Professional Documents

Culture Documents

Lecture 1. Classification of Manufacturing Processes, Safety and Housekeeping

Lecture 1. Classification of Manufacturing Processes, Safety and Housekeeping

Uploaded by

John0 ratings0% found this document useful (0 votes)

28 views26 pagesThe document provides information about the MEC131 Manufacturing Processes course including that it meets on Mondays and Thursdays from 2:30 PM to 5:30 PM. It then discusses various manufacturing processes classified by how they shape materials, machine parts to specific dimensions, achieve surface finishes, and join materials. It concludes with safety guidelines for machine shops, appropriate clothing and safety equipment, and good housekeeping practices.

Original Description:

Original Title

Lecture 1. Classification of Manufacturing Processes, Safety and Housekeeping_c6419a8b8c4cd3a42febfdbb59692797

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information about the MEC131 Manufacturing Processes course including that it meets on Mondays and Thursdays from 2:30 PM to 5:30 PM. It then discusses various manufacturing processes classified by how they shape materials, machine parts to specific dimensions, achieve surface finishes, and join materials. It concludes with safety guidelines for machine shops, appropriate clothing and safety equipment, and good housekeeping practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

28 views26 pagesLecture 1. Classification of Manufacturing Processes, Safety and Housekeeping

Lecture 1. Classification of Manufacturing Processes, Safety and Housekeeping

Uploaded by

JohnThe document provides information about the MEC131 Manufacturing Processes course including that it meets on Mondays and Thursdays from 2:30 PM to 5:30 PM. It then discusses various manufacturing processes classified by how they shape materials, machine parts to specific dimensions, achieve surface finishes, and join materials. It concludes with safety guidelines for machine shops, appropriate clothing and safety equipment, and good housekeeping practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 26

SUBJECT: MEC131

MANUFACTURING PROCESSES

TIME: 2:30 PM – 5:30 PM

DAYS: MONDAY AND THURSDAY

DEFINITION:

Manufacturing

Derived from the Latin word “manufactus”, manufacturing

means made by hand. It involves making products from raw

sources using different processes, by making use of hand tools,

machinery or even computers. Manufacturing process is that

part of the production process which is directly concerned with

the change of form or dimensions of the part being produced.

CLASSIFICATION OF MANUFACTURING PROCESSES:

Processes used to change the shape of materials.

Processes used for machining parts to a fixed

dimension.

Processes for obtaining a surface finish.

Processes used for joining parts of the material.

CLASSIFICATION OF MANUFACTURING PROCESSES:

Processes used to change the shape of materials.

Processes used primarily to change the shape of metals include the following:

• Casting • Roll Forming

• Rolling • Magnetic Forming

• Crushing • Plastic Molding

• Bending • Extruding

• Stretch Forming • Squeezing

• Explosive Forming • Swaging

• Powder Metal Forming • Spinning

• Forging • Torch Cutting

• Drawing • Electroforming

• Piercing • Electrohydraulic Forming

• Shearing

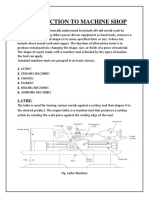

CLASSIFICATION OF MANUFACTURING PROCESSES:

Processes used for machining parts to a fixed

dimension.

a) In manufacturing any product there are usually a number of operations, which may

be classified as follows:

• Turning • Shaping

• Boring • Sawing

• Milling • Robbing

• Planning • Drilling

• Reaming • Broaching

• Grinding • Routing

CLASSIFICATION OF MANUFACTURING PROCESSES:

Processes used for machining parts to a fixed

dimension.

b) Non-traditional machining process:

• Ultrasonic • Electrical Discharge • Electro - Arc

• Optical Laser • Electromechanical • Chemical - Milling

• Abrasive Jet Cutting • Electro beam machining • Plasma Arc Machining

CLASSIFICATION OF MANUFACTURING PROCESSES:

Processes for obtaining a surface finish.

Surface finishing are used to insure a smooth surface, great accuracy, aesthetic

appearance, or protective coating.

Process used are the following:

• Polishing • Abrasive belt grinding • Barrel tumbling

• Electroplating • Honing • Lapping

• Super finishing • Metal spraying • Inorganic Coating

• Parkerizing • Anodizing • Sherardizing

CLASSIFICATION OF MANUFACTURING PROCESSES:

Processes used for joining parts of the material.

Products requiring the assembly of two or more parts are usually joined by one of the

following process:

• Welding • Brazing

• Pressing • Fastening

• Soldering • Sintering

• Riveting Screw • Adhesive joining

SAFETY IN THE MACHINE SHOP:

It is very important that safety must come first

before operating any machine tools.

Remember that safety is an attitude. Always

practice safety working habits in the workplace.

Always practice safe working procedures at all

times.

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

1. Be sure that all machines have

effective and properly working

guards that are always in place

when machines are operating.

2. Replace guards immediately after

any repairs.

Image courtesy of https://www.machinesafety.co.uk/free-downloads/workshop/

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

3. Do not attempt to oil, clean, adjust or repair

any machine while it is running. Stop the

machine and lock the power switch in the “off”

position.

4. Do not operate any machine unless authorized

to do so.

5. Even after the power is off, do not leave the

machine until it has stopped running.

Someone else may not noticed that it is still in Image courtesy of https://www.shutterstock.com/search/machine+accidents

motion and be injured.

6. Do not try to stop the machine with your

hands or body.

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

7. Always see that work and cutting tools

on any machine are clamped securely

before starting.

Image courtesy of https://www.dreamstime.com/royalty-free-stock-

photography-factory-worker-operator-drill-press-retro-image25163507

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

8. Keep the floor clear of metal chips or

curls and waste pieces. Put them in

the container provided for such

things. Scraps are tripping hazards,

and chips or curls may cut through a

shoe and injure the foot.

Image courtesy of https://www.dreamstime.com/stock-images-metal-chips-

image24931734

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

9. All setscrews should be flushed or recessed type. If they are not, move

with caution when near them. Projecting setscrews are very dangerous

because they may catch on sleeves or clothing.

Image courtesy of https://www.hobby-machinist.com/threads/enco- Image courtesy of https:// superlls.com/ index.php? main_page=product

13x40-d1-4-three-jaw-chuck-adjustment.31188/ info&products_id=86169

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

10. Get help for handling long or heavy pieces of material. Follow safe lifting

practices – lift with your leg muscles, not your back.

Image courtesy of https://www.shutterstock.com/image-vector/two-workers-lifting-heavy-wooden-

crate-1597625155

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

11. Do not lean against the machine.

Image courtesy of https://blog.creativesafetysupply.com/dangers-loose-clothing/

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

12. Concentrate on the work and do not

talk unnecessarily while operating the

machine.

13. Don’t talk to others when they are

operating a machine.

Image courtesy of https://safety-work.org/fileadmin/safety-work/articles/IVSS-

Unterweisung_Gefahrstellen_an_Maschinen/ISSA_108_Gefahrstellen.pdf

GENERAL SAFETY PRECAUTIONS IN THE

MACHINE SHOP:

14. Get first aid immediately for any injury.

Image courtesy of https://www.canstockphoto.com/illustration/first-aid.html

CLOTHING AND SAFETY EQUIPMENT:

1. Always wear safety glasses, goggles, or face shields

design for the type of work when operating any

machine.

Image courtesy of https://liggettlawgroup.com/blog/welding-injuries-are-all-too-common/

CLOTHING AND SAFETY EQUIPMENT:

2. Wear clothing suited for the job. Wear shoes with

thick soles – safety shoes if heavy work is being

done.

Image courtesy of https://ose.directory/article/safety-footwear/

CLOTHING AND SAFETY EQUIPMENT:

3. Do not wear rings, watches, bracelets, or other

jewelry that could get caught in moving machinery.

Image courtesy of https://www.seton.com/caution-no-jewelry-loose-clothing-industrial-osha-

machine-hazard-sign-l11450.html

CLOTHING AND SAFETY EQUIPMENT:

4. Do not wear neckties or loose or torn clothing of any

kind.

Image courtesy of https://in.pinterest.com/pin/429882726924059665/

CLOTHING AND SAFETY EQUIPMENT:

5. Wear shirts or jumpers with sleeves cut-off or rolled

above the elbows.

Image courtesy of https://www.clipartmax.com/max/m2i8G6i8Z5K9G6i8/

CLOTHING AND SAFETY EQUIPMENT:

6. Always remove gloves before

turning on or operating any

machine. If material is rough or

sharp and gloves must be worn,

place or handle material with

machine turned off.

Image courtesy of https://www.clipartmax.com/max/m2i8G6i8Z5K9G6i8/

HOUSEKEEPING:

1. Keep floors free of oil, grease, or any other liquid. Clean up

spilled liquids immediately; they are slipping hazards.

2. Aisles should be clear at all times to avoid tripping or other

accidents.

3. Store materials in such a way that they cannot become

tripping hazards.

HOUSEKEEPING:

4. Do not leave tools or work on the table

of a machine even if the machine is not

running. Tools or work may fall off and

cause toe or foot injury.

5. Put tools away when not in use.

6. Place all scrap in scrap boxes.

Image courtesy of https: //cartoondealer.com/

image/9284280/worker-working-lathe-machine.html

You might also like

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- N4 MechanotechnicsDocument27 pagesN4 MechanotechnicsAshly33% (3)

- Bridgeport VMC1022 PDFDocument98 pagesBridgeport VMC1022 PDFKrassi GlogovskiNo ratings yet

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- Machining Report (Lathe)Document11 pagesMachining Report (Lathe)Syah KlAte67% (3)

- Mold Maintenance ProgramDocument14 pagesMold Maintenance ProgramLordsonNo ratings yet

- Astm A325 PDFDocument8 pagesAstm A325 PDFRameez Bilwani100% (1)

- U-Values For Common Materials: Go Back To Heat Loss CalculationDocument3 pagesU-Values For Common Materials: Go Back To Heat Loss Calculationkenechidukor100% (1)

- Workshop Lathe ConventionalDocument7 pagesWorkshop Lathe Conventionalluqman04hakimiNo ratings yet

- Introduction To Engineering Practices Industrial SafetyDocument29 pagesIntroduction To Engineering Practices Industrial SafetyDhruv PathakNo ratings yet

- Benchwork Powerpoint PresentationDocument100 pagesBenchwork Powerpoint PresentationStewart StevenNo ratings yet

- 422ME-3 Production Engineering-3 Lab - ManualDocument35 pages422ME-3 Production Engineering-3 Lab - ManualSyed KhaleelullahNo ratings yet

- WORKSHOP. REVIEWER - FinalDocument14 pagesWORKSHOP. REVIEWER - FinalKamille NayraNo ratings yet

- Industrial Safety EngineeringDocument9 pagesIndustrial Safety EngineeringGowri SNo ratings yet

- Manufacturing Technology LAB: Practical FileDocument34 pagesManufacturing Technology LAB: Practical FileShuktika SrivastavaNo ratings yet

- Industrial Safety Engineering - 1Document10 pagesIndustrial Safety Engineering - 1Gowri SNo ratings yet

- RF 45Document48 pagesRF 45Daniel Lara100% (1)

- Workshop Technology Notes B.EDocument58 pagesWorkshop Technology Notes B.EMonikandonNo ratings yet

- Machiene GuardingDocument19 pagesMachiene GuardingMoon JNo ratings yet

- Module 1-1Document6 pagesModule 1-1gthegreat57No ratings yet

- Work Shop ManualDocument61 pagesWork Shop ManualÃłį HàmžåNo ratings yet

- Module 1. Prelims Workshop Theory and Practice 1ADocument7 pagesModule 1. Prelims Workshop Theory and Practice 1AmanuelNo ratings yet

- 1-Machine SafetyDocument59 pages1-Machine Safetyᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔100% (3)

- Guide For The Repairs Excavator Structures by Welding: Print No. 604.07.189.01 - EnglishDocument32 pagesGuide For The Repairs Excavator Structures by Welding: Print No. 604.07.189.01 - EnglishАнатолій ГуменюкNo ratings yet

- Lab ManualDocument34 pagesLab ManualSamuelPannierselvamShirleyNo ratings yet

- MAINTENANCEDocument8 pagesMAINTENANCEKirubel MogesNo ratings yet

- BALA - User - Manual - GeneralDocument62 pagesBALA - User - Manual - GeneralDouglas Tavares Machado100% (3)

- Research For ME ShopDocument37 pagesResearch For ME ShopGrace LuceroNo ratings yet

- J4102 Lab Sheet PDFDocument16 pagesJ4102 Lab Sheet PDFWanAhmadAzibNo ratings yet

- General SafetyDocument32 pagesGeneral SafetyLancel AlcantaraNo ratings yet

- MANUAL Auto Coating.Document28 pagesMANUAL Auto Coating.Hernando Galindo PintoNo ratings yet

- Introduction To Machine ShopDocument5 pagesIntroduction To Machine ShopPrashant SharmaNo ratings yet

- Workshop SafetDocument28 pagesWorkshop SafetSHAWN TAKAONANo ratings yet

- Safety RulesDocument2 pagesSafety RulesNordiana IdrisNo ratings yet

- Milling Lesson 4-01 AVADocument18 pagesMilling Lesson 4-01 AVAEason Aw Xiu JianNo ratings yet

- Machine Shop Technology II: Introduction To Machine Tool Safety 1.1. Safety PrecautionsDocument5 pagesMachine Shop Technology II: Introduction To Machine Tool Safety 1.1. Safety Precautionsabdi reta100% (1)

- Cylindrical Grinding MachineDocument28 pagesCylindrical Grinding MachineLal Singh KashyapNo ratings yet

- Me 8462-Mt-Ii Lab Manual PDFDocument39 pagesMe 8462-Mt-Ii Lab Manual PDFNagamani Rajesh50% (2)

- A5e43215508a Sicherheitshinweise Simotics GP SD DP FL En-UsDocument10 pagesA5e43215508a Sicherheitshinweise Simotics GP SD DP FL En-UsMudabbir Shan AhmedNo ratings yet

- AgempDocument7 pagesAgemppavan kumarNo ratings yet

- Type: Bulker Model: Serial NumberDocument14 pagesType: Bulker Model: Serial NumberManikantaSumanthNo ratings yet

- Safety in The ShopDocument39 pagesSafety in The ShopmarlitoNo ratings yet

- Maquina de Empaquetamiento WP Series wp-40Document51 pagesMaquina de Empaquetamiento WP Series wp-40Fernando Amaro Hernandez100% (2)

- SafetyDocument39 pagesSafetyItemogeng Bernatt BabeNo ratings yet

- Ted 221 - Machine Shop Practice 1Document34 pagesTed 221 - Machine Shop Practice 1Mr. MushahidNo ratings yet

- Shop Safety and Environmental CleanlinessDocument9 pagesShop Safety and Environmental CleanlinessrjkrtshNo ratings yet

- Digital Assignment Cad CamDocument2 pagesDigital Assignment Cad CamAshlinNo ratings yet

- Workshop Techology Ichapter 1 6Document68 pagesWorkshop Techology Ichapter 1 6FikruNo ratings yet

- Geith Coupler InstallationDocument32 pagesGeith Coupler Installationaesalazar3No ratings yet

- 01 Shop SafetyDocument35 pages01 Shop SafetyNino AngobNo ratings yet

- Engr 311 Compilation FINAL FINALDocument106 pagesEngr 311 Compilation FINAL FINALAngel GrospeNo ratings yet

- The Components of A Grinding MachineDocument5 pagesThe Components of A Grinding MachineNuman Zaman DipuNo ratings yet

- 1 Safety in ShopDocument4 pages1 Safety in Shopмσнαммєd ƒαιz ραтєlNo ratings yet

- Drill Press ManualDocument25 pagesDrill Press ManualitalianjeremyNo ratings yet

- 3 In1 Sheet Metal Machine: Operation & Maintenance InstructionsDocument36 pages3 In1 Sheet Metal Machine: Operation & Maintenance InstructionsDominicNo ratings yet

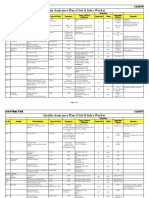

- Quality Assurance Management: Quality Control Inspection Safety ProceduresDocument5 pagesQuality Assurance Management: Quality Control Inspection Safety ProceduresclintonNo ratings yet

- Experiment #1 Objective:: Fig: 1.1 (Process Layout)Document5 pagesExperiment #1 Objective:: Fig: 1.1 (Process Layout)waseemjuttNo ratings yet

- PROFAB ESR 1580X2.0 Manual - 2017Document16 pagesPROFAB ESR 1580X2.0 Manual - 2017Kevin VargheseNo ratings yet

- Workshop TechnologyDocument80 pagesWorkshop TechnologyGokul Prasad ChettiNo ratings yet

- Machine GuardingDocument80 pagesMachine Guardingmohamed atefNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- ME 183 - C3... MechanismsDocument26 pagesME 183 - C3... MechanismsJohnNo ratings yet

- MEC183 RoboticsDocument2 pagesMEC183 RoboticsJohnNo ratings yet

- Lecture 2. Measuring Tools-Rules and CalipersDocument45 pagesLecture 2. Measuring Tools-Rules and CalipersJohnNo ratings yet

- The World's Best Place To Travel and Visit: by John Warren / ABC News Travel Editor - (Published) 3:03 PMDocument6 pagesThe World's Best Place To Travel and Visit: by John Warren / ABC News Travel Editor - (Published) 3:03 PMJohnNo ratings yet

- Asme Ii Part D Table 1a CSDocument20 pagesAsme Ii Part D Table 1a CSyar_nlNo ratings yet

- CH6 - Mix Design - Part1Document23 pagesCH6 - Mix Design - Part1Hamza Mo.No ratings yet

- Application: Type K' (Nicr/Ni)Document2 pagesApplication: Type K' (Nicr/Ni)Sudhanshu GuptaNo ratings yet

- Specification-LPG PipeLine WorksDocument5 pagesSpecification-LPG PipeLine Worksr_atneshNo ratings yet

- TDS AluPAC STD Alumichem ENDocument1 pageTDS AluPAC STD Alumichem ENlAURANo ratings yet

- Ground Floor Level and Foundation StructureDocument1 pageGround Floor Level and Foundation StructureRicky KhannaNo ratings yet

- Gambar 2 Mill Test Certificate Seamless Carbon Steel TubeDocument1 pageGambar 2 Mill Test Certificate Seamless Carbon Steel TubeDhidik 近江 KiraNo ratings yet

- DOE MethodDocument20 pagesDOE MethodNor Khuzaimah Ab HamidNo ratings yet

- Layout of Footing Draft-ModelDocument1 pageLayout of Footing Draft-ModelSanthosh BabuNo ratings yet

- One Way Simply-Supported and Continuous Solid SlabDocument39 pagesOne Way Simply-Supported and Continuous Solid Slabdixn__100% (13)

- Revised Final Estimate of Earth Mat - 220kV YardDocument116 pagesRevised Final Estimate of Earth Mat - 220kV YardMidhun VargheseNo ratings yet

- Sandvick Stainless Welding Products (S 236 Eng 2006)Document27 pagesSandvick Stainless Welding Products (S 236 Eng 2006)Anonymous yQ7SQrNo ratings yet

- Experimental Analysis of Punching Shear in Flat Slabs With Variation in The Anchorage of Shear ReinforcementDocument18 pagesExperimental Analysis of Punching Shear in Flat Slabs With Variation in The Anchorage of Shear ReinforcementJoão AlbuquerqueNo ratings yet

- Quality Assurance Plan - CivilDocument11 pagesQuality Assurance Plan - CivilDeviPrasadNathNo ratings yet

- County Standard - Retaining WallDocument2 pagesCounty Standard - Retaining WallRuffy OiraNo ratings yet

- Akshay Ferrocement WardrobeDocument1 pageAkshay Ferrocement Wardrobe1DC20AT025 Ganesh AkshayNo ratings yet

- Andalusite Vs Bauxite Based RefractoryDocument7 pagesAndalusite Vs Bauxite Based RefractorymaximootadoyNo ratings yet

- Y Strainer - ShieldDocument1 pageY Strainer - Shieldmilton rebelloNo ratings yet

- Appendix C.26 D: Single Cell RCC Box Culvert of Size 2 X 3 (U/S & D/S Pitching)Document7 pagesAppendix C.26 D: Single Cell RCC Box Culvert of Size 2 X 3 (U/S & D/S Pitching)Bilal Ahmed Barbhuiya100% (1)

- Alfa Laval Aalborg Shell and Tube Heat Exchangers - Product OverviewDocument1 pageAlfa Laval Aalborg Shell and Tube Heat Exchangers - Product Overviewagus sutiawanNo ratings yet

- CNC Manual Part ProgrammeDocument23 pagesCNC Manual Part ProgrammePradip PatelNo ratings yet

- Item 1 - GA10010207 PN 400819Document1 pageItem 1 - GA10010207 PN 400819Pablo GarcíaNo ratings yet

- Cement HandoutDocument3 pagesCement HandoutShishii Lee100% (1)

- Mix Design of SCCDocument4 pagesMix Design of SCCDebaraj BailungNo ratings yet

- Metric Tolerance Chart PDFDocument6 pagesMetric Tolerance Chart PDFSinan Yıldırım100% (1)

- Al Cast Plate G.AL® C250 Precision Milled: Alloy S CharacteristicsDocument1 pageAl Cast Plate G.AL® C250 Precision Milled: Alloy S CharacteristicsAzur OmranNo ratings yet

- 03 04 LewisDocument14 pages03 04 LewisDLM7No ratings yet

- Hilux Fire Book PDFDocument22 pagesHilux Fire Book PDFMadhava PadiyarNo ratings yet