Professional Documents

Culture Documents

Peltier Thermoelectric Cooling Module

Peltier Thermoelectric Cooling Module

Uploaded by

Mark Genesis AlanoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Peltier Thermoelectric Cooling Module

Peltier Thermoelectric Cooling Module

Uploaded by

Mark Genesis AlanoCopyright:

Available Formats

VOLUME-7, ISSUE-2, FEBRUARY-2018 • PRINT ISSN No 2277 - 8160

Original Research Paper ENGINEERING

PELTIER THERMOELECTRIC COOLING MODULE

Ankur Mishra IIMT College of Engineering, Greater Noida

Manoj Kumar IIMT College of Engineering, Greater Noida

The present air conditioning system produces cooling effect by refrigerants like Freon, Ammonia, etc..Using these

ABSTRACT refrigerants can get maximum output but one of the major disadvantages is harmful gas emission and global

warming. These problem can be overcome by using thermoelectric modules (Peltier effect) air-conditioner and their by protecting the

environment. The present paper deals with the study of Thermoelectric air conditioner using different modules is discussed. Thermoelectric

cooling systems have advantages over conventional cooling devices, such as compact in size, light in weight, high reliability, no mechanical

moving parts and no working uid.

KEYWORDS : Peltier effect, Thermoelectric Cooling

1. INTRODUCTION this effect may be reversed whereby a change in the direction of

Refrigeration is the process of heat-removal from a space in order to electric current ow will reverse the direction of heat ow

bring it to a lower temperature than surrounding temperature. In

this context, my seminar topic, “Peltier cooling module” which works 1.1.2 The Seebeck effect

on thermoelectric refrigeration, aims to provide cooling by using The Seebeck effect is the conversion of heat directly into electricity

thermoelectric effects rather than the more prevalent conventional at the junction of dissimilar electrical conductors. It is named for the

methods like ‘vapour compression cycle’ or the ‘vapour absorption Baltic German physicist Thomas Johann Seedbeck.

cycle’. There are three types of thermoelectric effect: The Seebeck

effect, the Peltier effect, the Thomson effect. From these three

effects, Peltier cooler works on the Peltier effect; which states that

when voltage is applied across two junctions of dissimilar electrical

conductors, heat is absorbed from one junction and heat is rejected

at another junction.

Peltier coolers are basically used as a cooling element in laser

diodes, CCD cameras (charge coupled device), blood analyzers,

portable picnic coolers laser diodes, microprocessors, blood

analyzers and portable picnic coolers As shown in Figure , the conductors are two dissimilar metals

denoted as material A and material B. The junction temperature at A

1.1 Thermoelectric effect is used as a reference and is maintained at a relatively cool

The thermoelectric effect is the direct conversion of temperature temperature (TC). The junction temperature at B is used as

differences to electric voltage and vice versa. A thermoelectric temperature higher than temperature TC. With heat applied to

device creates voltage when there is a different temperature on junction B, a voltage (Eout) will appear across terminals T1 and T2

each side. Conversely, when a voltage is applied to it, it creates a and hence an electric current would ow continuously in this closed

temperature difference. At the atomic scale, an applied temperature circuit. This voltage is known as the Seebeck EMF, can be expressed

gradient causes charge carriers in the material to diffuse from the as Eout = α (TH - TC)

hot side to the cold side. The term "thermoelectric effect"

encompasses three separately identi ed effects: the Seebeck effect, 1.1.3 The Thomson effect

Peltier effect, and Thomson effect. As per the Thomson effect, when an electric current is passed

through a conductor having a temperature gradient over its length,

1.1.1 The Peltier effect heat will be either absorbed by or expelled from the conductor.

Peltier found there was an opposite phenomenon to the Seebeck Whether heat is absorbed or expelled depends on the direction of

Effect, whereby thermal energy could be absorbed at one dissimilar both the electric current and temperature gradient. This

metal junction and discharged at the other junction when an phenomenon is known as the Thomson Effect.

electric current owed within the closed circuit.

In Figure above, the circuit is modi ed to obtain a different

con guration that illustrates the Peltier Effect, a phenomenon 2. Working of Peltier cooler

opposite that of the Seebeck Effect. If a voltage (Ein) is applied to The Peltier effect occurs whenever electrical current ows through

terminals T1 and T2, an electrical current (I) will ow in the circuit. As two dissimilar conductors; depending on the direction of current

a result of 3 the current ow, a slight cooling effect (QC) will occur at ow, the junction of the two conductors will either absorb or release

thermocouple junction A (where heat is absorbed), and a heating heat. In the world of thermoelectric technology, semiconductors

effect (QH) will occur at junction B (where heat is expelled). Note that (usually Bismuth Telluride) are the material of choice for producing

6 X GJRA - GLOBAL JOURNAL FOR RESEARCH ANALYSIS

VOLUME-7, ISSUE-2, FEBRUARY-2018 • PRINT ISSN No 2277 - 8160

the Peltier effect because they can be more easily optimized for

pumping heat. Using this type of material, a Peltier device (i.e.,

thermoelectric module) can be constructed in its simplest form

around a single semiconductor “pellet” which is soldered to

electrically-conductive material on each end (usually plated

copper). In this con guration, the second dissimilar material

required for the Peltier effect, is actually the copper connection

paths to the power supply.

3. Peltier cooling with N-type semiconductor

In Figure below, “N-type” semiconductor material is used to

fabricate the pellet so that electrons (with a negative charge) will be

the charge carrier employed to create the bulk of the Peltier effect. A typical TEC module comprises of two highly thermally conductive

N-type semi-conductor has a extra electron in its Fermi level (higher substrates (A12O3, AlN, BeO) that serve as Hot/Cold plates. An array

energy level). of p-type and n-type semiconductor (Bi2Te3, Sb2Te3, Bi2Se3, PbTe,

Si-Ge) pellets are connected electrically in series sandwiched

between the substrates. The device is normally attached to the cold

side of the TEC module, and a heat sink which is required for

enhanced heat dissipation is attached to the hot side. Solder is

normally used to connect the TEC elements onto the conducting

pads of the substrates. The construction of a single stage

thermoelectric module is shown in Figure

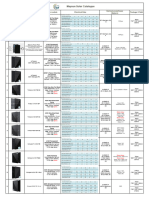

6. Speci cation

I max.: 6.0A, Delta T max.: 152.6°F, Voltage:15.4V, Q max.: 51.4W,

Number of couples: 127, Melcor type: CP1.4-127-06L, Dimensions:

1.6" x 1.6" x 0.15", Wire Lead Length: 8", Aluminium Heat Sink :

205W/Mk

7. Governing Equations

With a DC voltage source connected as shown, electrons will be 7.1 Cooling power

repelled by the negative pole and attracted by the positive pole of

the supply; due to this attraction, electrons at Fermi level move

towards positive terminal by releasing heat and creating the holes in

the Fermi level. Now, due to continuous supply of current, electrons

move from valance band (lower energy band) to Fermi level by 7.2 Power consumed

absorbing energy from the junction. With the electrons owing

through the N-type material from bottom to top, heat is absorbed at

the bottom junction and actively transferred to the top junction.

4. Peltier cooling with P & N type of semiconductors 7.3 Coefficient of performance

By arranging N and P-type pellets in a “couple” (see Figure ) and

forming a junction between them with a plated copper tab, it is

possible to con gure a series circuit which can keep all of the heat

moving in the same direction. As shown in the illustration, with the

free 8 (bottom) end of the P-type pellet connected to the positive

voltage potential and the free (bottom) end of the N-type pellet

7.4 Maximum cooling power

similarly connected to the negative side of the voltage. As we have

seen in previous section, for N-type of semiconductor, heat is

absorbed from the junction near to the negative terminal and heat

is releases at the junction near to the positive terminal. For P-type of

semiconductor, heat is absorbed from the junction near to positive

terminal and released at the junction near to negative terminal. 8. Conclusion

Since Peltier cooling is not efficient comparatively and due to its

small size applications, it is not widely used. It found its application

only in electronics cooling etc. But,we have seen that there is a huge

scope of research in this eld about thermoelectric materials,its

fabrication, heat sink design etc. Researcher are working on

reducing irreversibilities in the systems, because Peltier cooler has

more potential which we can see from the vast difference between

value of rst law efficiency and second law efficiency.

REFERENCES

1. Versteeg, Owen. "Peltier Element Identi cation". Retrieved 14 October 2013.

2. Kotlyarov, Evgeny; Peter de Crom; Raoul Voeten (2006). "Some Aspects of Peltier-

Cooler Optimization Applied for the Glove Box Air Temperature Control". SAE

5. Fabrication of Peltier cooler International

As we have seen in previous section, for producing thermoelectric 3. Hsu, Jeremy (2011-06-14). "Cold? Put this jacket on. Hot? Put this jacket on Climate-

controlled coat goes from zero to 100 degrees C 'in the ip of a button'". NBC News.

effect couples of P and N type semiconductors are connected in NBC. Retrieved 16 March 2013.

series by metal plates. By doing this it absorbs the heat from one side

and releases the heat to another side. So, when solid state P-N

materials are connected electrically in series and thermally in

parallel it makes one thermoelectric unit as shown in Figure.

GJRA - GLOBAL JOURNAL FOR RESEARCH ANALYSIS X 7

You might also like

- Thermoelectric Technical ReferenceDocument88 pagesThermoelectric Technical ReferencedmmaheshNo ratings yet

- Research Paper 23Document28 pagesResearch Paper 23Anshuman ShuklaNo ratings yet

- KedarIndian Conference PDFDocument5 pagesKedarIndian Conference PDFKedar A. MalusareNo ratings yet

- Introduction PeltierDocument8 pagesIntroduction PeltierShubham TiwariNo ratings yet

- Thermoelectric Technical ReferenceDocument54 pagesThermoelectric Technical ReferenceVikram BorkhediyaNo ratings yet

- Peltier Module and Its RefrigerationDocument7 pagesPeltier Module and Its RefrigerationAniket DusaneNo ratings yet

- Thermo Electric DevicesDocument5 pagesThermo Electric DevicesKedar A. MalusareNo ratings yet

- New Sistec Major ProjectDocument31 pagesNew Sistec Major ProjectArryan KhanNo ratings yet

- Thermoelectrics - Unit - VIIDocument8 pagesThermoelectrics - Unit - VIIAbdulbar kelilNo ratings yet

- Thermoelectric RefrigerationDocument58 pagesThermoelectric RefrigerationMaruthappan SundaramNo ratings yet

- Thermoelectric Devices: Cooling and Power GenerationDocument5 pagesThermoelectric Devices: Cooling and Power Generationankita awasthiNo ratings yet

- Thermoelectric Refrigerator For Travelling: Lalit Bansal Nitesh Kumar Jha Rohan Kanodiya Sandeep JhambDocument3 pagesThermoelectric Refrigerator For Travelling: Lalit Bansal Nitesh Kumar Jha Rohan Kanodiya Sandeep JhambLalit BanaalNo ratings yet

- Thermoelectric Power Generator Design and Selection From TE Cooling Module SpecificationsDocument4 pagesThermoelectric Power Generator Design and Selection From TE Cooling Module SpecificationschesskingNo ratings yet

- Bim Project ReportDocument4 pagesBim Project Reportelisha.owais1000No ratings yet

- Bicycle Based RefrigeratorDocument27 pagesBicycle Based RefrigeratorAanya SethNo ratings yet

- Solar Refrigeration Using Peltier EffectDocument15 pagesSolar Refrigeration Using Peltier EffectSyko GamingNo ratings yet

- InTech-A Review of Thermoelectric Mems Devices For Micro Power Generation Heating and Cooling ApplicationsDocument10 pagesInTech-A Review of Thermoelectric Mems Devices For Micro Power Generation Heating and Cooling ApplicationsSanooj SurendranNo ratings yet

- Thermoelectric Refrigerators - Docx FinalDocument12 pagesThermoelectric Refrigerators - Docx FinalShivam GaurNo ratings yet

- Peltier CoolingDocument13 pagesPeltier Coolingapi-243810683No ratings yet

- Peltier Effect ManualDocument5 pagesPeltier Effect ManualRangothri Sreenivasa SubramanyamNo ratings yet

- AppendixDocument20 pagesAppendixDexServNo ratings yet

- A Review On Generation of Electricity Using PeltieDocument5 pagesA Review On Generation of Electricity Using PeltieUsama SherwaniNo ratings yet

- Lect 16B Thermo Electric CoolersDocument17 pagesLect 16B Thermo Electric CoolersDian AhmedNo ratings yet

- Thermoelectric GeneratorDocument7 pagesThermoelectric GeneratorJinesh100% (1)

- SPICE Model of Thermoelectric Elements Including Thermal EffectsDocument5 pagesSPICE Model of Thermoelectric Elements Including Thermal EffectsLucas CarvalhoNo ratings yet

- Info para PreguntarDocument10 pagesInfo para PreguntarAgustin AvilaNo ratings yet

- Non - Conventional Energy Sources: 3 TopicDocument27 pagesNon - Conventional Energy Sources: 3 Topicshubham sharmaNo ratings yet

- Ref 1Document4 pagesRef 1soroushNo ratings yet

- Frequently Asked Questions About Our Cooling and Heating TechnologyDocument20 pagesFrequently Asked Questions About Our Cooling and Heating TechnologydoggybowNo ratings yet

- Fridge Using Pelteir CrystalDocument26 pagesFridge Using Pelteir CrystalSudhanshu BalodiNo ratings yet

- Fabrication of Solar Operated Heating and Cooling System Using Thermo-ElectricDocument5 pagesFabrication of Solar Operated Heating and Cooling System Using Thermo-ElectricCristhia CasasNo ratings yet

- Design and Fabrication of Thermo Electric RefrigeratorDocument6 pagesDesign and Fabrication of Thermo Electric RefrigeratorEditor IJTSRDNo ratings yet

- Thermoelectric Power Generation Peltier Element Versus Thermoelectric GeneratorDocument6 pagesThermoelectric Power Generation Peltier Element Versus Thermoelectric GeneratorMoh RhmNo ratings yet

- Thermoelectric Refrigeration: Comparision With Conventional Cooling SystemDocument15 pagesThermoelectric Refrigeration: Comparision With Conventional Cooling SystemKirandeep GandhamNo ratings yet

- Active Transducers - ThermocoupleDocument29 pagesActive Transducers - ThermocoupleKritika GuptaNo ratings yet

- Thermo Electric SeminarDocument17 pagesThermo Electric SeminarDebashish MohantyNo ratings yet

- Icmel 2008 4559288Document4 pagesIcmel 2008 4559288Mainul HossainNo ratings yet

- RaviDocument57 pagesRaviuntils139No ratings yet

- Project Work On Thermoelectric RefrigeratonDocument19 pagesProject Work On Thermoelectric RefrigeratonSatyajit RastogiNo ratings yet

- Final Peltier ReportDocument42 pagesFinal Peltier ReportChetan ChaudhariNo ratings yet

- Essentials of Thermoelectric (Te) Cooling: by Tony JosephDocument12 pagesEssentials of Thermoelectric (Te) Cooling: by Tony JosephsanjaydvgNo ratings yet

- ThermoelectricDocument21 pagesThermoelectricanupam kumarNo ratings yet

- Thermoelectric ConvertersDocument111 pagesThermoelectric ConvertersKamal Vijay Ram R SNo ratings yet

- Thermoelectric CoolingDocument68 pagesThermoelectric CoolingdabrevipulNo ratings yet

- Essentials of Thermoelectric CoolingDocument68 pagesEssentials of Thermoelectric Coolingvenkatesan appuNo ratings yet

- Thermoelectric Power GenerationDocument6 pagesThermoelectric Power GenerationDevi ArumugamNo ratings yet

- Unit ViDocument69 pagesUnit ViRavichandran SekarNo ratings yet

- Strachan Aspden - Electricity Without Magnetism?Document3 pagesStrachan Aspden - Electricity Without Magnetism?tak22No ratings yet

- PHYS430: Advanced Lab Laith Marzouka ID: Dr. Khaled Eid: Topic: Thermoelectric EffectDocument7 pagesPHYS430: Advanced Lab Laith Marzouka ID: Dr. Khaled Eid: Topic: Thermoelectric EffectLaith MarzoukaNo ratings yet

- Overview of Thermoelectric Power Generation Technologies-Various Opportunities With Solar'Document12 pagesOverview of Thermoelectric Power Generation Technologies-Various Opportunities With Solar'KISHORE PERUMALLANo ratings yet

- Fuzzy A Thermnoelectric Cooler: Temperature Control ofDocument6 pagesFuzzy A Thermnoelectric Cooler: Temperature Control ofAnupriya GhoshNo ratings yet

- Modeling and Analysis of Thermoelectric Modules: Simon Lineykin and Shmuel Ben-Yaakov, Member, IEEEDocument8 pagesModeling and Analysis of Thermoelectric Modules: Simon Lineykin and Shmuel Ben-Yaakov, Member, IEEErsrakesh97No ratings yet

- Application of Thermoelectric Modules As Renewable Energy SourcesDocument8 pagesApplication of Thermoelectric Modules As Renewable Energy SourcesSonsai QuiruNo ratings yet

- Thermoelectric Refrigeration SystemDocument9 pagesThermoelectric Refrigeration SystemIJRASETPublicationsNo ratings yet

- Thermoelectric Energy ConversionDocument4 pagesThermoelectric Energy ConversionMenchie LabadanNo ratings yet

- Design, Fabrication and Analysis of Thermo Electric RefrigeratorDocument5 pagesDesign, Fabrication and Analysis of Thermo Electric RefrigeratorMani KarthikeyanNo ratings yet

- Cogeneration Application Considerations: GE Power GenerationDocument24 pagesCogeneration Application Considerations: GE Power GenerationaustintanNo ratings yet

- Principles and Applications of Stirling Engines: C. D. WestDocument5 pagesPrinciples and Applications of Stirling Engines: C. D. WestChris BarolasNo ratings yet

- f2001254 Actuador BoosterDocument1 pagef2001254 Actuador BoosterWERMERMNo ratings yet

- NEW NEW: Silent Diesel Generating SetsDocument2 pagesNEW NEW: Silent Diesel Generating SetsMladen MarićNo ratings yet

- Exploring Solar Energy Student Guide (Seven Activities)Document17 pagesExploring Solar Energy Student Guide (Seven Activities)James KazoobaNo ratings yet

- Pachiyamman Body Builders SankariDocument6 pagesPachiyamman Body Builders SankariprabhakaranNo ratings yet

- (Judul) Stirling Engine PlansDocument6 pages(Judul) Stirling Engine PlansNandang Kuroshaki0% (1)

- High Pressure Boilers PDFDocument38 pagesHigh Pressure Boilers PDFgokul viratNo ratings yet

- Final Year Project 'Design of Waste Heat Recovery Unit For Engro Foods Sahiwal'Document1 pageFinal Year Project 'Design of Waste Heat Recovery Unit For Engro Foods Sahiwal'FarrukhAhmedKhanNo ratings yet

- Ge Mid Idm 6000 1.Lm6000 PerformanceDocument10 pagesGe Mid Idm 6000 1.Lm6000 PerformanceChristopher HamptonNo ratings yet

- 07 Visayas Indicative July 2023Document2 pages07 Visayas Indicative July 2023evhbartoloNo ratings yet

- Datasheet DXDocument2 pagesDatasheet DXAsnawirarrr100% (2)

- Diesel Cycle - Process, PV Diagram, Efficiency With Derivation & Applications (Explanation & PDF)Document7 pagesDiesel Cycle - Process, PV Diagram, Efficiency With Derivation & Applications (Explanation & PDF)Shivam SinghNo ratings yet

- Comparison of The Performance, Advantages and Disadvantages of Nuclear Power Generation Compared To Other Clean Sources of ElectricityDocument8 pagesComparison of The Performance, Advantages and Disadvantages of Nuclear Power Generation Compared To Other Clean Sources of ElectricityMbewu M'LuNo ratings yet

- 1250 kVA Genset Specifications PDFDocument8 pages1250 kVA Genset Specifications PDFRenny DevassyNo ratings yet

- Malik Eglf Ltac Opis - 30 Oct 2018 - Fir NotamDocument187 pagesMalik Eglf Ltac Opis - 30 Oct 2018 - Fir NotamAbdulazi AlnahdiNo ratings yet

- A Project Report Management Solar PlantDocument5 pagesA Project Report Management Solar PlantAditya LodhaNo ratings yet

- Maysun Solar CatalogueDocument3 pagesMaysun Solar CatalogueHaiducul DelteiNo ratings yet

- TweetersDocument67 pagesTweeterstunca_olcaytoNo ratings yet

- Conduc T: Market Interaction of FirmsDocument10 pagesConduc T: Market Interaction of FirmsChin Yee LooNo ratings yet

- Datasheet DZ Engine enDocument2 pagesDatasheet DZ Engine enMartin Kratky100% (1)

- MPPT (Victron Energy)Document14 pagesMPPT (Victron Energy)LucaNo ratings yet

- Repair & MaintenanceDocument14 pagesRepair & MaintenanceMohammad Ibnul Hossain100% (1)

- Applied Thermodynamics: Inst Ruct Ions T O Cand Idat EsDocument2 pagesApplied Thermodynamics: Inst Ruct Ions T O Cand Idat EsGourav BaliNo ratings yet

- Introduction To Direct Energy ConversionDocument33 pagesIntroduction To Direct Energy ConversionHuzaifa Wasim100% (3)

- Rumus Perhitungan Turbin UapDocument17 pagesRumus Perhitungan Turbin Uapricki yusufNo ratings yet

- Steam Turbine SolutionsDocument12 pagesSteam Turbine Solutionsdanioachim1945No ratings yet

- Betck105e Mod4@Azdocuments - inDocument17 pagesBetck105e Mod4@Azdocuments - inswathiswathi7895467No ratings yet

- PDD KelarDocument54 pagesPDD KelarKrishna SrinivasanNo ratings yet

- Steam System Basics: Watertube BoilersDocument4 pagesSteam System Basics: Watertube BoilersNaNo ratings yet