Professional Documents

Culture Documents

TORO 007: Technical Specification L00007-2 1/3

TORO 007: Technical Specification L00007-2 1/3

Uploaded by

Frank Prudencio ObregonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TORO 007: Technical Specification L00007-2 1/3

TORO 007: Technical Specification L00007-2 1/3

Uploaded by

Frank Prudencio ObregonCopyright:

Available Formats

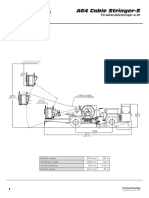

TECHNICAL SPECIFICATION

TORO 007 L00007-2

1/3

5377 (212“)

1745 (69“)

35°

3554 (140“)

2395 (94“)

1905 (75“)

1770 (70“)

4.6m³

(6.0 yd³)

810 (32“)

14°

420 (17“)

1268 (50“)

3017 (119“) 3500 (138“) 3164 (125“)

9681 (381“)

10199 (402“)

2550 (100“)

9“)

5 ( 12

6“)

25

R328

5(

42.5°

2 4 85

51

0 0 (9 8

24

R6

( 9 “)

5“

)

4193 (165“) 3-298972

131197JMI

SANDVIK TAMROCK reserves the right to change this ISO 9001

SANDVIK TAMROCK Corp., P.O. Box 434

specification without further notice FIN-20101 Turku, Finland

Tel. +358 20544131

Fax. +358 20544130

CERTIFICATED

www.toro.sandvik.com

FIRM

TECHNICAL SPECIFICATION

TORO 007 L00007-2

2/3

Main dimensions Standard tyres

Total length 9 680 mm (381") Size and type 18.00 x 25 L5S, Bridgestone

Width without bucket 2 485 mm (98") Air pressure, front 550 kPa (5,5 bar) (80 psi)

Maximum width 2 550 mm (100") Air pressure, rear 400 kPa (4,0 bar) (58 psi)

Std. height with safety canopy or cabin 2 395 mm (94") Other type of tyres available to user’s choice. In certain

Opt. height with safety canopy or cabin 2 515 mm (99") applications the productive capabilities of the loader may

Weights exceed the TKPH value given by tyre manufacturer.

Operating weight 26 200 kg (57 760 lb) Sandvik Tamrock recommend that the user consult their tyre

Total loaded weight 36 200 kg (79 800 lb) supplier to evaluate conditions and to find the best solution

Shipping weight 26 000 kg (57 320 lb) for application.

Axle weights without load: Standard Canopy

front axle 11 700 kg (25 800 lb) ROPS / FOPS certified canopy.

rear axle 14 500 kg (31 970 lb) Height 2395 mm (94”)

Axle weights with load: Steering hydraulics

front axle 27 050 kg (59 600 lb) Full hydraulic, centre-point articulation, power steering with

rear axle 9 150 kg (20 200 lb) two double acting cylinders. Steering controlled by stick.

Capacities Interlock protection. Emergency steering is optional.

Tramming capacity 10 000 kg (22 000 lb) Turning angle ±42,5°

Breakout force, lift 184 kN (18 800 kg) (41 400 lb) Turning radius with std bucket inner 3270 mm (129 ")

Breakout force, tilt 163 kN (16 600 kg) (36 600 lb) Turning radius with std bucket outer 6515 mm (256 ")

Tipping load 23 400 kg (51 600 lb) Main components in steering system:

Bucket std. 4,6 m3 (6.0yd3), HB500/400 Main valve Rexroth

Bucket motion times Servo control valve Rexroth

Raising time 7,5 sec. Steering cylinders 2 pcs, 125 mm (4.9 ")

Lowering time 4,0 sec. Steering and servo hydraulic Piston type, Rexroth

Tipping time 2,2 sec. pumps

Pressure settings:

Driving speeds forward and reverse Steering hydraulics, main relief valve 12.0MPa(120 bar)

1st gear 5,0 km/h (3.1 mph) Shock load valves 18.0MPa(180 bar)

2nd gear 9,2 km/h (5.7 mph)

3rd gear 15,2 km/h (9.4 mph) Bucket hydraulics

4th gear 26,5 km/h (16.5 mph) Monostick bucket and boom control (hydraulic). The bucket

hydraulics has two pumps. One is for the servo circuit and

Frame other delivers oil to the bucket hydraulic main valve. The oil

Rear and front frame Welded steel construction flow from steering hydraulic pump is directed to bucket

Material Raex 384 (St 52-3) hydraulics when steering is not used.

Central hinge Adjustable upper bearing Main components:

Material Raex 384 (St 52-3) Boom system Z-link

Tanks are welded to frame. Lift cylinders 2 pcs, ø160 mm (6.3 ")

Firewall Tilt cylinder 1 pcs, ø200 mm (7.9 ")

Standard engine Main valve Rexroth

Diesel engine Detroit S-50 DDEC IV Servo control valve Rexroth

(Euro Stage II / Tier II) Pump for bucket hydraulics Piston type, Rexroth

Output 187 kW (250 hp) / 1800-2100 r/min Fittings ORFS

Torque 1085 Nm/1350 r/min Hoses High temperature

Number of cylinders in line 4 Oil coolers for hydraulic &

Displacement 8 500 cm3 transmission oil,

Cooling system Water cooled up to 55°C ambient capability

Combustion principle 4-stroke/turbo, intercooler Pressure setting for:

Electric system 24V Servo circuit 3.5 MPa (35 bar)

Air filtering Donaldson Bucket hydraulics 25 Mpa (250 bar)

Exhaust system Catalytic purifier and muffler Shock load valves 28 MPa (280 bar)

Fuel tank capacity 310 l (80 gal.) Hydraulic oil tank capacity appr. 250 l (66 gal)

Standard converter and gearbox

Dana SOH, Electrical, logic controlled gear

MHR33425 selection

Standard axles

Front axle Dana SOH, 19D 2748 Posi-Stop, with Posi-

Torq differentials, fixed

Rear axle Dana SOH, 19D 2748 Posi-Stop, with Posi-

Torq differentials, oscillating ± 8°. Oscillation

with roller bearings

SANDVIK TAMROCK reserves the right to change this ISO 9001

SANDVIK TAMROCK Corp., P.O. Box 434

specification without further notice FIN-20101 Turku, Finland

Tel. +358 20544131

Fax. +358 20544130

CERTIFICATED

www.toro.sandvik.com

FIRM

TECHNICAL SPECIFICATION

TORO 007 L00007-2

3/3

Standard brakes Optional equipment

Service brakes are spring applied, hydraulically released * replaces standard equipment

multidisc wet brakes (Posi-Stop) on all wheels, two separate • * Deutz BF6M1013-ECP, 182 kW/2100 r/min (247hp)

circuits for the front and rear axle. Service brakes also • * Bucket size 4.0 m3 (5.2yd3), width 2550 mm(100”),

function as an emergency and parking brake. Electrically HB500/400.

driven pump for brake releasing. • * Bucket size 5.0 m3 (6.5yd3), width 2550 mm (100”),

Main components in the brake system: HB500/400.

Pressure accumulator Bosch • * Bucket size 5.4 m3 (7.0yd3), width 2550 mm (100”),

Brake pedal valve Mico HB500/400

Charging valve Parker • * Ejector bucket size 4.6 m³ (6.0yd³), width 2770 mm (109”),

Standard Lubrication system HB500/400.

Centralized manual lubrication, • * ROPS/FOPS safety cabin incl. air cond., Electric steering

dog bone pins with grease chamber & bucket & boom controls with sticks, height 2395 mm (94”).

Electrical equipment • * Automatic central lubrication.

Alternator 70 A • * Tyre 23,5* 25 L5 S/BS.

Batteries 2 x 12 V • Automatic gear shift control.

Starter 9 kW • Fire suppression system ANSUL, two tank system with 8

Driving and working lights front, 4 pcs (H1 55 W) nozzles (CEN).

rear, 4 pcs (H1 55 W) • Fire extinguisher 12 kg (CEN).

Electrical gauges fuel gauge,signal light for hydraulic oil • Additional spare part manual.

level • Additional workshop manual.

Others • Cat Base spare part manual.

Fire audited. • TORO RRC system, complete.

Decal language ENG/FIN/SWE/RUS/SPA/DEU/FRA. • RRC interface (TORO std.).

Standard manuals • RRC recovery kit, hook incl.

3pcs Spare part manual: • Automatic brake activation ABA.

Operation instructions main European languages • Ride control system for boom.

Maintenance instructions main European languages • Load weighing device, Tamtron PKV 200

Engine spare part information English • Emergency steering (CEN).

Machine spare part information English • Exhaust pipe covering, GREY SLEEVE (CEN).

Workshop manual • HTI covered Turbo.

Operation instructions main European languages • HTI covered exhaust manifold.

Maintenance instructions main European languages • Auto engine shut down, ANSUL / DDEC.

Engine workshop manual Original • Hydraulic oil fill up pump (through filter).

Power train components manual Original

• Repair kit for hydraulic pipes.

Optional equipment instructions English

• Spare wheel 18.00*25L5S/BS.

• Spare rim (18.00*25).

• Accordance with CE-norms (CEN).

• Disassembly needed shaft dim: _____ mm x _____ mm.

SANDVIK TAMROCK reserves the right to change this ISO 9001

SANDVIK TAMROCK Corp., P.O. Box 434

specification without further notice FIN-20101 Turku, Finland

Tel. +358 20544131

Fax. +358 20544130

CERTIFICATED

www.toro.sandvik.com

FIRM

You might also like

- Grove TMS540Document24 pagesGrove TMS540soporte tecnicoNo ratings yet

- Grove RT855BDocument22 pagesGrove RT855BMochamad RomiNo ratings yet

- GMK-5240 240T1Document16 pagesGMK-5240 240T1gabriel quinteroNo ratings yet

- The Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingFrom EverandThe Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingRating: 5 out of 5 stars5/5 (2)

- 314Document65 pages314dim4erema100% (3)

- Solid Works Tutorial 2001Document262 pagesSolid Works Tutorial 2001anurak.aun100% (9)

- MINI Cooper Service Manual: 2002-2006 - Table of ContentsDocument2 pagesMINI Cooper Service Manual: 2002-2006 - Table of ContentsBentley Publishers40% (5)

- How I Cured My Eye FloatersDocument6 pagesHow I Cured My Eye Floaters54321anon100% (2)

- Toro 50: Technical Specification T0050-3 1/2Document2 pagesToro 50: Technical Specification T0050-3 1/2GeotecoNo ratings yet

- Ficha TecnicaDocument14 pagesFicha TecnicaAna Karen Becerra LoeraNo ratings yet

- Toro50 SpecDocument3 pagesToro50 SpecAli Narváez quispeNo ratings yet

- Grove ATS540 SpecDocument26 pagesGrove ATS540 SpecHoward HoacNo ratings yet

- Sandvik LH409E (9 - 6t)Document3 pagesSandvik LH409E (9 - 6t)Дмитрий АсташонокNo ratings yet

- RT500DXL: Rough Terrain Hydraulic CraneDocument14 pagesRT500DXL: Rough Terrain Hydraulic CraneHoward Hoac100% (1)

- Grove RT500D SpecDocument14 pagesGrove RT500D SpecHoward HoacNo ratings yet

- Grove Yb4415 SpecificationsDocument22 pagesGrove Yb4415 SpecificationsGuillermo MendozaNo ratings yet

- Grove AT700DDocument14 pagesGrove AT700Djose jimenezNo ratings yet

- TORO 151 Electric: Technical Specification L00151E-2 1/3Document3 pagesTORO 151 Electric: Technical Specification L00151E-2 1/3EstyNo ratings yet

- Sandvik LH203: Technical SpecificationDocument6 pagesSandvik LH203: Technical SpecificationRigo McFly Casanova ArmijoNo ratings yet

- Sandvik LH203 15Document6 pagesSandvik LH203 15seidualimatu8364No ratings yet

- (LHD) Datasheet LH517Document7 pages(LHD) Datasheet LH517fik29100% (1)

- Dimensions: GROVE YB4415/YB4415XT 2Document21 pagesDimensions: GROVE YB4415/YB4415XT 2Howard HoacNo ratings yet

- Courtesy of Crane - MarketDocument18 pagesCourtesy of Crane - MarketCarlos Alberto Rosado VillanuevaNo ratings yet

- 109 6000 Series Eaton Char Lynn Parts 005 006.36180102Document8 pages109 6000 Series Eaton Char Lynn Parts 005 006.36180102Samuel Lopez Benites100% (1)

- 50tonne Crane Load ChartDocument13 pages50tonne Crane Load ChartmeowmeowchaiNo ratings yet

- GMK5240-Specifications Imperial 240 TONDocument16 pagesGMK5240-Specifications Imperial 240 TONGuillermo MendozaNo ratings yet

- Grove TMS700B NA BrochureDocument26 pagesGrove TMS700B NA BrochureNELSON CHAPARRONo ratings yet

- Toro 151 DDocument2 pagesToro 151 DFrank Pariona PaezNo ratings yet

- Grove AP206 SpecDocument10 pagesGrove AP206 SpecHoward HoacNo ratings yet

- At400 para 19 TonDocument18 pagesAt400 para 19 TonEdilsonNo ratings yet

- Grove GMK5200 GMK5240 SpecDocument10 pagesGrove GMK5200 GMK5240 SpecHoward HoacNo ratings yet

- Grove Rough Terrain Cranes Spec E160b3Document13 pagesGrove Rough Terrain Cranes Spec E160b3melNo ratings yet

- PDF Grove At400 DDDocument18 pagesPDF Grove At400 DDrichard cardenasNo ratings yet

- Rotator Baltrotors GR105Document3 pagesRotator Baltrotors GR105Anonymous 80HAPYsoNo ratings yet

- Grove Model Tm9120 - 120 Ton Capacity: Transportation Specs - Hydraulic Truck CranesDocument2 pagesGrove Model Tm9120 - 120 Ton Capacity: Transportation Specs - Hydraulic Truck CranesLudovic LandemaineNo ratings yet

- Grove GMK5150B SpecDocument26 pagesGrove GMK5150B SpecHoward HoacNo ratings yet

- 2023-01-21 - GROUND FLOOR - DETAIL-ModelDocument1 page2023-01-21 - GROUND FLOOR - DETAIL-ModelPranay GandhiNo ratings yet

- Rotator Baltrotors GR10Document3 pagesRotator Baltrotors GR10Anonymous 80HAPYsoNo ratings yet

- Sandvik LH307: Technical SpecificationDocument6 pagesSandvik LH307: Technical SpecificationRigo McFly Casanova ArmijoNo ratings yet

- LH307 PDFDocument6 pagesLH307 PDFRigo McFly Casanova Armijo100% (1)

- For Additional Details and Information. Please See Consult With Diebold Installation/Service BranchDocument4 pagesFor Additional Details and Information. Please See Consult With Diebold Installation/Service BranchDNSXNo ratings yet

- AirHawk MMR Air MaskDocument12 pagesAirHawk MMR Air MaskМеталл РокNo ratings yet

- Cementing: Applications Applications Applications Applications ApplicationsDocument2 pagesCementing: Applications Applications Applications Applications ApplicationsAquiles CarreraNo ratings yet

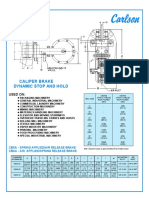

- Tech - Drawing - TD A64CableStringer S 01Document2 pagesTech - Drawing - TD A64CableStringer S 01MARTIN VALDEZNo ratings yet

- Carlson Energy Caliper BrakeDocument2 pagesCarlson Energy Caliper Brakehebert perezNo ratings yet

- Grove RT 890 SpecificationsDocument30 pagesGrove RT 890 SpecificationsNuno JesusNo ratings yet

- Track-Type Tractor D10T Track-Type Tractor RJG D10T Track-Type Tractor Rjg00001-Up (Machine) POWERED BY C27 EngineDocument3 pagesTrack-Type Tractor D10T Track-Type Tractor RJG D10T Track-Type Tractor Rjg00001-Up (Machine) POWERED BY C27 EnginemoisesNo ratings yet

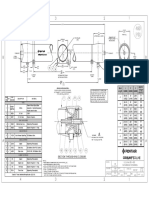

- Drawing No: Description: General TolerancesDocument2 pagesDrawing No: Description: General TolerancesCristian UrquidiNo ratings yet

- GMK5150L Product Guide Imperial 20200401Document36 pagesGMK5150L Product Guide Imperial 20200401Norman JeldesNo ratings yet

- Codeline Ecoline Drawing 80-450 Rev Q Total PDFDocument2 pagesCodeline Ecoline Drawing 80-450 Rev Q Total PDFHardik VavdiyaNo ratings yet

- 1TRS12 - StandardDocument1 page1TRS12 - StandardDass MNo ratings yet

- Grove RT750Document18 pagesGrove RT750Thibeault MesiliNo ratings yet

- All Terraln Hydrau1k:: CraneDocument18 pagesAll Terraln Hydrau1k:: CraneHoward HoacNo ratings yet

- Carraro 709 P2Document1 pageCarraro 709 P2davi henrique boazNo ratings yet

- GRT8100 Product Guide ImperialDocument32 pagesGRT8100 Product Guide ImperialMahfuja HoqueNo ratings yet

- NautoPilot 5000Document4 pagesNautoPilot 5000Richard Duran MolinaNo ratings yet

- Sandvik Off Highway Dump Trucks Spec 19f2aaDocument2 pagesSandvik Off Highway Dump Trucks Spec 19f2aaИгорь ИвановNo ratings yet

- Grove Crane YB4408aDocument14 pagesGrove Crane YB4408aAbrão GarciaNo ratings yet

- Especifications HP125B-LPDocument1 pageEspecifications HP125B-LPQike FlowersNo ratings yet

- GRT880 Product Guide ImperialDocument16 pagesGRT880 Product Guide ImperialMiguel HernandezNo ratings yet

- The Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsFrom EverandThe Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsNo ratings yet

- Empirical Dynamic Asset Pricing: Model Specification and Econometric AssessmentFrom EverandEmpirical Dynamic Asset Pricing: Model Specification and Econometric AssessmentRating: 4.5 out of 5 stars4.5/5 (3)

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- Worksheet MAPEH Arts Q4-W3Document4 pagesWorksheet MAPEH Arts Q4-W3Hezel Mercado EdrozoNo ratings yet

- Lightolier Lytecaster 7-11 Downlights Brochure 1980Document8 pagesLightolier Lytecaster 7-11 Downlights Brochure 1980Alan MastersNo ratings yet

- Week1 - FEE GIKIDocument38 pagesWeek1 - FEE GIKIHadeedAhmedSherNo ratings yet

- Management Science: Definition, Characteristics and ToolsDocument6 pagesManagement Science: Definition, Characteristics and ToolsAmzelle Diego LaspiñasNo ratings yet

- Codemap - 2021 No-Code Market ReportDocument34 pagesCodemap - 2021 No-Code Market ReportLogin AppsNo ratings yet

- Jeetendra Sharma ResumeDocument6 pagesJeetendra Sharma Resumer_awadhiyaNo ratings yet

- Sa Pula, Sa PutiDocument84 pagesSa Pula, Sa PutiLuvina Amor Belarma0% (2)

- Media Converter Datasheet: HighlightsDocument2 pagesMedia Converter Datasheet: HighlightsJames JamesNo ratings yet

- IPT Full MaterialsDocument197 pagesIPT Full Materialsabenezer milkiasNo ratings yet

- Tugas Uas Miss LennyDocument8 pagesTugas Uas Miss LennyZiyan Khoirun hakimNo ratings yet

- Journaling PDFDocument1 pageJournaling PDFMargarita Maria Botero PerezNo ratings yet

- Summary of VBA For Scientific Computing 9-25-2013 v1Document19 pagesSummary of VBA For Scientific Computing 9-25-2013 v1lionfierce123No ratings yet

- Flyer 2nd Page 2019 2020Document3 pagesFlyer 2nd Page 2019 2020Sandra JalmascoNo ratings yet

- Composition 1 S2 2020 FinalDocument46 pagesComposition 1 S2 2020 Finalelhoussaine.nahime00No ratings yet

- Documentation FlutterDocument12 pagesDocumentation FlutterIvhan SalazarNo ratings yet

- Honeywell Actuator M7410EDocument6 pagesHoneywell Actuator M7410EFrinaru CiprianNo ratings yet

- DisabilityDocument34 pagesDisabilitymeghnaumNo ratings yet

- MSTE Nov 2021 Licensure Exam - (2) - 220425 - 092318Document155 pagesMSTE Nov 2021 Licensure Exam - (2) - 220425 - 092318Chantal Faye GacusanNo ratings yet

- FBFP UserGuide 2 21Document88 pagesFBFP UserGuide 2 21Zlatko OžanićNo ratings yet

- Sikolohiyang Pilipino Midterm Summary OlfuDocument10 pagesSikolohiyang Pilipino Midterm Summary OlfuMark ShelloNo ratings yet

- Temperature Prediction For Reheating Furnace by Gated Recurrent Unit ApproachDocument8 pagesTemperature Prediction For Reheating Furnace by Gated Recurrent Unit ApproachRodrigo LimaNo ratings yet

- Qualitative Research NotesDocument8 pagesQualitative Research NotesAnanta SinhaNo ratings yet

- QuestionsDocument5 pagesQuestionsrajasamygopalNo ratings yet

- Bilassa Tablet ENG sPAR - 09001bee81ad53dbDocument3 pagesBilassa Tablet ENG sPAR - 09001bee81ad53dbnada mawaddahNo ratings yet

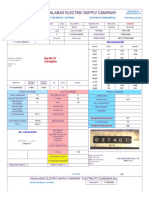

- Fesco Online BillDocument2 pagesFesco Online BillFaisal NaveedNo ratings yet

- English in The Middle AgesDocument216 pagesEnglish in The Middle AgesAna Basarte100% (2)