Professional Documents

Culture Documents

BTA Rotary Actuators: Saia-Burgess Solenoids

BTA Rotary Actuators: Saia-Burgess Solenoids

Uploaded by

Buenotech - Classificadores de frutasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BTA Rotary Actuators: Saia-Burgess Solenoids

BTA Rotary Actuators: Saia-Burgess Solenoids

Uploaded by

Buenotech - Classificadores de frutasCopyright:

Available Formats

BTA®

Rotary Actuators

15

(1.70)

10% Duty Cycle 320W

25% Duty Cycle 128W

50% Duty Cycle 64W

100% Duty Cycle 32W

Torque - lb-in (Nm)

10

(1.13)

5

(0.57)

saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624

BTA® Brushless Torque Actuators

■ Controllable velocity and ■ Completely enclosed

position construction

■ Quiet, shock-free operation ■ Excellent unit-to-unit

performance consistency

■ 100+ million cycle life

■ Low power consumption

■ No axial stroke

ROTARY BTA

■ Adaptable to closed loop

operation

BTA Principle of Operation BTA rotary, non-axial The bearing system

stroke actuators are a good consists of two ball-type

The BTA has a single phase coil with three stator poles

solution for applications bearings which are key to

and matching rotor poles. When the coil is energized, the

requiring reliable, low low hysteresis operation.

poles align along the flux path. With the three pole

hysteresis operation with a

design, it is possible to have a stroke of up to 45°. In

good torque profile as Quiet

practical usage, external stops should be used to attain

required for proportional The BTA can operate

maximum unit life. Subsequently, the stroke angle is

operation. virtually noise free.

slightly shorter. Use of such mechanical stops also serve

Using simple pulse width Electronically controlled,

to limit the actuator stroke to its optimum stroke/torque

modulation (PWM) to control the BTA provides soft,

capacity. By not requiring full stroke actuation, the BTA

coil current, the BTA shock-free cycling without

offers maximum design flexibility across a wide range of

allows open or closed loop the noise associated with

stroke angles and torque requirements.

velocity and position end-of-stroke mechanical

control. Such proportional stops.

control is ideal for silent, For machines such as the

shock-free actuation mail sorter pictured at

applications. (In open loop right, which utilizes

applications, PWM improves hundreds of these

;;;

yyy

;;; ;;;

yyy ;;;;

yyyy ;;;;

yyyy

yyy

;;;

yyy

;;;

yyy

;;;

yyy

;;;;

yyyy

;;;;

yyyy

;;;;

yyyy

;;;;

yyyy hysteresis over variable DC actuators, the BTA is used

;;;

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy

;;;

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy

;;;

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy voltage control.) in conjunction with

;;;

yyy

;;; ;;;

yyy ;;;;

yyyy ;;;;

yyyy

yyy

;;;

;;;

yyy ;;;;

yyyy ;;;;

yyyy

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy

;;;

yyy

;;;

yyy

;;;

yyy

;;;

yyy

;;;;

yyyy

;;;;

yyyy

;;;;

yyyy

;;;;

yyyy The addition of position cushioned external stops to

;;;

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy

;;;

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy feedback, and the minimize noise and extend

;;;

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy

;;;

yyy ;;;

yyy ;;;;

yyyy ;;;;

yyyy

;;;

yyy

;;; ;;;

yyy ;;;;

yyyy ;;;;

yyyy

yyy

;;;

;;;

yyy ;;;;

yyyy ;;;;

yyyy subsequent improved the unit’s life to that of the

yyy

;;;

;;;

yyy ;;;;

yyyy ;;;;

yyyy

yyy

;;;

;;;

yyy ;;;;

yyyy ;;;;

yyyy

yyy

;;;

yyy

;;;

yyy

;;;

yyy

;;;;

yyyy

;;;;

yyyy

;;;;

yyyy

;;;;

yyyy system stiffness and precision ball bearings.

accuracy, enables the BTA

to be used in closed loop

De-energized Energized applications.

B2 saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624

BTA® Brushless Torque Actuators

Rapid Cycling Design Considerations Power Requirements Typical Examples of

The BTA actuator Voltage applied to the Custom Features

requires only milliseconds Performance Curves actuator must be matched

to rotate through its entire The torque curves on the to the coil wire size for

stroke. It can maintain this following pages are typical proper operation.

extremely fast operating data taken with a 20°C coil Actuators are cataloged in

speed repetitively without and have not been derated. coil awgs ranging from #23

ROTARY BTA

Elliptical Clevis-grooved

diminishing accuracy or Typical derating factors up to #35 to accommodate

repeatability, or reducing are 30% due to coil your input power. Refer to

the overall life of the unit. heating. the individual model

specification pages for coil

Rugged Duty Cycle wire awg

The BTA design Duty cycle is determined recommendations. Many Flatted Clevis-tongue

eliminates the axial travel by: ON time/(ON + OFF other coil awg sizes are

associated with time). available. Please feel free

conventional rotary For example: an actuator to contact our application

actuators. In so doing, the operated for 30 seconds, engineering department

BTA eliminates loading on then off for 90 seconds. for availability.

Drilled hole Notched

associated mechanical 30 sec ON / (30 Sec ON + 90

linkages, and reduces the sec OFF) = 30/120 = 1/4 or Options and Modified

number of moving parts 25% duty cycle Designs

and the wear they receive. BTA actuators are rated Even though our

The BTA is self-contained for various duty cycles standard BTAs are in stock,

in an industry standard ranging from continuous to our customers often Threaded rod Tapped hole

size which enables easy 10% duty. require a product with

mounting and unique features or

interchangeability. The Life

performance capabilities.

unit is permanently When selecting a BTA In fact, almost 80% of all

lubricated and requires no actuator, as with any other products that we make are

adjustment or style, it is important to either modified or custom

maintenance over its consider the effects of heat built to meet our

entire life. on life. When used with a customers’ exact

constant voltage supply, an application requirements.

Powerful . . . increase in coil So, if you don’t find what

with Less Power temperature reduces the you’re looking for in the

The BTA actuator offers work output and the life of catalog, give us a call to

considerably more torque the unit. Standard life is discuss your needs with

than comparable sized more than 100,000,000 one of our application

rotary actuator designs. cycles. engineers.

Even with its high torque

output, the BTA requires

40% less power input than

competitive units. On high

volume applications such

as this mail sorter, the

BTA conserves as much as

18.9 watts per actuator

cycle.

saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624 B3

BTA® Selection

Brushless Torque BTA Selection Overview

Actuators are available in

Gross Starting Gross Ending

five sizes. Use the Package Maximum Torque (lb-in) Torque (lb-in)

selection overview chart to Dimensions (in) Stroke @ Specified Duty Cycle @ Specified Duty Cycle

determine which size Size Dia. Length (degrees) 100% 50% 25% 10% 100% 50% 25% 10%

offers the desired

2EV 1.188 0.719 45 N/A* 0.28 0.50 1.00 N/A* 0.19 0.33 0.58

performance and

mechanical specifications. 3EV 1.375 0.890 45 0.28 0.45 0.84 1.66 0.22 0.31 0.53 0.88

ROTARY BTA

Refer to the individual size 4EV 1.625 1.055 45 0.40 0.92 1.60 2.85 0.36 0.64 1.00 1.60

specification pages for

5EV 1.937 1.265 45 1.36 2.36 3.72 6.00 1.04 1.64 2.60 4.20

complete performance and

mechanical data. 6EV 2.312 1.625 45 3.40 5.80 8.60 12.90 2.00 3.70 5.00 7.00

All data is at 20°C coil temperature. Torque outputs degrade with elevated

temperatures.

* Not recommended for 100% duty.

How to Use BTA Performance Charts Performance

Maximum Duty Cycle 100% 50% 25% 10%

1. Select one of the four columns which provides the appropriate

duty cycle. (For example 50%.) Maximum ON Time (sec) ∞ 100 36 7

when pulsed continuously

2. Reading down this column provides a variety of performance Maximum ON Time (sec) ∞ 162 44 8

and electrical data including maximum on time, watts, and amp for single pulse

turns.

Typical Energize Time 20 15 11 8

(msec)

3. Following down the column further into the VDC ratings, select

the voltage which most closely matches your supply voltage. (For Watts (@ 20°C) 10 20 40 100

example, 7.6 for an 8 VDC power supply.) Ampere Turns (@ 20°C) 331 469 663 1048

4. Read across (to the left) to select the awg suffix to complete the Coil Data

part number when ordering. (In this example using our 2EV awg Resistance # VDC VDC VDC VDC

chart, 28 awg is required, thus to order, specify: 195190-028. (0XX)4 (@20°C) Turns5 (Nom) (Nom) (Nom) (Nom)

24 0.47 72 2.2 3.1 4.3 6.9

25 0.67 82 2.6 3.7 5.2 8.2

26 0.94 92 3.1 4.3 6.1 9.7

27 1.33 104 3.6 5.2 7.3 11.5

28 2.86 174 5.4 7.6 10.7 16.9

29 4.01 195 6.3 9.0 12.7 20.0

30 7.69 292 8.8 12.4 17.5 27.7

31 10.80 328 10.4 14.7 20.8 32.9

All specifications subject to change without notice. 32 19.26 460 13.9 19.6 27.8 43.9

33 26.96 515 16.4 23.2 32.8 52.0

34 45.82 690 21.4 30.3 42.8 68.0

35 63.76 768 25.3 35.7 50.0 80.0

B4 saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624

BTA® Size 2EV

Part Numbers: Clockwise Rotation 195190-0XX

Counter-Clockwise Rotation 195622-0XX

Performance Specifications

Maximum Duty Cycle* 50% 25% 10% Dielectric Strength 1000 VRMS

ROTARY BTA

Maximum ON Time (sec) 15 6 2 Recommended Maximum watts dissipated by

when pulsed continuously 1 Minimum Heat Sink solenoid are based on an unrestricted

flow of air at 20°C, with solenoid

Maximum ON Time (sec) 44 15 4 mounted on the equivalent of an

for single pulse2 aluminum plate measuring 3-3/8”

square by 1/8” thick

Typical Energize Time 15 11 8

(msec)3 Thermal Resistance 10.8 (°C/watt)

Rotor Inertia 2.56 (gm-cm2)

Watts (@ 20°C) 20 40 100 Weight 3.0 oz (85 gms)

Ampere Turns (@ 20°C) 469 663 1048 Dimensions Ø1.188" x 0.719" (See page B10)

Coil Data

awg Resistance # VDC VDC VDC

(0XX)4 (@20°C) Turns5 (Nom) (Nom) (Nom) How to Order

Add the coil awg number (0XX) to the part number (for

24 0.47 72 3.1 4.3 6.9

25 0.67 82 3.7 5.2 8.2 example: to order a 25% duty cycle clockwise rotation

26 0.94 92 4.3 6.1 9.7 unit rated at 12.7 VDC, specify 195190-029).

27 1.33 104 5.2 7.3 11.5 Please see www.ledex.com (click on Stock Products

28 2.86 174 7.6 10.7 16.9

tab) for our list of stock products available through our

29 4.01 195 9.0 12.7 20.0

30 7.69 292 12.4 17.5 27.7 North American distributors.

31 10.80 328 14.7 20.8 32.9

32 19.26 460 19.6 27.8 43.9 1

Continuously pulsed at stated watts and duty cycle

33 26.96 515 23.2 32.8 52.0 2

Single pulse at stated watts (with coil at ambient room

34 45.82 690 30.3 42.8 68.0

temperature 20°C)

35 63.76 768 35.7 50.0 80.0 3

*Not recommended for 100% duty cycle. Typical energize time based on a 0.5 oz-in torque load

including 14 gm-cm2 of inertia

4

Other coil awg sizes available — please consult factory

5

Reference number of turns

Size 2EV — Typical Torque @ 20°C

20 Notes:

(0.14)

10% Duty Cycle 100W

25% Duty Cycle 40W

Torque curves shown are

50% Duty Cycle 20W without spring.

15

(0.10)

Typical standard spring has a

Torque - oz-in (Nm)

torque of 1.0 oz-in.

Torque values are for

10 reference only.

(0.07)

5

(0.04)

All specifications subject to change without notice.

0 10 20 30 40 50

De-energized Energized

Stroke - Degrees

saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624 B5

BTA® Size 3EV

Part Numbers: Clockwise Rotation 195191-0XX

Counter-Clockwise Rotation 195623-0XX

Performance Specifications

Maximum Duty Cycle 100% 50% 25% 10% Dielectric Strength 1,000 VRMS (23-28 awg); 1,200 VRMS

(29-34 awg)

ROTARY BTA

Maximum ON Time (sec) ∞ 10 3 1

Recommended Maximum watts dissipated by

when pulsed continuously1

Minimum Heat Sink solenoid are based on an unrestricted

Maximum ON Time (sec) ∞ 26 10 4 flow of air at 20°C, with solenoid

for single pulse2 mounted on the equivalent of an

aluminum plate measuring 4-5/8”

Typical Energize Time 25 17 12 9 square by 1/8” thick

(msec)3

Thermal Resistance 8.53 (°C/watt)

Watts (@ 20°C) 13 26 52 130 Rotor Inertia 9.14 (gm-cm 2)

Ampere Turns (@ 20°C) 362 512 729 1,144 Weight 5.0 oz (142 gms)

Dimensions Ø1.375" x 0.890" (See page B10)

Coil Data

awg Resistance # VDC VDC VDC VDC

(0XX)4 (@20°C) Turns5 (Nom) (Nom) (Nom) (Nom) How to Order

Add the coil awg number (0XX) to the part number (for

23 0.26 44 1.9 2.6 3.7 5.9

24 0.38 50 2.2 3.1 4.4 7.0 example: to order a 25% duty cycle clockwise rotation

25 0.53 56 2.6 3.7 5.2 8.3 unit rated at 25.9 VDC, specify 195191-031).

26 1.54 126 4.5 6.3 9.0 14.2 Please see www.ledex.com (click on Stock Products

27 2.15 140 5.3 7.5 10.6 16.7

tab) for our list of stock products available through our

28 3.04 158 6.3 8.9 12.6 19.9

29 4.24 176 7.4 10.5 14.9 23.5 North American distributors.

30 9.16 297 10.9 15.4 21.8 34.5

31 12.90 333 12.9 18.3 25.9 40.9

32 18.04 372 15.3 21.6 30.6 48.4

1

33 34.10 552 21.0 29.8 42.1 66.5 Continuously pulsed at stated watts and duty cycle

34 47.70 616 25.0 35.2 49.8 78.7 2

Single pulse at stated watts (with coil at ambient room

temperature 20°C)

3

Typical energize time based on a 0.8 oz-in torque load

including 14 gm-cm2 of inertia

4

Other coil awg sizes available — please consult factory

5

Size 3EV — Typical Torque @ 20°C Reference number of turns

30 Notes:

(0.21)

10% Duty Cycle 130W

25% Duty Cycle 52W

Torque curves shown are

50% Duty Cycle 26W

100% Duty Cycle 13W

without spring.

Typical standard spring has a

Torque - oz-in (Nm)

20 torque of 1.9 oz-in.

(0.14)

Torque values are for

reference only.

10

(0.07)

All specifications subject to change without notice.

0 10 20 30 40 50

De-energized Energized

Stroke - Degrees

B6 saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624

BTA® Size 4EV

Part Numbers: Clockwise Rotation 190834-0XX

Counter-Clockwise Rotation 195624-0XX

Performance Specifications

Maximum Duty Cycle 100% 50% 25% 10% Dielectric Strength 1000 VRMS (23-24 awg); 1200 VRMS

(25-33 awg)

ROTARY BTA

Maximum ON Time (sec) ∞ 40 15 4

Recommended Maximum watts dissipated by

when pulsed continuously1

Minimum Heat Sink solenoid are based on an unrestricted

Maximum ON Time (sec) ∞ 108 34 9 flow of air at 20°C, with solenoid

for single pulse2 mounted on the equivalent of an

aluminum plate measuring 6-1/4”

Typical Energize Time 27 19 14 10 square by 1/8” thick

(msec)3

Thermal Resistance 7.63 (°C/watt)

Watts (@ 20°C) 14.5 29 58 145 Rotor Inertia 13.92 (gm-cm2)

Ampere Turns (@ 20°C) 510 721 1020 1613 Weight 8.0 oz (227 gms)

Dimensions Ø1.625" x 1.055" (See page B10)

Coil Data

awg Resistance # VDC VDC VDC VDC

(0XX)4 (@20°C) Turns5 (Nom) (Nom) (Nom) (Nom) How to Order

Add the coil awg number (0XX) to the part number (for

23 0.71 104 3.2 4.5 6.4 10.1

24 1.54 174 4.7 6.7 9.4 14.9 example: to order a 25% duty cycle clockwise rotation

25 2.15 195 5.6 7.9 11.2 17.6 unit rated at 13.2 VDC, specify 190834-026).

26 3.01 219 6.6 9.3 13.2 20.9 Please see www.ledex.com (click on Stock Products

27 5.78 328 9.2 12.9 18.3 28.9

tab) for our list of stock products available through our

28 8.09 368 10.8 15.3 21.7 34.3

29 14.40 515 14.5 20.4 28.9 45.7 North American distributors.

30 20.11 575 18.9 26.7 37.7 59.6

31 34.40 774 22.3 31.6 44.6 71.0

1

32 56.60 1008 28.7 40.5 57.0 91.0 Continuously pulsed at stated watts and duty cycle

33 91.40 1288 36.0 52.0 73.0 115.0 2

Single pulse at stated watts (with coil at ambient room

temperature 20°C)

3

Typical energize time based on a 2.4 oz-in torque load

including 14 gm-cm2 of inertia

4

Other coil awg sizes available — please consult factory

5

Reference number of turns

Size 4EV — Typical Torque @ 20°C

4 Notes:

(0.45)

10% Duty Cycle 145W

25% Duty Cycle 58W

Torque curves shown are

50% Duty Cycle 29W

100% Duty Cycle 14.5W

without spring.

3

(0.34)

Typical standard spring has a

torque of 3.0 oz-in.

Torque - lb-in (Nm)

Torque values are for

2 reference only.

(0.23)

1

(0.11)

All specifications subject to change without notice.

0 10 20 30 40 50

De-energized Energized

Stroke - Degrees

saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624 B7

BTA® Size 5EV

Part Numbers: Clockwise Rotation 190835-0XX

Counter-Clockwise Rotation 195625-0XX

Performance Specifications

Maximum Duty Cycle 100% 50% 25% 10% Dielectric Strength 1000 VRMS (23 awg); 1200 VRMS (24-33

awg)

∞

ROTARY BTA

Maximum ON Time (sec) 40 15 4

when pulsed continuously 1 Recommended Maximum watts dissipated by

Minimum Heat Sink solenoid are based on an unrestricted

Maximum ON Time (sec) ∞ 109 36 10 flow of air at 20°C, with solenoid

for single pulse2 mounted on the equivalent of an

Typical Energize Time 27 18 14 10 aluminum plate measuring 7-1/2”

(msec)3 square by 1/8” thick

Thermal Resistance 5.36 (°C/watt)

Watts (@ 20°C) 21 42 84 210 Rotor Inertia 30.36 (gm-cm2)

Ampere Turns (@ 20°C) 621 878 1242 1964 Weight 13.5 oz (382 gms)

Dimensions Ø1.937" x 1.265" (See page B10)

Coil Data

awg Resistance # VDC VDC VDC VDC

(0XX)4 (@20°C) Turns5 (Nom) (Nom) (Nom) (Nom) How to Order

23 1.05 128 4.7 6.6 9.4 14.8 Add the coil awg number (0XX) to the part number (for

24 2.24 213 6.9 9.7 13.7 21.7 example: to order a 25% duty cycle clockwise rotation

25 3.16 240 8.1 11.5 16.3 25.8 unit rated at 26.7 VDC, specify 190835-027).

26 4.45 270 9.7 13.7 19.3 30.6

27 8.50 404 13.4 18.9 26.7 42.2 Please see www.ledex.com (click on Stock Products

28 11.90 452 15.8 22.3 31.6 50.0 tab) for our list of stock products available through our

29 21.10 630 21.0 29.7 42.1 67.0 North American distributors.

30 29.50 705 24.9 35.2 49.8 78.7

31 50.30 948 32.5 46.0 65.0 103.0

32 82.70 1232 41.7 59.0 83.0 132.0 1

Continuously pulsed at stated watts and duty cycle

33 134.00 1576 53.0 75.0 106.0 168.0 2

Single pulse at stated watts (with coil at ambient room

temperature 20°C)

3

Typical energize time based on a 5.0 oz-in torque load

including 14 gm-cm2 of inertia

4

Other coil awg sizes available — please consult factory

5

Reference number of turns

Size 5EV — Typical Torque @ 20°C

8 Notes:

(0.90)

10% Duty Cycle 210W

25% Duty Cycle 84W

Torque curves shown are

50% Duty Cycle 42W

100% Duty Cycle 21W

without spring.

6

(0.68)

Typical standard spring has a

Torque - lb-in (Nm)

torque of 4.0 oz-in.

Torque values are for reference

4 only.

(0.45)

2

(0.23)

All specifications subject to change without notice.

0 10 20 30 40 50

De-energized Energized

Stroke - Degrees

B8 saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624

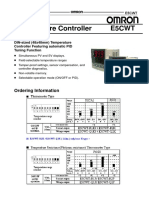

BTA® Size 6EV

Part Numbers: Clockwise Rotation 190836-0XX

Counter-Clockwise Rotation 195626-0XX

Performance Specifications

Maximum Duty Cycle 100% 50% 25% 10% Dielectric Strength 1,000 VRMS (23 awg); 1200 VRMS (24-

33 awg)

ROTARY BTA

Maximum ON Time (sec) ∞ 40 15 5

when pulsed continuously1 Recommended Maximum watts dissipated by

Minimum Heat Sink solenoid are based on an unrestricted

Maximum ON Time (sec) ∞ 143 47 11 flow of air at 20°C, with solenoid

for single pulse2 mounted on the equivalent of an

Typical Energize Time 48 21 15 11 aluminum plate measuring 12-3/8”

(msec)3 square by 1/8” thick

Thermal Resistance 3.58 (°C/watt)

Watts (@ 20°C) 32 64 128 320 Rotor Inertia 67.15 (gm-cm2)

Ampere Turns (@ 20°C) 980 1386 1960 3100 Weight 25.0 oz (709 gms)

Dimensions Ø2.312" x 1.625" (See page B10)

Coil Data

awg Resistance # VDC VDC VDC VDC

(0XX)4 (@20°C) Turns5 (Nom) (Nom) (Nom) (Nom) How to Order

23 2.65 267 9.2 13.0 18.4 29.1 Add the coil awg number (0XX) to the part number (for

24 5.02 396 12.7 17.9 25.4 40.1 example: to order a 25% duty cycle clockwise rotation

25 7.03 444 15.0 21.2 30.0 47.4 unit rated at 25.4 VDC, specify 190836-024).

26 12.60 625 20.1 28.4 40.2 63.5

27 17.60 700 23.8 33.6 47.5 75.1 Please see www.ledex.com (click on Stock Products

28 29.90 936 30.9 43.7 61.9 97.8 tab) for our list of stock products available through our

29 49.50 1225 39.8 56.0 80.0 126.0 North American distributors.

30 79.70 1560 51.0 71.0 101.0 160.0

31 126.50 1962 64.0 90.0 127.0 201.0

32 198.30 2440 80.0 113.0 159.0 252.0 1

Continuously pulsed at stated watts and duty cycle

33 306.20 2992 99.0 140.0 198.0 313.0 2

Single pulse at stated watts (with coil at ambient room

temperature 20°C)

3

Typical energize time based on a 14.0 oz-in torque load

including 14 gm-cm2 of inertia

4

Other coil awg sizes available — please consult factory

5

Reference number of turns

Size 6EV — Typical Torque @ 20°C

15 Notes:

(1.70)

10% Duty Cycle 320W Torque curves shown are

25% Duty Cycle 128W

50% Duty Cycle 64W without spring.

100% Duty Cycle 32W

Typical standard spring has a

Torque - lb-in (Nm)

10 torque of 8.0 oz-in.

(1.13)

Torque values are for

reference only.

5

(0.57)

All specifications subject to change without notice.

0 10 20 30 40 50

De-energized Energized

Stroke - Degrees

saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624 B9

BTA® Dimensions

inches (mm)

Size 2EV Size 3EV

0.381 +- 0.031 0.1861 +- 0.001 dia 0.558 +- 0.031

0.481 ± 0.015 (9.68 +- 0.78)

0.1553 +- 0.001 dia (12.2 ± 0.38) (Ø4.726 +- 0.025) 0.479 ± 0.015 (14.17 +- 0.78)

(12.17 ± 0.38)

ROTARY BTA

Shaft rotation (Ø3.945 +- 0.025) Shaft rotation both ends

both ends

CCW CW 0.719 CCW CW 0.890

0.55 0.67

1.188 +- 0.015 dia (18.26) (13.97) 1.375 +- 0.015 dia (22.61) (17.02)

+ max max

(Ø30.17 - 0.38) max (Ø34.93 +- 0.38) max

3-48 UNC 0.719 5-40 NC 0.875

(18.26) 2A thds (22.23)

2A thds

0.375

1.112 ± 0.015 (9.53) 0.360 +- 0.010 0.375 0.438 +- 0.010

(9.13 +- 0.25) (9.53)

(28.24 ± 0.38) 1.242 ± 0.015 (11.12 +- 0.25)

10.0 10.0

(254.0) (31.55 ± 0.38) (254.0)

0.11 min leads min leads

REF #26 AWG 0.16 #26 AWG

(2.8) REF

(4.1)

Size 4EV Size 5EV

0.2360 +- 0.001 dia 0.497 +- 0.015 0.607 +- 0.031 0.2493 +- 0.001 dia 0.508 +- 0.015 0.604 +- 0.031

(Ø5.994 +- 0.025) (12.62 +- 0.38) (15.42 +- 0.78) (Ø6.332 +- 0.025) (12.90 +- 0.38) (15.34 +- 0.78)

Shaft rotation both ends

Shaft rotation both ends

1.055 CCW CW 1.265

CCW CW 0.81 0.88

1.625 +- 0.015 dia (26.80) (20.6) 1.937 +- 0.015 dia 0.0010dia (32.13) (22.4)

max (Ø49.20 +- 0.38) max

(Ø41.28 + - 0.38) max max

6-32 UNC 1.062 8-32 UNC 1.250

2A thds (26.97) 2A thds (31.75)

0.375 0.531 +- 0.010 0.375 0.625 +- 0.010

(9.53) (9.53) (15.88 +- 0.25)

1.414 +- 0.025 (13.49 +- 0.25)

1.627 +- 0.025 10.0

(35.92 +- 0.64) 10.0

(254.0) (41.33 +- 0.64) (254.0)

0.16 min leads min leads

(4.1) REF 0.19 #22 AWG

#22 AWG (4.8) REF

Size 6EV

0.3116 +- 0.001 dia 0.665 ± 0.015 0.722 +- 0.031

(Ø7.915 +- 0.025) (16.89 ± 0.38) (18.34 +- 0.78)

Shaft rotation both ends

CCW CW 1.625

1.03

2.312 +- 0.015 dia (41.27) (26.2)

(Ø58.72 +- 0.38) max max

10-32 UNF 1.438

2A thds (36.53)

All specifications subject to change without notice.

0.500 0.719 +- 0.010

(12.70) (18.26 +- 0.25)

2.111 ± 0.025 10.0

(53.62 ± 0.64) (254.0)

min leads

0.25 #22 AWG

REF

(6.4)

B10 saia-burgess Solenoids 1-800-998-2298 www.saia-burgess-usa.com/ledex Fax: 1-937-898-8624

You might also like

- MAN TGA 33 480 6x4 BBS Specifications-1 PDFDocument4 pagesMAN TGA 33 480 6x4 BBS Specifications-1 PDFFilmon TesfayNo ratings yet

- New Monarch Nice 3000 PDFDocument233 pagesNew Monarch Nice 3000 PDFIrwaenk Sevenfold78% (32)

- Generador StamfordDocument8 pagesGenerador StamfordGustavo ZavalaNo ratings yet

- Tbma Mechanical TypesDocument306 pagesTbma Mechanical Typesmagdyfdl100% (1)

- Manual Lava Louça CCR200 - MDIK80-00 LIVRETO PDFDocument132 pagesManual Lava Louça CCR200 - MDIK80-00 LIVRETO PDFJulyanorigoniNo ratings yet

- Sinutrain: Getting Started 02.10 EditionDocument64 pagesSinutrain: Getting Started 02.10 EditioncorreiaferNo ratings yet

- 9.5 in TRTK Tech SheetDocument2 pages9.5 in TRTK Tech SheetpendexxNo ratings yet

- High Torque, Low Inertia, Compact Design: Combination Clutch/BrakeDocument8 pagesHigh Torque, Low Inertia, Compact Design: Combination Clutch/Brakegrupa2904No ratings yet

- Magtrol: AHB Series Compressed-Air-Cooled Hysteresis BrakesDocument12 pagesMagtrol: AHB Series Compressed-Air-Cooled Hysteresis Brakessezgin bayramNo ratings yet

- Schenck Type CS 30Document2 pagesSchenck Type CS 30Jufadlan ArifNo ratings yet

- Catalog Cba-30 enDocument12 pagesCatalog Cba-30 enRizkiary RamadhanNo ratings yet

- Magtrol Load ISP521Document11 pagesMagtrol Load ISP521irfanNo ratings yet

- YAMAHA SCARA Robots - Everybody Wants These Great Features!: Product Lineup / Selection GuideDocument2 pagesYAMAHA SCARA Robots - Everybody Wants These Great Features!: Product Lineup / Selection Guidehophuong_dhvNo ratings yet

- 0806 Apex Brushless MotorsDocument5 pages0806 Apex Brushless MotorsJosé Luis RuizNo ratings yet

- Makita Jig SawDocument1 pageMakita Jig Sawwedha darmawanNo ratings yet

- Kubota 2016 KV RM Plough IENDocument24 pagesKubota 2016 KV RM Plough IENdejanflojdNo ratings yet

- GTB - Servo Positioning Rotary TableDocument2 pagesGTB - Servo Positioning Rotary Tabletony canNo ratings yet

- AXU Series PDFDocument20 pagesAXU Series PDFminhtrieu999No ratings yet

- td022d ViewDocument2 pagestd022d ViewkasperskycloudsolutionsNo ratings yet

- Series BDV ValvesDocument20 pagesSeries BDV ValvesMuhammad NaeemNo ratings yet

- D85ESS-2A: Horsepower Net: 149 KW Operating Weight 20670 KGDocument8 pagesD85ESS-2A: Horsepower Net: 149 KW Operating Weight 20670 KGHeronimus RigoNo ratings yet

- D85ESS-2A: With Steering Clutch/Brake SystemDocument8 pagesD85ESS-2A: With Steering Clutch/Brake SystemVidya SagarNo ratings yet

- Kel Univ ECatDocument8 pagesKel Univ ECatShAi_MyStERiOuSNo ratings yet

- Tsubaki MCD Zip Chain Actuator 2020Document56 pagesTsubaki MCD Zip Chain Actuator 2020Ruben PauwelsNo ratings yet

- Puma V400P: High Productivity Vertical Turning CenterDocument4 pagesPuma V400P: High Productivity Vertical Turning CenterMirko GallonNo ratings yet

- Spring Cylinder Rotary ActuatorDocument12 pagesSpring Cylinder Rotary ActuatorLuis Gustavo HernandezNo ratings yet

- Doosan Puma V400-550-2SP Series Brochure PDFDocument16 pagesDoosan Puma V400-550-2SP Series Brochure PDFPSIX FACTORYNo ratings yet

- 4 - Hci434fDocument8 pages4 - Hci434fmnezamiNo ratings yet

- Dctorque-Km BR 000385 Reva Ecn3Document12 pagesDctorque-Km BR 000385 Reva Ecn3Basam RazNo ratings yet

- Alpha Mechatronic Systems TPM enDocument56 pagesAlpha Mechatronic Systems TPM enmuratpatanNo ratings yet

- Erco Bender 76Document1 pageErco Bender 76Johan SneiderNo ratings yet

- EI Series BalancingDocument12 pagesEI Series BalancingJorge OrtegaNo ratings yet

- Electric Chain HoistDocument12 pagesElectric Chain HoistMAHMOUD YOUNISNo ratings yet

- 6991 1767 01b - Diamec U4 - LRDocument4 pages6991 1767 01b - Diamec U4 - LRPABLONo ratings yet

- 6991 1767 01 - DiamecU4 Techspec - LowresDocument4 pages6991 1767 01 - DiamecU4 Techspec - Lowresrevemin2024No ratings yet

- Amb24 3 SDocument5 pagesAmb24 3 SWagner OliveiraNo ratings yet

- Ad Actuator 106 en ADocument4 pagesAd Actuator 106 en AhermanNo ratings yet

- Miller Electric Submerged Arc Welding TractorDocument4 pagesMiller Electric Submerged Arc Welding TractorVictor PATIÑONo ratings yet

- Fuji E11 CatalogueDocument24 pagesFuji E11 CatalogueShujhat AhmedNo ratings yet

- D85ess 2aDocument8 pagesD85ess 2aahmadfaathirNo ratings yet

- HBT50 10 60RSDocument2 pagesHBT50 10 60RSVũ Bình PhanNo ratings yet

- Rectilinear Displacement Transducer With Bearing Tip: Technical Data Mechanical DimensionsDocument3 pagesRectilinear Displacement Transducer With Bearing Tip: Technical Data Mechanical DimensionsSathish J EceNo ratings yet

- Balancing of General Rotors: Horizontal Hard-Bearing Balancing Machine UHK 11.1 / 12.1Document2 pagesBalancing of General Rotors: Horizontal Hard-Bearing Balancing Machine UHK 11.1 / 12.1Eric21No ratings yet

- Merlin Range - ML 173Document2 pagesMerlin Range - ML 173MohamedNo ratings yet

- On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 VDocument5 pagesOn/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 VdbricchiNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson PhinniNo ratings yet

- An001 enDocument13 pagesAn001 enQuynh NguyenNo ratings yet

- Three-Axis Active Control Magnetic Bearing With Asymmetric Structure For High-Temperature MachinesDocument1 pageThree-Axis Active Control Magnetic Bearing With Asymmetric Structure For High-Temperature Machinesxiaoqi dengNo ratings yet

- Pioneer PL300 BrochureDocument4 pagesPioneer PL300 BrochureAlejandro CaballeroNo ratings yet

- Str-X67xxseries An en PDFDocument19 pagesStr-X67xxseries An en PDFRenn PaculanangNo ratings yet

- Power Electronics: Ministart Softstarter BA 9010, BN 9011Document4 pagesPower Electronics: Ministart Softstarter BA 9010, BN 9011Manel EstebanNo ratings yet

- PI044H - Technical Data Sheet Winding 05Document7 pagesPI044H - Technical Data Sheet Winding 05juan echeverryNo ratings yet

- Product Leaflet - ESAB Portable CNC MachineDocument2 pagesProduct Leaflet - ESAB Portable CNC Machinegaurav lakheraNo ratings yet

- Ficha TecnicaDocument2 pagesFicha TecnicajoseNo ratings yet

- Motor Technologies: Stepper MotorsDocument5 pagesMotor Technologies: Stepper MotorsmdkhandaveNo ratings yet

- Delta Ia-Asda Asda-A3 C en 20210104 WebDocument52 pagesDelta Ia-Asda Asda-A3 C en 20210104 WebXuan Tien VuNo ratings yet

- LTW90 1 000 1 500Document2 pagesLTW90 1 000 1 500Electricidad IngecablesNo ratings yet

- Alternator AKSA AK6480Document8 pagesAlternator AKSA AK6480Cris_eu09No ratings yet

- TECS-WL-M Modular Water-Cooled Oil-Free Centrifugal Chiller B212 CCU 01-03-2019 EN-SHDocument7 pagesTECS-WL-M Modular Water-Cooled Oil-Free Centrifugal Chiller B212 CCU 01-03-2019 EN-SHxuyen tranNo ratings yet

- Futaba GY240Document2 pagesFutaba GY240philaskNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Biodata Abhishek PalitDocument4 pagesBiodata Abhishek PalitRana BiswasNo ratings yet

- Temperature Controller E5Cwt: Ordering InformationDocument10 pagesTemperature Controller E5Cwt: Ordering InformationWaheed MidoNo ratings yet

- Experiment 2 Open-Loop Dynamics Response of Second Order Systems 1. ObjectivesDocument7 pagesExperiment 2 Open-Loop Dynamics Response of Second Order Systems 1. ObjectivessinadasqNo ratings yet

- 362 Technical Requirement of 800 KV Substation and AboveDocument224 pages362 Technical Requirement of 800 KV Substation and AboveepriNo ratings yet

- Electricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFDocument331 pagesElectricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFMiguel CbNo ratings yet

- MB Manual Ga-G41mt-S2pt e PDFDocument40 pagesMB Manual Ga-G41mt-S2pt e PDFLeonel AtaramaNo ratings yet

- Signat Audio Folder 08Document16 pagesSignat Audio Folder 08Sérgio Marques0% (1)

- Unit 2: CNC Hardware Basics: Prepared By: MR.B.K Patil, DTCDocument91 pagesUnit 2: CNC Hardware Basics: Prepared By: MR.B.K Patil, DTCDEVARAJU VNo ratings yet

- Class Exercise: Motor Protection: Prot405 - Exercise - Motorprotectionexercise - R4 1Document13 pagesClass Exercise: Motor Protection: Prot405 - Exercise - Motorprotectionexercise - R4 1polNo ratings yet

- Service Manual: PPP PP PDocument194 pagesService Manual: PPP PP Prd6iNo ratings yet

- MAIN Electrical Parts List: Sec Code Design LOC DescriptionDocument5 pagesMAIN Electrical Parts List: Sec Code Design LOC DescriptionAlan AhmedNo ratings yet

- Accuracy of Voltage Sag AnalysisDocument29 pagesAccuracy of Voltage Sag AnalysisLalita VNo ratings yet

- B01-TB16I-PHO-003 - TB16IN-PHO Basic Installation Instructions V1.0 - ENGDocument2 pagesB01-TB16I-PHO-003 - TB16IN-PHO Basic Installation Instructions V1.0 - ENGDavinYudikaNo ratings yet

- Panelboard 61439 BrochureDocument8 pagesPanelboard 61439 BrochureShane DeathNo ratings yet

- What's The Difference Between CTS, Multisource CTS, and Clock MeshDocument7 pagesWhat's The Difference Between CTS, Multisource CTS, and Clock MeshRenju TjNo ratings yet

- Ip Camera/Nvr Management System: Camera Models: Aircam, Aircam Dome, Aircam MiniDocument8 pagesIp Camera/Nvr Management System: Camera Models: Aircam, Aircam Dome, Aircam MinijuharieNo ratings yet

- Lab 3Document4 pagesLab 3vroody555No ratings yet

- SM Power408 v2.1Document25 pagesSM Power408 v2.1GuillermoHernandezNo ratings yet

- Applications of UPQC For Power Quality Improvement: Yash Pal, A. Swarup, Senior Member, IEEE, and Bhim SinghDocument6 pagesApplications of UPQC For Power Quality Improvement: Yash Pal, A. Swarup, Senior Member, IEEE, and Bhim SinghGuru AnkiNo ratings yet

- EE314 Lab 1 FinalDocument19 pagesEE314 Lab 1 FinalCarlos BabuNo ratings yet

- Axis EN Brochure July 21Document32 pagesAxis EN Brochure July 21harshvardhansamratliveNo ratings yet

- Encoder Basics: Output Signals of Incremental EncodersDocument34 pagesEncoder Basics: Output Signals of Incremental EncodersMelchor VasquezNo ratings yet

- Excite User ManualDocument83 pagesExcite User ManualNando MendonçaNo ratings yet

- C - Mount Lens For M4 - 3Document33 pagesC - Mount Lens For M4 - 3kwok hang TongNo ratings yet

- Kepad Password Report&Document12 pagesKepad Password Report&eugeni madaNo ratings yet

- Base Device ProfilesDocument15 pagesBase Device ProfilesAamazNo ratings yet

- GAD8XXXW Series High Power EDFA WDM Module)Document4 pagesGAD8XXXW Series High Power EDFA WDM Module)Vargas JavierNo ratings yet