Professional Documents

Culture Documents

435NBX Basic Ladder Logix Setup: Real Time Automation, Inc. 1 1-800-249-1612

435NBX Basic Ladder Logix Setup: Real Time Automation, Inc. 1 1-800-249-1612

Uploaded by

dobCopyright:

Available Formats

You might also like

- Interfacing GSM With 8051Document14 pagesInterfacing GSM With 8051Mohammad Ali100% (1)

- K300 ML1400 Indexing Example v1 - 0Document7 pagesK300 ML1400 Indexing Example v1 - 0Emanuel Falcon100% (1)

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- 9 1EN - r1Document146 pages9 1EN - r1Jordi Segura FaríasNo ratings yet

- Mutants & Masterminds 3e - Power Profile - Plant PowersDocument6 pagesMutants & Masterminds 3e - Power Profile - Plant PowersMichael Morgan100% (1)

- Monokote Field Application Manual PDFDocument136 pagesMonokote Field Application Manual PDFJohn Doe100% (2)

- 435 490NBX LadderLogixDocument10 pages435 490NBX LadderLogixi_aordazNo ratings yet

- 435USB-NNAU Userguide PDFDocument41 pages435USB-NNAU Userguide PDFi_aordazNo ratings yet

- Monitorizar Estado de Red ControlnetDocument7 pagesMonitorizar Estado de Red ControlnetkillnueveNo ratings yet

- Message From Micro800 To Logix On Ethernet - IPDocument3 pagesMessage From Micro800 To Logix On Ethernet - IPEdgardoNo ratings yet

- SPAN Port Mirroring - Tech PDFDocument6 pagesSPAN Port Mirroring - Tech PDFmurisNo ratings yet

- 460MMBS-N34 Protocol Gateway: Product User GuideDocument65 pages460MMBS-N34 Protocol Gateway: Product User GuideManuel CentenoNo ratings yet

- 287tr SW - Spec r13Document39 pages287tr SW - Spec r13crhistofirochaNo ratings yet

- Micronet SoftwaresDocument4 pagesMicronet SoftwaresHasan FarooqNo ratings yet

- D Link ConfiguratiuonDocument250 pagesD Link ConfiguratiuonabdulnizarvNo ratings yet

- DES-3028 28P 52 52P CLI v1.00Document250 pagesDES-3028 28P 52 52P CLI v1.00Regivaldo PereiraNo ratings yet

- A76XX Series - SImComDocument22 pagesA76XX Series - SImComMargarita Florez MartinezNo ratings yet

- Logger BestPractices 7.2.2Document44 pagesLogger BestPractices 7.2.2sumen007No ratings yet

- Connecting Compax3 I22T11 and Allen Bradley / Rockwell Plcs Via DevicenetDocument27 pagesConnecting Compax3 I22T11 and Allen Bradley / Rockwell Plcs Via DevicenetIngeniería 2 ICMANo ratings yet

- Micro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesDocument44 pagesMicro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesBrice TOSSAVINo ratings yet

- PLC, PLC Ladder, PLC Ebook, PLC ProgrammingDocument5 pagesPLC, PLC Ladder, PLC Ebook, PLC ProgrammingAmar ThakurNo ratings yet

- SEL-3505/SEL-3505-3 Real-Time Automation Controller: Major Features and BenefitsDocument16 pagesSEL-3505/SEL-3505-3 Real-Time Automation Controller: Major Features and BenefitsHectorNo ratings yet

- AT89S8252 In-System ProgrammingDocument38 pagesAT89S8252 In-System ProgrammingPramod JainNo ratings yet

- ACT350 PROFINET PLC EngineeringNote EN 202004Document34 pagesACT350 PROFINET PLC EngineeringNote EN 202004Lê Kim HàoNo ratings yet

- Using Siemens S7 Plcs Via ProfinetDocument15 pagesUsing Siemens S7 Plcs Via ProfinetMrdinh2014No ratings yet

- Gfs-384 m12 Maxon Rx3iDocument35 pagesGfs-384 m12 Maxon Rx3ihassanaagibNo ratings yet

- Plx-Daq HelpDocument25 pagesPlx-Daq HelpAnonymous C05BLcNo ratings yet

- 460ESUSB-N70U Userguide PDFDocument88 pages460ESUSB-N70U Userguide PDFi_aordazNo ratings yet

- Logix Hot Backup Code Generator ToolDocument3 pagesLogix Hot Backup Code Generator ToolAhmadTaufikMuradNo ratings yet

- Plugin-Ha Solution Axigen Heartbeat DRDBDocument17 pagesPlugin-Ha Solution Axigen Heartbeat DRDBJacko WijaNo ratings yet

- 1784 KTDocument22 pages1784 KTJoseNo ratings yet

- Produce and Consume Tags Between 5580 and Older RSLogix 5000 Based ControllersDocument5 pagesProduce and Consume Tags Between 5580 and Older RSLogix 5000 Based ControllersAlejandra PadillaNo ratings yet

- An 095Document11 pagesAn 095tazzo2No ratings yet

- Logix5000 Controllers - CPU Clock SpeedsDocument3 pagesLogix5000 Controllers - CPU Clock SpeedsMarisolNo ratings yet

- PC2 - Erick MezaDocument13 pagesPC2 - Erick MezaAragonZNo ratings yet

- In System Programming With 8051Document7 pagesIn System Programming With 8051vmateixeiraNo ratings yet

- Troubleshooting Network and CommunicationDocument14 pagesTroubleshooting Network and CommunicationnetpazNo ratings yet

- 193 At001 - en PDocument24 pages193 At001 - en PMauricio Oropeza CabreraNo ratings yet

- 460MSA-N34 UserguideDocument82 pages460MSA-N34 UserguideSamNo ratings yet

- LogRhythm HA DR Install Guide 10.1 RevDDocument38 pagesLogRhythm HA DR Install Guide 10.1 RevDkoteswaranNo ratings yet

- GlossaryDocument320 pagesGlossaryMeghanacherry MNo ratings yet

- CalAmp LMU Series Protocol Adapter SDK Setup GuideDocument11 pagesCalAmp LMU Series Protocol Adapter SDK Setup GuidePRSNo ratings yet

- TCP Port Probe Utility For Some Commonly Used Rockwell ProductsDocument3 pagesTCP Port Probe Utility For Some Commonly Used Rockwell ProductsmarceloNo ratings yet

- Rl-Arm Gs 01Document33 pagesRl-Arm Gs 01Tính Nguyễn VănNo ratings yet

- Cryptographic Algorithm Validation ProgramDocument21 pagesCryptographic Algorithm Validation Programmarvel homesNo ratings yet

- Creating An Ethernet Devices DriverDocument15 pagesCreating An Ethernet Devices DriverMark MerrimanNo ratings yet

- FS-8700-07 Bacnet Arcnet: Driver ManualDocument13 pagesFS-8700-07 Bacnet Arcnet: Driver ManualEric DunnNo ratings yet

- Condition-Based Maintenance: Business Process ProcessingDocument7 pagesCondition-Based Maintenance: Business Process Processingnag_gvnr100% (1)

- Hawk WinDocument80 pagesHawk WinAnonymous GKTRypNo ratings yet

- 460ETCUSB-N70U Datasheet PDFDocument2 pages460ETCUSB-N70U Datasheet PDFi_aordazNo ratings yet

- VOS Accouting Facility (r281m-00)Document14 pagesVOS Accouting Facility (r281m-00)kennycheungNo ratings yet

- FMB640 and Tacho Solution V1.0Document16 pagesFMB640 and Tacho Solution V1.0Дмитрий ДмитриевичNo ratings yet

- Agile Product Lifecycle Management: Agile PLM Data Mart - Setup GuideDocument56 pagesAgile Product Lifecycle Management: Agile PLM Data Mart - Setup GuideMuhammad Asad QureshiNo ratings yet

- AN2771Document4 pagesAN2771WayneNo ratings yet

- Setting Up The LAN Instrument NetworkDocument23 pagesSetting Up The LAN Instrument NetworkSilvioRodrigues100% (1)

- PCNSEDocument95 pagesPCNSEanon_721082701100% (1)

- m2x3c I500c en M C Manual GBDocument88 pagesm2x3c I500c en M C Manual GBdinakaran2020No ratings yet

- About The Keil CompilerDocument6 pagesAbout The Keil CompilerGaurav SainiNo ratings yet

- Torpedo Ladle Management System and LAN Functional Specification Document - For BSPDocument4 pagesTorpedo Ladle Management System and LAN Functional Specification Document - For BSPAbhishek KumarNo ratings yet

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- Securing Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildFrom EverandSecuring Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildNo ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Anti Tie DownDocument1 pageAnti Tie DowndobNo ratings yet

- Lsu 9804Document9 pagesLsu 9804dobNo ratings yet

- Disable USB Ports On Windows PC Via RegistryDocument1 pageDisable USB Ports On Windows PC Via RegistrydobNo ratings yet

- Basic QNX Neutrino CommandsDocument2 pagesBasic QNX Neutrino CommandsdobNo ratings yet

- Run Acronis TIB As Virtual MachineDocument15 pagesRun Acronis TIB As Virtual MachinedobNo ratings yet

- Geomatics Engineering - A Practical Guide To Project DesignDocument298 pagesGeomatics Engineering - A Practical Guide To Project DesignChaitra A RNo ratings yet

- Loctite SF 790™: Technical Data SheetDocument2 pagesLoctite SF 790™: Technical Data SheetEdwin GallegosNo ratings yet

- Test Bank For Management 12th Edition by DaftDocument20 pagesTest Bank For Management 12th Edition by Daftdinerottalptqq100% (51)

- AEAPIDocument710 pagesAEAPIHishamAlruainiNo ratings yet

- Thermo Scientific SL40 Thermo Scientific SL40RDocument56 pagesThermo Scientific SL40 Thermo Scientific SL40RJesus Rafael MarcanoNo ratings yet

- DilojanalosasawidiwisaDocument3 pagesDilojanalosasawidiwisashihyanghuangNo ratings yet

- PDF Sergei Prokofiev A Biography 1St Edition Harlow Robinson Ebook Full ChapterDocument48 pagesPDF Sergei Prokofiev A Biography 1St Edition Harlow Robinson Ebook Full Chapterfrank.meza701100% (1)

- DevelopDocument21 pagesDevelopssdownloadNo ratings yet

- Mighty Corporation Vs e & J Gallo Winery DigestDocument6 pagesMighty Corporation Vs e & J Gallo Winery DigestRegine Joy MagaboNo ratings yet

- Magic HatDocument24 pagesMagic Hattrixter11793100% (2)

- Apx823, Apx824, Apx825a r4-2 Diodes PDFDocument13 pagesApx823, Apx824, Apx825a r4-2 Diodes PDFCarlos MacielNo ratings yet

- Passing Edtpa ScoresDocument7 pagesPassing Edtpa Scoresapi-280094934No ratings yet

- Instant Download Management Fundamentals Concepts Applications and Skill Development 7th Edition Lussier Test Bank PDF Full ChapterDocument27 pagesInstant Download Management Fundamentals Concepts Applications and Skill Development 7th Edition Lussier Test Bank PDF Full ChapterAngelaHarveyofgz100% (10)

- MicrosoftDynamicsGP18 6Document33 pagesMicrosoftDynamicsGP18 6Maria Esperanza HerreraNo ratings yet

- DK 12Document52 pagesDK 12aris armadaNo ratings yet

- Next-Generation BSR How To-V26Document15 pagesNext-Generation BSR How To-V26Elliott LandinNo ratings yet

- OpenText Vendor Invoice Management 75 SP2 Release NotesDocument53 pagesOpenText Vendor Invoice Management 75 SP2 Release Notesshetkars0% (1)

- Formax v. Alkar-RapidPak-MP Equipment Et. Al.Document7 pagesFormax v. Alkar-RapidPak-MP Equipment Et. Al.PriorSmartNo ratings yet

- 3afe68237432 Ac800m PDFDocument94 pages3afe68237432 Ac800m PDFHenry Hernan Salinas CastañedaNo ratings yet

- Case StudyDocument21 pagesCase StudyShardul Vikram SinghNo ratings yet

- 7) Shangri-La v. Developers Group Case DigestDocument2 pages7) Shangri-La v. Developers Group Case DigestIvan Dizon100% (1)

- Eastman Turbo Oil 2197 TDS PDFDocument2 pagesEastman Turbo Oil 2197 TDS PDFstas2moskalenkoNo ratings yet

- BSC/RNC Clock Feature Parameter DescriptionDocument21 pagesBSC/RNC Clock Feature Parameter DescriptionSam FicherNo ratings yet

- TeacupDragon CareGuideDocument11 pagesTeacupDragon CareGuideGregoire DessolesNo ratings yet

- Quiz 2 Finals LawDocument7 pagesQuiz 2 Finals Lawbangtani kimNo ratings yet

- MSC Nastran 2020 Thermal Analysis User GuideDocument532 pagesMSC Nastran 2020 Thermal Analysis User GuidekadoNo ratings yet

- Universal Mills Corporation V Universal Textile MillsDocument8 pagesUniversal Mills Corporation V Universal Textile MillsAlyssa Mari ReyesNo ratings yet

435NBX Basic Ladder Logix Setup: Real Time Automation, Inc. 1 1-800-249-1612

435NBX Basic Ladder Logix Setup: Real Time Automation, Inc. 1 1-800-249-1612

Uploaded by

dobOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

435NBX Basic Ladder Logix Setup: Real Time Automation, Inc. 1 1-800-249-1612

435NBX Basic Ladder Logix Setup: Real Time Automation, Inc. 1 1-800-249-1612

Uploaded by

dobCopyright:

Available Formats

435NBX Basic Ladder

Logix Setup

Real Time Automation, Inc. 1 1-800-249-1612

Trademarks

CompactLogix, ControlLogix, & PLC-5 are registered trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of the ODVA.

MicroLogix, RSLogix 500, and SLC are trademarks of Rockwell Automation, Inc.

Microsoft, Windows, and Internet Explorer are registered trademarks of Microsoft Corporation.

®

BACnet is a registered trademark of American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

All other trademarks and registered trademarks are the property of their holders.

Limited Warranty

Real Time Automation, Inc. warrants that this product is free from defects and functions properly.

EXCEPT AS SPECIFICALLY SET FORTH ABOVE, REAL TIME AUTOMATION, INC. DISCLAIMS ALL OTHER WARRANTIES, BOTH

EXPRESSED AND IMPLIED, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR APPLICATION. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER

RIGHTS, WHICH VARY FROM STATE TO STATE.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular application, Real Time Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams. Except as specifically set forth above, Real Time Automation and its distributors and dealers will in no event be liable

for any damages whatsoever, either direct or indirect, including but not limited to loss of business profits, income, or use of data. Some states

do not allow exclusion or limitation of incidental or consequential damages; therefore, the limitations set forth in this agreement may not apply

to you.

No patent liability is assumed by Real Time Automation with respect to use of information, circuits, equipment, or software described in this

manual.

Government End-Users

If this software is acquired by or on behalf of a unit or agency of the United States Government, this provision applies: The software (a) was

developed at private expense, is existing computer software, and was not developed with government funds; (b) is a trade secret of Real Time

Automation, Inc. for all purposes of the Freedom of Information Act; (c) is “restricted computer software” submitted with restricted rights in

accordance with subparagraphs (a) through (d) of the Commercial “Computer Software-Restricted Rights” clause at 52.227-19 and its

successors; (d) in all respects is proprietary data belonging solely to Real Time Automation, Inc.; (e) is unpublished and all rights are reserved

under copyright laws of the United States. For units of the Department of Defense (DoD), this software is licensed only with “Restricted Rights”:

as that term is defined in the DoD Supplement of the Federal Acquisition Regulation 52.227-7013 (c) (1) (ii), rights in Technical Data and

Computer Software and its successors, and: Use, duplication, or disclosures is subject to restrictions as set forth in subdivision (c) (1) (ii) of the

Rights in Technical Data and Computer Software clause at 52.227-7013. If this software was acquired under GSA schedule, the U.S.

Government has agreed to refrain from changing or removing any insignia or lettering from the Software or documentation that is provided or

from producing copies of the manual or media. Real Time Automation, Inc., 150 S. Sunnyslope Rd. Suite 130, Brookfield, WI 53005.

© 2013 Real Time Automation, Inc. All rights reserved.

Real Time Automation, Inc. 2 1-800-249-1612

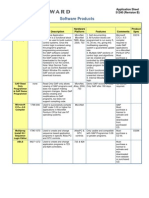

Overview

This document will explain the basic ladder logic that will be needed for the 435NBX gateway.

435NBX Setup

ASCII to ControlLogix: A bar code reader is scanning 82 characters and is going to transfer the data over

to the PLC Tag Name (RTA_read) with the data type of a string.

ControlLogix to ASCII: From the PLC Tag Name (RTA_write), 82 characters will be sent to the ASCII

device.

Real Time Automation, Inc. 3 1-800-249-1612

RSLogix 5000 Tag Setup

Expand the Controller rta_test folder and create the two Tags that were created in the gateway. The

Name and Data Types must match what is set up in the gateway or an error will occur and will be

reported on our diagnostic page.

Real Time Automation, Inc. 4 1-800-249-1612

RSLogix 5000 Ladder Logic Examples

Rung 0 Logic - ASCII to ControlLogix : This rung is set up to zero out the RTA_read.LEN tag when the tag

RTA_read reaches 84 characters. For diagnostic purposes, a counter can be added to moniter when the

.LEN field does not get cleared out. The value of that counter should match our Wr ASCII Msg to PLC

counter on the Diagnostics page of the gateway. The ? specifies where you want to move the data. The

gateway will not send the next ASCII message to the PLC unless the .LEN field for that Tag is zeroed out.

Real Time Automation, Inc. 5 1-800-249-1612

Rung 1 Logic - ControlLogix to ASCII: This rung is set up so that when the Tag (RTA_write) sends data to

the gateway, it will automatically set the number of bytes into the .LEN field after it copies the .DATA.

The gateway will automatically zero out the .LEN field when it processes the message.

Rung 2 Logic: This Logic is the same as Rung 1; the only difference is there is a separate command to

copy the .DATA part of the message first and then the .LEN field is filled in. Using this Logic is a safer

approach, as it assures that the .LEN field gets filled in after the .DATA field is copied.

Real Time Automation, Inc. 6 1-800-249-1612

Rung 3 Logic: This Logic is using Rung 2 to implement a write from the PLC to ASCII direction,

which will loop back into the ASCII to PLC direction, and using Rung 0 to read it back into the

PLC. Rung 1 can also be used instead of Rung 2. As suggested earlier, use Rung 2 for a safer

approach to ensure that the .LEN field gets written after the .DATA field.

Support Hours are Monday-Friday 8am-5pm CST

Support: 262-439-4022

Toll free: 800-249-1612

Email: support@rtaautomation.com

Real Time Automation, Inc. 7 1-800-249-1612

You might also like

- Interfacing GSM With 8051Document14 pagesInterfacing GSM With 8051Mohammad Ali100% (1)

- K300 ML1400 Indexing Example v1 - 0Document7 pagesK300 ML1400 Indexing Example v1 - 0Emanuel Falcon100% (1)

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- 9 1EN - r1Document146 pages9 1EN - r1Jordi Segura FaríasNo ratings yet

- Mutants & Masterminds 3e - Power Profile - Plant PowersDocument6 pagesMutants & Masterminds 3e - Power Profile - Plant PowersMichael Morgan100% (1)

- Monokote Field Application Manual PDFDocument136 pagesMonokote Field Application Manual PDFJohn Doe100% (2)

- 435 490NBX LadderLogixDocument10 pages435 490NBX LadderLogixi_aordazNo ratings yet

- 435USB-NNAU Userguide PDFDocument41 pages435USB-NNAU Userguide PDFi_aordazNo ratings yet

- Monitorizar Estado de Red ControlnetDocument7 pagesMonitorizar Estado de Red ControlnetkillnueveNo ratings yet

- Message From Micro800 To Logix On Ethernet - IPDocument3 pagesMessage From Micro800 To Logix On Ethernet - IPEdgardoNo ratings yet

- SPAN Port Mirroring - Tech PDFDocument6 pagesSPAN Port Mirroring - Tech PDFmurisNo ratings yet

- 460MMBS-N34 Protocol Gateway: Product User GuideDocument65 pages460MMBS-N34 Protocol Gateway: Product User GuideManuel CentenoNo ratings yet

- 287tr SW - Spec r13Document39 pages287tr SW - Spec r13crhistofirochaNo ratings yet

- Micronet SoftwaresDocument4 pagesMicronet SoftwaresHasan FarooqNo ratings yet

- D Link ConfiguratiuonDocument250 pagesD Link ConfiguratiuonabdulnizarvNo ratings yet

- DES-3028 28P 52 52P CLI v1.00Document250 pagesDES-3028 28P 52 52P CLI v1.00Regivaldo PereiraNo ratings yet

- A76XX Series - SImComDocument22 pagesA76XX Series - SImComMargarita Florez MartinezNo ratings yet

- Logger BestPractices 7.2.2Document44 pagesLogger BestPractices 7.2.2sumen007No ratings yet

- Connecting Compax3 I22T11 and Allen Bradley / Rockwell Plcs Via DevicenetDocument27 pagesConnecting Compax3 I22T11 and Allen Bradley / Rockwell Plcs Via DevicenetIngeniería 2 ICMANo ratings yet

- Micro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesDocument44 pagesMicro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesBrice TOSSAVINo ratings yet

- PLC, PLC Ladder, PLC Ebook, PLC ProgrammingDocument5 pagesPLC, PLC Ladder, PLC Ebook, PLC ProgrammingAmar ThakurNo ratings yet

- SEL-3505/SEL-3505-3 Real-Time Automation Controller: Major Features and BenefitsDocument16 pagesSEL-3505/SEL-3505-3 Real-Time Automation Controller: Major Features and BenefitsHectorNo ratings yet

- AT89S8252 In-System ProgrammingDocument38 pagesAT89S8252 In-System ProgrammingPramod JainNo ratings yet

- ACT350 PROFINET PLC EngineeringNote EN 202004Document34 pagesACT350 PROFINET PLC EngineeringNote EN 202004Lê Kim HàoNo ratings yet

- Using Siemens S7 Plcs Via ProfinetDocument15 pagesUsing Siemens S7 Plcs Via ProfinetMrdinh2014No ratings yet

- Gfs-384 m12 Maxon Rx3iDocument35 pagesGfs-384 m12 Maxon Rx3ihassanaagibNo ratings yet

- Plx-Daq HelpDocument25 pagesPlx-Daq HelpAnonymous C05BLcNo ratings yet

- 460ESUSB-N70U Userguide PDFDocument88 pages460ESUSB-N70U Userguide PDFi_aordazNo ratings yet

- Logix Hot Backup Code Generator ToolDocument3 pagesLogix Hot Backup Code Generator ToolAhmadTaufikMuradNo ratings yet

- Plugin-Ha Solution Axigen Heartbeat DRDBDocument17 pagesPlugin-Ha Solution Axigen Heartbeat DRDBJacko WijaNo ratings yet

- 1784 KTDocument22 pages1784 KTJoseNo ratings yet

- Produce and Consume Tags Between 5580 and Older RSLogix 5000 Based ControllersDocument5 pagesProduce and Consume Tags Between 5580 and Older RSLogix 5000 Based ControllersAlejandra PadillaNo ratings yet

- An 095Document11 pagesAn 095tazzo2No ratings yet

- Logix5000 Controllers - CPU Clock SpeedsDocument3 pagesLogix5000 Controllers - CPU Clock SpeedsMarisolNo ratings yet

- PC2 - Erick MezaDocument13 pagesPC2 - Erick MezaAragonZNo ratings yet

- In System Programming With 8051Document7 pagesIn System Programming With 8051vmateixeiraNo ratings yet

- Troubleshooting Network and CommunicationDocument14 pagesTroubleshooting Network and CommunicationnetpazNo ratings yet

- 193 At001 - en PDocument24 pages193 At001 - en PMauricio Oropeza CabreraNo ratings yet

- 460MSA-N34 UserguideDocument82 pages460MSA-N34 UserguideSamNo ratings yet

- LogRhythm HA DR Install Guide 10.1 RevDDocument38 pagesLogRhythm HA DR Install Guide 10.1 RevDkoteswaranNo ratings yet

- GlossaryDocument320 pagesGlossaryMeghanacherry MNo ratings yet

- CalAmp LMU Series Protocol Adapter SDK Setup GuideDocument11 pagesCalAmp LMU Series Protocol Adapter SDK Setup GuidePRSNo ratings yet

- TCP Port Probe Utility For Some Commonly Used Rockwell ProductsDocument3 pagesTCP Port Probe Utility For Some Commonly Used Rockwell ProductsmarceloNo ratings yet

- Rl-Arm Gs 01Document33 pagesRl-Arm Gs 01Tính Nguyễn VănNo ratings yet

- Cryptographic Algorithm Validation ProgramDocument21 pagesCryptographic Algorithm Validation Programmarvel homesNo ratings yet

- Creating An Ethernet Devices DriverDocument15 pagesCreating An Ethernet Devices DriverMark MerrimanNo ratings yet

- FS-8700-07 Bacnet Arcnet: Driver ManualDocument13 pagesFS-8700-07 Bacnet Arcnet: Driver ManualEric DunnNo ratings yet

- Condition-Based Maintenance: Business Process ProcessingDocument7 pagesCondition-Based Maintenance: Business Process Processingnag_gvnr100% (1)

- Hawk WinDocument80 pagesHawk WinAnonymous GKTRypNo ratings yet

- 460ETCUSB-N70U Datasheet PDFDocument2 pages460ETCUSB-N70U Datasheet PDFi_aordazNo ratings yet

- VOS Accouting Facility (r281m-00)Document14 pagesVOS Accouting Facility (r281m-00)kennycheungNo ratings yet

- FMB640 and Tacho Solution V1.0Document16 pagesFMB640 and Tacho Solution V1.0Дмитрий ДмитриевичNo ratings yet

- Agile Product Lifecycle Management: Agile PLM Data Mart - Setup GuideDocument56 pagesAgile Product Lifecycle Management: Agile PLM Data Mart - Setup GuideMuhammad Asad QureshiNo ratings yet

- AN2771Document4 pagesAN2771WayneNo ratings yet

- Setting Up The LAN Instrument NetworkDocument23 pagesSetting Up The LAN Instrument NetworkSilvioRodrigues100% (1)

- PCNSEDocument95 pagesPCNSEanon_721082701100% (1)

- m2x3c I500c en M C Manual GBDocument88 pagesm2x3c I500c en M C Manual GBdinakaran2020No ratings yet

- About The Keil CompilerDocument6 pagesAbout The Keil CompilerGaurav SainiNo ratings yet

- Torpedo Ladle Management System and LAN Functional Specification Document - For BSPDocument4 pagesTorpedo Ladle Management System and LAN Functional Specification Document - For BSPAbhishek KumarNo ratings yet

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- Securing Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildFrom EverandSecuring Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildNo ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Anti Tie DownDocument1 pageAnti Tie DowndobNo ratings yet

- Lsu 9804Document9 pagesLsu 9804dobNo ratings yet

- Disable USB Ports On Windows PC Via RegistryDocument1 pageDisable USB Ports On Windows PC Via RegistrydobNo ratings yet

- Basic QNX Neutrino CommandsDocument2 pagesBasic QNX Neutrino CommandsdobNo ratings yet

- Run Acronis TIB As Virtual MachineDocument15 pagesRun Acronis TIB As Virtual MachinedobNo ratings yet

- Geomatics Engineering - A Practical Guide To Project DesignDocument298 pagesGeomatics Engineering - A Practical Guide To Project DesignChaitra A RNo ratings yet

- Loctite SF 790™: Technical Data SheetDocument2 pagesLoctite SF 790™: Technical Data SheetEdwin GallegosNo ratings yet

- Test Bank For Management 12th Edition by DaftDocument20 pagesTest Bank For Management 12th Edition by Daftdinerottalptqq100% (51)

- AEAPIDocument710 pagesAEAPIHishamAlruainiNo ratings yet

- Thermo Scientific SL40 Thermo Scientific SL40RDocument56 pagesThermo Scientific SL40 Thermo Scientific SL40RJesus Rafael MarcanoNo ratings yet

- DilojanalosasawidiwisaDocument3 pagesDilojanalosasawidiwisashihyanghuangNo ratings yet

- PDF Sergei Prokofiev A Biography 1St Edition Harlow Robinson Ebook Full ChapterDocument48 pagesPDF Sergei Prokofiev A Biography 1St Edition Harlow Robinson Ebook Full Chapterfrank.meza701100% (1)

- DevelopDocument21 pagesDevelopssdownloadNo ratings yet

- Mighty Corporation Vs e & J Gallo Winery DigestDocument6 pagesMighty Corporation Vs e & J Gallo Winery DigestRegine Joy MagaboNo ratings yet

- Magic HatDocument24 pagesMagic Hattrixter11793100% (2)

- Apx823, Apx824, Apx825a r4-2 Diodes PDFDocument13 pagesApx823, Apx824, Apx825a r4-2 Diodes PDFCarlos MacielNo ratings yet

- Passing Edtpa ScoresDocument7 pagesPassing Edtpa Scoresapi-280094934No ratings yet

- Instant Download Management Fundamentals Concepts Applications and Skill Development 7th Edition Lussier Test Bank PDF Full ChapterDocument27 pagesInstant Download Management Fundamentals Concepts Applications and Skill Development 7th Edition Lussier Test Bank PDF Full ChapterAngelaHarveyofgz100% (10)

- MicrosoftDynamicsGP18 6Document33 pagesMicrosoftDynamicsGP18 6Maria Esperanza HerreraNo ratings yet

- DK 12Document52 pagesDK 12aris armadaNo ratings yet

- Next-Generation BSR How To-V26Document15 pagesNext-Generation BSR How To-V26Elliott LandinNo ratings yet

- OpenText Vendor Invoice Management 75 SP2 Release NotesDocument53 pagesOpenText Vendor Invoice Management 75 SP2 Release Notesshetkars0% (1)

- Formax v. Alkar-RapidPak-MP Equipment Et. Al.Document7 pagesFormax v. Alkar-RapidPak-MP Equipment Et. Al.PriorSmartNo ratings yet

- 3afe68237432 Ac800m PDFDocument94 pages3afe68237432 Ac800m PDFHenry Hernan Salinas CastañedaNo ratings yet

- Case StudyDocument21 pagesCase StudyShardul Vikram SinghNo ratings yet

- 7) Shangri-La v. Developers Group Case DigestDocument2 pages7) Shangri-La v. Developers Group Case DigestIvan Dizon100% (1)

- Eastman Turbo Oil 2197 TDS PDFDocument2 pagesEastman Turbo Oil 2197 TDS PDFstas2moskalenkoNo ratings yet

- BSC/RNC Clock Feature Parameter DescriptionDocument21 pagesBSC/RNC Clock Feature Parameter DescriptionSam FicherNo ratings yet

- TeacupDragon CareGuideDocument11 pagesTeacupDragon CareGuideGregoire DessolesNo ratings yet

- Quiz 2 Finals LawDocument7 pagesQuiz 2 Finals Lawbangtani kimNo ratings yet

- MSC Nastran 2020 Thermal Analysis User GuideDocument532 pagesMSC Nastran 2020 Thermal Analysis User GuidekadoNo ratings yet

- Universal Mills Corporation V Universal Textile MillsDocument8 pagesUniversal Mills Corporation V Universal Textile MillsAlyssa Mari ReyesNo ratings yet