Professional Documents

Culture Documents

Iso-Superior Glycols-Plain: Product Features & Applications

Iso-Superior Glycols-Plain: Product Features & Applications

Uploaded by

Eldiyar Azamatov0 ratings0% found this document useful (0 votes)

24 views1 pageISO Resin is a medium viscosity polyester resin based on isophthalic acid and superior glycols. It exhibits good mechanical and electrical properties with good chemical resistance compared to general purpose resins. ISO Resin is well suited for making glass reinforced equipment for handling chemicals due to its superior resistance to acids, solvents, and oils. Typical applications include chemical tanks, ducts, bath tubs, and boats. The document provides test results showing the resin's properties meet industry standards for strength, hardness, heat resistance and chemical exposure. Proper post curing is recommended to achieve optimum mechanical properties.

Original Description:

Original Title

ISO-Resin

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentISO Resin is a medium viscosity polyester resin based on isophthalic acid and superior glycols. It exhibits good mechanical and electrical properties with good chemical resistance compared to general purpose resins. ISO Resin is well suited for making glass reinforced equipment for handling chemicals due to its superior resistance to acids, solvents, and oils. Typical applications include chemical tanks, ducts, bath tubs, and boats. The document provides test results showing the resin's properties meet industry standards for strength, hardness, heat resistance and chemical exposure. Proper post curing is recommended to achieve optimum mechanical properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

24 views1 pageIso-Superior Glycols-Plain: Product Features & Applications

Iso-Superior Glycols-Plain: Product Features & Applications

Uploaded by

Eldiyar AzamatovISO Resin is a medium viscosity polyester resin based on isophthalic acid and superior glycols. It exhibits good mechanical and electrical properties with good chemical resistance compared to general purpose resins. ISO Resin is well suited for making glass reinforced equipment for handling chemicals due to its superior resistance to acids, solvents, and oils. Typical applications include chemical tanks, ducts, bath tubs, and boats. The document provides test results showing the resin's properties meet industry standards for strength, hardness, heat resistance and chemical exposure. Proper post curing is recommended to achieve optimum mechanical properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

ISO-SUPERIOR GLYCOLS-PLAIN

PROPERTIES OF CAST RESIN LAMINATE(on base resin)

PRODUCT FEATURES & APPLICATIONS

ISO Resin is a medium viscosity, medium reactive polyester resin

based on Isophthalic acid and superior glycols. Properties Units Results TS

It exhibits good mechanical and electrical properties together * Post a) Barcol Hardness BHU 40* ASTM D – 2583

cured results TS- Test Standards with good chemical resistance b) Heat Distortion Temp. 0

100 ISO- 75

C

compared to general-purpose and moldings. Its superior chemicals c) Specific Gravity - 1.20± 0.02 IS0-1183

resistance towards most mineral and organic acids, solvents and oils d) Volume Shrinkage on cure % 7-8 ISO-3521

makes ISO is an ideal choice for making glass reinforced chemical e) Tensile Strength N/sq.mm 60+5 ISO – 527

f) Tensile Modulus N/sq.mm 3000-3200 ISO – 527

process equipment, storage tanks, tankers, ducting, hoods etc. Note: T.S- g) Elongation at break % 2.5 – 3.0 ISO – 527

Test sample as per standard for handling chemicals at ambient temperature. h) Flexural Strength N/sq.mm 100 - 110 ISO –178

Moulds, boats and bathtubs etc can also be made i) Flexural Modulus N/sq.mm 3100 - 3400 ISO – 178

Test Data:- Exposed the Plain Cast Resin (Post Cured)

resins.ISO Resin

TYPICAL APPLICATION rapidly wets the surface of glass fiber in Samples as per

Chemical Tanks/pipelines, fume extractor, Duct, Hood, Bath Tub, Standard ASTM C-581 / ISO R62 & ISO R75 0 the

Chemical equipment, Tanker, Boat form of cloth mat or chopped fiber to produce laminates

to Fluid and Tested at 28 Days at 25 C

PHYSICAL DATA IN LIQUID STATE AT 25OC# [Confirm to Exposed Solvent Units Standards Results

IS 6746-1994 and BS 3532-1990] Distilled Water mg/T.S ISO R62 Max 80

Properties Unit Value TM N-Heptane mg/T.S ISO R75 20 – 30

Appearance - Pale Yellow TM-31 N-Heptane/O-Xylene (60/40) Mg/T.S ISO R75 20 - 60

Specific Gravity. - 1.11 + 0.02 TM-11

Viscosity -Ford Cup 4 @ 30oC - Seconds mPa 120 + 20 TM-04 APPLICATION METHODS O Optional Yes

Brookfield RVT model s(cP) 500 ± 100 TM-05

Hand lay-up

Acid value mgKOH/gm 15±5 TM-06

Spray-up O

Volatile Content % 37 ± 3 TM-08

Geltime @ 250C * Minutes 15 ± 3 TM-07 Filament Winding

0

Peak Exotherm Temp. 140 – 160 TM-07 Continuous Laminating O

C

Stability in the Dark Months 3 TM-32 Casting

Resin Transfer Moulding

* Using Accelerator, Co (2%) 1 ml, Catalyst, MEKP1.5ml, the gel time, cure time and Cold Press

Peak Exotherm measured.

Hot Press ( Sheet - Bulk Moulding Compound )

Packing: Regularly available 35 Kgs (Carboys) 220 Kgs

(Drums/Barrel) Optional Bulk: Tanker – 16 MT / 23 MT TM- Test Pultrusion ( Profile )

Method Other

Revision Description Date

USAGE & POST CURING: ISO-SUPERIOR

ISO- 9001- 2008 Rev-00 16.08.2010

GLYCOLSPLAIN

* The Isophthalic polyester resin performs best if the Prepared by laminate is completely post cured. The quantity of catalyst and

accelerator can be adjusted to get a shorter or longer geltime.

* It is recommended to mature the products for 24 hours and post curing should be done for minimum of six hours at 80 deg

centigrade. This is recommended for getting the optimum properties.

You might also like

- RESEARCH GCS AdecDocument62 pagesRESEARCH GCS Adec07 FARAH ATHIRAH BINTI MOH FUZINo ratings yet

- Orthophthalic Food Grade Espol 14.01: Technical SpecificationDocument1 pageOrthophthalic Food Grade Espol 14.01: Technical SpecificationrohanbagadiyaNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Solid Surface Resin - SpecsDocument3 pagesSolid Surface Resin - SpecsAmr Abdelmegid abdelsalam husseinNo ratings yet

- Product Technical Data Sheet: Unit Value MethodDocument2 pagesProduct Technical Data Sheet: Unit Value Methodhamza OUADINo ratings yet

- PP Mosten EH 501: Technical DatasheetDocument2 pagesPP Mosten EH 501: Technical DatasheetBanupriya BalasubramanianNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- SABIC® LLDPE - 118WJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJ - Global - Technical - Data - Sheetsysp92yybvNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- Product Data: Turbinol XDocument2 pagesProduct Data: Turbinol XdedyhidNo ratings yet

- TDS - Premix Marine ThixotropeDocument3 pagesTDS - Premix Marine ThixotropegmNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Top Coat Blue Pool Iso-Npg enDocument4 pagesTop Coat Blue Pool Iso-Npg enVICTOR MARCOSNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- Espol 38.00 Revised 07032016Document2 pagesEspol 38.00 Revised 07032016Vinay YadavNo ratings yet

- Epovia Optimum® KRF 1051: Technical Data SheetDocument1 pageEpovia Optimum® KRF 1051: Technical Data SheetsidsaleemNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Impeller STD Resin - Dion 9800 PDFDocument5 pagesImpeller STD Resin - Dion 9800 PDFWilmer AndresNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Shell Morlina s2 B 100Document4 pagesShell Morlina s2 B 100PT Tunggal Karya PratamaNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Atlac-580 001610Document2 pagesAtlac-580 001610flavio fiumiNo ratings yet

- TGSB (M) Turbine OilDocument3 pagesTGSB (M) Turbine OilQuy NguyenNo ratings yet

- Datasheet CX02-81Document2 pagesDatasheet CX02-81jprodriguezNo ratings yet

- Kanatol 400 (M)Document2 pagesKanatol 400 (M)buildguard7No ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- TDS Hips 2551Document3 pagesTDS Hips 2551jokotrianto13No ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- 002DP48 PDFDocument2 pages002DP48 PDFDiadam SharmaNo ratings yet

- Omega Amide Nylon Pa CatalogueDocument5 pagesOmega Amide Nylon Pa Cataloguesoni10483No ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Tds of Eterset 2844Document2 pagesTds of Eterset 2844Nandkumar PawarNo ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- ETERSET 2960 Data SheetDocument2 pagesETERSET 2960 Data Sheetahmed mahmoudNo ratings yet

- Enersyn MP-S RangeDocument2 pagesEnersyn MP-S RangecarmaNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Eriks - Pmma DatasheetDocument3 pagesEriks - Pmma DatasheetNaruto UzumakiNo ratings yet

- Loctite 3568 TDSDocument3 pagesLoctite 3568 TDSShareduwan SannosiNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- Shell GT32 1451468381Document2 pagesShell GT32 1451468381Pramod SokhariyaNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Technical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantDocument3 pagesTechnical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantSantaj TechnologiesNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Zytel FR50 NC010 ADocument9 pagesZytel FR50 NC010 ADario de SantiagoNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- 9907X0036 - 3 Operating InstructionsDocument6 pages9907X0036 - 3 Operating InstructionsEldiyar AzamatovNo ratings yet

- Analysis of Residual Products in Triethylbenzylammonium Chloride by HPLC. Study of The Retention MechanismDocument6 pagesAnalysis of Residual Products in Triethylbenzylammonium Chloride by HPLC. Study of The Retention MechanismEldiyar AzamatovNo ratings yet

- Us 20190099915 A 1Document13 pagesUs 20190099915 A 1Eldiyar AzamatovNo ratings yet

- Pressure Loss 53 Vertical InstallationDocument3 pagesPressure Loss 53 Vertical InstallationEldiyar AzamatovNo ratings yet

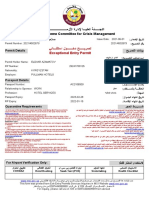

- Approved Return PermitDocument1 pageApproved Return PermitEldiyar AzamatovNo ratings yet

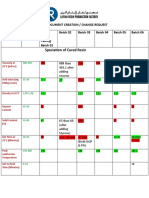

- Properties ComparisonDocument2 pagesProperties ComparisonEldiyar AzamatovNo ratings yet

- Valve Pressure DropDocument4 pagesValve Pressure DropEldiyar AzamatovNo ratings yet

- Hempadur 15553: Product CharacteristicsDocument4 pagesHempadur 15553: Product CharacteristicsEldiyar AzamatovNo ratings yet

- Above Ground Fuel Tank RequirementsDocument8 pagesAbove Ground Fuel Tank RequirementsEldiyar AzamatovNo ratings yet

- Styrene Safe Handling Guide EnglishDocument40 pagesStyrene Safe Handling Guide EnglishEldiyar AzamatovNo ratings yet

- 03 KosarDocument8 pages03 KosarEldiyar AzamatovNo ratings yet

- Applied: Measuring TBC (Polymerization Inhibitor)Document4 pagesApplied: Measuring TBC (Polymerization Inhibitor)Eldiyar AzamatovNo ratings yet

- Isophthalic Polyester Resin: Durable and Stable ResinDocument3 pagesIsophthalic Polyester Resin: Durable and Stable ResinEldiyar AzamatovNo ratings yet

- Crystic 625PA: Isophthalic Resin For Large StructuresDocument2 pagesCrystic 625PA: Isophthalic Resin For Large StructuresEldiyar AzamatovNo ratings yet

- Durability of Isophthalic Polyester Composites Used in Civil Engineering ApplicationsDocument14 pagesDurability of Isophthalic Polyester Composites Used in Civil Engineering ApplicationsEldiyar AzamatovNo ratings yet

- Tech Data - Hi IsoDocument1 pageTech Data - Hi IsoEldiyar AzamatovNo ratings yet

- EUL 0658-037-00 DiagnosticKit COVID-19 AntigenTest ColloidalGold v1.0Document24 pagesEUL 0658-037-00 DiagnosticKit COVID-19 AntigenTest ColloidalGold v1.0Maciej OONo ratings yet

- Quest Circular Motion 1 KeyDocument5 pagesQuest Circular Motion 1 KeyCarlos Ortiz100% (1)

- Biologi K2Document16 pagesBiologi K2Nnmarziana NickNo ratings yet

- 2-2 Letter To Sarah BallouDocument4 pages2-2 Letter To Sarah BallouLuis AsteteNo ratings yet

- by The Radisson Hotel Group, Managed by Sarovar Hotels: Park Plaza, LudhianaDocument14 pagesby The Radisson Hotel Group, Managed by Sarovar Hotels: Park Plaza, Ludhianasaurabh kumarNo ratings yet

- PARCO Pakistan HRMDocument38 pagesPARCO Pakistan HRMfujimukazu100% (1)

- Final Health 1-10 01.09.2014Document66 pagesFinal Health 1-10 01.09.2014Jinsen Paul Martin100% (1)

- L6S Final Examination Students)Document12 pagesL6S Final Examination Students)Fazliawati MahayuddinNo ratings yet

- XC975 EV 英语译文Document2 pagesXC975 EV 英语译文abangNo ratings yet

- Overflow With Hope - Joel OsteenDocument7 pagesOverflow With Hope - Joel OsteenJHON RAY OTAÑESNo ratings yet

- ASTM Method For Distillation of Petroleum Products at Atmospheric PressureDocument7 pagesASTM Method For Distillation of Petroleum Products at Atmospheric PressureSaiVenkatNo ratings yet

- Ilovepdf MergedDocument95 pagesIlovepdf MergedYoussef El bahiNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Installation, Operation, & Maintenance ManualDocument48 pagesInstallation, Operation, & Maintenance ManualEdinsonUribeTorresNo ratings yet

- Analytical Research PapersDocument4 pagesAnalytical Research PapersabimubNo ratings yet

- Ashridge Business School, UK: Scientist-PractitionerDocument1 pageAshridge Business School, UK: Scientist-PractitionerSharma ShikhaNo ratings yet

- Charmaine V. Rosales: Our Lady of Fatima University Graduate SchoolDocument6 pagesCharmaine V. Rosales: Our Lady of Fatima University Graduate SchoolCharmaine RosalesNo ratings yet

- Usb Cam LogDocument1 pageUsb Cam LogВладислав МаньківськийNo ratings yet

- 2020 Micropropagation of Medicinal Plants - Review Micropropagation of Medicinal Plants - ReviewDocument8 pages2020 Micropropagation of Medicinal Plants - Review Micropropagation of Medicinal Plants - ReviewMuhilan MahendhiranNo ratings yet

- dsmc0020 en Medc hd1 Heat DetectorDocument2 pagesdsmc0020 en Medc hd1 Heat DetectorAbdul Hakeem MohammedNo ratings yet

- HortorumCultusOrijinal 1Document16 pagesHortorumCultusOrijinal 1Mohamad ArifNo ratings yet

- 9500-WGEL-G000-ISGP-G00000-CX-7880 - Specification For Structural Fire ProofingDocument15 pages9500-WGEL-G000-ISGP-G00000-CX-7880 - Specification For Structural Fire ProofingArshad IqbalNo ratings yet

- Grade 6 DLL Mapeh q4 Week 6Document4 pagesGrade 6 DLL Mapeh q4 Week 6Ivy PacateNo ratings yet

- Method Predicts Well Bore ScaleDocument8 pagesMethod Predicts Well Bore ScaleAnonymous JJ29r2oCNo ratings yet

- Bomba Hidráulica FestoDocument8 pagesBomba Hidráulica FestoAlex TamayoNo ratings yet

- Stock List Material Medika Plaza PER 02 MARET 2021Document4 pagesStock List Material Medika Plaza PER 02 MARET 2021medika plazaNo ratings yet

- Design and Fabrication of Pesticide Solar SprayerDocument6 pagesDesign and Fabrication of Pesticide Solar SprayerK IsmailNo ratings yet

- 529 Ema Ratna Kartinawati Ikatan Dokter Indonesia15570678505ccef84b102a3Document1 page529 Ema Ratna Kartinawati Ikatan Dokter Indonesia15570678505ccef84b102a3Ema Ratna KartinawatiNo ratings yet

- Online Ordering DocuDocument55 pagesOnline Ordering Docuvinalyn apolinarNo ratings yet