Professional Documents

Culture Documents

New Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!

New Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!

Uploaded by

Byron LvzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!

New Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!

Uploaded by

Byron LvzCopyright:

Available Formats

WellTech 4X™ EMI Rig Floor Tubing Inspection System

For Tubing 2 3/8” - 4 1/2” O.D. (with coupling)

Upgraded system with many improvements over the WellTech IV™

New WellTech 4X™ systems are Certified Class 1 Division 2 as a standard feature!

The WellTech 4X™ Computerized Rig Floor Tubing Inspec-

tion System is designed to perform a quick and quality inspection of

tubing on the well service rig floor as it is being pulled from the

well. The Electronics System is packaged in a compact and durable

container. Settings (gain settings, wall, split and flaw calibration,

etc.) are controlled with the ruggedized laptop computer. Inspection

for service-induced flaws typical to used tubing (i.e. pitting, cracks,

rod wear and wall thinning, etc.) is performed by a solid state Hall

effect detection system that encircles the pipe, located inside a pow-

erful DC magnetizing coil. Pipe can travel through the head bi-

directionally, but the inspection process takes place as the pipe is

pulled out of the well. The WellTech 4X™ utilizes the latest solid

state Hall effect wall monitoring technology and DOES NOT USE

GAMMA RADIATION.

The multiple function WellTech 4X™ detects

Pitting WellTech 4X™ Canister

Corrosion

Transverse cracks

Work hardening

Rod wear

Wall thinning

Holes and splits

What’s included with the WellTech 4X™?

Certified Class 1 Division 2 for hazardous areas

WellTech 4X™ canister with r ig “lift” hooks (10% shorter than WellTech

IV™)

Stationary baseplate for tr uck or tr ailer mounting

WellTech 4X™ electronics cabinet with USB connection for PC

Digital constant current mag power supply WellTech 4X™ on Rig Floor

Ruggedized Dell laptop PC with Windows® based softwar e

Complete set of cables with built-in strain relief (standard length: 100 ft.)

Safety “lock out” on canister (cannot be opened and cables disconnect-

ed during operation)

2 HP air compressor (110 Volt)

Handheld cordless signal pulse calibration device

WellTech 4X™ software and “Well Profile Report” (easy interpretation

of data and info sharing)

1 day operational training at New Tech’s Facility

OPTIONAL Installation in customer’s vehicle (customer to supply mini-

mum 4500 watt generator/220/110V output)

OPTIONAL Wall, flaw, and split detector inserts for pipe sizes 1.900” to

4½”

OPTIONAL Calibration standards for pipe sizes 1.900” to 4½” WellTech 4X™ Truck Mounted

The Industry’s Leading Manufacturer of Quality Pipe

Inspection Equipment & Related Products with

Systems in Over 50 Countries.

Mansfield, TX Office: (817) 779-6262 - Louisiana Office: (337) 839-2674

Midland, TX Office: (432) 561-5393

Email: contact@newtechsystems.com

What’s new on the WellTech 4X™?

The new and improved WellTech 4X™ has been designed from the ground up with our customer needs in mind for easy operation

and maintenance

Cable Junction Box (J-Box) has been eliminated for easier setup. Cables connect directly to the coil and sensor detector head for

minimal connections (See Figure 1)

Safety “lock out” Front Panel for added safety and security (See Figure 2)

Just one hand tool required to change out different detector head inserts. Easily change out rubber centralizer wipers and split/hole

detector (See Figure 3, 4, 5)

All new Detector Insert System has been engineered for faster change-over between tubing sizes. One detector insert for each size of

tubing (See Figure 6)

Requires up to 75% less size change out and maintenance time compared to WellTech IV™

Wall Ring has been replaced with wall monitoring sensors mounted on top of the inspection shoes for easier maintenance

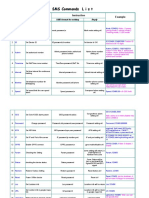

(Figure 1) (Figure 2) (Figure 3) (Figure 4) (Figure 5) (Figure 6)

Internal Cable Hookup, Lockable Panel for Hand Removable Wipers for Split Detector Installs Top Wiper Assembly One Detector Insert Per

No More (J-Box) Safety and Security Easier Maintenance From Side Easily Removable Tubing Size

The WellTech 4X™ Features

PC-Based electronics system with digital signal presentation

Solid state wall monitoring with Hall effect technology

Exclusive 3-dimensional flaw detection system with solid state Hall ef-

fect technology. Includes TRUEWALL thickness monitoring. Flaw sen-

sors are located a small distance from the pipe surface to detect pitting,

cracks, and holes (unlike other systems with sensors too far off the pipe

to detect small flaws)

Separate wall and flaw sensors for more accurate inspection

Detects smaller flaws than most competing systems

Cordless remote calibration device Well Profile Report

“Well profile report” custom inspection report for ongoing well manage-

ment

New and improved flaw detector suspension allows pipe to pass bi-

directionally at any speed with minimal to no risk of damage to sensors

(extremely low maintenance)

Exclusive SPLIT-Check pneumatic longitudinal split and hole detector to

detect holes and splits full length and closer to the coupling, compared to

other EMI/Eddy current systems that are subject to a large “magnetic end

effect” / dead area (in some cases up to 24”/610mm on each side of the

coupling), where most holes and splits are missed

Digital Presentation Software

VISIT OUR WEBSITE: www.newtechsystems.com

WellTech 4X™ EMI Rig Floor Tubing Inspection System

For Tubing 2 3/8” - 4 1/2” (with coupling)

Upgraded system with many improvements over the WellTech IV™

Tubing inspection capacity: 2 3/8" to 4 1/2" O.D. (with coupling)

Inspection speed range: Up to 150 ft./min.

Detection functions: Transverse cracks, pitting, holes, splits and monitoring for large area wall loss

due to corrosion, rod wear, etc. (NO RADIATION)

PC-Based electronics: Flaw detection with solid state Hall effect technology. Console includes solid

state Hall effect with exclusive TRUEWALL™ wall thickness monitoring sys-

tem, SPLIT-Check pneumatic longitudinal split and hole detection system, dig-

ital constant current mag power supply, computerized data acquisition system,

and a ruggedized laptop computer

Inspection head: Exclusive “TFD” (True Flaw Detection) system with solid state Hall effect sensors

TRUEWALL™ solid state wall monitoring system

Guide/wipers built into head for pipe centralization and wiping of tube O.D.

Heavy-duty aluminum housing with rig “lift” hooks

Separate inserts for each tubing size for quick change out

Magnetizing coil: Powerful magnetizing coil with mil-spec connector and sealed from moisture

Cables: 100 ft. cable set, heavy duty insulation with strain relief (longer cables availa-

ble)

Software features: Windows® based software, with digital charts and a data acquisition spread-

sheet program is included for documentation by operator of pipe information

i.e. reject data, joint number, etc. Each section of pipe is numbered and stored

to disk. The included “Well Profile Report” indicates problem areas in string

and is an excellent string management tool for your customer

Power requirements: 110V/60HZ, 5KW generator or house electrical service (220V and 50Hz power

optional)

Operating temperature: -30C to +50C

Certifications: All new WellTech 4X™ systems are certified Class 1 Division 2 for hazardous

areas by the CSA (Canadian Standards Association ).

VISIT OUR WEBSITE: www.newtechsystems.com

The Industry’s Leading Manufacturer of Quality Pipe

Inspection Equipment & Related Products with

Systems in Over 50 Countries.

Mansfield, TX Office: (817) 779-6262 - Louisiana Office: (337) 839-2674

Midland, TX Office: (432) 561-5393

Email: contact@newtechsystems.com

You might also like

- Free CBAP Exam QuestionsDocument9 pagesFree CBAP Exam QuestionsTechcanvassNo ratings yet

- Rocket Loan MethodDocument10 pagesRocket Loan MethodЕлена Романова89% (9)

- DD Tallybook Nick's 2014.2Document19 pagesDD Tallybook Nick's 2014.2مريم مظهر مصطفي بدر Mariam MazharNo ratings yet

- BDK CatalogDocument344 pagesBDK CatalogloucifNo ratings yet

- Stimcommander: Automated Stimulation Delivery PlatformDocument2 pagesStimcommander: Automated Stimulation Delivery PlatformAgung PratamaNo ratings yet

- Well ArchitectDocument1 pageWell ArchitectSandesh ChavanNo ratings yet

- 7.000 X 2.875 ASI-X w-SHEAR RELEASE BOTTOM (17.0-26.0) (26.0-32#) 603-7000-064-FDocument11 pages7.000 X 2.875 ASI-X w-SHEAR RELEASE BOTTOM (17.0-26.0) (26.0-32#) 603-7000-064-FHarry HudiniNo ratings yet

- MSC.97 (73) HSC Code 2000Document239 pagesMSC.97 (73) HSC Code 2000Rajnish KumarNo ratings yet

- The Hytorc Nut Replaces Fasteners, Minimizes Stresses, and Covers A Wide Range of Sizes and Applications Tn-Series Hytorc NutDocument4 pagesThe Hytorc Nut Replaces Fasteners, Minimizes Stresses, and Covers A Wide Range of Sizes and Applications Tn-Series Hytorc NutRajiv GandhiNo ratings yet

- Weco Unions Chicksan Swivel CatalogDocument38 pagesWeco Unions Chicksan Swivel CatalogHarry SuprisnoNo ratings yet

- WFT 5.5 - 15Document194 pagesWFT 5.5 - 15wuillian barretoNo ratings yet

- Westco Tubing Spider Slipse Model CHDDocument28 pagesWestco Tubing Spider Slipse Model CHDNaser JawadNo ratings yet

- Vendor Supplied Document: Contents: ET 200B Distributed I/O Station ChapterDocument194 pagesVendor Supplied Document: Contents: ET 200B Distributed I/O Station ChapterBijan SalehpourNo ratings yet

- Intelliserv Product Catalog d392004875 MKT 001 Rev 01Document12 pagesIntelliserv Product Catalog d392004875 MKT 001 Rev 01carlosorizabaNo ratings yet

- HYTORC NUT CT-Series Specification Guide-060220Document4 pagesHYTORC NUT CT-Series Specification Guide-060220Tran TruongNo ratings yet

- Caltec I-SEPDocument1 pageCaltec I-SEPscribdbalmedieNo ratings yet

- API - Mesh ConverterDocument1 pageAPI - Mesh Convertersaa6383No ratings yet

- Api Spec 6a Gate Valves BRDocument18 pagesApi Spec 6a Gate Valves BRravikumarNo ratings yet

- Pipe Racking: "Helping Our Customers Achieve Superior Results"Document6 pagesPipe Racking: "Helping Our Customers Achieve Superior Results"KACEM100% (1)

- Drill ViewDocument2 pagesDrill ViewJohn Rong100% (1)

- Wellsharp Definitions Reference DocumentDocument15 pagesWellsharp Definitions Reference DocumentBarbare RenNo ratings yet

- Frac Rhino-TC Pumping Trailer OP ManualDocument50 pagesFrac Rhino-TC Pumping Trailer OP ManualAlessonNo ratings yet

- Unprotected TC8225 7 PDFDocument428 pagesUnprotected TC8225 7 PDFVRV.RELATORIO.AVARIA RELATORIO.AVARIANo ratings yet

- FC Catalogue 100112 LowDocument452 pagesFC Catalogue 100112 LowEduardo OyarzunNo ratings yet

- 26 in FMC Procedures With Cam ToolDocument15 pages26 in FMC Procedures With Cam Toolyehia sayedNo ratings yet

- AchieverDocument2 pagesAchieverL'Usine NouvelleNo ratings yet

- Cleancut CCB PDFDocument2 pagesCleancut CCB PDFbruce lian100% (1)

- FEA Analysis of Rectangular Pressure Vessel BoxesDocument13 pagesFEA Analysis of Rectangular Pressure Vessel BoxesIJARSCT JournalNo ratings yet

- PSC Ergodyne Range 2021Document45 pagesPSC Ergodyne Range 2021Project Sales CorpNo ratings yet

- TDS-Xypex Admix C 1000 NFDocument4 pagesTDS-Xypex Admix C 1000 NFDamodharNo ratings yet

- Blak-JAK Liner Retention IOM - 12P160Document20 pagesBlak-JAK Liner Retention IOM - 12P160APEXINDONo ratings yet

- Warrior 8 Software FOMDocument612 pagesWarrior 8 Software FOMPamela Hancock100% (1)

- Scada 1Document17 pagesScada 1Elxan HacinskiNo ratings yet

- Camesa Cable SpecDocument1 pageCamesa Cable SpecShashank Anand MishraNo ratings yet

- IWCF Surface Vertical Kill Sheet - API Field Units - Revised July 2010Document4 pagesIWCF Surface Vertical Kill Sheet - API Field Units - Revised July 2010rverretNo ratings yet

- SS Gauge CarriersDocument2 pagesSS Gauge CarriersGonza PfNo ratings yet

- ROVNAV Set Up Through Prizm 1Document6 pagesROVNAV Set Up Through Prizm 1Guilherme NevesNo ratings yet

- PB DDM 026Document3 pagesPB DDM 026Jim SharpNo ratings yet

- Offshore 2005 Jackuprig PSTRDocument1 pageOffshore 2005 Jackuprig PSTRGuido FloresNo ratings yet

- ATWOOD Advantage BrochureDocument2 pagesATWOOD Advantage Brochurespong1ertzNo ratings yet

- Atwood Advantage Brochure1Document2 pagesAtwood Advantage Brochure1wangnaNo ratings yet

- Electronics Catalog: Propulsion ControlsDocument24 pagesElectronics Catalog: Propulsion ControlsElliot CapsonNo ratings yet

- Pob January 2017Document339 pagesPob January 2017Makhzanul FahmiNo ratings yet

- 003 - Presentation From Nabors Drilling PDFDocument16 pages003 - Presentation From Nabors Drilling PDFVi Et100% (1)

- TDS-11SA 直连编码器sch86fex-specifications-23Document5 pagesTDS-11SA 直连编码器sch86fex-specifications-23هايتاو ليNo ratings yet

- Parker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Document2 pagesParker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Seyedeh Roghayeh SeyediNo ratings yet

- BP Exploration Limited - Casing ProgramDocument66 pagesBP Exploration Limited - Casing ProgramBrunoPestanaNo ratings yet

- ÅBS Produktblad Elmotor BEVI - 3SIE PDFDocument9 pagesÅBS Produktblad Elmotor BEVI - 3SIE PDFAmandaNo ratings yet

- XLX 3000 With Dynacon LARS Rev3Document2 pagesXLX 3000 With Dynacon LARS Rev3Jen QianhuiNo ratings yet

- HT-400 Fluid End Onshore, Facility and Offshore InspectionDocument21 pagesHT-400 Fluid End Onshore, Facility and Offshore InspectionFrancisco javierNo ratings yet

- RigSense Electronic Drilling Recorder FlyerDocument1 pageRigSense Electronic Drilling Recorder Flyermohamed godaNo ratings yet

- 11MCC H8puDocument32 pages11MCC H8pujuliancansenNo ratings yet

- Is Your Motor POWERED by Dyna-Drill?: 2013 Rotary Steerable Drilling Systems DirectoryDocument6 pagesIs Your Motor POWERED by Dyna-Drill?: 2013 Rotary Steerable Drilling Systems DirectoryPutu Yusna ArmitaNo ratings yet

- CATALOGO-Bombas WarrenDocument4 pagesCATALOGO-Bombas Warrenjlrllfn81No ratings yet

- LandRig PosterDocument1 pageLandRig PosterRaúl MárquezNo ratings yet

- 01 Bolt Tightening ToolDocument30 pages01 Bolt Tightening ToolabdulfetahNo ratings yet

- 05 Unconventional Completions PDFDocument34 pages05 Unconventional Completions PDFAlexandru AndreiNo ratings yet

- Dando Watertec 4000 Waterwell Drilling RigDocument2 pagesDando Watertec 4000 Waterwell Drilling RigTom WayNo ratings yet

- DX ConnectorDocument8 pagesDX ConnectorpooNo ratings yet

- Camesa TechBulletin-022Document1 pageCamesa TechBulletin-022FauzanNo ratings yet

- Baylor Brake 2025BDocument116 pagesBaylor Brake 2025BTAHRI BELGACEMNo ratings yet

- TechScope EZT-IIDocument2 pagesTechScope EZT-IIMIS WORKSHOPNo ratings yet

- Gv-R55xtoc-4gd 1.0 NP PDFDocument28 pagesGv-R55xtoc-4gd 1.0 NP PDFjrestilo3No ratings yet

- Step 1: Schema To Connect OV7670 To Arduino DueDocument14 pagesStep 1: Schema To Connect OV7670 To Arduino DueRaeedNo ratings yet

- Comandos B2Document3 pagesComandos B2Aurélio FariaNo ratings yet

- Application Form: Berlin Music Video Awards Music Video InformationDocument7 pagesApplication Form: Berlin Music Video Awards Music Video InformationAugusto Gerardi RoussetNo ratings yet

- Python Regular Expression (Regex) Cheat Sheet: by ViaDocument3 pagesPython Regular Expression (Regex) Cheat Sheet: by ViaDimitris LyberisNo ratings yet

- Em351 / Em357: High-Performance, Integrated Zigbee/802.15.4 System-On-ChipDocument244 pagesEm351 / Em357: High-Performance, Integrated Zigbee/802.15.4 System-On-ChipSamuel Ulises Leon GonzalezNo ratings yet

- LogDocument5 pagesLogtezla animeNo ratings yet

- The Brown Bauhaus STUDIO ARCHITECTURE: Fundamental Course - Comprehensive Ale Review + Preparation ProgramDocument10 pagesThe Brown Bauhaus STUDIO ARCHITECTURE: Fundamental Course - Comprehensive Ale Review + Preparation ProgramClaro III TabuzoNo ratings yet

- Monitor System From SESV1679 - D10RIDocument16 pagesMonitor System From SESV1679 - D10RIkhaled boulahlibNo ratings yet

- Iso 8041 2005Document15 pagesIso 8041 2005estevaomoraesNo ratings yet

- Fulfillments and Failures of Virtual Learning Environment (VLE) : A Systematic ReviewDocument12 pagesFulfillments and Failures of Virtual Learning Environment (VLE) : A Systematic ReviewInternational Journal of Recent Innovations in Academic ResearchNo ratings yet

- Module 4 - Privacy in The CyberspaceDocument15 pagesModule 4 - Privacy in The CyberspaceOchoa Bryan-sanNo ratings yet

- BJ08001sensor Gauges D85Document3 pagesBJ08001sensor Gauges D85FerdianNo ratings yet

- Nowy Moduå Igbt 2mbi400tb-060 A50l-0001-0340 600V 400a Fuji DatasheetDocument18 pagesNowy Moduå Igbt 2mbi400tb-060 A50l-0001-0340 600V 400a Fuji DatasheetItalo SilvaNo ratings yet

- Design of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsDocument2 pagesDesign of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsARSENo ratings yet

- Samsung Business Monitor: LC34H890WJWXXLDocument12 pagesSamsung Business Monitor: LC34H890WJWXXLAnushaNo ratings yet

- SANY SY80C-9, Excellent Performance With Superior QualityDocument6 pagesSANY SY80C-9, Excellent Performance With Superior QualityANANTH JNo ratings yet

- Siddaganga Institute of Technology, Tumakuru - 572 103: Usn 1 S I 7EE03Document2 pagesSiddaganga Institute of Technology, Tumakuru - 572 103: Usn 1 S I 7EE03Ranjan GandhiNo ratings yet

- Lab Course File EC 601 DSPDocument17 pagesLab Course File EC 601 DSPPrachi ParasharNo ratings yet

- BoschpinjDocument3 pagesBoschpinjMohamed AdelNo ratings yet

- Audi Logo Guideline 2009Document13 pagesAudi Logo Guideline 2009Nicole QinNo ratings yet

- PWC Internet Cookies FinalDocument91 pagesPWC Internet Cookies FinalshabiumerNo ratings yet

- Cbi Price List 2021 2022Document108 pagesCbi Price List 2021 2022CalvinNo ratings yet

- Drafting - Exercise 1Document12 pagesDrafting - Exercise 1Japan Fo4mobileNo ratings yet

- Project Raspberrypi WebServerDocument6 pagesProject Raspberrypi WebServeragung indotechNo ratings yet

- Fundementals of Information Technology: Take Home AssignmentDocument15 pagesFundementals of Information Technology: Take Home Assignmentkesh mellowNo ratings yet

- Dash ™ 3000/4000/5000 Patient Monitor: Service ManualDocument8 pagesDash ™ 3000/4000/5000 Patient Monitor: Service ManualSERGIO PEREZNo ratings yet

- Aws Direct Connect-UgDocument163 pagesAws Direct Connect-UgPrashant GarjeNo ratings yet