Professional Documents

Culture Documents

Application of IEC-Cenelec-European Equipment To Hazardous L

Application of IEC-Cenelec-European Equipment To Hazardous L

Uploaded by

Jellyn BaseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of IEC-Cenelec-European Equipment To Hazardous L

Application of IEC-Cenelec-European Equipment To Hazardous L

Uploaded by

Jellyn BaseCopyright:

Available Formats

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

Application Of IEC/Cenelec/European

Equipment To Hazardous Locations

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramco’s

employees. Any material contained in this document which is not

already in the public domain may not be copied, reproduced, sold, given,

or disclosed to third parties, or otherwise used in whole, or in part,

without the written permission of the Vice President, Engineering

Services, Saudi Aramco.

Chapter : Electrical For additional information on this subject, contact

File Reference: EEX20804 W.A. Roussel on 874-1320

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

CONTENTS PAGES

INTERNATIONAL, EUROPEAN AND NORTH AMERICAN

TERMINOLOGY FOR HAZARDOUS LOCATIONS .........................................1

Major Standards Organizations ..................................................................1

International Electrotechnical Commission (IEC) ..........................1

European Electrotechnical Standards Committee

(CENELEC) ....................................................................................2

Underwriters Laboratories (UL)......................................................2

Factory Mutual Research Corporation (FM)...................................3

Similar Terms and Definitions....................................................................3

List of International and European Standards ............................................5

CONVERTING NORTH AMERICAN HAZARDOUS LOCATION

DESIGNATIONS TO THE EQUIVALENT INTERNATIONAL/

EUROPEAN TERMS ............................................................................................7

Class Versus Group ....................................................................................7

Division Versus Zone .................................................................................8

Group Versus Subgroup .............................................................................8

Temperature Class ......................................................................................9

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

DETERMINING REQUIREMENTS FOR INSTALLATION OF

EUROPEAN EQUIPMENT IN HAZARDOUS LOCATION

APPLICATIONS .................................................................................................10

Intrinsic Safety .........................................................................................10

Selection Of Equipment Relative To Area Classification .............10

Allowable Capacitance And Inductance In The

Intrinsically Safe Loop..................................................................11

Increased Safety .......................................................................................11

Hermetically Sealed..................................................................................12

Explosionproof (Flameproof)...................................................................12

Philosophy Regarding Completeness Of Enclosures ....................12

Selection Of Equipment Relative To Area Classification .............13

Wiring Techniques........................................................................13

Non-incendive ..........................................................................................13

Pressurization (Purging) ...........................................................................13

Philosophical Difference In Approach..........................................14

Wiring Techniques........................................................................14

Continuous Dilution......................................................................14

Oil Immersion...........................................................................................14

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

INTERPRETING NAMEPLATE DATA ON

IEC/CENELEC/EUROPEAN EQUIPMENT USED IN

HAZARDOUS LOCATIONS..............................................................................15

Markings Necessary for Equipment in Hazardous Locations...................15

Manufacturer's Name....................................................................16

Manufacturer's Type Identification...............................................16

Atmosphere Protection..................................................................16

Type of Protection ........................................................................17

Group Classification .....................................................................17

Subgroup Classification - Group II...............................................18

Temperature Class ........................................................................19

Serial Number ...............................................................................19

Certifying Authority......................................................................20

Special Conditions ........................................................................20

Markings for a Specific Type of Protection..................................20

General Nameplate Markings .......................................................21

Nameplate Marking and Attachment Requirements.................................21

Data Arrangement on Nameplate .............................................................22

IDENTIFYING IEC LISTED EQUIPMENT ALLOWED FOR USE

IN SAUDI ARAMCO HAZARDOUS LOCATIONS .........................................23

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

WORK AID 1: RESOURCES USED TO CONVERT NORTH

AMERICAN DESIGNATIONS TO THE

EQUIVALENT INTERNATIONAL/ EUROPEAN

TERMS........................................................................................24

WORK AID 2: REFERENCES USED TO DETERMINE

REQUIREMENTS FOR INSTALLATION OF

EUROPEAN EQUIPMENT IN HAZARDOUS

LOCATION APPLICATIONS....................................................27

WORK AID 3: REFERENCES FOR INTERPRETING NAMEPLATE

DATA ON IEC/CENELEC/EUROPEAN

EQUIPMENT USED IN HAZARDOUS LOCATIONS.............28

WORK AID 4: REFERENCES USED TO IDENTIFY IEC-LISTED

EQUIPMENT ALLOWED FOR USE IN SAUDI

ARAMCO HAZARDOUS LOCATIONS...................................31

Limitations on the Use of Electrical Equipment in Hazardous

Locations of Saudi Aramco Installations..................................................32

GLOSSARY ........................................................................................................33

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

INTERNATIONAL, EUROPEAN AND NORTH AMERICAN TERMINOLOGY FOR

HAZARDOUS LOCATIONS

Because the Saudi Aramco Electrical Engineer must deal with electrical equipment that is

manufactured in many locations, he must be familiar with the terminology that is used on all

electrical equipment. This section provides information on the following topics:

• Major Standards Organization

• Similar Terms and Definitions

• List of International and European Standards

Major Standards Organizations

There are hundreds of organizations throughout the world that prepare standards concerning

the application of electrical equipment for hazardous locations. This section provides a brief

description of the following major organizations that prepare such standards:

• International Electrotechnical Commission (IEC)

• European Electrotechnical Standards Committee (CENELEC)

• Underwriters Laboratories (UL)

• Factory Mutual Research Corporation (FM)

It should be noted that there is a major philosophical difference in the approach to preparing

IEC/CENELEC standards and those of North America or at least the USA. The IEC and

CENELEC standards focus on construction requirements for the various protection techniques

with tests specified as required. The US approach focuses more on performance of the design

techniques giving minimum constructions that are automatically accepted if met. Different

constructions from those recognized may be used if the performance test results for the

specific issue are satisfactory.

International Electrotechnical Commission (IEC)

The major organization for worldwide electrical standards is the International Electrotechnical

Commission (IEC), based in Geneva. The IEC was founded in 1906 and has grown so that

there are now over forty member countries. The IEC is responsible for electrical

standardization activities.

The IEC committee that is directly responsible for all hazardous location equipment is

Technical Committee 31. Technical Committee 31 has the following seven subcommittees

that deal with specific types of construction or classification of areas and installation rules:

Saudi Aramco DeskTop Standards 1

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

SC/ 31A - Flameproof enclosures

SC/ 31B - Sand-filled apparatus

SC/ 31C - Increased safety apparatus

SC/ 31D - Pressurization and associated techniques

SC/ 31G - Intrinsically safe apparatus

SC/ 31H - Apparatus for use in the presence of ignitable dust

SC/ 31J - Classification of hazardous locations and installation requirements

IEC standards are printed and issued through IEC headquarters in Geneva.

European Electrotechnical Standards Committee (CENELEC)

The European Electrotechnical Standards Committee (CENELEC) is the result of the

European Common Market. The Commission of the European Communities issued a

directive in the mid-1970s to harmonize standards for electrical equipment for use in

hazardous locations. The purpose of this directive was to facilitate trade within the

Community through the adoption of harmonized standards. The CENELEC Organization was

assigned this task and was directed to base their new standards on the IEC standards. In

addition to the Common Market countries, other Western European countries have adopted

CENELEC standards. Basically, all of the Western European countries follow these

standards.

The CENELEC committee structure is identical to that of the IEC, and it even uses the same

basic committee numbering system. Under the “New Directive” procedures adopted in

conjunction with the formation of the European Union (EU), an aggressive program of

standards development has been initiated. All EU countries are mandated to exclusively use

CENELEC standards for hazardous location equipment by the year 2003. Today most

companies marketing equipment in Europe use the CENELEC criteria.

CENELEC standards are similar to the IEC standards, but some differences do exist.

Engineers should obtain the applicable CENELEC standard when a particular application calls

for a CENELEC specification.

Underwriters Laboratories (UL)

Underwriters Laboratories (UL) is a North American organization that publishes a number of

different standards and proposed standards that provide detailed construction and

performance requirements for equipment for use in hazardous locations. Many of the UL

standards also are recognized as American National Standards. These standards are used by

UL to investigate the acceptability of equipment for use in hazardous locations and as a basis

for permitting the UL listing mark or label on the equipment.

Saudi Aramco DeskTop Standards 2

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Factory Mutual Research Corporation (FM)

The Factory Mutual Research Corporation (FM) is another North American organization that

publishes standards and guides, although FM also uses the requirements of other

organizations in the investigation of equipment for use in hazardous locations.

Similar Terms and Definitions

All of the major standards organizations use similar terminology to describe the different

types of protection that are available for electrical equipment in hazardous locations. The

following list is a summary of the similar terms and their definitions. The definitions are

based on "Electrical Installations in Hazardous locations," by Schram and Earley.

• Explosionproof - An enclosure that is designed for electrical equipment; that

will withstand, without damage, an explosion of a prescribed flammable gas or

vapor within the enclosure; that will prevent the transmission of flame or sparks

that would ignite the external prescribed flammable gas or vapor for which the

enclosure is designed; and that normally operates at an external temperature

that will not ignite the external, prescribed flammable gas or vapor. An

explosionproof enclosure will not necessarily be weatherproof or dustproof.

• Flameproof - An enclosure for electrical apparatus that will withstand an

internal explosion of the flammable gas or vapor that may enter it. This

enclosure will not suffer damage from the internal explosion, and it will

prevent propagation of the explosion through any joints or structural openings

in the enclosure to the external atmosphere flammable gas or vapor for which it

is designed. Flameproof is the IEC term that is comparable to the term

explosionproof.

• Pressurized - For electrical machines and equipment, an enclosure in which

the entry of flammable gases or vapors is prevented by maintaining a protective

gas within the enclosure at a specified pressure above the pressure of the

external atmosphere with flow as necessary to account for leakage.

• Purged - The North American definition states that purging is a process where

a sufficient flow of fresh air or inert gas is maintained through the electrical

equipment enclosure to prevent the entry of any flammable gas or vapor that

may be present in the ambient atmosphere in which the enclosure is installed.

The definition also includes the initial clearing out of flammable materials

before applying power to the electrical equipment.

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

The international definition for purging states that it is the operation of passing

a quantity of protective gas through a room or enclosure prior to the equipment

being energized such that the original atmosphere is exchanged and the

remaining atmosphere is well below the lower explosive limit.

• Oil-Immersed - Electrical equipment on which the following parts are

immersed in oil or protected by another recognized method: parts on which

arcs may occur in normal service and live parts on which arcs do not occur in

normal service. For parts that are immersed in oil, immersion is to a depth that

is sufficient to prevent ignition of an explosive gas/air mixture that may be

present above the surface of the oil.

• Sand-Filled - For electrical equipment, an enclosure in which all live parts of

the equipment are entirely embedded in a mass of powdery material that has the

consistency of sand in such a way that if, under the condition of use for which

the equipment is designed, an arc occurs within the enclosure, this arc will not

ignite the outer explosive atmosphere either by the transmission of flame or by

the overheating of the walls of the enclosure.

• Increased Safety - A method of protection in which measures additional to

those adopted in ordinary industrial practice are applied to give increased

security against the possibility of excessive temperatures and against the

occurrence of arcs or sparks in an electrical apparatus that does not produce

arcs or sparks in normal service.

• Intrinsically Safe - In reference to a circuit or part of a circuit, when any

sparking that is produced normally by breaking or making the circuit or that is

produced accidentally (e.g., by short-circuit or earthfault), is incapable of

causing ignition of a prescribed gas or vapor under prescribed test conditions.

• Special Protection - A designation that permits certification of types of

electrical apparatus that, by their nature, do not comply with the constructional

or other requirements specified for apparatus with established types of

protection but that nevertheless can be shown to be suitable for use in

prescribed zones within hazardous locations.

• Hermetically Sealed - Equipment that is permanently sealed to prevent entry

of liquids, gas, or vapor.

• Non-Sparking - Electrical equipment that is of normal industrial design and

that has no ignition-capable sparking parts during normal operation.

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

• Encapsulation - The intimate surrounding of electrical equipment with a

material that will, under the conditions for which the equipment has been

designed, prevent occurrence of an external condition that could ignite the

outer explosive atmosphere either by transmission of flame or by overheating

of any part.

• Restricted Breathing - Apparatus that are constructed to prevent the

combination of explosive mixtures of gas or vapor with air inside an enclosure

during a certain time limit. Such construction ensures that an explosion will

not be caused by external parts.

List of International and European Standards

The following is a list of the standards that have been developed by the IEC. Engineers

should reference these standards when a particular application calls for an IEC specification.

• 79-0 General Requirements

• 79-1 Construction and test of flameproof enclosures of electrical apparatus

• 79-1 Amendment #1

• 79-1A Method of test for ascertaining of maximum experimental safe gap

• 79-2 Electrical Apparatus, type of protection "p"

• 79-3 Spark test apparatus for intrinsically safe circuits

• 79-4 Method of test for ignition temperature

• 79-4A Method of test for ignition temperature

• 79-5 Sand-filled apparatus

• 79-6 Oil-immersed apparatus

• 79-7 Construction and test of electrical apparatus, type of protection "e"

• 79-8 Classification of maximum surface temperature

• 79-9 Marking

• 79-10 Classification of hazardous locations

• 79-11 Construction and test of intrinsically safe and associated apparatus

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

• 79-12 Classifications of mixtures of gases or vapors with air according to their

maximum experimental safe gaps and minimum igniting currents

• 79-13 Construction and use of rooms or buildings protected by pressurization

• 79-14 Electrical installations in explosive gas atmospheres (other than mines)

The following is a list of the standards that have been developed by CENELEC. Engineers

should reference these standards when a particular application calls for a CENELEC

specification.

• EN 50014 General Requirements

• EN 50015 Oil-Immersion

• EN 50016 Pressurized Apparatus

• EN 50017 Powder Filling

• EN 50018 Flameproof Enclosure

• EN 50019 Increased Safety

• EN 50020 Intrinsic Safety

• EN 50028 Encapsulation

• EN 50039 Intrinsic Safe Electrical Systems

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

CONVERTING NORTH AMERICAN HAZARDOUS LOCATION DESIGNATIONS

TO THE EQUIVALENT INTERNATIONAL/EUROPEAN TERMS

The International/European terminology for use in describing hazardous locations is different

from North American terminology. This section will provide a comparison of the key terms

and will include the following specific sections:

• Class Versus Group

• Division Versus Zone

• Group Versus Subgroup

• Temperature Class

Class Versus Group

International/European terminology uses the word "Group" to describe the general location

where electrical equipment may be installed in an area made hazardous by the presence of

flammable/ignitable materials. Two such locations are identified - one below ground (gassy

mines), and the other above the surface. To the extent that such locations exist due to the

presence of flammable/ignitable materials, it is roughly equivalent to the North American

"Class" designation. However, it differs from the "Class" designation in that the

International/European "Group" does not distinguish the type of hazard present (i.e., gas,

vapor or dust), except for "gassy mines". The two general groups addressed in

International/European standards are:

• Group I designates areas below the earth's surface (gassy mines) that require

electrical equipment suitable for use specifically in mines susceptible to fire-

damp (methane).

• Group II designates areas above the earth's surface that require electrical

equipment suitable for use in areas that contain flammable gases/vapors.

The North American term that is roughly equivalent of Group II is Class I. North American

terminology does not have a separate class that is equivalent to an International/European

Group I area that contains underground methane (e.g., gassy mines).

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Division Versus Zone

International/European terminology uses the word "Zone" instead of the word "Division" to

further divide hazardous locations in accordance with the degree of the hazards that are

present. International/European Standards use the following three Zones to subdivide above

ground areas that contain flammable gases/vapors:

• Zone 0 is an area that is always hazardous or that is hazardous for long periods

of time.

• Zone 1 is an area in which an explosive mixture is likely to occur during

normal operation.

• Zone 2 is an area in which an explosive mixture is not likely to occur or in

which an explosive mixture would occur only for a short period of time.

These Zones are equivalent to the two Divisions used in North American Standards. The

North American term of Division 1 combines Zone 0 and Zone 1. Zone 2 is similar to the

North American term Division 2.

Electrical equipment that is suitable for use in Zone 2 also is suitable for use in Division 2.

However, electrical equipment suitable for use in Zone 1 may not be suitable for use in

Division 1, because a Division 1 location can be hazardous at all times. This limitation would

certainly be true for intrinsic safety; however, flameproof (explosionproof) enclosures

approved for Zone 1 are the same design as those approved for Division 1 and would be

interchangeable in their application. This limitation would also be true for purged/pressurized

enclosures. However, it should be noted that prudent users in North America will take extra

precautions when flammable materials are present for long periods, such as in sumps, where

an explosionproof motor may additionally be purged/pressurized.

Note: The 1996 edition of the National Electrical Code will include the Division 0, 1, 2

concept equivalent to the International/CENELEC Zone 0, 1, 2. When that occurs, the

differences described above will no longer exist. This will also be true in Canada where

similar revisions are in process for the Canadian Electrical Code.

Group Versus Subgroup

International/European Group II hazardous locations are further subdivided into three

subgroups: IIA, IIB, and IIC. The grouping of gases in the subgroups is primarily based on

the maximum experimental safe gap (MESG) and/or the minimum ignition current (MIC).

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

The International/European Subgroups (IIA, IIB, and IIC) of gases are similar to the North

American groups (A, B, C, and D) of gases. There are a few exceptions, however, since the

European tests do not consider the pressure piling or the turbulent effects on the MESG

because European wiring practice does not include the use of rigid metal conduit raceways. In

addition, carbon disulfide is not classified, and hydrogen and acetylene are in separate groups

in North America. Work Aid 1 contains a table that compares the International/European

subgroups for common flammable gases to the North American groups.

Temperature Class

All International, European, and North American Standards recognize that the maximum

surface temperature of electrical equipment is important due to the possibility of auto ignition

of a flammable gas. All countries require that electrical equipment be marked with a

temperature class or a specific temperature referenced to a 40°C (104°F) ambient temperature.

The temperature class gives the maximum surface operating temperature of the equipment.

North American Standards contain 14 separate temperature classes, while

International/European standards only contain six temperature classes. Work Aid 1 provides

a table that compares the two temperature classes.

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

DETERMINING REQUIREMENTS FOR INSTALLATION OF EUROPEAN

EQUIPMENT IN HAZARDOUS LOCATION APPLICATIONS

The hazardous location design standards of North America and Europe (CENELEC) agree

fundamentally; however, there are differences in detail that affect applications and installation

practices. Some of these differences result from the difference in the classification system,

but most of these differences are due to the different approach that is taken in developing the

standards. When planning an installation, Saudi Aramco engineers should take into account

the source of the equipment; that is, the country where the equipment was produced. This

section will provide information on the differences in each of the techniques listed below.

• Intrinsic Safety

• Increased Safety

• Hermetically Sealed

• Explosionproof (Flameproof)

• Non-incendive

• Pressurization (Purging)

• Oil Immersion

Intrinsic Safety

There are several constructional and rating differences within the design requirements for the

intrinsic safety technique, however, most of these differences are transparent to the user of the

equipment. There are two key factors that must be considered when planning an intrinsic

safety system installation as follows:

• Selection of equipment relative to area classification

• Allowable capacitance and inductance in the intrinsically safe loop

Selection Of Equipment Relative To Area Classification

Saudi Aramco installations use the area classification scheme as described in the National

Electrical Code (NEC) and API 500 as discussed earlier. This classification scheme differs

from the European (CENELEC) scheme in that the European Zone 0 and Zone 1 are included

in the NEC Division 1. The CENELEC standards for intrinsic safety recognize two levels of

protection, ‘ia’ and ‘ib’, for Zone 0 and Zone 1, respectively. In selecting equipment that has

been certified to the CENELEC standards, the engineer must assure that the equipment is

rated for ‘ia’ service in order to use the equipment in an NEC Division 1 hazardous location

and to ensure compatibility of the safety design with the conditions that could exist in the

hazardous location.

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Note: The next edition of the NEC (1996) will recognize the Division 0, Division 1,

Division 2 area classification concept in order to agree with the international classification

scheme. This change will allow compatibility with European practice and lead the way to use

of the ‘ia’ and ‘ib’ concepts in the USA.

Allowable Capacitance And Inductance In The Intrinsically Safe Loop

When planning an intrinsically safe loop, the source of supply for the loop determines how

much unprotected capacitance and inductance can be connected in the load and

interconnecting wiring. These values are based on the maximum voltage and current from the

source whether it be a Zener barrier device or other type of design that powers the loop.

These limits may be found either on the data label of the source device, or the literature for

the source device. The European values are decidedly more conservative than comparable

North American values. Using European values can result in much shorter allowable cable

lengths than when using North American values. The manufacturer's literature will discuss

this issue and provide values of typical cable parameters. If cable parameters are not

available, a capacitance of 60 pF/ft and inductance of 0.20 uH/ft may be used for all typical

cables. Although based on North American practice, ISA-RP 12.6, Wiring Practices for

Hazardous (Classified) Locations Instrumentation - Part I: Intrinsic Safety is an excellent

reference for covering installation of intrinsically safe systems which is included in this

module as a classroom reference.

Increased Safety

The increased safety technique is presently peculiar to Europe and is applied to devices such

as motors and lighting fixtures intended for use in a European Zone 1 hazardous location.

The coming change to the NEC mentioned above will lead to the acceptance of the increased

safety technique in North America including recognition in the NEC. It is unlikely that this

technique will be used in a Saudi Aramco facility unless the European classification scheme is

used for the area in question. Use of the European classification scheme may be worth

consideration since the equipment covered in this category results in a lower installed cost.

This technique was established based on the installation using the standard European cabling

techniques for hazardous locations where the cable is installed using a cable gland seal at the

terminal box of the device. Alternative wiring techniques are possible such as those permitted

in the NEC as the hole provided for the cable gland fitting can be used equally well for the

NEC acceptable wiring techniques including rigid metal conduit.

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Hermetically Sealed

The major difference between a North American and an European hermetically sealed device

is the hazardous location in which it can be used. In North American practice, a hermetically

sealed device is acceptable for use only in a Division 2 hazardous location. In Europe, there

are circumstances when a hermetically sealed device may be used in a Zone 1 hazardous

location. Although it is not exactly clear under what circumstances this would be allowed, it

would be a location where a flammable material may be present in normal operation only

briefly and only occasionally. With NEC classification schemes in use at Saudi Aramco

facilities, there is no circumstance where a hermetically sealed device is acceptable for use in

a Division 1 hazardous location.

Most applications of hermetically sealed devices occurs within a primary enclosure such as

relays or other types of switches as part of a non-incendive product. There are no differences

in installation between European and North American practice when used as a Division

2/Zone 2 technique.

Explosionproof (Flameproof)

The North American explosionproof technique is equivalent to European flameproof. There

are several differences in these techniques that affect the installation as follows.

• Philosophy regarding completeness of enclosure

• Selection of equipment relative to area classification

• Wiring techniques

Philosophy Regarding Completeness Of Enclosures

North American practice provides for completing the explosionproof enclosure as part of the

installation. Wiring terminations are normally inside the explosion-proof enclosure. The

enclosure becomes complete when the approved wiring is installed including seals as

required. The normal European practice is to provide an enclosure that is complete relative to

being explosionproof (flameproof) when it leaves the factory. For such designs the

connection terminals are external to the enclosure reaching the inside of the enclosure via

explosionproof feedthroughs from the wiring compartment. The wiring compartment and

terminals are required to meet the increased safety requirements. The European standards do

allow direct entry using the North American technique so that many products, particularly in

the instrumentation field, use the latter technique. This acceptance of North American

techniques leads to items to consider when using European (CENELEC) approved equipment

in Saudi Aramco facilities.

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Selection Of Equipment Relative To Area Classification

In Europe the explosionproof (flameproof) technique is designated as a Zone 1 technique.

The North American version is considered to be a Division 1 technique. This would suggest

that the European version should not be used in a Division 1 location. However, based on the

safety record of these designs in North America and the similarity of the design requirements,

the European flameproof approach is safely usable in Division 1 locations if the design of the

enclosure follows the North American practice of direct entry of the connection wiring. If the

design uses an external increased safety connection box that is not explosionproof, then the

enclosure is not suitable for use in a Division 1 hazardous location.

Wiring Techniques

The normal wiring technique intended for European installation is a cable using sealing type

cable glands. This is true whether the design is direct or indirect entry although the latter was

included mostly to accommodate the UK that uses the rigid metal conduit wiring technique in

the majority of their installations. With Saudi Aramco routinely using the NEC wiring

techniques, it is important to know that European enclosures will accommodate such wiring.

Therefore, direct entry European enclosures can be specified using NEC wiring installation

techniques.

Non-incendive

European (CENELEC) standards have not been published covering the non-incendive

technique. However, the non-incendive technique has been used extensively in some parts of

Europe, particularly in the UK. The practices, for the most part, follow those of North

America. The IEC document on this subject generally follows North American practice.

There are few European companies that market equipment for Zone 2, however, when such

equipment is available, the wiring techniques of the NEC can be applied.

Pressurization (Purging)

If pressurization is used in a given installation, the Saudi Aramco engineer should consult

with the appropriate standards including NFPA 496, ISA-RP 12.4, and EN 50016

(CENELEC) for details. The following points of difference between North American and

European practice are discussed.

• Philosophical difference in approach

• Wiring techniques

• Continuous dilution

Saudi Aramco DeskTop Standards 13

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Philosophical Difference In Approach

The European approach to the technique is strictly from the construction requirements point

of view defining likely conditions and building a set of requirements around each condition.

The North American approach is based on reducing the classification inside the enclosure and

what requirements must be in place to maintain the classification. The end result is essentially

the same, especially since the North American standard was the basis for developing both the

IEC standard and the CENELEC standard.

Wiring Techniques

Wiring techniques for European installations are normally based on the use of cable

acceptable for hazardous locations. Wiring techniques allowed per the NEC are equally

acceptable and can be used in conjunction with any European electrical equipment certified as

meeting the pressurization requirements.

Continuous Dilution

The term "continuous dilution" is not used in the international community. Continuous

dilution usually refers to an enclosure that has a release of flammable material inside the

enclosure. An example of continuous dilution is an analyzer type device where flammable

materials are intentionally introduced to the enclosure. The NFPA-496 standard addressing

purged and pressurized enclosures addresses the requirements associated with this technique.

It is a form of pressurization, especially if there is a hazardous atmosphere external to the

equipment enclosure. However, the fundamental objective is to clear the internal atmosphere

of flammable gases and vapors prior to startup, and then flood the internals of the enclosure

with either fresh air or an inert gas such as nitrogen to keep the internal atmosphere of the

enclosure well below the lower explosive limit of the gas(es) involved. In all cases the

requirements are similar; the fundamental difference is the European approach describes

construction requirements while the North American approach is based on reducing the

classification of the atmosphere within the enclosure.

Oil Immersion

There are no known differences in the application of the oil immersion technique.

Saudi Aramco DeskTop Standards 14

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

INTERPRETING NAMEPLATE DATA ON IEC/CENELEC/EUROPEAN

EQUIPMENT USED IN HAZARDOUS LOCATIONS

Electrical equipment that is suitable for use in hazardous locations will have a nameplate with

the appropriate North American or IEC designations. Electrical Engineers must be able to

interpret both North American and IEC designations because Saudi Aramco uses electrical

equipment that is manufactured according to both North American and International

Standards. The information that is pertinent to North American Standards was presented in

Module EEX 208.03. This section will provide the necessary information to interpret

nameplates with IEC designations and will include the following topics:

• Markings Necessary for Equipment in Hazardous locations

• Nameplate Marking and Attachment Requirements

• Data Arrangement on Nameplate

Markings Necessary for Equipment in Hazardous Locations

The IEC requires that twelve areas of information listed below be included on the nameplate

of all electrical equipment approved by the IEC for use in hazardous locations. The ability of

an Electrical Engineer to understand and interpret this nameplate information is critical to the

proper application of electrical equipment. For small sized equipment that does not have

enough room on the nameplate to provide all the required marking, abbreviated marking

information is permitted if full information is provided in the accompanying documentation.

• Manufacturer's Name

• Manufacturer's Type Identification

• Atmosphere Protection

• Type of Protection

• Group Classification

• Subgroup Classification

• Temperature Class

• Serial Number

• Certifying Authority

• Special Conditions

• Markings for a Specific Type of Protection Used

• General Nameplate Markings

Saudi Aramco DeskTop Standards 15

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Manufacturer's Name

The equipment manufacturer's name must be prominently displayed on the equipment

nameplate. The name on the nameplate must be the full, correct name of the manufacturer.

An example of a full, correct name is Asea Brown Boveri.

IEC Publication 79 allows the manufacturer's name to be replaced with a registered

trademark. Figure 1 shows an example of a manufacturer's registered trademark that is

acceptable for replacement of the manufacturer's name. The trademark example is for Asea

Brown Boveri.

ABB Figure 1. Manufacturer Registered Trademarks

Manufacturer's Type Identification

The manufacturer's type identification is used to differentiate between similar pieces of

equipment (e.g., to differentiate between two 25 HP motors of different design). A more

common name for the manufacturer's type identification would be the model number. The

manufacturer's type identification is unique to each manufacturer. The Electrical Engineer

must have a list from the appropriate manufacturer to understand the codes that are used in

this area of the nameplate.

Atmosphere Protection

IEC 79 requires that all equipment for hazardous locations be marked with Ex. The Ex

designation indicates that the electrical equipment has been constructed and tested for use in

an explosive atmosphere. The type of atmosphere for which the equipment is approved is not

covered by the Ex designation.

The Ex designation does not have a direct counterpart in North American Standards. North

American Standards combine the Ex designation with the type of protection designation that

is discussed in the next section.

Saudi Aramco DeskTop Standards 16

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Type of Protection

Many types of protection are available for use in electrical equipment. The type of protection

that is used determines the areas in which the equipment can be used. The IEC uses a series

of symbols to represent the type of protection that is provided. The various types of

protection have been described earlier in this Module. The exact area in which each type of

protection is appropriate is presented in Work Aid 3. The following is a list of the IEC

symbols that are used on electrical equipment nameplates and the associated type of

protection:

• o - oil-immersed apparatus (not allowed at Saudi Aramco)

• p - pressurized enclosures

• q - sand-filled apparatus

• d - flameproof enclosures

• e - increased safety

• ia - intrinsic safety category a

• ib - intrinsic safety category b

• n - non-incendive

• m - encapsulation

• h - sealed

Group Classification

The group classification is the IEC method of showing the general location and atmospheric

hazards for which the equipment is rated. The IEC specifies two group classifications: Group

I and Group II. The following is a description of the general atmosphere hazards that are

designated by the IEC group classifications:

• Group I - Electrical equipment for use in mines that are susceptible to fire-

damp (methane).

• Group II - Electrical equipment for use in explosive gas atmospheres other than

mines that are susceptible to fire-damp (methane).

Saudi Aramco DeskTop Standards 17

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Subgroup Classification - Group II

Group II classifications are further divided into subgroups. The designation of subgroups that

are found on equipment nameplates can be general and refer to a variety of gases, or can be

very specific and refer to a certain gas. The following general subgroups are designated by a

letter that follows the group number II, as follows:

• IIA

• IIB

• IIC

Figure 5 in Work Aid 1 lists the various gases that comprise each subgroup.

The basis for the general group classification is to identify a variety of gases and vapors

having similar chemical and ignition characteristics as described in Module EEX 208.01. The

general subgroup is determined by the maximum experimental safe gap (MESG) or the ratio

of the minimum ignition current (MIC) of the gas with the MIC of laboratory methane. The

equipment must meet these distance or current ratios to be used in a specific area.

The subgroup codes and the associated MESG and MIC ratios are shown in Figure 2. The

requirements become more strict for each successive subgroup.

Group/Subgroup MESG MIC Ratio

IIA >.9 mm >.8

IIB >.5 mm but <.9 mm between .45 and .8

IIC <.5 mm <.45

Figure 2. Subgroup Codes and Associated MESG and MIC

Ratios

The stricter requirements for successive subgroups means that an apparatus that is marked IIB

is suitable for applications that require Group IIA apparatus. Similarly, an apparatus that is

marked IIC is suitable for applications that require Group IIA or Group IIB apparatus.

When electrical equipment is certified for use in an atmosphere that contains a particular gas,

the general subgroup classification will not be on the nameplate. The nameplate will show

the particular gas for which the equipment is approved. The equipment nameplate

designation will be the symbol II followed by the chemical formula or name of the gas.

Saudi Aramco DeskTop Standards 18

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Temperature Class

The nameplates for Group II electrical equipment will have one of the following types of

temperature designations:

• IEC temperature class symbol

• The actual maximum surface operating temperature in degrees Celsius

• The IEC temperature class symbol and the actual maximum surface operating

temperature in degrees Celsius

Figure 3 shows the IEC temperature class symbols and the maximum surface operating

temperature ranges that are associated with each symbol. Electrical Engineers should note

that nameplates for electrical equipment that operates in excess 450°C will indicate the actual

maximum surface operating temperature in degrees Celsius. Such equipment will not have an

IEC temperature class symbol.

IEC Temperature Class Maximum Surface

Symbols Temperature (°C)

T1 ²450

T2 ²300

T3 ²200

T4 ²135

T5 ²100

T6 ² 85

Figure 3. IEC Temperature Class Symbols

and Associated Temperature Ranges

Work Aid 1 contains a table that compares IEC temperature classes and North American

temperature classes.

Serial Number

Each piece of electrical equipment must have a unique serial number for purposes of

identification. The serial number always should be used in communications with the

manufacturer. Serial numbers are unique to each manufacturer and do not follow any

prescribed rules.

Saudi Aramco DeskTop Standards 19

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

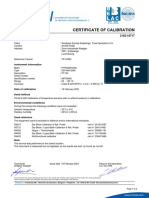

Certifying Authority

The organization that certifies a piece of electrical equipment for use in a hazardous location

must place its name or symbol on the nameplate. The year of certification and the serial

number of the certificate also must be marked on the nameplate.

Work Aid 4 contains a list of the authorities that can certify electrical equipment for use in

hazardous locations of Saudi Aramco facilities. Electrical Engineers can only specify

electrical equipment that has been labeled, listed, approved or certified by these authorities.

Special Conditions

A piece of electrical equipment that is acceptable for use in hazardous locations only under

special conditions must have the special condition designation "/X" placed on the nameplate

after the reference to the certifying authority's certificate. Electrical engineers must consult

either the certificate of the appropriate authority or the accompanying documentation

provided by the equipment manufacturer to determine the special conditions under which the

equipment can be used.

Markings for a Specific Type of Protection

Certain types of protection require that additional information be included on the equipment

nameplate. The required information is different for different types of protection. Some

types of protection do not require additional information. The following types of protection

require additional nameplate information:

• Sand-filled

• Oil-immersed

• Pressurized

Sand-Filled - The following additional information is required on the nameplates of sand-

filled electrical equipment

:

• Maximum permissible arcing current and duration

• Test gas description

Oil-Immersed - The following additional information is required on the nameplates of oil-

immersed electrical equipment:

• Rated making and breaking capacity of the equipment

• Rated short time current

Saudi Aramco DeskTop Standards 20

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Electrical engineers should note that oil-immersion is not allowed as a method of protection at

Saudi Aramco facilities.

Pressurized - The following additional information is required on the nameplates of

pressurized electrical equipment:

• Minimum and maximum operating pressure

• Minimum flow rate of protective gas

• Type of protective gas

• Minimum volume of protective gas

• Purge time required to initially clear enclosure

• Warnings regarding opening of doors.

General Nameplate Markings

All electrical equipment must have certain information on the nameplate to identify the

operating parameters of the equipment. The general nameplate markings will vary with the

manufacturer and type of equipment. The following are examples of the general markings

that can be included on electrical equipment nameplates:

• kilowatts

• kVA

• amps

• volts

• operating time (duty cycle)

Nameplate Marking and Attachment Requirements

The IEC has specific guidelines on how electrical equipment nameplates are to be marked and

mounted. The nameplate markings must remain legible over the entire life of the equipment.

To ensure that the characters are always legible, the characters may be recessed or raised as

part of the equipment casting or molding. Also, the characters may be directly engraved onto

the enclosure of the electrical apparatus or may be on a plate that is securely fixed to the

enclosure.

Saudi Aramco DeskTop Standards 21

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

The label must be fixed to the principal part of the enclosure by one the following methods:

• By soldering or brazing, either directly or by means of a frame.

• By screws with sunken heads that are locked in place by punching or soldering.

• By riveting throughout the wall of the enclosure, if permitted, by the type of

protection concerned.

• By bonding into a recess in the case of plastic enclosures.

• By drive screws not intended to be removed.

• Other means acceptable to the certifying/approving agency.

Data Arrangement on Nameplate

Most of the information on the nameplate can be arranged in any order as long as the

information is presented in a clear, logical manner. The only parts of the nameplate that must

be placed in a certain order are the codes that pertain to the type and level of protection for

which the equipment is approved. The information will be given in the following order:

• Atmosphere Protection

• Type of Protection

• Group Classification

• Subgroup Classification

• Temperature Class

The following are examples of the order of information on equipment nameplates:

• Ex d I - Electrical apparatus in flameproof enclosure for Group I.

• Ex d I/IIB T3 - Electrical apparatus in flameproof enclosure for Group I and

for Group IIB, temperature class T3.

• Ex ep II 125°C (T4), Ex ep II 125°C, or Ex ep II T4 - Increased safety

electrical apparatus and a pressurized enclosure for Group II (e.g., increased

safety motor fitted with slip rings in a pressurized enclosure) with a maximum

surface temperature of 125°C.

Saudi Aramco DeskTop Standards 22

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

IDENTIFYING IEC LISTED EQUIPMENT ALLOWED FOR USE IN SAUDI

ARAMCO HAZARDOUS LOCATIONS

Electrical equipment for use in hazardous locations is produced in many countries throughout

the world. Most countries that produce electrical equipment have a set of rules and guidelines

that must be followed in order for a piece of equipment to be used in a hazardous location.

The actual requirements will vary slightly from country to country due to opinions and testing

methods, but the goal will remain the same. The objective of setting standards is to ensure

safe installation and operation of the equipment.

Many countries also have testing organizations to ensure that equipment that is produced in

that country meets the requirements for installation in hazardous locations. The different

agencies will use slightly different methods of testing and possibly different codes for

indicating the level of protection for which the equipment is approved. Saudi Aramco does

not recognize all of these testing organizations as acceptable for certifying electrical

equipment for use in Saudi Aramco facilities. Work Aid 4 contains an excerpt from Saudi

Aramco Standard SAES-P-100 that lists the equipment that is built to IEC/European

Standards that is acceptable for use in Saudi Aramco installations. Work Aid 4 also contains

a list of limitations on the use of electrical equipment in hazardous locations of Saudi Aramco

installations.

Saudi Aramco DeskTop Standards 23

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

WORK AID 1: RESOURCES USED TO CONVERT NORTH AMERICAN

DESIGNATIONS TO THE EQUIVALENT INTERNATIONAL/

EUROPEAN TERMS

This Work Aid is designed to assist the Participant in performing Exercise 1.

1. Use the following table to compare International/European terminology to North

American terminology.

International & Definition North American

European Terminology Equivalent

Group I Area designation for equipment in Class I

gassy mines.

Group II Above ground area containing Class I

hazardous gases & vapors.

Subgroup A, B, or C A grouping of gases/vapors according Group A, B, C or D

to MESG and/or minimum ignition

current (MIC).

Temperature Class The maximum allowable surface Temperature Class

temperature for electrical equipment

in hazardous locations.

Zone 0 An area that always has flammable Division 1

gases/vapors present or that has

flammable gases/vapors present for

long periods of time.

Zone 1 An area that is likely to have Division 1

flammable gases/vapors present

during normal operation.

Zone 2 An area in which an explosive Division 2

mixture of flammable gases/vapors is

not likely to occur or occurs only for

short periods.

Figure 6. IEC/North American Terminology Comparison

Saudi Aramco DeskTop Standards 24

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

2. Use the following table to compare International/European grouping of gases to North

American grouping of gases.

North American Equivalent

International/European

Grouping of Gases Group Ignition Temperature

(°C) (°F)

Subgroup A (IIA)

Acetaldehyde C 175 347

Acetic Acid D 464 867

Acetone D 465 869

Jet Fuel D 230 446

Ammonia D 498 928

Benzene D 498 928

Carbon Monoxide C 607 1128

Diesel Fuel D 210 410

Ethane D 472 882

Ethyl Acetate D 427 800

Methanol D 385 725

n-Butane D 288 550

n-Hexane D 225 437

Propane D 450 842

Subgroup B (IIB)

Diethyl Ether C 472 882

Ethylene C 450 842

Subgroup C (IIC)

Acetylene A 305 581

Carbon Disulfide N/A 90 194

Hydrogen A 520 968

Figure 7. IEC/North American Gas Subgroups

Saudi Aramco DeskTop Standards 25

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

3. Use the following table to compare International/European Temperature classes to

North American Temperature Classes.

International/ North American Maximum Surface

European Temperature (°C)

T1 T1 450

T2 T2 300

T2A 280

T2B 260

T2C 230

T2D 215

T3 T3 200

T3A 180

T3B 165

T3C 160

T4 T4 135

T4A 120

T5 T5 100

T6 T6 85

Figure 8. IEC/North American Temperature Classes

Saudi Aramco DeskTop Standards 26

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

WORK AID 2: REFERENCES USED TO DETERMINE REQUIREMENTS FOR

INSTALLATION OF EUROPEAN EQUIPMENT IN

HAZARDOUS LOCATION APPLICATIONS

The Participant should refer to ISA RP 12.6 Wiring Practices for Hazardous (Classified)

Locations, Instrumentation - Part 1: Intrinsic Safety. Follow the steps outlined in this

reference to determine the cable length requirements.

Saudi Aramco DeskTop Standards 27

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

WORK AID 3: REFERENCES FOR INTERPRETING NAMEPLATE DATA ON

IEC/CENELEC/EUROPEAN EQUIPMENT USED IN HAZARDOUS

LOCATIONS

This Work Aid is designed to assist the Participants in performing Exercise 3.

1. Use the following table to compare IEC designations to North American designations

and allowable areas of usage.

IEC North American Where it

Symbol Equivalent Can Be Used

d flameproof Zone 1, 2, Division 1, 2*

p pressurized Zone 1, 2, Division 1, 2

o oil-immersed Zone 1, 2, Division 1, 2

q sand filled Zone 1, 2, Division 1, 2

e increased safety Zone 1, Division 2

ia intrinsic safety category a Zone 0, 1, 2, Division 1, 2

ib intrinsic safety category b Zone 1, 2, Division 2

n non-incendive Zone 2, Division 2

m encapsulation Zone 1, Division 1

h hermetically sealed Zone 2, Division 2

* With direct wiring connections only.

Figure 9. IEC/North American Protection Types

Use the following table to compare IEC Group designation.

IEC Designations Group Explanation

I Electrical equipment for use in mines that are

susceptible to fire-damp (methane).

II Electrical equipment for use in above ground areas that

contain flammable gases/vapors.

Figure 10. IEC Group Designations

Saudi Aramco DeskTop Standards 28

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

2. Use the following table to compare International/European grouping of gases to North

American grouping of gases.

International/European North American

Grouping of Gases Equivalent

Subgroup A (IIA) Group

Acetaldehyde C

Acetic Acid D

Acetone D

Jet Fuel D

Ammonia D

Benzene D

Carbon Monoxide C

Diesel Fuel D

Ethane D

Ethyl Acetate D

Ethyl Alcohol D

i-Amylacetate D

Methanol D

n-Butane D

n-Butylalcohol D

n-Hexane D

Petrol D

Propane D

Figure 11. IEC/North American Gas Groupings

Saudi Aramco DeskTop Standards 29

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

3. Use the following table to compare IEC Temperature Classes to North American

Temperature Classes.

IEC North American

Temperature Maximum Surface Temperature Maximum Surface

Class Temperature (°C) Class Temperature (°C)

T1 450 T1 450

T2 300 T2 300

T2A 280

T2B 260

T2C 230

T2D 215

T3 200 T3 200

T3A 180

T3B 165

T3C 160

T4 135 T4 135

T4A 120

T5 100 T5 100

T6 85 T6 85

Figure 12. IEC/North American Temperature Classes

Saudi Aramco DeskTop Standards 30

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

WORK AID 4: REFERENCES USED TO IDENTIFY IEC-LISTED EQUIPMENT

ALLOWED FOR USE IN SAUDI ARAMCO HAZARDOUS

LOCATIONS

International/European Electrical Equipment Suitable for Use in Hazardous Locations

of Saudi Aramco Installations

International/European equipment that the NEC requires to be approved for use in hazardous

locations must be labeled, or listed, or certified by any of the following authorities:

UK British Approvals Services for Electrical Certified

Equipment in Flammable Atmospheres (BASEEFA)

France Centre d'Etudes et Recherches de Charbonnages Certified

de France (CHERCHAR)

Belgium Institute National des Industries Extractives Certified

(INIEX)

France Laboratoire Central de Industries Electriques Certified

(LCIE)

Germany Physikalisch Technische Bundesanstalt (PTB) Certified

Switzerland Schweizerischer Elektrotechnischer Verein (SEV) Certified

Italy Centro Elettrotecnico Sperimentale Italiano Certified

(CESI)

Netherlands Keuring van Electrotechnische Materialen (KEMA) Certified

North American Electrical Equipment Suitable for Use in Hazardous Locations of Saudi

Aramco Installations

North American equipment that the NEC requires to be approved must be labeled, or listed, or

approved, or certified by any of the following authorities:

USA Underwriters Laboratories, Inc. (UL) Labeled or Listed

USA Factory Mutual Research Corp. (FM) Approved

Canada Canadian Standards Assn. (CSA) Certified

Saudi Aramco DeskTop Standards 31

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

Limitations on the Use of Electrical Equipment in Hazardous Locations of Saudi

Aramco Installations

Conduit sealing fittings must be labeled, listed, approved, or certified by Underwriters

Laboratories, Inc. (UL), Factory Mutual Research Corp. (FM), or Canadian Standards

Association (CSA).

Flameproof enclosures EEx d II and increased safety apparatus EEx e II are permitted in Class

I, Division 2 locations.

Flameproof enclosures EEx d II are permitted in Class I, Division 1 locations, provided: (i)

all cables enter the enclosure through rigid steel conduit, with approved sealing fittings, and

(ii) the entire enclosure - not only its components - is flameproof EEx d II (explosionproof).

Saudi Aramco DeskTop Standards 32

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

GLOSSARY

CENELEC European Electrotechnical Standards Committee

encapsulation The intimate surrounding of electrical equipment with material that will,

under the conditions for which the equipment has been designed,

prevent occurrence of an external condition that could ignite the outer

explosive atmosphere either by transmission of flame or by overheating

of any part within the encapsulation.

explosionproof An enclosure that is designed for electrical equipment; that will

withstand, without damage, an explosion of a prescribed flammable gas

or vapor within the enclosure; that will prevent the transmission of

flame or sparks that would ignite the external prescribed flammable gas

or vapor for which the enclosure is designed; and that normally

operates at an external temperature that will not ignite the external

prescribed flammable gas or vapor. An explosionproof enclosure will

not necessarily be weatherproof or dustproof.

FM Factory Mutual Research Corporation, Inc.

group I Area designation for equipment in mines susceptible to fire-damp

(methane).

group II An above-ground area containing hazardous gases and vapors or the

designation of equipment that are acceptable for use in such above

ground areas.

hermetically Equipment that is permanently sealed to prevent entry of liquids, gas,

sealed or vapor.

IEC International Electrotechnical Commission

increased safety A method of protection in which measures additional to those adopted

in ordinary industrial practice are applied to give increased security

against the possibility of excessive temperatures and against the

occurrence of arcs or sparks in electrical apparatus which does not

produce arcs or sparks in normal service.

intrinsically safe In reference to a circuit or part of a circuit, when any sparking that is

produced normally by breaking or making the circuit or that is

produced accidentally, e.g., by short circuit or earth fault or by any

temperature rise associated therewith, is incapable of causing ignition of

a prescribed gas or vapor under prescribed test conditions.

Saudi Aramco DeskTop Standards 33

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

MESG Maximum experimental safe gap.

MIC Minimum ignition current.

non-sparking Electrical equipment that is of normal industrial design and that has no

sparking parts during normal operation.

oil-immersed Electrical equipment on which the following parts are immersed in oil

or protected by another recognized method: parts on which arcs may

occur in normal service and live parts on which arcs do not occur in

normal service. For parts that are immersed in oil, immersion is to a

depth that is sufficient to prevent ignition of an explosive gas/air

mixture that may be present above the surface of the oil.

pressurized For electrical machines and equipment, an enclosure in which the entry

of flammable gases or vapors is prevented by maintaining the air (or

other non-flammable gas) within the enclosure at a specified pressure

above the pressure of the external atmosphere.

purged For electrical equipment an enclosure through which a sufficient flow

of fresh air or inert gas is maintained to prevent the entry of any

flammable gas or vapor that may be present in the ambient atmosphere

in which the enclosure is installed. Also, the initial flow of protective

gas through an enclosure to clear out flammable gases or vapors

initially present before applying power to the equipment.

restricted Apparatus that are constructed to prevent the breathing combination of

breathing explosive mixtures of gas or vapor with air inside an enclosure during a

certain time limit. Such construction ensures that no ignition that

would propagate to the external atmosphere will occur inside the

enclosure.

sand-filled For electrical equipment, an enclosure in which all live parts of the

equipment are entirely embedded in a mass of powdery material that

has the consistency of sand in such a way that if, under the condition of

use for which the equipment is designed, an arc occurs within the

enclosure, this arc will not ignite the outer explosive atmosphere either

by the transmission of flame or by the overheating of the walls of the

enclosure.

special protection A designation that permits the certification of types of electrical

apparatus that, by their nature, do not comply with the constructional or

other requirements specified for apparatus with established types of

protection but that nevertheless can be shown to be suitable for use in

Saudi Aramco DeskTop Standards 34

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

prescribed zones within hazardous locations.

Saudi Aramco DeskTop Standards 35

Engineering Encyclopedia Electrical

Application of IEC/Cenelec/European

Equipment to Hazardous Locations

subgroup A grouping of gases/vapors according to MESG and/or MIC.

temperature class The maximum allowable surface temperature for electrical equipment

in hazardous locations.

UL Underwriters' Laboratories, Inc.

Zone 0 An area in which an explosive gas-air mixture is continuously present

or present for long periods of time.

Zone 1 An area in which explosive gas-air mixture is likely to occur during

normal operation.

Zone 2 An area in which an explosive gas-air mixture is not likely to occur or

in which such a mixture would exist only for a short time.

Saudi Aramco DeskTop Standards 36

You might also like

- IB Chemistry IA: EnergeticsDocument10 pagesIB Chemistry IA: EnergeticsMomina Amjad88% (56)

- Problem 81 90Document20 pagesProblem 81 90maria katherine pantojaNo ratings yet

- 6951-Anchor Bolt and Base Plate DesignDocument38 pages6951-Anchor Bolt and Base Plate DesignOmprakash Khodke100% (1)

- 17 Samss 502Document25 pages17 Samss 502umerNo ratings yet

- 14 Samss 533 PDFDocument14 pages14 Samss 533 PDFMudabbir HussainNo ratings yet

- Leaf SpringDocument16 pagesLeaf SpringThayumanavan KSNo ratings yet

- Assignment 2Document5 pagesAssignment 2Chaitanya KumarNo ratings yet

- Commissioning Motor Control Centers PDFDocument59 pagesCommissioning Motor Control Centers PDFsachinrdandare6754No ratings yet

- Selecting Low Voltage Motor StartersDocument114 pagesSelecting Low Voltage Motor StartersJellyn BaseNo ratings yet

- Motor Protection RequirementsDocument84 pagesMotor Protection RequirementsJellyn Base100% (1)

- Eex10505 Fundamentals of UPSDocument71 pagesEex10505 Fundamentals of UPSHonesto Bautista100% (1)

- Evaluating Insulation TestsDocument73 pagesEvaluating Insulation TestsJellyn Base100% (1)

- Eex10506 Fund of Hazardous LocationsDocument52 pagesEex10506 Fund of Hazardous LocationsHonesto BautistaNo ratings yet

- Engineering Encyclopedia: Instrumented ScrapersDocument16 pagesEngineering Encyclopedia: Instrumented ScrapersabyNo ratings yet

- EEX10401 Industrial Facility SubstationDocument64 pagesEEX10401 Industrial Facility SubstationHonesto Bautista100% (1)

- EEX10602 Protection OverviewDocument40 pagesEEX10602 Protection OverviewHonesto Bautista100% (1)

- Eex10601 PDFDocument29 pagesEex10601 PDFcvg ertd100% (1)

- Commissioning Switchgear Low Voltage and Circuit Breakers PDFDocument59 pagesCommissioning Switchgear Low Voltage and Circuit Breakers PDFAhmed AlnagarNo ratings yet

- Ap Atm Explosiva en Rev01 PDFDocument158 pagesAp Atm Explosiva en Rev01 PDFHarishNo ratings yet

- Evaluating Circuit Resistance TestsDocument59 pagesEvaluating Circuit Resistance TestsJellyn Base100% (1)

- Materials System SpecificationDocument6 pagesMaterials System SpecificationEagle SpiritNo ratings yet

- 34 Samss 815Document9 pages34 Samss 815Eagle SpiritNo ratings yet

- Ground System TestingDocument31 pagesGround System TestingJellyn BaseNo ratings yet

- Epoch LTCDocument4 pagesEpoch LTCNaveen ChodagiriNo ratings yet

- Engineering Encyclopedia: Basic Properties of SectionsDocument62 pagesEngineering Encyclopedia: Basic Properties of SectionsVijay KumarNo ratings yet

- Electric Motor 7Document84 pagesElectric Motor 7abdulkadhirNo ratings yet

- EEX 208.01 Classification of and Protection For Hazardous LocationsDocument33 pagesEEX 208.01 Classification of and Protection For Hazardous LocationsMo'tasem Serdaneh100% (1)

- Sabp P 004Document17 pagesSabp P 004Hassan MokhtarNo ratings yet

- 36 Samss 001Document78 pages36 Samss 001Eagle SpiritNo ratings yet

- PMT 10103Document9 pagesPMT 10103cvg ertdNo ratings yet

- 15 Saip 51Document5 pages15 Saip 51malika_00No ratings yet

- 175 023400Document2 pages175 023400Abu Anas M.SalaheldinNo ratings yet

- Electrical MotorDocument55 pagesElectrical Motorabdulkadhir100% (1)

- Engineering Encyclopedia: Generator FundamentalsDocument139 pagesEngineering Encyclopedia: Generator FundamentalsCorey Porter100% (1)

- Electrical Storage Batteries For Stationary System: Functional SpecificationDocument20 pagesElectrical Storage Batteries For Stationary System: Functional SpecificationKthiri WaelNo ratings yet

- Acceptability of Disconnect SwitchesDocument55 pagesAcceptability of Disconnect SwitchesJellyn BaseNo ratings yet

- Electric Motor 9Document54 pagesElectric Motor 9abdulkadhirNo ratings yet

- 34 Samss 619Document14 pages34 Samss 619naruto256No ratings yet

- 34 Samss 122Document13 pages34 Samss 122naruto256No ratings yet

- Saes J 002Document25 pagesSaes J 002Dinesh BoopalanNo ratings yet

- Sabp P 060Document22 pagesSabp P 060Hassan Mokhtar100% (1)

- Specification of TransformerDocument43 pagesSpecification of TransformerJaaffer AliNo ratings yet

- Saes P 114Document31 pagesSaes P 114aglegarteNo ratings yet

- Select Instrum TransfmerDocument75 pagesSelect Instrum TransfmerJheny B. Bayon100% (1)

- Spare Parts: Dep SpecificationDocument25 pagesSpare Parts: Dep SpecificationmusabammadkhanNo ratings yet

- Guidelines For HV Installations PDFDocument16 pagesGuidelines For HV Installations PDFhanyalramadyNo ratings yet

- EEX 107.07 Fundamentals of Cable Fault LocalizationDocument28 pagesEEX 107.07 Fundamentals of Cable Fault LocalizationJellyn Base100% (1)

- Grounding 4 PDF FreeDocument74 pagesGrounding 4 PDF FreeShiaTVfanNo ratings yet

- Engineering Encyclopedia: Severe Service Control Valve Specification IssuesDocument19 pagesEngineering Encyclopedia: Severe Service Control Valve Specification Issuescvg ertdNo ratings yet

- Saep 747Document20 pagesSaep 747Anonymous 4IpmN7OnNo ratings yet

- 16 Samss 502 - PDFDocument12 pages16 Samss 502 - PDFShahraiz KhanNo ratings yet

- 16 Samss 506Document40 pages16 Samss 506HatemS.MashaGbehNo ratings yet

- Transformer Accessories and Support EquipmentDocument44 pagesTransformer Accessories and Support EquipmentJellyn Base100% (1)