Professional Documents

Culture Documents

PNGE-492 Geothermal Energy Technologies: Exploration Techniques and Drilling

PNGE-492 Geothermal Energy Technologies: Exploration Techniques and Drilling

Uploaded by

Reach SelfbloodCopyright:

Available Formats

You might also like

- Vacuum Pump Removal - Installation (Skyactiv-D 2.2)Document3 pagesVacuum Pump Removal - Installation (Skyactiv-D 2.2)toywrc100% (2)

- Dipmeter Surveys in Petroleum ExplorationFrom EverandDipmeter Surveys in Petroleum ExplorationRating: 5 out of 5 stars5/5 (1)

- Back Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelDocument4 pagesBack Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelWisnu Andra Isdianto100% (1)

- Astm B344-01Document3 pagesAstm B344-01Srinivasan KrishnamoorthyNo ratings yet

- ECG353 - Chapter 1 - Sub Surface Exploration - Part 1Document32 pagesECG353 - Chapter 1 - Sub Surface Exploration - Part 1Faiz JaafarNo ratings yet

- Module 3 - Prospecting and ExplorationDocument17 pagesModule 3 - Prospecting and ExplorationSkeptical DoolaNo ratings yet

- Res Lab 1Document10 pagesRes Lab 1Ali NasirNo ratings yet

- Ce 902Document12 pagesCe 902Ak AyonNo ratings yet

- 2012.11.14 - How To Read and Understand A Geotechnical Report (Part 2)Document24 pages2012.11.14 - How To Read and Understand A Geotechnical Report (Part 2)UALU333No ratings yet

- Well DesignDocument92 pagesWell Designammarrafei100% (1)

- Water Well Drilling &developmentDocument94 pagesWater Well Drilling &developmentZiad AshrafNo ratings yet

- Foundation Eng. 2015-2016Document138 pagesFoundation Eng. 2015-2016Shekibullah MoushfiqNo ratings yet

- Expression of Interest Design of Earth Cut Stability by The Use of Slope/W and WallapDocument6 pagesExpression of Interest Design of Earth Cut Stability by The Use of Slope/W and WallapUý ĐạiNo ratings yet

- Allowable Set For Large Dia PilesDocument2 pagesAllowable Set For Large Dia Pileserkarthik85No ratings yet

- Exam For Hydrogeologist (2005)Document22 pagesExam For Hydrogeologist (2005)Workneh TemesgenNo ratings yet

- Ministry of Higher Education and Scientific Research Karbala University College of Engineering Petroleum Engineering DepartmentDocument10 pagesMinistry of Higher Education and Scientific Research Karbala University College of Engineering Petroleum Engineering Departmentسجاد كريم هاشم سماويNo ratings yet

- Trench and Excavation Support Options and Excavation Slope Design - An Online Course For Engineers and ArchitectsDocument8 pagesTrench and Excavation Support Options and Excavation Slope Design - An Online Course For Engineers and ArchitectsAlejandro GonzalezNo ratings yet

- Coring & Coring Analysis 2Document21 pagesCoring & Coring Analysis 2Reband Azad100% (1)

- Foundation Handout PDFDocument78 pagesFoundation Handout PDFአንተነህ ኃይሌ ክንፈገብርኤል100% (1)

- Final IntershipDocument18 pagesFinal IntershipRiya SantoshwarNo ratings yet

- Sample Chapter - Oil and Gas Well Drilling Technology PDFDocument19 pagesSample Chapter - Oil and Gas Well Drilling Technology PDFDavid John100% (1)

- Site Investigation-ObjectivesDocument22 pagesSite Investigation-ObjectivesTaimoor AhmadNo ratings yet

- Actual Geotech GRP WRKDocument11 pagesActual Geotech GRP WRKOtwua ArthurNo ratings yet

- Work Procedure Auger Bore Secant Pile Sta 8.600 PT - Ejjv - HJBLDocument7 pagesWork Procedure Auger Bore Secant Pile Sta 8.600 PT - Ejjv - HJBLejjv.indonesia.123No ratings yet

- Foundation Engineering Course: Fourth Year of Civil EngDocument43 pagesFoundation Engineering Course: Fourth Year of Civil Engarno assassinNo ratings yet

- Chapter 3Document14 pagesChapter 3Stephen SogahNo ratings yet

- Chapter 4: Subsurface InvestigationDocument21 pagesChapter 4: Subsurface InvestigationHisham MohamadNo ratings yet

- UZ CE406 Course Design - February 2020-1Document5 pagesUZ CE406 Course Design - February 2020-1kundayi shavaNo ratings yet

- 31 MI136 Rock Mechanics IIDocument2 pages31 MI136 Rock Mechanics IISealdeSaNo ratings yet

- IEM Bored Pile Supervision - 19112015Document81 pagesIEM Bored Pile Supervision - 19112015TanNo ratings yet

- Ecg 353 Mini ProjectDocument20 pagesEcg 353 Mini ProjectFaiz JaafarNo ratings yet

- 5 Tunnels PDFDocument21 pages5 Tunnels PDFMalik Muhammad Nauman ZiaNo ratings yet

- Cle2013 Advanced-foundation-Engineering TH 1.1 47 Cle2013Document2 pagesCle2013 Advanced-foundation-Engineering TH 1.1 47 Cle2013Mani chandanNo ratings yet

- Foundation EngineeringDocument170 pagesFoundation Engineeringprabeshkarkiii143No ratings yet

- Title Defense: Yangon Technological University Department of Petroleum EngineeringDocument17 pagesTitle Defense: Yangon Technological University Department of Petroleum EngineeringJames MilzerNo ratings yet

- 02 Drilling Preparation - UI 15 Sep 2006Document18 pages02 Drilling Preparation - UI 15 Sep 2006Dian L.No ratings yet

- Introduction To Geotechnical EngineeringDocument25 pagesIntroduction To Geotechnical EngineeringgeethaNo ratings yet

- Reservoir Petrophysics Q PDFDocument11 pagesReservoir Petrophysics Q PDFhusseinNo ratings yet

- Chapter 5 (Subsurface Exploration)Document46 pagesChapter 5 (Subsurface Exploration)nabihahNo ratings yet

- Recovery of Samples: Abdul Matin Department of Geology University of CalcuttaDocument18 pagesRecovery of Samples: Abdul Matin Department of Geology University of CalcuttaArghyadip MukherjeeNo ratings yet

- Fe Unit 1Document48 pagesFe Unit 1Duraid FalihNo ratings yet

- Stub Setting ReportDocument7 pagesStub Setting ReportUanaid Van RooyenNo ratings yet

- Geotechnical InvestigationsDocument85 pagesGeotechnical InvestigationsAmpumuza MmukundaNo ratings yet

- Meng 471 Assignment 2Document19 pagesMeng 471 Assignment 2AkibNo ratings yet

- Proposal Ready 4 (Dr. Aneela Wakeel) RevisedDocument15 pagesProposal Ready 4 (Dr. Aneela Wakeel) RevisedIrfanButtNo ratings yet

- 2013 Lab ManualDocument92 pages2013 Lab Manualaumi77No ratings yet

- Syllabi M.Tech. WRDMDocument114 pagesSyllabi M.Tech. WRDMMadhab KoiralaNo ratings yet

- Lec 2 Subsurface Investigation or ExplorationDocument22 pagesLec 2 Subsurface Investigation or ExplorationShahid KhanNo ratings yet

- Subsurface Exploration: Garbage in Garbage OutDocument77 pagesSubsurface Exploration: Garbage in Garbage OutMuhammad Usama Butt0% (1)

- School of Civil Engineering Assignment Ecg353: Semester Oct. 2021 - March 2022Document31 pagesSchool of Civil Engineering Assignment Ecg353: Semester Oct. 2021 - March 2022dzakirin hannan100% (1)

- Peng 311Document2 pagesPeng 311Abdul AhadNo ratings yet

- What Is Site Investigation?Document12 pagesWhat Is Site Investigation?Syazaa SalimNo ratings yet

- Earth & Rock Fill Dams 0MGT206 (PEC) : Syllabus For Master of Technology Civil Engineering (Geotechnical)Document3 pagesEarth & Rock Fill Dams 0MGT206 (PEC) : Syllabus For Master of Technology Civil Engineering (Geotechnical)krupaNo ratings yet

- Course Book of Foundation For Civil Engineering 2012-2013 PDFDocument23 pagesCourse Book of Foundation For Civil Engineering 2012-2013 PDFMomayKradookkradic100% (2)

- Fishing and Stuck Pipe PreventionDocument13 pagesFishing and Stuck Pipe Preventionairaghidario100% (1)

- Foundation Engineering IDocument70 pagesFoundation Engineering IbulchaNo ratings yet

- Foundation HandoutDocument78 pagesFoundation HandoutMc KaLiNo ratings yet

- Site InvestgationDocument11 pagesSite Investgationone engNo ratings yet

- Site Investigation: (Principal Steps) Literature SearchDocument4 pagesSite Investigation: (Principal Steps) Literature SearchInam UllahNo ratings yet

- Site InvestigationDocument5 pagesSite InvestigationKenneth KimondoNo ratings yet

- Guide To Cavern EngineeringDocument149 pagesGuide To Cavern EngineeringTan Jee PohNo ratings yet

- Geotech II Course OutlineDocument2 pagesGeotech II Course OutlineGbonga100% (1)

- Masonry 10 2nd Quarter Week 1Document6 pagesMasonry 10 2nd Quarter Week 1STEPHEN ANDRESNo ratings yet

- Fluid Mechanics Assignment TitleDocument3 pagesFluid Mechanics Assignment TitleReach SelfbloodNo ratings yet

- Dangerous Goods - Bayhanli-2 - O.1034682.04 - 13apr2023Document1 pageDangerous Goods - Bayhanli-2 - O.1034682.04 - 13apr2023Reach SelfbloodNo ratings yet

- Ad 2010Document1 pageAd 2010Reach SelfbloodNo ratings yet

- Taxi N.Document1 pageTaxi N.Reach SelfbloodNo ratings yet

- Vour Order NumberDocument1 pageVour Order NumberReach SelfbloodNo ratings yet

- 8505 E8-01Document1 page8505 E8-01Reach SelfbloodNo ratings yet

- Quiz 2 PNGE-492Document4 pagesQuiz 2 PNGE-492Reach SelfbloodNo ratings yet

- Quiz For Geoheat PumpsDocument2 pagesQuiz For Geoheat PumpsReach SelfbloodNo ratings yet

- Assoc. Prof. Dr. Attila AYDEMIRDocument26 pagesAssoc. Prof. Dr. Attila AYDEMIRReach SelfbloodNo ratings yet

- Quiz For Dry-SteamDocument4 pagesQuiz For Dry-SteamReach SelfbloodNo ratings yet

- TD 302 Cemp EEx-d Technische Catalogus ATEX 63-315Document87 pagesTD 302 Cemp EEx-d Technische Catalogus ATEX 63-315TrePcaNo ratings yet

- RNPP-311M - EN Phase FailureDocument8 pagesRNPP-311M - EN Phase FailureZhak M. MuneneNo ratings yet

- Screw CompressorDocument12 pagesScrew Compressorantiokia100% (2)

- Lecture Notes: Volume-1Document109 pagesLecture Notes: Volume-1jitendra23157No ratings yet

- C6 6Document34 pagesC6 6alejandro sanchez100% (1)

- Presentation - Gate FixingDocument11 pagesPresentation - Gate FixingAshutosh DubeyNo ratings yet

- Linear Motor For Maglev TrainDocument3 pagesLinear Motor For Maglev TrainSandeep ThakurNo ratings yet

- New TendersDocument88 pagesNew TendersPradeep Kumar100% (1)

- PT Arutmin Indonesia Future Product Alternative and Potential MarketDocument6 pagesPT Arutmin Indonesia Future Product Alternative and Potential MarketkresnoNo ratings yet

- Technical Data: TimberjackDocument4 pagesTechnical Data: TimberjackOgnjen KovacevicNo ratings yet

- Oil Treaters: (Simplified Schematic of A Vertical Heater-Treater)Document7 pagesOil Treaters: (Simplified Schematic of A Vertical Heater-Treater)rohit aroraNo ratings yet

- DH 10cDocument2 pagesDH 10cmohammed8051No ratings yet

- Robo WarsDocument10 pagesRobo Warsmanish kumarNo ratings yet

- Craftsman Hedge Trimmer Attachment 316.792490Document20 pagesCraftsman Hedge Trimmer Attachment 316.792490Dan CarsonNo ratings yet

- Sandvik DL431 TS2-274 - 03Document4 pagesSandvik DL431 TS2-274 - 03Anonymous UXEtI80kNo ratings yet

- Cooling Coil Design (SI Units)Document3 pagesCooling Coil Design (SI Units)Christopher PersaudNo ratings yet

- Fdocuments - in Compeo User Manual v224 Engl Corr Flytec As With All The Other Operating InstructionsDocument53 pagesFdocuments - in Compeo User Manual v224 Engl Corr Flytec As With All The Other Operating InstructionsVladimir PetrovNo ratings yet

- MaxDNA Based EHTC Calibration ProcedureDocument3 pagesMaxDNA Based EHTC Calibration ProcedureSanjay Chakraborty100% (1)

- Sound - Wikipedia, The Free EncyclopediaDocument6 pagesSound - Wikipedia, The Free EncyclopediaRoshanaManjunathNo ratings yet

- 606tiristor PDFDocument1 page606tiristor PDFHernan G SalazarNo ratings yet

- Catalog KSH KSO 170 330Document16 pagesCatalog KSH KSO 170 330pmagneticsNo ratings yet

- Standard Industri Pembinaan: Construction Industry Development Board MalaysiaDocument61 pagesStandard Industri Pembinaan: Construction Industry Development Board MalaysiaMeredith Ham Anyi100% (1)

- LG Double Oven lwd3081st User ManualDocument36 pagesLG Double Oven lwd3081st User ManualFrankieNo ratings yet

- Piggyback TuningDocument11 pagesPiggyback TuningNilesh YengantiNo ratings yet

- RGB5050LEDDocument8 pagesRGB5050LEDEko SutjiptoNo ratings yet

- Catalogo de Partes Lycoming O 235Document81 pagesCatalogo de Partes Lycoming O 235Rodol MarskeNo ratings yet

PNGE-492 Geothermal Energy Technologies: Exploration Techniques and Drilling

PNGE-492 Geothermal Energy Technologies: Exploration Techniques and Drilling

Uploaded by

Reach SelfbloodOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PNGE-492 Geothermal Energy Technologies: Exploration Techniques and Drilling

PNGE-492 Geothermal Energy Technologies: Exploration Techniques and Drilling

Uploaded by

Reach SelfbloodCopyright:

Available Formats

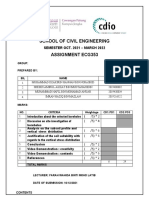

PNGE-492 Geothermal Energy Technologies

Exploration Techniques and Drilling

Name and Surname :

Department :

No :

QUESTIONS

1. Write 3 items of the phases of exploration program.

2. What kind of results and/or maps are obtained after a geological survey program.

3. What kind of results and/or maps are obtained after a hydrological survey program.

4. What kind of measurements and/or surveys are performed during a geophysical program.

5. Try to remember 3 elements in a well-pad and write them.

6. Explain the drill string elemets and explain what is the role of drill-collars.

7. Write the functions of drilling mud.

8. Why do we run the casing and cement the well-bore?

9. What is the reason for the “Deepwater Horizon” disaster?

10. What is the role of Blow-out Preventer (BOP) in the drilling rig?

ANSWERS

1. Well Site Selection, Well Design, Drilling Plan

2. The results which may give information about rock types, sediments and faults.

3. The results gives how much water exist there and helps us to analyze whether we

should drill a well there or not.

4. The seismic surveys, gravity analysis, resistivity can be given as a example.

5. Reserve pit, Suction tank and Shaker tank

6. Drillpipes: Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is

used on drilling rigs

BHA: It is a component of a drilling rig. It is the lowest part of the drill string,

extending from the bit to the drill pipe.

Drill Bit: A drill bit is a tool used to cut or crush rock.

Drill Collar: Their principal purpose in the drill string is to provide the axial force

needed to advance the drill bit

7. The functions of drilling mud, removes cuttings from well, suspend and release

cuttings, control formation pressures, maintain wellbore stability and cools lubricates

and supports the bit and drilling assembly.

8. Because restriction of fluid movement between permeable zones, provision of

mechanical support of the casing string, protection of casing from corrosion, support

of the well-bore walls to prevent collapse of formations are needed.

9. The people who planned the well did not include enough cement between the 7-inch

production casing and the 9 7/8-inch protection casing.

10. It is a safety equipment designed to prevent uncontrolled flow of formation fluids

during drilling and completion operations.

You might also like

- Vacuum Pump Removal - Installation (Skyactiv-D 2.2)Document3 pagesVacuum Pump Removal - Installation (Skyactiv-D 2.2)toywrc100% (2)

- Dipmeter Surveys in Petroleum ExplorationFrom EverandDipmeter Surveys in Petroleum ExplorationRating: 5 out of 5 stars5/5 (1)

- Back Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelDocument4 pagesBack Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelWisnu Andra Isdianto100% (1)

- Astm B344-01Document3 pagesAstm B344-01Srinivasan KrishnamoorthyNo ratings yet

- ECG353 - Chapter 1 - Sub Surface Exploration - Part 1Document32 pagesECG353 - Chapter 1 - Sub Surface Exploration - Part 1Faiz JaafarNo ratings yet

- Module 3 - Prospecting and ExplorationDocument17 pagesModule 3 - Prospecting and ExplorationSkeptical DoolaNo ratings yet

- Res Lab 1Document10 pagesRes Lab 1Ali NasirNo ratings yet

- Ce 902Document12 pagesCe 902Ak AyonNo ratings yet

- 2012.11.14 - How To Read and Understand A Geotechnical Report (Part 2)Document24 pages2012.11.14 - How To Read and Understand A Geotechnical Report (Part 2)UALU333No ratings yet

- Well DesignDocument92 pagesWell Designammarrafei100% (1)

- Water Well Drilling &developmentDocument94 pagesWater Well Drilling &developmentZiad AshrafNo ratings yet

- Foundation Eng. 2015-2016Document138 pagesFoundation Eng. 2015-2016Shekibullah MoushfiqNo ratings yet

- Expression of Interest Design of Earth Cut Stability by The Use of Slope/W and WallapDocument6 pagesExpression of Interest Design of Earth Cut Stability by The Use of Slope/W and WallapUý ĐạiNo ratings yet

- Allowable Set For Large Dia PilesDocument2 pagesAllowable Set For Large Dia Pileserkarthik85No ratings yet

- Exam For Hydrogeologist (2005)Document22 pagesExam For Hydrogeologist (2005)Workneh TemesgenNo ratings yet

- Ministry of Higher Education and Scientific Research Karbala University College of Engineering Petroleum Engineering DepartmentDocument10 pagesMinistry of Higher Education and Scientific Research Karbala University College of Engineering Petroleum Engineering Departmentسجاد كريم هاشم سماويNo ratings yet

- Trench and Excavation Support Options and Excavation Slope Design - An Online Course For Engineers and ArchitectsDocument8 pagesTrench and Excavation Support Options and Excavation Slope Design - An Online Course For Engineers and ArchitectsAlejandro GonzalezNo ratings yet

- Coring & Coring Analysis 2Document21 pagesCoring & Coring Analysis 2Reband Azad100% (1)

- Foundation Handout PDFDocument78 pagesFoundation Handout PDFአንተነህ ኃይሌ ክንፈገብርኤል100% (1)

- Final IntershipDocument18 pagesFinal IntershipRiya SantoshwarNo ratings yet

- Sample Chapter - Oil and Gas Well Drilling Technology PDFDocument19 pagesSample Chapter - Oil and Gas Well Drilling Technology PDFDavid John100% (1)

- Site Investigation-ObjectivesDocument22 pagesSite Investigation-ObjectivesTaimoor AhmadNo ratings yet

- Actual Geotech GRP WRKDocument11 pagesActual Geotech GRP WRKOtwua ArthurNo ratings yet

- Work Procedure Auger Bore Secant Pile Sta 8.600 PT - Ejjv - HJBLDocument7 pagesWork Procedure Auger Bore Secant Pile Sta 8.600 PT - Ejjv - HJBLejjv.indonesia.123No ratings yet

- Foundation Engineering Course: Fourth Year of Civil EngDocument43 pagesFoundation Engineering Course: Fourth Year of Civil Engarno assassinNo ratings yet

- Chapter 3Document14 pagesChapter 3Stephen SogahNo ratings yet

- Chapter 4: Subsurface InvestigationDocument21 pagesChapter 4: Subsurface InvestigationHisham MohamadNo ratings yet

- UZ CE406 Course Design - February 2020-1Document5 pagesUZ CE406 Course Design - February 2020-1kundayi shavaNo ratings yet

- 31 MI136 Rock Mechanics IIDocument2 pages31 MI136 Rock Mechanics IISealdeSaNo ratings yet

- IEM Bored Pile Supervision - 19112015Document81 pagesIEM Bored Pile Supervision - 19112015TanNo ratings yet

- Ecg 353 Mini ProjectDocument20 pagesEcg 353 Mini ProjectFaiz JaafarNo ratings yet

- 5 Tunnels PDFDocument21 pages5 Tunnels PDFMalik Muhammad Nauman ZiaNo ratings yet

- Cle2013 Advanced-foundation-Engineering TH 1.1 47 Cle2013Document2 pagesCle2013 Advanced-foundation-Engineering TH 1.1 47 Cle2013Mani chandanNo ratings yet

- Foundation EngineeringDocument170 pagesFoundation Engineeringprabeshkarkiii143No ratings yet

- Title Defense: Yangon Technological University Department of Petroleum EngineeringDocument17 pagesTitle Defense: Yangon Technological University Department of Petroleum EngineeringJames MilzerNo ratings yet

- 02 Drilling Preparation - UI 15 Sep 2006Document18 pages02 Drilling Preparation - UI 15 Sep 2006Dian L.No ratings yet

- Introduction To Geotechnical EngineeringDocument25 pagesIntroduction To Geotechnical EngineeringgeethaNo ratings yet

- Reservoir Petrophysics Q PDFDocument11 pagesReservoir Petrophysics Q PDFhusseinNo ratings yet

- Chapter 5 (Subsurface Exploration)Document46 pagesChapter 5 (Subsurface Exploration)nabihahNo ratings yet

- Recovery of Samples: Abdul Matin Department of Geology University of CalcuttaDocument18 pagesRecovery of Samples: Abdul Matin Department of Geology University of CalcuttaArghyadip MukherjeeNo ratings yet

- Fe Unit 1Document48 pagesFe Unit 1Duraid FalihNo ratings yet

- Stub Setting ReportDocument7 pagesStub Setting ReportUanaid Van RooyenNo ratings yet

- Geotechnical InvestigationsDocument85 pagesGeotechnical InvestigationsAmpumuza MmukundaNo ratings yet

- Meng 471 Assignment 2Document19 pagesMeng 471 Assignment 2AkibNo ratings yet

- Proposal Ready 4 (Dr. Aneela Wakeel) RevisedDocument15 pagesProposal Ready 4 (Dr. Aneela Wakeel) RevisedIrfanButtNo ratings yet

- 2013 Lab ManualDocument92 pages2013 Lab Manualaumi77No ratings yet

- Syllabi M.Tech. WRDMDocument114 pagesSyllabi M.Tech. WRDMMadhab KoiralaNo ratings yet

- Lec 2 Subsurface Investigation or ExplorationDocument22 pagesLec 2 Subsurface Investigation or ExplorationShahid KhanNo ratings yet

- Subsurface Exploration: Garbage in Garbage OutDocument77 pagesSubsurface Exploration: Garbage in Garbage OutMuhammad Usama Butt0% (1)

- School of Civil Engineering Assignment Ecg353: Semester Oct. 2021 - March 2022Document31 pagesSchool of Civil Engineering Assignment Ecg353: Semester Oct. 2021 - March 2022dzakirin hannan100% (1)

- Peng 311Document2 pagesPeng 311Abdul AhadNo ratings yet

- What Is Site Investigation?Document12 pagesWhat Is Site Investigation?Syazaa SalimNo ratings yet

- Earth & Rock Fill Dams 0MGT206 (PEC) : Syllabus For Master of Technology Civil Engineering (Geotechnical)Document3 pagesEarth & Rock Fill Dams 0MGT206 (PEC) : Syllabus For Master of Technology Civil Engineering (Geotechnical)krupaNo ratings yet

- Course Book of Foundation For Civil Engineering 2012-2013 PDFDocument23 pagesCourse Book of Foundation For Civil Engineering 2012-2013 PDFMomayKradookkradic100% (2)

- Fishing and Stuck Pipe PreventionDocument13 pagesFishing and Stuck Pipe Preventionairaghidario100% (1)

- Foundation Engineering IDocument70 pagesFoundation Engineering IbulchaNo ratings yet

- Foundation HandoutDocument78 pagesFoundation HandoutMc KaLiNo ratings yet

- Site InvestgationDocument11 pagesSite Investgationone engNo ratings yet

- Site Investigation: (Principal Steps) Literature SearchDocument4 pagesSite Investigation: (Principal Steps) Literature SearchInam UllahNo ratings yet

- Site InvestigationDocument5 pagesSite InvestigationKenneth KimondoNo ratings yet

- Guide To Cavern EngineeringDocument149 pagesGuide To Cavern EngineeringTan Jee PohNo ratings yet

- Geotech II Course OutlineDocument2 pagesGeotech II Course OutlineGbonga100% (1)

- Masonry 10 2nd Quarter Week 1Document6 pagesMasonry 10 2nd Quarter Week 1STEPHEN ANDRESNo ratings yet

- Fluid Mechanics Assignment TitleDocument3 pagesFluid Mechanics Assignment TitleReach SelfbloodNo ratings yet

- Dangerous Goods - Bayhanli-2 - O.1034682.04 - 13apr2023Document1 pageDangerous Goods - Bayhanli-2 - O.1034682.04 - 13apr2023Reach SelfbloodNo ratings yet

- Ad 2010Document1 pageAd 2010Reach SelfbloodNo ratings yet

- Taxi N.Document1 pageTaxi N.Reach SelfbloodNo ratings yet

- Vour Order NumberDocument1 pageVour Order NumberReach SelfbloodNo ratings yet

- 8505 E8-01Document1 page8505 E8-01Reach SelfbloodNo ratings yet

- Quiz 2 PNGE-492Document4 pagesQuiz 2 PNGE-492Reach SelfbloodNo ratings yet

- Quiz For Geoheat PumpsDocument2 pagesQuiz For Geoheat PumpsReach SelfbloodNo ratings yet

- Assoc. Prof. Dr. Attila AYDEMIRDocument26 pagesAssoc. Prof. Dr. Attila AYDEMIRReach SelfbloodNo ratings yet

- Quiz For Dry-SteamDocument4 pagesQuiz For Dry-SteamReach SelfbloodNo ratings yet

- TD 302 Cemp EEx-d Technische Catalogus ATEX 63-315Document87 pagesTD 302 Cemp EEx-d Technische Catalogus ATEX 63-315TrePcaNo ratings yet

- RNPP-311M - EN Phase FailureDocument8 pagesRNPP-311M - EN Phase FailureZhak M. MuneneNo ratings yet

- Screw CompressorDocument12 pagesScrew Compressorantiokia100% (2)

- Lecture Notes: Volume-1Document109 pagesLecture Notes: Volume-1jitendra23157No ratings yet

- C6 6Document34 pagesC6 6alejandro sanchez100% (1)

- Presentation - Gate FixingDocument11 pagesPresentation - Gate FixingAshutosh DubeyNo ratings yet

- Linear Motor For Maglev TrainDocument3 pagesLinear Motor For Maglev TrainSandeep ThakurNo ratings yet

- New TendersDocument88 pagesNew TendersPradeep Kumar100% (1)

- PT Arutmin Indonesia Future Product Alternative and Potential MarketDocument6 pagesPT Arutmin Indonesia Future Product Alternative and Potential MarketkresnoNo ratings yet

- Technical Data: TimberjackDocument4 pagesTechnical Data: TimberjackOgnjen KovacevicNo ratings yet

- Oil Treaters: (Simplified Schematic of A Vertical Heater-Treater)Document7 pagesOil Treaters: (Simplified Schematic of A Vertical Heater-Treater)rohit aroraNo ratings yet

- DH 10cDocument2 pagesDH 10cmohammed8051No ratings yet

- Robo WarsDocument10 pagesRobo Warsmanish kumarNo ratings yet

- Craftsman Hedge Trimmer Attachment 316.792490Document20 pagesCraftsman Hedge Trimmer Attachment 316.792490Dan CarsonNo ratings yet

- Sandvik DL431 TS2-274 - 03Document4 pagesSandvik DL431 TS2-274 - 03Anonymous UXEtI80kNo ratings yet

- Cooling Coil Design (SI Units)Document3 pagesCooling Coil Design (SI Units)Christopher PersaudNo ratings yet

- Fdocuments - in Compeo User Manual v224 Engl Corr Flytec As With All The Other Operating InstructionsDocument53 pagesFdocuments - in Compeo User Manual v224 Engl Corr Flytec As With All The Other Operating InstructionsVladimir PetrovNo ratings yet

- MaxDNA Based EHTC Calibration ProcedureDocument3 pagesMaxDNA Based EHTC Calibration ProcedureSanjay Chakraborty100% (1)

- Sound - Wikipedia, The Free EncyclopediaDocument6 pagesSound - Wikipedia, The Free EncyclopediaRoshanaManjunathNo ratings yet

- 606tiristor PDFDocument1 page606tiristor PDFHernan G SalazarNo ratings yet

- Catalog KSH KSO 170 330Document16 pagesCatalog KSH KSO 170 330pmagneticsNo ratings yet

- Standard Industri Pembinaan: Construction Industry Development Board MalaysiaDocument61 pagesStandard Industri Pembinaan: Construction Industry Development Board MalaysiaMeredith Ham Anyi100% (1)

- LG Double Oven lwd3081st User ManualDocument36 pagesLG Double Oven lwd3081st User ManualFrankieNo ratings yet

- Piggyback TuningDocument11 pagesPiggyback TuningNilesh YengantiNo ratings yet

- RGB5050LEDDocument8 pagesRGB5050LEDEko SutjiptoNo ratings yet

- Catalogo de Partes Lycoming O 235Document81 pagesCatalogo de Partes Lycoming O 235Rodol MarskeNo ratings yet