Professional Documents

Culture Documents

China State Construction Engineering Corporation. LTD

China State Construction Engineering Corporation. LTD

Uploaded by

Amila SampathOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

China State Construction Engineering Corporation. LTD

China State Construction Engineering Corporation. LTD

Uploaded by

Amila SampathCopyright:

Available Formats

China State Construction Engineering Corporation.

LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

EXISTING LAYER PROFILE

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 06.05.2021

Type Thickness (mm)

Asphalt 60

ABC 110

Sub base 230

Macadam 60

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

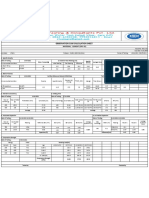

SIEVE ANALYSIS TEST

AASHTO - T88/ BS- 1377

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 18.06.2021

Weight of Sample Before Washing (g) 2712

Weight of Sample After Washing (g) 2020

Sieve Size Weight Retained Retained (%) Passing (%)

(mm) (g)

50 0.0 0.0 100.0

37.5 0.0 0.0 100.0

20 63.0 2.3 97.7

5 525.0 19.4 78.3

2.36 271.0 10.0 68.3

1.18 303.0 11.2 57.2

0.425 250.0 9.2 47.9

0.3 115.0 4.2 43.7

0.075 493.0 18.2 25.5

110

100

90

80

Passing (%)

70

60

50

40

30

20

0.01 0.1 1 10 100

Sieve Size (mm)

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

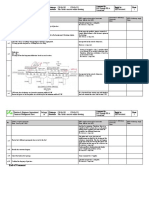

ATTERBERG LIMITS TEST

AASHTO T-89 & T-90

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 23.06.2021

Liquid Limit

Test No 1 2 3 4

Number of Blows 42 33 25 15

Can No 13 14 15 16

Weight of Can + Wet Soil (g) 37.51 36.02 40.34 39.39

Weight of Can + Dry Soil (g) 33.78 32.52 35.65 35.40

Weight of Can (g) 17.66 17.98 17.24 20.6

Weight of Water (g) 3.73 3.50 4.69 3.99

Weight of Dry Soil (g) 16.12 14.54 18.41 14.8

Moisture Content (%) 23.14 24.07 25.48 26.96

30

29

28

Moisture Content (%)

27

26

25

24

23

22

21

20

10 1 2 3

Number of Blows (in Log Scale)

Plastic Limit

Test No A B

Can No 17 18

Weight of Can + Wet Soil (g) 26.8 25.13

Weight of Can + Dry Soil (g) 25.41 23.88 Liqued Limit (LL) 25.2

Weight of Can (g) 18.84 17.88 Plastic Limit (PL) 21.0

Weight of Water (g) 1.39 1.25 Plastic Index (PI) 4.2

Weight of Dry Soil (g) 6.57 6.00

Moisture Content (%) 21.16 20.83

Average Moisture Content (%) 21.0

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

PROCTOR COMPACTION TEST

AASHTO : T 180-98 (Method - D)

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 11.06.2021

Weight of Mould (g) 4814

Volume (cm3) 996

Trail No 1 2 3 4 5

Weight of Wet Soil + Mould (g) 6877 7008 7031 6992 6932

Weight of Wet Soil (g) 2063 2194 2217 2178 2118

Wet Density (g/cm3) 2.071 2.203 2.226 2.187 2.127

Can No 11 12 13 14 15

Weight of Wet Soil + Can (g) 332.6 284.46 308.21 369.17 320.16

Weight of Dry Soil + Can (g) 322.42 273.78 293.59 345.20 296.97

Weight of Moisture (g) 10.2 10.7 14.6 24.0 23.2

Weight of Can (g) 116 111 125 123 116

Weight of Dry Soil (g) 206.4 162.8 168.6 222.2 181.0

Moisture Content (%) 4.9 6.6 8.7 10.8 12.8

Dry Density (g/cm3) 1.974 2.067 2.048 1.974 1.886

2.080

2.060

2.040

Dry Density (g/cm3)

2.020

2.000

1.980

1.960

1.940

1.920

1.900

1.880

4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0

Moisture Content (%)

Optimum Moisture Content (OMC) (%) 7.2

Maximum Dry Density (MDD) (g/cm3) 2.072

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF FIELD DRY DENSITY

SAND REPLACEMENT METHOD (BS 1377 - Part 9)

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 06.05.2021

Depth from Surface (mm) 460

Depth of Hole Excavated (mm) 150

Mass of Standard Sand Before Pouring (g) 8000

Mass of Standard Sand After Pouring (g) 3952

Mass of standard Sand in Hole & Cone (g) 4048

Mass of Standard Sand in Cone (g) 1109

Mass of Standard Sand in Hole (g) 2939

Density of Standard Sand (g/cm3) 1.337

Volume of Hole (cm3) 2198

Mass of Container + Wet Soil (g) 5102

Mass of Container (g) 341

Mass of Wet Soil (g) 4761

Wet Density of Soil (cm3) 2.166

Moisture Container No R

Mass of Can + Wet Soil (g) 336.0

Mass of Can + Dry Soil (g) 321.0

Mass of Can (g) 120.0

Mass of Dry Soil (g) 201.0

Mass of Moisture (g) 15.0

Moisture Content of Soil (Field) (%) 7.5

Field Dry Density of Soil (FDD) (g/cm3) 2.015

Maximum Dry Density of Soil (Lab) (g/cm3) 2.072

Optimum Moisture Content of Soil (Lab) (%) 7.2

Degree of Compaction (%) 97.3

Specified Degree of Compaction (%) 95

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method - BS 1377: PART 4 : 1990

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 19.06.2021

Identification of the Specimen 7

Specified Dry Density (g/cm3) 2.015

Specified Moisture Content (%) 7.5

Bulk Density (g/cm3) 2.166

Calibrated Volume of CBR Mould (cm3) 2304

Calibrated Height of Mould (mm) 127

Maximum Dry Density of Soil (MDD)(cm3) 2.072

Specified Degree of Compaction (%) 97.3

SPECIMEN BEFORE SOAKING

Calculated Mass of Dry Soil in Mould (g) 4643

Initial / Field Moisture Content of Sample (%) 1.4

Calculated Mass of Sample Taken for Test (g) 4708

Volume of Water Required to Add (ml) 283.2

Mass of Specimen + Mould With Base Plate Before Soaking (g) 9297

Mass of Mould With Base Plate (g) 4306

Mass of Compacted Specimen in Mould Before Soaking (g) 4991

Bulk Density of Unsoaked Speciman (cm3) 2.166

Moisture Content of Soil While Casting (%) 7.5

Dry Density of Soil Before Soaking (Unsoaked) (cm3) 2.015

Degree of Compaction Before Soaking (%) 97.3

SPECIMEN AFTER 4 DAYS SOAKING

Mass of Specimen + Mould With Base Plate After Soaking (g) 9449

Mass of Compacted Specimen in Mould After Soaking (g) 5143

Bulk Density of Soaked Speciman (cm3) 2.232

Moisture Content of Soil After Soaking (%) 10.5

Dry Density of Soil After Soaking ( Soaked )(cm3) 2.020

Degree of Compaction After Soaking (%) 97.5

Initial Reading of Swell Gauge (Div) 0

Final Reading of Swell Gauge (Div) 25

Swell of Specimen (mm) 0.25

Precentage Swell (%) 0.20

Tested by Checked by Certified by

Materials Technician Engineer Engineer

V.V.KARUNARATNE & CO.

Engineering Laboratory Temple Road, Daladagama, Mahawa

Head Office - No 579,Bulugaha Junction,Kandy Road ,Kelaniya Sri Lanka.

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method AASHTO T-193 (1999)

Project Construction of Upper Elahera Canal from 27+509km to 55+600km Including

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Employer Ministry of Irrigation - Mahaweli Water Security Investment Program

Consultant 0

Description Sabgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 16.09.2016

Identification of the Specimen 1 2 3

Decided Nos of Blows per Layer (Blows) 10 30 65

Identification No of CBR Mould and Base Plate S T U

Calibrated Volume of CBR Mould (cm3) 2117.8 2125 2121

Calibrated Height of Mould (mm) 116.77 116.8 116.52

Maximum Dry Density of Soil (g/cm3) 2.072

Moisture Content at Which the Sample is Cast ( OMC) 7.2

SPECIMEN BEFORE SOAKING

Initial / Field Moisture Content of Sample (%) 1.4 1.4 1.4

Mass of Sample Taken for Test (g) 6000 6000 6000

Volume of Water Required to Add (ml) 343 343 343

Mass of Specimen + Mould With Base Plate Before Soaking (g) 12254 12685 12912

Mass of Mould With Base Plate (g) 8071 8142 8080

Mass of Compacted Specimen in Mould Before Soaking (g) 4183 4543 4832

Bulk Density of Unsoaked Speciman (g/cm3) 1.975 2.138 2.278

Moisture Content of Soil While Casting (%) 7.2 7.2 7.2

Dry Density of Soil Before Soaking ( Unsoaked )(g/cm3) 1.843 1.994 2.125

Degree of Compaction Before Soaking (%) 88.9 96.3 102.6

SPECIMEN AFTER SOAKING

Mass of Specimen + Mould With Base Plate After Soaking (g) 12635 12985 13080

Mass of Compacted Specimen in Mould After Soaking (g) 4564 4843 5000

Bulk Density of Soaked Speciman (g/cm3) 2.16 2.28 2.36

Moisture Content of Soil After Soaking (%) 15.9 12.6 10.5

Dry Density of Soil After Soaking ( Soaked ) (g/cm3) 1.859 2.024 2.133

Degree of Compaction After Soaking (%) 89.7 97.7 103.0

Initial Reading of Swell Gauge (Div) 0 0 0

Final Reading of Swell Gauge (Div) 31 22 10

Swell of Specimen (mm) 31 22 10

Precentage Swell (%) 0.27 0.19 0.09

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Penetration (mm) Dial Reading (Div.) Load on Plunger (KN)

B-10 B-30 B-65 B-10 B-30 B-65

0.00 0 0 0 0.00 0.00 0.00

0.25 3 5 6 0.13 0.21 0.25

0.50 4 8 9 0.17 0.34 0.38

0.75 5 9 11 0.21 0.38 0.47

1.00 6 11 12 0.25 0.47 0.51

1.25 7 12 14 0.30 0.51 0.59

1.50 8 14 15 0.34 0.59 0.64

1.75 9 15 17 0.38 0.64 0.72

2.00 10 16 21 0.42 0.68 0.89

2.25 11 17 23 0.47 0.72 0.98

2.50 12 18 25 0.51 0.76 1.06

2.75 13 19 27 0.55 0.81 1.14

3.00 14 20 28 0.59 0.85 1.19

3.25 15 21 30 0.64 0.89 1.27

3.50 16 22 32 0.68 0.93 1.36

3.75 17 23 35 0.72 0.98 1.48

4.00 18 25 37 0.76 1.06 1.57

4.25 19 27 39 0.81 1.14 1.65

4.50 20 28 41 0.85 1.19 1.74

4.75 21 29 43 0.89 1.23 1.82

5.00 22 30 45 0.93 1.27 1.91

5.25 23 31 48 0.98 1.31 2.04

5.50 24 32 50 1.02 1.36 2.12

5.75 25 33 53 1.06 1.40 2.25

6.00 26 34 56 1.10 1.44 2.37

6.25 27 35 58 1.14 1.48 2.46

Load Ring Factor 0.0424 KN/Div.

Penetration (mm) 2.5 5

Standard Load (KN) 13.24 19.96

B-10 0.51 0.93

Force on Plunger (KN) B-30 0.76 1.27

B-65 1.06 1.91

B-10 3.8 4.7

CBR (%) B-30 5.8 6.4

B-65 8 9.6

Maximum Dry Density (MDD) 2.072

Field Dry Density (FD) (g/cm3) 2.02

10 Blows 30 Blows 65 Blows 95 % MDD FD

Dry Density (g/cm3) 1.843 1.994 2.125 1.968 2.02

CBR (%) 4.7 6.4 9.6 6.0 6.8

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

CBR Test Result Curves

3.0

2.5

2.0

Load (KN)

1.5

1.0

0.5

0.0

0 1 2 3 4 5 6 7

Penetration (mm)

10 Blows Polynomial (10 Blows) 30 Blows

Polynomial (30 Blows) 65 Blows Polynomial (65 Blows)

Dry Density/Dry Density Relationship

12

10

8

CBR (%)

0

1.80 1.85 1.90 1.95 2.00 2.05 2.10 2.15

Dry Density (g/cm3)

Tested by Checked by Witnessed by Certyfied by

Materials Technician Materials Engineer Materials Technician Materials Engineer

(Contractor) (Contractor) (Consultant) (Consultant)

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method - BS 1377: PART 4 : 1990

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 19.06.2021

Penetration (mm) Dial Reading (Div.) Load on Plunger (KN)

Top Bottom Top Bottom

0.00 0 0 0.00 0.00

0.25 7 8 0.32 0.37

0.50 12 13 0.55 0.60

0.75 15 19 0.69 0.87

1.00 21 24 0.96 1.10

1.25 26 27 1.19 1.24

1.50 30 31 1.37 1.42

1.75 34 36 1.56 1.65

2.00 36 39 1.65 1.79

2.25 39 42 1.79 1.92

2.50 43 45 1.97 2.06

2.75 47 49 2.15 2.24

3.00 51 54 2.34 2.47

3.25 55 59 2.52 2.70

3.50 59 63 2.70 2.89

3.75 63 65 2.89 2.98

4.00 65 69 2.98 3.16

4.25 68 73 3.11 3.34

4.50 71 77 3.25 3.53

4.75 73 82 3.34 3.76

5.00 75 85 3.44 3.89

5.25 77 88 3.53 4.03

5.50 79 91 3.62 4.17

5.75 81 93 3.71 4.26

6.00 83 95 3.80 4.35

6.25 85 98 3.89 4.49

Load Ring Factor 0.0458 kN/Div.

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method - BS 1377: PART 4 : 1990

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Carriageway Section/01+200 RHS/1.65m from Existing Center

Lab Reference No ED/2021/SOIL/058 Field Reference No TP/03

Date of Sampling 06.05.2021 Date of Test 19.06.2021

CBR Test Result Curves

5.0

4.5

4.0

3.5

3.0

Load (KN)

2.5

2.0

1.5

1.0

0.5

0.0

0 1 2 3 4 5 6 7

Penetration (mm)

Top Polynomial (Top) Bottom Polynomial (Bottom)

Penetration (mm) 2.5 5

Standard Load (kN) 13.24 19.96

Top 1.97 3.44

Force on Plunger (kN)

Bottom 2.06 3.89

Top 14.9 17.2

Soaked CBR (%)

Bottom 15.6 19.5

Accepted Soaked CBR (%) 18.4

Tested by Checked by Certified by

Materials Technician Engineer Engineer

You might also like

- Mix Design Concrete ExcelDocument7 pagesMix Design Concrete ExcelJoshua NdaloNo ratings yet

- Spectrophotometric Analysis of CopperDocument4 pagesSpectrophotometric Analysis of CopperOmSilence2651No ratings yet

- RP c208 - 2013 06Document66 pagesRP c208 - 2013 06Vivi GouriotiNo ratings yet

- Compressor Performance TestDocument9 pagesCompressor Performance TestPartha Pratim Ghosh100% (1)

- 007 Magmatip Filling Results enDocument7 pages007 Magmatip Filling Results enpurushothaman1234566No ratings yet

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- Gatch MaterialDocument7 pagesGatch MaterialamesbNo ratings yet

- Mix Desian DBM Gr-IIDocument126 pagesMix Desian DBM Gr-IISatish JaysiNo ratings yet

- Draft Report BhandaribaghDocument25 pagesDraft Report BhandaribaghrameshNo ratings yet

- Test Results of Aggregate Impact Value: Lab IDDocument7 pagesTest Results of Aggregate Impact Value: Lab IDyoseph dejeneNo ratings yet

- Test Results of Gradation and Atterberg Limits For WMMDocument13 pagesTest Results of Gradation and Atterberg Limits For WMMLalit KumarNo ratings yet

- Test Certificate-Geostrap5-02Document6 pagesTest Certificate-Geostrap5-02bineetmishra1990No ratings yet

- SIEVE ANALYSIS of Fine Aggregate FinalDocument40 pagesSIEVE ANALYSIS of Fine Aggregate FinalShaiful IslamNo ratings yet

- Test Report For Gabion Wire: Parameters ResultDocument1 pageTest Report For Gabion Wire: Parameters ResultmirwaisNo ratings yet

- Rumus Lab AdnanDocument33 pagesRumus Lab AdnanNaim DarmawanNo ratings yet

- Summary of Cut Section (Sub Grade) Material Test Result and Approval Record SheetDocument12 pagesSummary of Cut Section (Sub Grade) Material Test Result and Approval Record SheetAshebirNo ratings yet

- (IS: 2720 Part 16-1997) : California Bearing Ratio TestDocument4 pages(IS: 2720 Part 16-1997) : California Bearing Ratio Testmeerut nazibabad projectNo ratings yet

- Ecg524 Dec 2019Document8 pagesEcg524 Dec 2019Hairul AsyrafNo ratings yet

- Government of The Peoples Republic of Bangladesh Local Government Engineering Department Office of The Executive Engineer Lged, ChandpurDocument14 pagesGovernment of The Peoples Republic of Bangladesh Local Government Engineering Department Office of The Executive Engineer Lged, ChandpurShaiful IslamNo ratings yet

- A) Design Stipulation For ProportioningDocument5 pagesA) Design Stipulation For ProportioningSandip RoyNo ratings yet

- Sieve Analysis BH 3Document74 pagesSieve Analysis BH 3inam ulhaqNo ratings yet

- 04 - PT. VUB Bandara Kediri (Pasir Kayan Kalimantan) PDFDocument11 pages04 - PT. VUB Bandara Kediri (Pasir Kayan Kalimantan) PDFDeny PutraNo ratings yet

- WMM Moisture Correction SheetDocument34 pagesWMM Moisture Correction SheetQuality JamNo ratings yet

- Styrofoam ResultsDocument5 pagesStyrofoam Resultsmpairwe cliffortNo ratings yet

- Old Test SheetDocument13 pagesOld Test SheetImran SikandarNo ratings yet

- Tchumene Access Project Project Quality Management System (QMS)Document9 pagesTchumene Access Project Project Quality Management System (QMS)Loforte CumbeNo ratings yet

- Construction of Patenga Container Terminal (PCT) Package - 2A (Revision - O2)Document4 pagesConstruction of Patenga Container Terminal (PCT) Package - 2A (Revision - O2)Engr.Estiaq AhmedNo ratings yet

- Laboratory Test Report: Faculty of Engineering & TechnologyDocument6 pagesLaboratory Test Report: Faculty of Engineering & TechnologySourav SahaNo ratings yet

- Use of Industrial Wastes in The Construction of Flexible PavementsDocument6 pagesUse of Industrial Wastes in The Construction of Flexible Pavementssai venkateshNo ratings yet

- CEng2142 REG 2011 Test1 Examination Paper SetDocument10 pagesCEng2142 REG 2011 Test1 Examination Paper SetCaalchisaa MargaaNo ratings yet

- 05 Final Report - Uji Lab (Fisis) - Material Tanah PT Riung Mitra Lestari Site Muara TewehDocument31 pages05 Final Report - Uji Lab (Fisis) - Material Tanah PT Riung Mitra Lestari Site Muara TewehHafidz ArsenalNo ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- 04 - PT. VUB Bandara Kediri (Pasir Kelud) PDFDocument11 pages04 - PT. VUB Bandara Kediri (Pasir Kelud) PDFDeny PutraNo ratings yet

- Civ T Qac 00134 ProctorDocument6 pagesCiv T Qac 00134 ProctorIsaiahogedaNo ratings yet

- Sieve Analysis Data Sheet: ASTM D422-63 (2007)Document4 pagesSieve Analysis Data Sheet: ASTM D422-63 (2007)Rudolf FerdionNo ratings yet

- Summary of Cutting Material Test Result: Total Qty-9000 MDocument1 pageSummary of Cutting Material Test Result: Total Qty-9000 MSalimNo ratings yet

- Lime Stabilization TechniquesDocument24 pagesLime Stabilization TechniquesARTI PALEKARNo ratings yet

- ActualDocument28 pagesActualrheyjc09No ratings yet

- UTS Mekanika Tanah 1 D3 Teknik Sipil Kelas 2C - NIM GenapDocument2 pagesUTS Mekanika Tanah 1 D3 Teknik Sipil Kelas 2C - NIM GenapAhmad FauzanNo ratings yet

- Netc DBMDocument34 pagesNetc DBMMorya RonakNo ratings yet

- SD 221Document2 pagesSD 221peter njugunaNo ratings yet

- Laboratorium Mekanika Tanah Dan Geologi: Fakultas Teknik Universitas BrawijayaDocument3 pagesLaboratorium Mekanika Tanah Dan Geologi: Fakultas Teknik Universitas Brawijayadimas syahputraNo ratings yet

- Radhey Testing & Consultants Pvt. Ltd. Agra: Observation Cum Calculation SheetDocument1 pageRadhey Testing & Consultants Pvt. Ltd. Agra: Observation Cum Calculation SheetChandan MondalNo ratings yet

- Pour Card: Correction For Moisture Content For DLCDocument1 pagePour Card: Correction For Moisture Content For DLCQuality JamNo ratings yet

- A 2Document3 pagesA 2Mohamed KadryNo ratings yet

- S.No.1106 0 6 Awendo On 04 02 2021Document2 pagesS.No.1106 0 6 Awendo On 04 02 2021Derrick MandelaNo ratings yet

- Full ThesisDocument145 pagesFull ThesisMd. Shofiul IslamNo ratings yet

- 15 ME 171 (Project Report)Document11 pages15 ME 171 (Project Report)MomenNaeemNo ratings yet

- California Bearing Ratio (CBR) Test Report: Hyundai Engineering & Const. Co., Ltd. Indonesia Sarulla GPP ProjectDocument7 pagesCalifornia Bearing Ratio (CBR) Test Report: Hyundai Engineering & Const. Co., Ltd. Indonesia Sarulla GPP ProjectRango Santoso100% (1)

- Pour Card: Correction For Moisture Content For DLCDocument1 pagePour Card: Correction For Moisture Content For DLCQuality JamNo ratings yet

- Department of Public Works and Highways: % Relative WTDocument2 pagesDepartment of Public Works and Highways: % Relative WTAljie CañeteNo ratings yet

- Sample Source: Date: Sample Designation:: K1+960R (16KM) Borrow Pit KM 2+160 - 2+200 2017/8/26Document10 pagesSample Source: Date: Sample Designation:: K1+960R (16KM) Borrow Pit KM 2+160 - 2+200 2017/8/26kwameNo ratings yet

- Yinka PowerDocument38 pagesYinka PowerAbdullahi MuhammadNo ratings yet

- Blanket Gradation 08.02.2020Document2 pagesBlanket Gradation 08.02.2020Devendra SinghNo ratings yet

- Project Accomplishment Report: Removal of Actual Structures/ ObstructionDocument2 pagesProject Accomplishment Report: Removal of Actual Structures/ ObstructionNiño De LeonNo ratings yet

- Sieve Analysis DataDocument2 pagesSieve Analysis DataAT NM100% (2)

- Sieve Analysis Data Sheet: ASTM D422-63 (2007)Document2 pagesSieve Analysis Data Sheet: ASTM D422-63 (2007)Er VenkatNo ratings yet

- California Bearing Ratio Test: MDD 2.055 GM/CC Omc 8.2 %Document2 pagesCalifornia Bearing Ratio Test: MDD 2.055 GM/CC Omc 8.2 %RotiNo ratings yet

- CHAPTER FOUR ChakjoDocument10 pagesCHAPTER FOUR ChakjoChris ArtecoNo ratings yet

- Ball Mill Work Index Test Report: Bmwi Test Results SummaryDocument5 pagesBall Mill Work Index Test Report: Bmwi Test Results SummaryJulio OrtegaNo ratings yet

- Bit OilDocument42 pagesBit OilAmila SampathNo ratings yet

- Policy FrameworkDocument19 pagesPolicy FrameworkAmila SampathNo ratings yet

- Industrial Disputes (Amendment) Act No 32 of 1990Document5 pagesIndustrial Disputes (Amendment) Act No 32 of 1990Amila SampathNo ratings yet

- WP Econ 2012 15Document43 pagesWP Econ 2012 15Amila SampathNo ratings yet

- 60 149Document70 pages60 149Amila SampathNo ratings yet

- 9negotiableinstruments 120527122657 Phpapp01Document33 pages9negotiableinstruments 120527122657 Phpapp01Amila SampathNo ratings yet

- Sex Selection AbortionDocument15 pagesSex Selection AbortionAmila SampathNo ratings yet

- 02international Trade LawDocument14 pages02international Trade LawAmila SampathNo ratings yet

- 135 161Document26 pages135 161Amila SampathNo ratings yet

- Carriageofgoodbysea 121110020207 Phpapp02Document29 pagesCarriageofgoodbysea 121110020207 Phpapp02Amila SampathNo ratings yet

- Mwzzaning FramingDocument1 pageMwzzaning FramingAmila SampathNo ratings yet

- To Lasaght For Pricing - (01-09-2020)Document2 pagesTo Lasaght For Pricing - (01-09-2020)Amila SampathNo ratings yet

- Act 56 EDocument5 pagesAct 56 EAmila SampathNo ratings yet

- Comment Management Sheet (CMS) 20m Girder 40+202 - 20180111Document2 pagesComment Management Sheet (CMS) 20m Girder 40+202 - 20180111Amila SampathNo ratings yet

- VIEW - 'X': Key PlanDocument1 pageVIEW - 'X': Key PlanAmila SampathNo ratings yet

- 542) Cida-Dev-Ccr-Fo-07 (E)Document4 pages542) Cida-Dev-Ccr-Fo-07 (E)Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 20181107Document1 pageComment Management Sheet (CMS) P-A Ramp C A1 20181107Amila SampathNo ratings yet

- The Engineer:: Central Expressway Project Section - 03Document1 pageThe Engineer:: Central Expressway Project Section - 03Amila SampathNo ratings yet

- Structural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Document1 pageStructural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Amila SampathNo ratings yet

- Bluescope Lysaght Lanka (PVT) LTD: Colombo OfficeDocument3 pagesBluescope Lysaght Lanka (PVT) LTD: Colombo OfficeAmila SampathNo ratings yet

- BAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMDocument1 pageBAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMAmila SampathNo ratings yet

- Beam Bar ScheduleDocument12 pagesBeam Bar ScheduleAmila SampathNo ratings yet

- Comment Management Sheet (CMS) 20171221 - Structural DesignDocument2 pagesComment Management Sheet (CMS) 20171221 - Structural DesignAmila SampathNo ratings yet

- Comment Management Sheet (CMS) Design Calculations of Expansion Joints For All Expressway Viaducts (30m Girder) - 20181126Document2 pagesComment Management Sheet (CMS) Design Calculations of Expansion Joints For All Expressway Viaducts (30m Girder) - 20181126Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Document3 pagesComment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A2 20181029-4893Document3 pagesComment Management Sheet (CMS) P-A Ramp C A2 20181029-4893Amila SampathNo ratings yet

- Comment Management Sheet (CMS) A2 - 38+620-39+073 - 20181112Document1 pageComment Management Sheet (CMS) A2 - 38+620-39+073 - 20181112Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Bridge 58+164.2 C 20190326Document2 pagesComment Management Sheet (CMS) Bridge 58+164.2 C 20190326Amila SampathNo ratings yet

- GB 11263-2010 EnglishDocument23 pagesGB 11263-2010 EnglishGanesh Srinivasan67% (3)

- Sem 3 - Lab Metacentric ApparatusDocument7 pagesSem 3 - Lab Metacentric ApparatusLuqman HakimNo ratings yet

- Prefixes and SuffixesDocument15 pagesPrefixes and SuffixesRita Otero100% (1)

- 215 Padurean PDFDocument4 pages215 Padurean PDFFolpoNo ratings yet

- PF Index 1953 09 10Document128 pagesPF Index 1953 09 10Gigel IceNo ratings yet

- Course OutlineDocument2 pagesCourse OutlineHevi Angelo Rios TadenaNo ratings yet

- 662633-2025-Specimen-Paper-2 2Document16 pages662633-2025-Specimen-Paper-2 2biologyexpert158No ratings yet

- Israel Flores Valvula 2Document2 pagesIsrael Flores Valvula 2Israel Flores MamaniNo ratings yet

- Finite Element by Tarun KantDocument7 pagesFinite Element by Tarun KantVijayraj11No ratings yet

- ALGEBRA PowerpointDocument14 pagesALGEBRA PowerpointNurul Hafiqah100% (1)

- Physics 11-04 Total Internal ReflectionDocument2 pagesPhysics 11-04 Total Internal ReflectionBALI RAONo ratings yet

- Network SolDocument189 pagesNetwork Solsandeep12911050% (2)

- Data Sheet: 74HC/HCT238Document7 pagesData Sheet: 74HC/HCT238Andrew S OlmosnNo ratings yet

- SD7 OperatingInstructions Amplifire e PDFDocument115 pagesSD7 OperatingInstructions Amplifire e PDFkrishnaNo ratings yet

- Emerging Trends in Uranium Mining in IndiaDocument10 pagesEmerging Trends in Uranium Mining in IndiaS.Alec KnowleNo ratings yet

- Pressure Vessel Design CalcDocument48 pagesPressure Vessel Design CalcSyed Zain AliNo ratings yet

- Lect 5 Failure Criteria AnisotropyDocument16 pagesLect 5 Failure Criteria AnisotropyOttoman Empire “Ottoman Empire wars”No ratings yet

- Spherical TensorsDocument5 pagesSpherical TensorsSunny GuhaNo ratings yet

- Terzaghi, Bishop and The Practical Application of The Principle of Effective StressDocument7 pagesTerzaghi, Bishop and The Practical Application of The Principle of Effective StressliliclopNo ratings yet

- ECE 140 L C: Inear IrcuitsDocument10 pagesECE 140 L C: Inear IrcuitsPaola RamírezNo ratings yet

- Unit 1: Intro, Forces, Motion and Energy: 7 Grade Science Mrs. MindyDocument5 pagesUnit 1: Intro, Forces, Motion and Energy: 7 Grade Science Mrs. MindyJaelanNo ratings yet

- Infinity - Lillian R. Lieber - 1953Document370 pagesInfinity - Lillian R. Lieber - 1953unbeing100% (2)

- Daily Lesson Plan School Grade Level Teacher Mr. Herbert J. Magango Learning Area Teaching Date and Time QuarterDocument2 pagesDaily Lesson Plan School Grade Level Teacher Mr. Herbert J. Magango Learning Area Teaching Date and Time QuarterJennifer MagangoNo ratings yet

- Unit 2Document55 pagesUnit 2darrylthebestNo ratings yet

- Tissue Adaptation To Physical Stress: A Proposed "Physical Stress Theory" To Guide Physical Therapist Practice, Education, and ResearchDocument21 pagesTissue Adaptation To Physical Stress: A Proposed "Physical Stress Theory" To Guide Physical Therapist Practice, Education, and ResearchGavin Cao100% (1)

- Screw JackDocument4 pagesScrew Jackkaushal bhagatNo ratings yet