Professional Documents

Culture Documents

Che1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 Acp

Che1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 Acp

Uploaded by

blub blueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Che1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 Acp

Che1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 Acp

Uploaded by

blub blueCopyright:

Available Formats

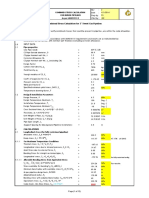

CHE1005 MOMENTUM TRANSFER L T P J C

3 0 2 0 4

Pre-requisite NIL Syllabus version

1.1

Course Objectives:

1. Understand the fluid properties, the fundamental principles and theorem related to

momentum transfer

2.Apply the physical and mathematical models to analyse the fluid flow phenomena in

engineering applications

3. Solve the steady state and un-steady state momentum transfer problems

Course Outcomes :

1. Explain the properties of Newtonian and Non-Newtonian fluid and basic principles of

momentum transfer

2. Classify the governing equations related to the momentum transfer phenomena

3. Summarize the different types of flow measuring devices related to the momentum transfer

4. Solve the problems related to the losses incurred during the flow of fluid

5. Analyze the different non-dimensional numbers based on the theorems

6. Evaluate the fluid flow phenomena through packed and fluidized bed

Student Learning Outcomes (SLO): 1,2,9

1. Ability to apply mathematics and science in engineering applications

2. Clear understanding of the subject related concepts and of contemporary issues

9. Problem solving ability solving social issues and engineering applications

Module:1 Basic Concept of Momentum Transfer 5 hours

Introduction and Significance of Momentum Transfer in Chemical Engineering. Definition of

fluid - Classification of fluids Newtonian fluid Characteristic properties of fluids Non -

aw and Hydrostatic law of

equilibrium; Pressure and its measurement- Manometers

Module:2 Concept of Fluid Flow Phenomena 7 hours

Kinematics of fluid flow, Dynamics of fluid flow Basic equations governing fluid flow types

of fluid flow. Equation of Continuity and its application, Equation of motion Derivation of

Module:3 Flow Measuring Devices 5 hours

Importance of metering Classification flow measuring devices, Principle and working of

Orifice meter, Venturi meter, Pitot tube, Variable area meters: Rotameter

Module:4 Flow through Circular Pipes 8 hours

Flow of fluids in Laminar regime Velocity Profile, Shear Stress Distribution Hagen

Poiseuille equation - Concept of average velocity Concept of Kinetic energy correction factor,

Concept of Fluid friction Skin friction Form friction Factors affecting friction Friction

factor

Module:5 Dimensional Analysis 4 hours

Dimensional homogeneity Non-dimensional

numbers, Model laws

Module:6 Fluid Flow through Packed and Fluidized Bed 7 hours

Flow past immersed bodies Significance of form friction - Concept of Drag, Drag

Coefficients and Particle Reynolds number - Drag Coefficient vs. Particle Reynolds number

curves for regular and irregular shaped solid particles. Flow of fluids through packed beds

Packing and types of packing -Pressure drop across packed beds Kozeny Carman equation

- Loading and Flooding Packed Beds. Concept of Fluidization Condition

for Solid particles to be in a suspended condition in a flowing fluid minimum fluidization

velocity

Module:7 Transportation of Fluids 7 hours

Transportation Components -Pipe, Fittings and Valves, Types of Fittings, valves -Stuffing

Boxes, Mechanical Seals Estimation of head loss from fittings and valves, Concept of minor

losses- types of minor losses. Fluid Moving Machinery: Pumps Classification and working of

Centrifugal Pumps and Positive Displacement Pumps Basic Principles of Centrifugal Pumps

Pump Characteristics Concept of Specific Speed, Net Positive Suction Head - Factors

influencing selection of pump

Module:8 Contemporary issues 2 hours

Total Lecture hours: 45 hours

Text Books

1. Mc Cabe, Smith, Harriott, Unit Operations of Chemical Engineering 7th ed., McGraw

Hill, New York, 2014.

2. Cengel Y.A., Cimbala J.M., Fluid Mechanics (SIE): Fundamentals and Applications, 3 rd

ed., Mcgraw Hill, New York, 2014.

Reference Books

1. Bansal R.K., Fluid Mechanics and Hydraulic Machines, 9th ed., Laxmi Publication (P) Ltd.,

New Delhi, 2017.

2. Fox R.W., McDonald A.T., Pirtchard P.J., Mitchell J. W., Introduction to Fluid Mechanics,

9th ed., Wiley Publications, 2015.

Mode of evaluation: Continuous Assessment Test, Quizzes, Assignments, Final Assessment Test

Laboratory Experiments 30 hours

1. Determination of coefficient of discharge of venturimeter

2. Calibration of an orifice meter

3. Determination of friction factor for flow through circular pipe

4. Determination of loss of coefficient due to sudden enlargement, sudden contraction, bend and

elbow

5. Determination of Reynolds apparatus

6.

7. Performance characteristics of centrifugal pump at rated speed

8. Determination of pressure drop per unit length as a function of superficial velocity of

fluidization medium

9. Verification of relationship between fluid flow and pressure drop per unit length of packing

10. Determination of friction factor for flow through noncircular pipe

Mode of evaluation: Continuous Assessment Test, Quizzes, Assignments, Final Assessment Test

Recommended by Board of Studies 15.04.2019

Approved by Academic Council 55 Date 13.06.2019

You might also like

- REPORT Design Helicopter 2 - Seat PDFDocument44 pagesREPORT Design Helicopter 2 - Seat PDFThanh NguyenNo ratings yet

- Che1005 Momentum-Transfer Eth 1.1 47 Che1005 28 PDFDocument3 pagesChe1005 Momentum-Transfer Eth 1.1 47 Che1005 28 PDFAbhishek KarpeNo ratings yet

- Bche205l Momentum-Transfer TH 1.0 70 Bche205lDocument2 pagesBche205l Momentum-Transfer TH 1.0 70 Bche205lLuha Fathima BasheerNo ratings yet

- SYLLABUSDocument3 pagesSYLLABUSInzamam Ul HaqueNo ratings yet

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentDocument5 pagesS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrNo ratings yet

- Bmee204l Fluid-Mechanics-And-Machines TH 1.0 67 Bmee204lDocument3 pagesBmee204l Fluid-Mechanics-And-Machines TH 1.0 67 Bmee204lKrijayNo ratings yet

- Fluid and Particle Mechanics Lab ExperimentsDocument4 pagesFluid and Particle Mechanics Lab ExperimentsSaiVenkatNo ratings yet

- Gujarat Technological University: Fluid Flow Operation B.E. Semester: IIIDocument3 pagesGujarat Technological University: Fluid Flow Operation B.E. Semester: IIIMohammad ImranNo ratings yet

- Fluid MechanicsDocument3 pagesFluid MechanicsinstrutechNo ratings yet

- ME200-Fluid Mechanics and MachineryDocument3 pagesME200-Fluid Mechanics and Machinerynandan144No ratings yet

- Fluid Flow Operations - 9201Document5 pagesFluid Flow Operations - 9201Ankit PatelNo ratings yet

- PDFDocument4 pagesPDFPradeep KumarNo ratings yet

- Fluid Mechanics & HydraulicsDocument4 pagesFluid Mechanics & HydraulicsHiral GamitNo ratings yet

- Fluid MechanicsDocument3 pagesFluid MechanicsRudransh KatiyarNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19suraj nakumNo ratings yet

- Sem 3Document29 pagesSem 3rajindermechNo ratings yet

- CIVIL Fluid Mechanics SyllabusDocument2 pagesCIVIL Fluid Mechanics Syllabusdurga sharmaNo ratings yet

- FM - FP - CompressedDocument215 pagesFM - FP - CompressedKumar SubramanianNo ratings yet

- Fluid Mechanics CLB 11003: By: Madam Norulakmal Nor Hadi Ext: 2031 Room 11Document10 pagesFluid Mechanics CLB 11003: By: Madam Norulakmal Nor Hadi Ext: 2031 Room 11amyozNo ratings yet

- Ce8302 FM PresentationDocument102 pagesCe8302 FM PresentationRON SAMUEL 401935100% (1)

- Fluid MechanicsDocument3 pagesFluid MechanicsVipin KallingalNo ratings yet

- Instructor Dr.K. Nagamalleswararao Emp Id: 14768 Associate Professor CDMM Vit, VelloreDocument148 pagesInstructor Dr.K. Nagamalleswararao Emp Id: 14768 Associate Professor CDMM Vit, VellorePriyesh SinghNo ratings yet

- Course Learning Outcome 1Document3 pagesCourse Learning Outcome 1engineer63No ratings yet

- ME111 Fluid Mechanics and Machinery: Suggested ReadingsDocument1 pageME111 Fluid Mechanics and Machinery: Suggested ReadingsRabinNo ratings yet

- Course Outline - NAME 213Document5 pagesCourse Outline - NAME 213A'raf Bin Islam SwapnilNo ratings yet

- 5th Sem 7 Mechanical EngineeringDocument44 pages5th Sem 7 Mechanical EngineeringEmperorNo ratings yet

- Course Folder (Fluid Mechanics - II)Document3 pagesCourse Folder (Fluid Mechanics - II)fawad naeemNo ratings yet

- 3.1 FLUID Flow: RationaleDocument16 pages3.1 FLUID Flow: RationaleAli übeyitoğullarıNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19SURAJ NAKUMNo ratings yet

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Mechanical Engineering JUL. 2008Document52 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Mechanical Engineering JUL. 2008ephremNo ratings yet

- FMM Syllabus Revised (2014-15)Document4 pagesFMM Syllabus Revised (2014-15)avcschaudhariNo ratings yet

- Fluid Mechanics (BTME-301-18)Document13 pagesFluid Mechanics (BTME-301-18)Surjit Kumar GandhiNo ratings yet

- Course Code Course/Subject Name Credits CHC303 Fluid Flow 4Document3 pagesCourse Code Course/Subject Name Credits CHC303 Fluid Flow 4sddalviNo ratings yet

- Fluid Mechanics & Hydraulics-1Document1 pageFluid Mechanics & Hydraulics-1Arman AlvaroNo ratings yet

- 3ME05 Fluid Mechanics: Course Learning ObjectivesDocument3 pages3ME05 Fluid Mechanics: Course Learning Objectivesgotu123No ratings yet

- Syllabus MEE1004 FM PDFDocument3 pagesSyllabus MEE1004 FM PDFSidhant JaiswalNo ratings yet

- ME200-Fluid Mechanics and MachineryDocument3 pagesME200-Fluid Mechanics and MachineryvishnuNo ratings yet

- FM SyllabusDocument3 pagesFM SyllabusParmeshwarPaulNo ratings yet

- Semester IiiDocument178 pagesSemester IiiAkshil ShahNo ratings yet

- 3rd Sem SyllabusDocument33 pages3rd Sem SyllabusSUHOTRA guptaNo ratings yet

- B Tech Syllabus of Mechanical 4thDocument19 pagesB Tech Syllabus of Mechanical 4thprakashkumarsenNo ratings yet

- M.tech. Chemical EngineeringDocument20 pagesM.tech. Chemical EngineeringRajkamal TheGraduateNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Nisarg ShahNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Bhaveshkumar PatelNo ratings yet

- Mechanical (Automobile) EngineeringDocument96 pagesMechanical (Automobile) Engineeringshiyas sNo ratings yet

- Sub Code: 15IM/IP 32 IA Marks: 25 Hrs/week: 04 Exam Hours: 03 Total Lecture HRS: 50 Exam Marks: 100Document14 pagesSub Code: 15IM/IP 32 IA Marks: 25 Hrs/week: 04 Exam Hours: 03 Total Lecture HRS: 50 Exam Marks: 100Biswajeet MohantyNo ratings yet

- Ce 2211 Applied HydraulicsDocument4 pagesCe 2211 Applied HydraulicsGERARD HAULENo ratings yet

- Probability and Statistics: Inferences Concerning ProportionsDocument31 pagesProbability and Statistics: Inferences Concerning ProportionsPriya PooriNo ratings yet

- 3B2Document2 pages3B2imanadibiNo ratings yet

- ME 203 Mechanics of FluidsDocument3 pagesME 203 Mechanics of FluidsSherwinNo ratings yet

- BH023332 HNCD L45 in Engineering Units 070610Document4 pagesBH023332 HNCD L45 in Engineering Units 070610Eng Islam Kamal ElDinNo ratings yet

- Physics Fluid MechanicsDocument27 pagesPhysics Fluid MechanicsCHO ACHIRI HUMPHREYNo ratings yet

- ME212 Fluid MechanicsDocument2 pagesME212 Fluid Mechanicsnandan144No ratings yet

- Lecture Plan Instructor K S RajmohanDocument4 pagesLecture Plan Instructor K S RajmohanSwapnil TripathiNo ratings yet

- B.E. Manufacturing Science Engineering Updated On 27.11.2018 Syla 7 8 PDFDocument40 pagesB.E. Manufacturing Science Engineering Updated On 27.11.2018 Syla 7 8 PDFGautham G NambiarNo ratings yet

- M.Tech (Full Time) - Chemical Engineering Curriculum & Syllabus 2013 - 2014Document40 pagesM.Tech (Full Time) - Chemical Engineering Curriculum & Syllabus 2013 - 2014hmasif456No ratings yet

- CHE-221: Fluid Mechanics-I: Dr. Zaib JahanDocument10 pagesCHE-221: Fluid Mechanics-I: Dr. Zaib JahanBilal JuttNo ratings yet

- Fluid Mechanics SyllabusDocument4 pagesFluid Mechanics Syllabusjohn@gmail.com0% (1)

- Laminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisFrom EverandLaminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisNo ratings yet

- USS OMR Paper-II SAMPLEDocument2 pagesUSS OMR Paper-II SAMPLEblub blue67% (3)

- Cascade ControllerDocument5 pagesCascade Controllerblub blueNo ratings yet

- Module I Heat TransferDocument57 pagesModule I Heat Transferblub blueNo ratings yet

- Fluid Flow Through Packed and Fluidized Bed: Momentum Transfer CHE1005Document69 pagesFluid Flow Through Packed and Fluidized Bed: Momentum Transfer CHE1005blub blueNo ratings yet

- Dimensional Analysis: Momentum Transfer CHE1005Document41 pagesDimensional Analysis: Momentum Transfer CHE1005blub blueNo ratings yet

- WINSEM2021-22 CSE1002 LO VL2021220501708 Reference Material I 08-03-2022 Default ArguementsDocument44 pagesWINSEM2021-22 CSE1002 LO VL2021220501708 Reference Material I 08-03-2022 Default Arguementsblub blueNo ratings yet

- Mechanical Tests For MetalsDocument32 pagesMechanical Tests For Metalsblub blueNo ratings yet

- Impeller Types: Figure 1: Laminar Flow ImpellersDocument3 pagesImpeller Types: Figure 1: Laminar Flow Impellersblub blueNo ratings yet

- WINSEM2020-21 CHE1001 TH VL2020210506044 Reference Material I 01-Mar-2021 Class V Heat Treatment of MetalsDocument16 pagesWINSEM2020-21 CHE1001 TH VL2020210506044 Reference Material I 01-Mar-2021 Class V Heat Treatment of Metalsblub blueNo ratings yet

- CENG 197 - CE Competency Appraisal II Problem Set 5 Translation and Rotation of Liquid MassesDocument17 pagesCENG 197 - CE Competency Appraisal II Problem Set 5 Translation and Rotation of Liquid MassesApple AterradoNo ratings yet

- Compound PendulumDocument7 pagesCompound PendulumNuman9660% (1)

- Warning ErrorsDocument18 pagesWarning ErrorsRakesh KRNo ratings yet

- Rigid or Flexible DiaphragmDocument2 pagesRigid or Flexible DiaphragmManishNo ratings yet

- Work and Power: By: Jeffrey Chen and Daniel LeeDocument9 pagesWork and Power: By: Jeffrey Chen and Daniel LeeAshley JohnsNo ratings yet

- Shear Wall and Frame Interaction TerminologyDocument5 pagesShear Wall and Frame Interaction TerminologyGRD Journals100% (1)

- Chapter 11: Dynamic Force AnalysisDocument34 pagesChapter 11: Dynamic Force AnalysisSurenderan LoganNo ratings yet

- Extended Abstract Design of Transverse Stiffeners of High Strength Steel Plate GirdersDocument10 pagesExtended Abstract Design of Transverse Stiffeners of High Strength Steel Plate GirdersRaymundNo ratings yet

- Physic Form 4 KSSM - Wave (DLP)Document4 pagesPhysic Form 4 KSSM - Wave (DLP)NURUL IMAN ADRIANA BINTI MOHD MAZNI MoeNo ratings yet

- Emd Part2Document372 pagesEmd Part2kgrhoadsNo ratings yet

- Aerodynamics of Wind TurbinesDocument4 pagesAerodynamics of Wind TurbinesIoanna KaloNo ratings yet

- LectureEKC216 CH7Document38 pagesLectureEKC216 CH7Siva SangaryNo ratings yet

- 230kv Cable Sizing 1Document6 pages230kv Cable Sizing 1Thirunavukkarasu VaratharajanNo ratings yet

- Galilean RelativityDocument29 pagesGalilean Relativitysamuel_okenyNo ratings yet

- Aircraft Stability and Control - Lec02 PDFDocument12 pagesAircraft Stability and Control - Lec02 PDFHaidar HeroNo ratings yet

- Country Electrical Supply 1 PH & 3 PH ListDocument14 pagesCountry Electrical Supply 1 PH & 3 PH Listmohdazlan hassanNo ratings yet

- Practical Design of Rudders - PARTB-1Document40 pagesPractical Design of Rudders - PARTB-1Shikha Bordia83% (6)

- 09-07-22 JR - Super60 (Incoming) Jee-Main WTM-06 Key & Sol'sDocument14 pages09-07-22 JR - Super60 (Incoming) Jee-Main WTM-06 Key & Sol'sAnil KonkatiNo ratings yet

- SVKM J.V. Parekh International School Grade: VI Div: Subject: Physics Topic: Gravity Name of The Student: Roll NoDocument9 pagesSVKM J.V. Parekh International School Grade: VI Div: Subject: Physics Topic: Gravity Name of The Student: Roll NoWere WolfNo ratings yet

- GravityDocument2 pagesGravitySebastian EcheverriaNo ratings yet

- 07 Chapter 5 Aktuell Page SetupDocument33 pages07 Chapter 5 Aktuell Page SetupHO Vinh-QuynhNo ratings yet

- Ramakant Sir Physics Tutorials: (Magnetism) DURATION: 45mins MARKS: 50Document5 pagesRamakant Sir Physics Tutorials: (Magnetism) DURATION: 45mins MARKS: 50Kshitij BichaveNo ratings yet

- Metu NCC Fall Semester (2017-1) PHY 105 General Physics I (3580105) Course SyllabusDocument3 pagesMetu NCC Fall Semester (2017-1) PHY 105 General Physics I (3580105) Course SyllabusErgin ÖzdikicioğluNo ratings yet

- Pavement EvaluationDocument45 pagesPavement EvaluationAffan JalilNo ratings yet

- Stability, Determinacy of StructuresDocument90 pagesStability, Determinacy of StructuresSaad UllahNo ratings yet

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- FRANC3D V7 Training - Part 1 - Intro PDFDocument41 pagesFRANC3D V7 Training - Part 1 - Intro PDFsanthoshnlNo ratings yet