction of NOx. For

range for SCR is 600oF to 700oF. preheating system. convectional combustion, the optimal

SCR removes 70 to 90% of the NOx, range for NH3 injection is 1600o to

using between 0.9 to 1.0 mole NH3 for Selective noncatalytic reduction (SNCR) 1,750oF; for urea, 1,000o to 1,900oF. As

every mole of NOx; this leaves behind 5 is a post combustion-control method that the temperature increases, the NH3 reacts

to 10 ppm of unreacted NH3. The major

components of an SCR system are a Figure 3: Popular post-combustion methods of removing NOx

catalyst bed reactor, an ammonia injection include selective catalytic reduction (left part of figure) and

grid, and an ammonia storage unit. fluegas recirculation.

Ammonia can be injected in anhydrous

form or as an aqueous solution. Typically

a residence time of 0.5 to 1.0s allows for

adequate mixing of the ammonia and NOx

before the catalyst bed.

Several factors in addition to

operating temperature influence SCR

performance. These include the catalyst

composition and configuration, sulfur and

metals content of the fuel, and the design

of the ammonia-injection system.

Catalysts are commercially

available in a wide variety of materials.

These include such metals (such as

titanium, vanadium and platinum),

zeolites and ceramics. Catalyst shapes

include honeycomb plates, parallel-ridged

plates, rings and pellets.

Each combination presents

advantages and disadvantages in terms of

allowable operating temperatures, catalyst

fouling and pressure drop. Typical gas

velocities over the catalyst are around

20ft/s, and the pressure drop is 3-4 in.

(water column.)

The early applications of SCR had

been prone to a number of problems.

These include: catalyst plugging by fine-

particle dust; catalyst poisoning by SO 2;

conversion of SO 2 to SO 3; formation of

ammonium bisulfate; and the deposition

of ammonium bisulfate on the catalyst at

temperatures below 518oF.

All these factors lead to catalyst

Furnace Improvements Services

www.heatflux.com 4

Trimming NOx from Furnaces

While SCR and SNCR maintain control

over NOx after is has been formed in

the combustion reaction, modifications

of the combustion equipment or the

burners can also significantly reduce

NOx formation. There are a number of

advantages in using such modified

burners, the major ones being

simplicity and low cost. At the same

time, since burners form the heart of a

furnace. The process of implementing

new ones should always be tried

cautiously.

Staged air burner systems divide the

incoming combustion air into primary

and secondary paths: All of the fuel is

injected into the throat of the burner

and is combined with the primary air,

which floss through the venturi and

burns (Figure 4).

In this fuel-rich zone, the fuel

partially burns and the nitrogen is

Figure 4: Two ways of modifying the fuel air stoichiometry during com- converted into reducing agents.

bustion is to use a staged fuel burner (left) or a staged air burner. These nitrogenous compounds are

subsequently oxidized to elemental

more with oxygen than with NO, forming to be used along with a second NOx- nitrogen, thereby minimizing the

more NOx. At flue gas temperatures reduction technique. generation of fuel NOx.

below the optimal range, the rate of Also, the peak flame temperature is

reaction declines, resulting in reduced Redesigning The Equipment lowered in the fuel-rich primary

NOx control and greater amounts of combustion zone, since the generated heat

unreacted NH3 slipping into the dissipates rapidly. Recirculation of

effluent. combustion products within the burner

The NOx reduction achieved is of further cuts the flame temperature and

the order of 50-60%, with the NH3 slip oxygen concentration, reducing NOx (in

in the 20 to 30 ppm range. The this case the thermal NOx even more. In

technique is effective in the presence of the secondary-combustion zone,

carbon monoxide, and with oxygen additional air is injected through

contents of up to 1% (calling for very refractory ports to complete combustion

close control of excess air). and optimize the flame profiles.

The disadvantages of SNCR are Staged air burners are simple and

similar to those of SCR: Ammonium inexpensive, and NOx reductions as high

salts, namely ammonium sulfate and as 20 to 35% have been demonstrated.

bisulfate, may form if excess NH3 The main disadvantage of the burners is

reacts with sulfuric acid, form a prior the long flames, which need to be

reaction between SO 3 and water. controlled. Further, staged-air burners

Ammonium bisulfate can contribute to have proven to be quite successful in

fouling and corrosion in low formed-draft applications, and have even

temperature heat-recovery equipment. been used with flue gas-recirculation

Ammonium chloride can also be systems.

formed, which is undesirable since it

causes visible plumes. High levels of Staged fuel burners inject a portion of the

NH3 slip, up to 50 to 100 ppm, can fuel gas into the combustion air, and the

occur if the NH3-to-NOx ratio is not resulting combustion is very lean (i.e. air

optimized. Overall, the method has not rich). This lean combustion reduces

become widely popular with process thermal NOx. The remainder of the fuel

fired heaters since it cannot meet gas is injected into a secondary

NOx-reduction requirements by Figure 5. NOx levels can be cut very low combustion zone through secondary

levels by combining staged fuel burners with

itself, and needs nozzles (Figure 4).

internal fluegas recirculation

Furnace Improvements Services

www.heatflux.com 5

Trimming NOx from Furnaces

used to reduce NOx to very low levels. In

this design, the fuel gas’s pressure or

external agents, such as medium-pressure

steam or compressed air, are used to

induce flue gas recirculation within the

burner.

Low excess-air burners works on the

principle that low levels of excess air

suppress NO x formation. Typically, excess

air levels are maintained at 5%. The

burners are often of a forced-draft design,

and employ a self-recirculating technique

to produce a multi-stage combustion

effect. A NOx level of 0.06 to 0.08 lb/

million Btu is typically encountered.

Generally, it has been found that reducing

excess air from 30% to 10% cuts NOx

emissions by 30%.

References

Air Pollution Engineering Manual, AP-

42, U.S. Environmental Protection

Agency.

NOx Control In fired heaters, Martin,

R.R. and W.M. John Zink Co.

Cleaning Up NOx Emissions, McInnes,

R., and M.B. Van Wormer, Chem.

Eng., Sept 1990

Reduce Heater NOx In the Burners,

Seabold, J.G., Hydrocarbon Process,

Nov. 1982.

The author

The combustion products and inert flame length, and at lower excess-air levels

gases from the primary zone reduce the than can staged air burners. The flames in

peak temperatures and oxygen staged fuel burners are about one and a Ashutosh Garg is Manager of Thermal

concentration in the secondary zone, half times longer than those in standard Engineering at Kinetics Technology

further the inhibiting NOx formation. burners. Staged fuel burners have been International Corp. He has more than 18

Some of the NOx formed in the first stage found more effective in reducing NOx in years of experience in process design,

combustion zone is reduced by the gas-fired heaters and, so, the majority of sales and troubleshooting of all

hydrogen and carbon monoxide that is the applications are gas fired. combustion systems. He graduated in

formed in staged combustion. chemical engineering in 1974 from Indian

Staged fuel burners can reduce NOx Ultra Low NOx Burners, a combination of Institute of Technology, Kanpur. He is

emissions by as much as 50-60%. This staged fuel burning and internal flue gas registered professional engineer in

type of burner can operate with a small circulation (Figure 5), have recently been California, and a member of AIChE.

Furnace Improvements Services

www.heatflux.com 6

You might also like

- Lurgi MegamethanolDocument8 pagesLurgi MegamethanolAngeloNo ratings yet

- Uop Merox Process: G. A. DziabisDocument12 pagesUop Merox Process: G. A. DziabisBharavi K SNo ratings yet

- Project 6 AmmoniaDocument10 pagesProject 6 AmmoniaAhmed AliNo ratings yet

- Sulphur Recovery UnitDocument39 pagesSulphur Recovery UnitWoMeiYouNo ratings yet

- AspenHYSYSRefiningV7 3 OpsDocument478 pagesAspenHYSYSRefiningV7 3 OpsAnonymous w46Y2Qf84No ratings yet

- Ultralow NOx BurnersDocument3 pagesUltralow NOx Burnersdatalogger123456100% (2)

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Methanol DistillationDocument6 pagesMethanol DistillationNaseeb AliNo ratings yet

- Steam Methane Reforming Reaction Process Intensification by Using A ReactorDocument14 pagesSteam Methane Reforming Reaction Process Intensification by Using A ReactorserchNo ratings yet

- Modeling and Analysis A MethanolDocument10 pagesModeling and Analysis A MethanolVidal TxusNo ratings yet

- Dewatering Column AA Grade MethanolDocument15 pagesDewatering Column AA Grade MethanolIrma BrennanNo ratings yet

- Ammonia Energy - EfficiencyDocument4 pagesAmmonia Energy - Efficiencyanupam01013787No ratings yet

- Effect of Reactor Inlet Temperature in A HydrotreaterDocument5 pagesEffect of Reactor Inlet Temperature in A HydrotreaterAlexNo ratings yet

- Paper - Thermal Cracking of PropaneDocument13 pagesPaper - Thermal Cracking of PropaneshampexNo ratings yet

- 11 8783 WP Column Analysis PDFDocument22 pages11 8783 WP Column Analysis PDFHassanNo ratings yet

- FCC Propylene Production Tech PaperDocument8 pagesFCC Propylene Production Tech PaperMaría Belén JaureguiNo ratings yet

- Kinetics of MethanationDocument12 pagesKinetics of MethanationGabriela Campos DávilaNo ratings yet

- Catalytic ConversionDocument27 pagesCatalytic ConversionKuldeep singh ChandelNo ratings yet

- Catalytic Beds Protection: Procatalyse Catalysts & AdsorbentsDocument1 pageCatalytic Beds Protection: Procatalyse Catalysts & Adsorbentsmohsen ranjbarNo ratings yet

- Alternative Production of Methanol From Industrial CO2Document25 pagesAlternative Production of Methanol From Industrial CO2Ayman FawzyNo ratings yet

- At 05415 WP Acid Gas Cleaning Using Amine Solvents 2019 1125Document63 pagesAt 05415 WP Acid Gas Cleaning Using Amine Solvents 2019 1125Muhammad NaeemNo ratings yet

- XP Flare Article ReprintDocument5 pagesXP Flare Article ReprintAnonymous cuOIjrLINo ratings yet

- Evaluating Hydrogen Rich Fuel Gas FiringDocument4 pagesEvaluating Hydrogen Rich Fuel Gas FiringVenkatesh Kumar RamanujamNo ratings yet

- Nicholas Oligomerization PDFDocument16 pagesNicholas Oligomerization PDFTanase DianaNo ratings yet

- Aiche 36 012problematic Low Temperature ShiftDocument10 pagesAiche 36 012problematic Low Temperature ShiftHsein WangNo ratings yet

- Energy Analysis On A Natural Gas PlantDocument13 pagesEnergy Analysis On A Natural Gas PlantVu TranNo ratings yet

- Maximization of Natural Gas Liquids Production From An Existing Gas PlantDocument9 pagesMaximization of Natural Gas Liquids Production From An Existing Gas PlantFranco Camacho CanchariNo ratings yet

- Hydroprocessing: Hydrocracking & HydrotreatingDocument45 pagesHydroprocessing: Hydrocracking & HydrotreatingRobin ZwartNo ratings yet

- PEP Review On Ethylene ProcessDocument9 pagesPEP Review On Ethylene Processarman0% (1)

- 1848167504Document1,035 pages1848167504Jayen BarochiaNo ratings yet

- Sweetening LPG With AminesDocument8 pagesSweetening LPG With AminessizwehNo ratings yet

- Simulation and Performance Analysis of Propane Propylene SplitterDocument4 pagesSimulation and Performance Analysis of Propane Propylene SplitterAnonymous UY9QffNo ratings yet

- POWER Magazine - May 2023-1Document43 pagesPOWER Magazine - May 2023-1MarcialgonzalezpNo ratings yet

- Catalyst Stripper Improves FCC Unit Performance - PTQ 3Q12Document4 pagesCatalyst Stripper Improves FCC Unit Performance - PTQ 3Q12dionarasimNo ratings yet

- Hydrotreating - UOP - A Honeywell CompanyDocument59 pagesHydrotreating - UOP - A Honeywell CompanySamNo ratings yet

- Electrochemical Reduction of CO To Oxalic Acid: V.S. Boor Thesis Defense 09-04-2020Document36 pagesElectrochemical Reduction of CO To Oxalic Acid: V.S. Boor Thesis Defense 09-04-2020Marcela FragozoNo ratings yet

- Topsoe Sec Ref Cat RKS 2Document5 pagesTopsoe Sec Ref Cat RKS 2Vo Duc Minh MinhNo ratings yet

- Boiler Steam Cycle HYSYSv8.6Document28 pagesBoiler Steam Cycle HYSYSv8.6Andriano Suryawan UtamaNo ratings yet

- 07 Catalytic Cracking PDFDocument37 pages07 Catalytic Cracking PDFjeedanNo ratings yet

- Ammonia CrackerDocument2 pagesAmmonia CrackerPuneet Kumar SharmaNo ratings yet

- Design Guidelines For Proplyene Splitters - Rev inDocument10 pagesDesign Guidelines For Proplyene Splitters - Rev intotongopNo ratings yet

- The Star Process by Uhde: Industrial SolutionsDocument24 pagesThe Star Process by Uhde: Industrial SolutionsAjaykumarNo ratings yet

- SCR Reactor Performance Profiling and Results Analysis PDFDocument7 pagesSCR Reactor Performance Profiling and Results Analysis PDFkangsungjinNo ratings yet

- Updating Refinery Planning Submodels - FCC - An Application ExampleDocument53 pagesUpdating Refinery Planning Submodels - FCC - An Application ExampleRebekah SchmidtNo ratings yet

- Amine Sweetening With DEADocument14 pagesAmine Sweetening With DEARoza SavitriNo ratings yet

- Hydrogen From Refinery Off GasDocument3 pagesHydrogen From Refinery Off Gaskulaspiro100% (1)

- Saidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFDocument10 pagesSaidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFRuben Alejandro Velandia UsugaNo ratings yet

- FCCU Optimization - A Minimum Capital ApproachDocument6 pagesFCCU Optimization - A Minimum Capital Approachsaleh4060No ratings yet

- H P 2011 02 PDFDocument97 pagesH P 2011 02 PDFErvin WatzlawekNo ratings yet

- Hydrocarbon Processing TOV Offer Advantages in Emergency Services PDFDocument4 pagesHydrocarbon Processing TOV Offer Advantages in Emergency Services PDFSu KaNo ratings yet

- Conversion of Syngas To Diesel - Article Ptq-EnglishDocument6 pagesConversion of Syngas To Diesel - Article Ptq-Englishrkhandelwal96040% (1)

- Design and Assessment of A Membrane and Absorption Based Carbon Dioxide Removal Process For Oxidative Coupling of MethaneDocument11 pagesDesign and Assessment of A Membrane and Absorption Based Carbon Dioxide Removal Process For Oxidative Coupling of MethanechristiancandidoNo ratings yet

- Choudari Et Al. (2012) - Distillation Optimization Vapor RecompressionDocument5 pagesChoudari Et Al. (2012) - Distillation Optimization Vapor Recompressionvazzoleralex6884No ratings yet

- Process DescriptionDocument6 pagesProcess Descriptionافكر اشتري كورياNo ratings yet

- Ethylene Production Via Partial Oxidation and Pyrolysis of Ethane - M. Dente, A. Berettal, T. Faravelli, E. Ranzi, A. Abbr, M. Notarbartolo PDFDocument6 pagesEthylene Production Via Partial Oxidation and Pyrolysis of Ethane - M. Dente, A. Berettal, T. Faravelli, E. Ranzi, A. Abbr, M. Notarbartolo PDFAlejandro HernandezNo ratings yet

- Biomass Gasification ProcessDocument27 pagesBiomass Gasification ProcessTony AppsNo ratings yet

- Modeling of Naphtha Reforming Unit Applying Detailed 2014 Chemical EngineerDocument30 pagesModeling of Naphtha Reforming Unit Applying Detailed 2014 Chemical Engineerdownload100% (1)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- Process Safety Time For Fired HeatersDocument22 pagesProcess Safety Time For Fired HeatersDeepika UmlaniNo ratings yet

- Carbon Dioxide Emissions From Fired Heaters: Matthew Martin XRG TechnologiesDocument7 pagesCarbon Dioxide Emissions From Fired Heaters: Matthew Martin XRG TechnologiesDeepika UmlaniNo ratings yet

- Heat Recovery Solves Carbon Capture IssuesDocument5 pagesHeat Recovery Solves Carbon Capture IssuesDeepika UmlaniNo ratings yet

- ProcheatDocument316 pagesProcheatDeepika UmlaniNo ratings yet

- RW720FPT1X User ManualDocument12 pagesRW720FPT1X User ManualHuma SultanNo ratings yet

- MonoreleaseDocument2 pagesMonoreleaseosama mohNo ratings yet

- Titration of Sodium Carbonate With Hydrochloric AcidDocument4 pagesTitration of Sodium Carbonate With Hydrochloric AcidMark 00vvNo ratings yet

- Pesticide Manuelreview 2001Document2 pagesPesticide Manuelreview 2001gusti darmawanNo ratings yet

- Unit 4 - Review On Basic Principles Applied in Analytical ChemistryDocument7 pagesUnit 4 - Review On Basic Principles Applied in Analytical Chemistryariel egonNo ratings yet

- 2.6 Ogilvie - 2019 - REG VOLUXDocument10 pages2.6 Ogilvie - 2019 - REG VOLUXvmx45ncwd7No ratings yet

- Ethiopia Country Case Study Mining Sector Feb 2018Document7 pagesEthiopia Country Case Study Mining Sector Feb 2018Fekadu AlemayhuNo ratings yet

- ASTM B275-05 Codification of Certain Metals and AlloysDocument7 pagesASTM B275-05 Codification of Certain Metals and AlloysDemian LópezNo ratings yet

- # Specimen For ODOR, FOGGING & VOC Test Must Be Wrapped With Aluminium Foil and Enclosed in Plastic Bag at The Time of SubmissionDocument2 pages# Specimen For ODOR, FOGGING & VOC Test Must Be Wrapped With Aluminium Foil and Enclosed in Plastic Bag at The Time of SubmissionBaljeetNo ratings yet

- Root Cause Analysis of Defects in Duplex PDFDocument9 pagesRoot Cause Analysis of Defects in Duplex PDFSajan JamesNo ratings yet

- Amberlyst 15 Dry H Form CAS NO 39389-20-3: Material Safety Data Sheet Sds/MsdsDocument6 pagesAmberlyst 15 Dry H Form CAS NO 39389-20-3: Material Safety Data Sheet Sds/MsdsMuhammad Dion ArfiNo ratings yet

- MOC63u Demo ManualDocument19 pagesMOC63u Demo ManualJinal Jyoti JoshiNo ratings yet

- Connoly 2005 Introduction To X-Ray Powder DiffractionDocument9 pagesConnoly 2005 Introduction To X-Ray Powder DiffractionFris BeeNo ratings yet

- CH 44 Organic Reactions - Supp Ex 2Document4 pagesCH 44 Organic Reactions - Supp Ex 2伊貝P-No ratings yet

- Reaction Paper - Video 13A and 13BDocument1 pageReaction Paper - Video 13A and 13BChilton John DuatNo ratings yet

- Virtual Lab-Water QualityDocument7 pagesVirtual Lab-Water Qualityapi-268159571No ratings yet

- E Tech Consultant (Introduction Profile)Document10 pagesE Tech Consultant (Introduction Profile)E Tech ConsultantNo ratings yet

- Vacuum Packing Machine Operation Manual 101113Document33 pagesVacuum Packing Machine Operation Manual 101113devit penjolNo ratings yet

- XCS - Station Killark, ESTACIÓN MANUAL DE PRUEBADocument8 pagesXCS - Station Killark, ESTACIÓN MANUAL DE PRUEBAtitoNo ratings yet

- Super Bond Group: Industrial AdhesivesDocument6 pagesSuper Bond Group: Industrial AdhesivesVishnuNo ratings yet

- ResearchDocument44 pagesResearchGwend MemoracionNo ratings yet

- Biomolecules NotesDocument104 pagesBiomolecules Notessamay gujratiNo ratings yet

- CG - 2017 PDFDocument292 pagesCG - 2017 PDFkimsioNo ratings yet

- Anion AnalysisDocument3 pagesAnion AnalysisPatrick Juacalla100% (2)

- Iv Generation Nuclear Reactors: Danilo NoriDocument12 pagesIv Generation Nuclear Reactors: Danilo NoriPutu BrahmandaNo ratings yet

- Lecture1 CH317 2020 Fall Statistics Part4 GGclasssDocument21 pagesLecture1 CH317 2020 Fall Statistics Part4 GGclasssshanicejames7867No ratings yet

- Tech 6 (Solved)Document7 pagesTech 6 (Solved)Saif Ullah100% (3)

- Pengaruh Penambahan Etanol Dan Lama Fermentasi Lanjutan Cairan Pulpa Hasil Samping Fermentasi Biji Kakao Terhadap Karakteristik Cuka KakaoDocument11 pagesPengaruh Penambahan Etanol Dan Lama Fermentasi Lanjutan Cairan Pulpa Hasil Samping Fermentasi Biji Kakao Terhadap Karakteristik Cuka KakaoAgus PurnamaNo ratings yet

- Construction and Building Materials: E. Adamopoulou, P. Pipilikaki, M.S. Katsiotis, M. Chaniotakis, M. KatsiotiDocument8 pagesConstruction and Building Materials: E. Adamopoulou, P. Pipilikaki, M.S. Katsiotis, M. Chaniotakis, M. KatsiotiYane CoutinhoNo ratings yet