Professional Documents

Culture Documents

Pressure Seal Bonnet Design: Dedication To Delivery

Pressure Seal Bonnet Design: Dedication To Delivery

Uploaded by

lutCopyright:

Available Formats

You might also like

- Pokémon Unbound Mission List+ v2.1.0Document8 pagesPokémon Unbound Mission List+ v2.1.0Kokot100% (3)

- Wouter Witzel Corporate Brochure NewDocument11 pagesWouter Witzel Corporate Brochure NewMohamed RjebNo ratings yet

- Isolation & Control Butterfly ValvesDocument62 pagesIsolation & Control Butterfly Valvesmanmohansingh1999No ratings yet

- Brochure - Valco - Presentatation For Export - EnglishDocument2 pagesBrochure - Valco - Presentatation For Export - EnglishMeet JaniNo ratings yet

- VST Valves Presentation General AADocument46 pagesVST Valves Presentation General AAJaydeep PanchalNo ratings yet

- Kanon Green Binder Rev 2Document202 pagesKanon Green Binder Rev 2AZLAN ABDULLAINo ratings yet

- Dovewell Oilfield Services LTDDocument28 pagesDovewell Oilfield Services LTDlibyashuaaNo ratings yet

- Thermosolar Catalogue PDFDocument28 pagesThermosolar Catalogue PDFbagastcNo ratings yet

- VBO - Triple Offset Butterfly ValveDocument14 pagesVBO - Triple Offset Butterfly ValveFabio Peres de LimaNo ratings yet

- Pentair Valves & Control OverviewDocument32 pagesPentair Valves & Control OverviewArief PrabowoNo ratings yet

- Gas Division: ArfluDocument56 pagesGas Division: ArfluDammnNo ratings yet

- Pressure Seal Bonnet Design: Dedication To DeliveryDocument44 pagesPressure Seal Bonnet Design: Dedication To DeliveryMeet JaniNo ratings yet

- Severe Service SolutionsDocument22 pagesSevere Service SolutionsAnonymous HGZfO4IQNo ratings yet

- CVA Gate Globe Check Strainers CatalogDocument95 pagesCVA Gate Globe Check Strainers CatalogRiss0No ratings yet

- VGE - Company ProfileDocument24 pagesVGE - Company Profile85126439No ratings yet

- Catalog: Trunnion Mounted Ball ValveDocument84 pagesCatalog: Trunnion Mounted Ball ValveGerardo Taborda NuñezNo ratings yet

- Online Pressure Safety Valve TestingDocument2 pagesOnline Pressure Safety Valve TestingKauffman LOKONo ratings yet

- Valvula Bola 1500 PsiDocument8 pagesValvula Bola 1500 PsibetojulioNo ratings yet

- Severe Service Valve SolutionsDocument22 pagesSevere Service Valve SolutionsHector Flores Marcos100% (1)

- ValvTechnologies 01 - Zero Leakage Valve Solution PDFDocument20 pagesValvTechnologies 01 - Zero Leakage Valve Solution PDFNanangdp48No ratings yet

- 04 HIT VALVE Control Ball Valves Product CatalogueDocument20 pages04 HIT VALVE Control Ball Valves Product CatalogueRAVINDR.KNo ratings yet

- Complete Solution For Industrial Valves: Neway ValveDocument24 pagesComplete Solution For Industrial Valves: Neway ValveLuis Felipe Cortes PachecoNo ratings yet

- Check Valves WeightDocument16 pagesCheck Valves WeightИлья БересневNo ratings yet

- CheckValve Walworth - DualPlate Setpoint PDFDocument40 pagesCheckValve Walworth - DualPlate Setpoint PDFfernandez2011No ratings yet

- Test Pump WindlassDocument40 pagesTest Pump WindlassMd.farman Ali AhmedNo ratings yet

- Catalogue 2018 D.PDocument18 pagesCatalogue 2018 D.PPhongsak SihanatNo ratings yet

- B-Fire Products BrochureDocument12 pagesB-Fire Products Brochurejeronimo113No ratings yet

- Complete Catalog API Din Uniflow Data Sheet en Ds20Document222 pagesComplete Catalog API Din Uniflow Data Sheet en Ds20Tuesou MachereNo ratings yet

- ControlDocument26 pagesControlritesh sharmaNo ratings yet

- 12 585 Rov Latches Brochure v3 Web 1 PDFDocument8 pages12 585 Rov Latches Brochure v3 Web 1 PDFIZayvenkoNo ratings yet

- Catalog: Expanding GateDocument32 pagesCatalog: Expanding GateAndersson Benito HerreraNo ratings yet

- Heeco Transformer BrouchersDocument4 pagesHeeco Transformer BrouchersFahadNo ratings yet

- Ball Valve Weight EstDocument31 pagesBall Valve Weight EstLincoln ChauNo ratings yet

- Brochure TrunnionDocument52 pagesBrochure TrunnionZts MksNo ratings yet

- EB174 ERIKS Flow ControlDocument12 pagesEB174 ERIKS Flow ControlKunming WangNo ratings yet

- 04-Fire Fighting Valves and Hydrants SVMCDocument14 pages04-Fire Fighting Valves and Hydrants SVMCIgor NhamanoNo ratings yet

- AVK Philipppines Price List 2022-2023Document52 pagesAVK Philipppines Price List 2022-2023Mark Philip BaliwisNo ratings yet

- EN Company Profile EmailDocument16 pagesEN Company Profile EmailSonakshi HuddaNo ratings yet

- Capelec 2024 Catalog CompressedDocument56 pagesCapelec 2024 Catalog CompressedDuarteSilvaNo ratings yet

- Subsea Valves BRDocument14 pagesSubsea Valves BRFrancesco AntoniniNo ratings yet

- Torex Ilv SeriesDocument52 pagesTorex Ilv SeriesElton Da Silva FariasNo ratings yet

- Weir Ball ValveDocument20 pagesWeir Ball ValveAmr ZayanNo ratings yet

- WH Scott - Crane Services BrochureDocument2 pagesWH Scott - Crane Services Brochurejithinjose86No ratings yet

- 2024 Company ProfileDocument15 pages2024 Company ProfileSomen SarkarNo ratings yet

- Catalog: Industrial Bronze ValvesDocument60 pagesCatalog: Industrial Bronze ValvesFederico MoranNo ratings yet

- TFTUK 201909 X Stream Brochure PWDocument12 pagesTFTUK 201909 X Stream Brochure PWArturNo ratings yet

- AVK NL Industrie EngDocument32 pagesAVK NL Industrie EngADRIAN SUŁAWANo ratings yet

- Catalog Ach OldDocument25 pagesCatalog Ach Oldprakash1010No ratings yet

- On Site Engineering - CompressedDocument12 pagesOn Site Engineering - CompressedanthonythiaNo ratings yet

- Zero-Leakage Valve Solutions: Product & Capabilities OverviewDocument20 pagesZero-Leakage Valve Solutions: Product & Capabilities OverviewAndry HermawanNo ratings yet

- Control Valv3Document12 pagesControl Valv3Михаил ПолковниковNo ratings yet

- Walworth Cast Steel Catalog 2012 1Document100 pagesWalworth Cast Steel Catalog 2012 1Andersson Benito HerreraNo ratings yet

- Válvulas de Seguridad y Alivio de AceroDocument80 pagesVálvulas de Seguridad y Alivio de Aceromarco lezcanoNo ratings yet

- Corporate Presentation At3wDocument19 pagesCorporate Presentation At3wReinaldo Sciliano juniorNo ratings yet

- Descarga 1170758086Document20 pagesDescarga 1170758086Federico AraujoNo ratings yet

- Twin Plate Check Valves: General CatalogueDocument32 pagesTwin Plate Check Valves: General CatalogueeajNo ratings yet

- Catalogue enDocument155 pagesCatalogue enworkingNo ratings yet

- Wavin: Inspection ChambersDocument62 pagesWavin: Inspection ChambersXAVIER RUBIONo ratings yet

- Tech Product CatalogDocument52 pagesTech Product CatalogJelan FanarNo ratings yet

- Catalog: Safety and Relief BronzeDocument32 pagesCatalog: Safety and Relief BronzeAndersson Benito HerreraNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Kpop Songs LyricsDocument15 pagesKpop Songs LyricsAsh Alizer TesaniNo ratings yet

- Maur MeyerDocument488 pagesMaur MeyerItachi KunNo ratings yet

- Data Siswa Kelas Xii 2018Document84 pagesData Siswa Kelas Xii 2018Kang Mas HurieyNo ratings yet

- Gererac Guardián 7.5 KWDocument52 pagesGererac Guardián 7.5 KWOPERACIONES TORRESANo ratings yet

- Victorian Compromise and Literary Movements PDFDocument2 pagesVictorian Compromise and Literary Movements PDFChuii MuiiNo ratings yet

- Solubility of Benzoic Acid in Organic SolventsDocument2 pagesSolubility of Benzoic Acid in Organic Solventssrshah67% (6)

- Lhamo Lomagyonma PracticeDocument4 pagesLhamo Lomagyonma Practicemozollis22No ratings yet

- Weighted Least Squares Kinetic Upwind Method Using Eigen Vector BasisDocument55 pagesWeighted Least Squares Kinetic Upwind Method Using Eigen Vector BasiskonarkaroraNo ratings yet

- BEP 359 - Virtual Teams 1: Video Conference MeetingsDocument12 pagesBEP 359 - Virtual Teams 1: Video Conference MeetingsPatrickNo ratings yet

- FRERES DORIENTConstantinople 1054 or 1090Document15 pagesFRERES DORIENTConstantinople 1054 or 1090Er Might100% (5)

- List of Accessories, Materials and Equipments - PictorialDocument12 pagesList of Accessories, Materials and Equipments - PictorialnasiseidrscribdNo ratings yet

- 1Document14 pages1netsa_marNo ratings yet

- HMP Openser Sip AnDocument9 pagesHMP Openser Sip Anchingo9252No ratings yet

- The Philippine Marketing Environment: Bruto, Ivy Marijoyce Magtibay, Sarah Jane Guno, RhizaDocument26 pagesThe Philippine Marketing Environment: Bruto, Ivy Marijoyce Magtibay, Sarah Jane Guno, Rhizakenghie tv showNo ratings yet

- Characterization and Modeling of Oriented Strand CompositesDocument208 pagesCharacterization and Modeling of Oriented Strand CompositesBeatriz SilvaNo ratings yet

- Wellness Campus Song LyricsDocument2 pagesWellness Campus Song LyricsIshmael NarioNo ratings yet

- C955 Pre-Assessment - MindEdge Alignment Table - Sheet1Document3 pagesC955 Pre-Assessment - MindEdge Alignment Table - Sheet1Robert Allen Rippey0% (1)

- RUSLEDocument16 pagesRUSLEVivek KasarNo ratings yet

- Conversion Optimization FrameworkDocument34 pagesConversion Optimization FrameworkKavya GopakumarNo ratings yet

- Case StudyDocument5 pagesCase StudyRushabh AjmeraNo ratings yet

- Memorandum To Governor - Assam Mojuri Srameek UnionDocument4 pagesMemorandum To Governor - Assam Mojuri Srameek UnionArup BaisyaNo ratings yet

- Service Marketing: BY, Bhavithra AsokanDocument20 pagesService Marketing: BY, Bhavithra AsokanDomnic SavioNo ratings yet

- Rough Main Project KansaiDocument91 pagesRough Main Project KansaisuganyaambaNo ratings yet

- GE OEC 9800 Operator Manual and SupplementDocument160 pagesGE OEC 9800 Operator Manual and SupplementC CraigNo ratings yet

- Eni MP Grease 2 - 1720 - 5.0 - ENDocument16 pagesEni MP Grease 2 - 1720 - 5.0 - ENMuhammad Abdul RehmanNo ratings yet

- HY USMLE Review Part IVDocument31 pagesHY USMLE Review Part IVDr.2020100% (1)

- Mecha v. INS, 4th Cir. (2000)Document4 pagesMecha v. INS, 4th Cir. (2000)Scribd Government DocsNo ratings yet

- CV - Banjubi Boruah - FMS - NIFT - Shillong PDFDocument2 pagesCV - Banjubi Boruah - FMS - NIFT - Shillong PDFruchi mishraNo ratings yet

- End Term Question Paper Linux For Devices 2021Document2 pagesEnd Term Question Paper Linux For Devices 2021KeshavNo ratings yet

Pressure Seal Bonnet Design: Dedication To Delivery

Pressure Seal Bonnet Design: Dedication To Delivery

Uploaded by

lutOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Seal Bonnet Design: Dedication To Delivery

Pressure Seal Bonnet Design: Dedication To Delivery

Uploaded by

lutCopyright:

Available Formats

PRESSURE SEAL BONNET DESIGN

VALCO GROUP

TM TM TM

Dedication to delivery

1 / 44

MALBRANQUE SNRI VVS

+ Catalogue Valco A4 V7.indd 1 18/09/12 09:44

VALCO GROUP

IC N, MALBRANQUE, NRI

VALCO VALVES SERVICES

rands

>G , MALBRANQUE, : manu acturers o industrial valves

> VVS alco alves ervices in house and on site maintenance

factories based in Ruffec, west rance near ordeau and

hamb r east rance, near Grenoble

R P

SNRI MALBRANQUE brands, as well as Guichon alves, are recogni ed

as world wide valves manu acturers alco Group develop and produces

valves or il Gas, etrochemical, Marine G, ower, uclear,

hemical, ol mers, av , and pharmaceutical applications in customi ed

and standard versions

TM

2 / 44

VALC O

+ Catalogue Valco A4 V7.indd 2 18/09/12 09:44

AN EXPERIENCED VALVE MANUFACTURER

Our expertise extends from the design

MACHINING CENTRES to the testing of the valves .

Range of production :

> Gate, Globe, Check, r ogenic and

afety valves

> Class 150# to 2500# and ISO standards

Sales Department attentive to customer

needs.

An experienced Engineering roduction Dept

of engineers and technicians who work to

continuall improve our products to meet

WELDING DEPOSIT

demanding customer requirements .

A Production Engineering Department.

Efficient production tools :

> Machining centres

> Numerical and conventional machines

> Welding deposit stations

> Hydraulic test benches

> Cryogenic test benches

> Fugitive Emission test capability

> Sandblasting / Painting

TESTS

> Packaging and Shipping

Control Dept :

> inspection

> M

> Dry penetrant

> Hardness test

> a via our partner

service provider

ur ualit oda , is ours omorrow

3 / 44

+ Catalogue Valco A4 V7.indd 3 18/09/12 09:44

SERVICES SUPPORT

VALCO VALVES SERVICES : VVS

Our Services do not stop with the completion of the installation and commissioning of the valve

package according to the requirements of shipyards. To maintain the high performance of your

valves, our dedicated Servicing company VALCO VALVES SERVICES is able to propose a specific

Support plan according to your maintenance policy.

Coordinated from our SNRI, Malbranque Guichon ales o ices, the VVS team can operate and

assist you along the way, with genuine spare parts (to ensure valid classification type aproval).

Our Service Engineers are fully trained for the valves Maintenance and continuously work for

industrial applications within difficult environments (Petroleum and Offshore platforms, Nuclear

power plants) Their versatilit and expertise enable them to perform preventive and curative

maintenance for any types of valves and actuators, including utterfly and ontrol valves.

Also available is a power valve serviceability review and remplacement, including retrofit or overhaul

of the main components.

We are able to propose a complete revamping program, including replacement of obsolete actuators

with the latest designs .

TM

4 / 44

VALC O

+ Catalogue Valco A4 V7.indd 4 18/09/12 09:44

AN EFFICIENT TEAM AT YOUR SERVICE

VVS factory is located next to SNRI

Workshop : 1500 m2

Team : 50 employees

Many production tools

Training possibilities :

Module 1 : Introduction to valves technologies

Module 2 : Appropriate valves selection

Module 3 : Quality / Control

Module 4 : Advanced quality / control

Module 5 : Advanced appropriate valves selection

Module 6 : Maintenance

Module 7 : Advanced quality / Control or specific

valves

Modules S1 / S2 : Safety Valves

SNRI, Malbranque and Guichon brands

work together with VVS, to meet new

servicing challenges !

5 / 44

+ Catalogue Valco A4 V7.indd 5 18/09/12 09:44

HIGH PRESSURE VALVES FOR

OIL GAS INDUSTRIES

POWER COGENERATION PLANTS

WEDGE AND PARALLEL SLIDE GATE VALVES :

Design ASME B16-34 / EN 12516 ...

Flanged or Butt Welded

Size range 2’’ up to 36’’, according to your request

Pressure rating Class 900 - 1500 - 2500#

Temperature range up to 575 °C

Materials ASTM / EN ...

GLOBE VALVES :

Design ASME B16-34 / EN 12516 ...

Flanged or Butt Welded

Size range 2’’ up to 30’’, according to your request

Pressure rating Class 900 - 1500 - 2500#

Temperature range up to 575 °C

Materials ASTM / EN ...

CHECK VALVES :

Design ASME B16-34 / EN 12516 ...

Flanged or Butt Welded

Size range 2’’ up to 48’’, according to your request

Pressure rating Class 900 - 1500 - 2500#

Temperature range up to 575 °C

Materials ASTM / EN ...

TM

6 / 44

VALC O

+ Catalogue Valco A4 V7.indd 6 18/09/12 09:44

P E CONTENTS

GATE VALVES

- Flexible wedge gate valves 8- 9

- Parallel slide gate valves 10 - 11

- Wedge or parallel valves dimensions / Examples of special gate valves 12 - 13

GLOBE VALVES

- Globe valves sizes 2-3-4’’, and higher 14 - 17

st - Globe valves dimensions / Examples of special globe valves 18 - 19

- Globe and piston check valves ‘’ Y’’ pattern 20 - 21

CHECK VALVES

- Swing check valves 22 - 23

- Non slam tilting disc check valves, 24 - 25

- Check valves dimensions - Examples of special check valves 26 - 27

MORE DETAILS

- Pressure seal bonnet design sizes up to 4’’, and sizes > 4’’ 28 - 29

- Bonnet sealing design, Bleeder screw design 28 - 29

- Stuffing box sealing design 30 - 31

- Parallel slide gate valve, disc assembly 32

OPTIONAL DEVICES

st

Equalization devices

- Design with wedge hole or balancing pipe 3

- Design with balancing bypass one direction 3

- Design with balancing bypass, bidirectional flow 3

- Design with pressure relief valve, bidirectional flow 3

Locking devices

- Design for handwheel valves, for valves with gearbox 3

Switching devices

- Design for handwheel valves, for valves with gearbox 3

HIGH PRESSURE VALVES, BOLTED BONNET DESIGN

st TEST CAPABILITIES

QUALITY CERTIFICATION

7 / 44

+ Catalogue Valco A4 V7.indd 7 18/09/12 09:44

FLEXIBLE WEDGE GATE VALVE

Stem nut

Bearing

Yoke

Stem

Bleeder screw

Packing

Segment

retaining ring

Spacer ring

Gasket

Bonnet

Backseat

Wedge Seat Body SEE MORE DESIGN DETAILS :

> Wedge (Gate and Slide)

> Pressure seal bonnet gasket

> Yoke and Bleeder screw

> Packing

TM

8 / 44

VALC O

+ Catalogue Valco A4 V7.indd 8 18/09/12 09:44

EXI E ED E PE REN EX

DESIGN :

Reinforced flexible wedge. Sealing ensured by the elasticity of the wedge

ADVANTAGES :

Sealing ensured whatever the temperature conditions

Easy closing and opening due to the low friction design

Stellite thickness over 2,5 mm to meet your requirements

This wedge can be easily repaired

Used on all applications ( Petrochemical, Energy, Gas, cryogenic)

DESCRIPTION :

> Permanent contact with the seat, (Area 1) : Flat and rigid contact

surface to ensure good sealing

> Flexible characteristics, "spring effect", (Area 2) : Split wedge to ensure

good flexibility, deformations due to thermal expansion are compensed .

> Swiveling characteristics, (Area 3) : Perfect contact between the seat and

the wedge made possible by the swiveling fonctionality .

RECOMMENDATIONS :

To ensure a good operation, motorized valves shall be stopped either in the

opening or closing position.

SOME EXAMPLES THAT DEMONSTRATE OUR EFFICIENCY :

> Power station : ENRON Teesside (England), KEPCO Yonghung (Korea),

Alstom Medupi (South Africa ), Kusile Shoiba (Saudi Arabia)

> Furnace : EXXON KEMYA (S.A), CHIYODA (Singapore )

> Boiler, Cogeneration : CMI (...)

> Petrochemical : SHELL, TOTAL, SONATRACH OURHOUD, UDHE SAFCO …

PETROFAC, BECHTEL JAMNAGAR …

> Gas : AIR LIQUIDE IPG (Singapore HP cl 600 to 2500#)

9 / 44

+ Catalogue Valco A4 V7.indd 9 18/09/12 09:44

PARALLEL SLIDE GATE VALVE

Stop ring

Gap 2 mm

Stem nut

Bearing

Yoke

Stem

Bleeder screw

Packing

Segment

retaining ring

Spacer ring

Gasket

Bonnet

Backseat

Body

Security stop

Gap 2mm

Disc Seat

SEE MORE DESIGN DETAILS :

> Wedge (Gate and Parallel)

> Pressure seal bonnet gasket

> Yoke and Bleeder screw

TM

> Packing

10 / 44

VALC O

+ Catalogue Valco A4 V7.indd 10 18/09/12 09:44

PARALLEL SEATS

DESIGN :

Reinforced disc :

The force applied on the disc permits a good sealing on the opposite side.

ADVANTAGES :

Very good adaptation to temperature variations.

Free expansion of the internal parts : stem, disc, therefore no jamming.

Stellite deposit can be over 2,5 mm.

The disc can be easily repaired.

Steam services (Nuclear and conventional plants).

DESCRIPTION :

> Parallel slide discs (2) and seats (1) :

The contact between the discs and the seats is ensured

by a spring (3) generaly made of inconel.

> The collar (4) guides the discs (2) during the opening and

closing procedures.

> The stroke is limited by two security stops to prevent any

damage on the discs.

RECOMMENDATIONS :

To ensure a good operation, motorized valves shall be

stopped by switches in the opened or closed position.

In the closed position, the collar (4) is not in contact with the body.

SOME EXAMPLES THAT DEMONSTRATE OUR EFFICENCY :

> Power station : EDF France, EDF Vietnam, Alstom, ...

> Furnace : eurte etrochemical

> Boiler, Cogeneration : CMI (...)

> Petrochemicals : SHELL, TOTAL, ...

> Gas

11 / 44

+ Catalogue Valco A4 V7.indd 11 18/09/12 09:44

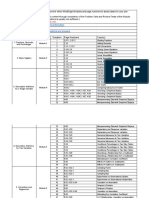

WEDGE OR PARALLEL SLIDE

GATE VALVES DIMENSIONS

VALVES CLASS 600# :

Only per request, the PSB design

is not recommended for this

pressure level.

VALVES CLASS 900 #

Size Gearbox

Inch mmmm ØØ ID

ID GG HH J K LL Jm HgbH gb LLgb

gb Weight CV

Weight CV

2" 50 50 45 216

216 350

350 454 551

551 604 448

448 75 130 75 130

2"1/2 65 66 254 500 508 605 677 496 80 240

3" 80 66 305 500 508 605 677 496 84 300

4" 100 90 356 500 601 698 794 589 110 660

5" 125 110 432 500 695 804 922 686 120 1200

6" 150 133 508 778 924 648 300 968 230 1760

8" 200 173 660 953 1134 790 300 1160 395 3360

10" 250 216 788 1221 1455 1054 400 1510 647 7500

12" 300 256 914 1310 1585 1150 560 1662 1145 11900

14" 350 282 991 1446 1741 1252 560 1920 1370 14400

16" 400 322 1092 1535 1882 1359 560 2077 1795 18950

18" 450 377 1219 1765 2162 1538 560 2337 2144 26000

20" 500 402 1321 1912 2331 1655 560 2454 2694 29700

22" 550 480 1321 2325 2831 2002 710 2989 3558 42300

24" 600 480 1549 2325 2831 2002 710 2989 3793 42300

VALVES CLASS 1500 #

Size Gearbox

Inch mm Ø ID G H J K L Jm H gb L gb Weight CV

2" 50 45 216 350 454 551 604 448 75 130

2"1/2 65 66 254 500 508 605 677 496 80 240

3" 80 66 305 500 508 605 677 496 84 300

4" 100 83 406 500 587 686 779 574 117 560

5" 125 125 483 826 959 715 300 1035 265 1020

6" 150 125 559 826 959 715 300 1035 270 1550

8" 200 162 711 1043 1215 876 560 1282 495 2940

10" 250 199 864 1284 1504 1075 560 1537 835 6700

12" 300 238 991 1327 1587 1092 560 1604 1445 9170

14" 350 262 1067 1390 1670 1180 560 1798 2120 12460

16" 400 300 1194 1587 1910 1340 560 2039 2594 16430

18" 450 336 1346 1624 1986 1361 560 2163 2743 20600

20" 500 376 1473 1905 2310 1651 710 2538 4168 26000

22" 550 450 1473 2280 2750 1965 710 2953 5430 37300

24" 600 450 1549 2280 2750 1965 710 2953 5550 37300

Valves Class 2500 #

Size Gearbox

Inch mm Ø ID G H J K L Jm H gb L gb Weight CV

2" 50 36 279 350 417 514 553 410 60 80

2"1/2 65 53 330 500 489 592 650 477 82 160

3" 80 53 369 500 489 592 650 477 85 190

4" 100 66 457 500 570 683 755 560 133 300

5" 125 102 533 923 1044 762 400 1124 465 600

6" 150 102 610 923 1044 762 400 1124 495 1020

8" 200 133 762 1016 1165 838 560 1250 685 1760

10" 250 168 914 1280 1467 1073 400 1600 820 3160

12" 300 199 1042 1398 1618 1209 560 1786 1734 6390

14" 350 219 1118 1428 1670 1215 630 1868 2294 7750

16" 400 250 1245 1553 1820 1338 630 1991 3594 11340

18" 450 282 1397 2030 2338 1403 630 2155 4343 14400

20" 500 312 1366 1860 2210 1580 630 2417 4966 17660

22" 550 376 1366 2075 2500 1775 800 2781 8470 26000

24" 600 376 1600 2075 2500 1775 800 2781 8870 26000

TM

12 / 44

VALC O

+ Catalogue Valco A4 V7.indd 12 18/09/12 09:44

EXAMPLES OF GATE VALVES

WITH LINEAR ACTUATORS

GAS APPLICATION :

Valves size : 10’’ Class 1500 #

HAMWORTHY COMBUSTION project

FURNACE APPLICATION :

Valves size : 20’’ Class 2500 #

CHIYODA Singapore project

POWER APPLICATION :

Valves size : 18’’ Class 900 #

ALSTOM project

13 / 44

+ Catalogue Valco A4 V7.indd 13 18/09/12 09:44

GLOBE VALVE SIZE 2"- 3"- 4"

Stem nut

Bearing

Yoke

Guide

Stem

Packing

Segment

retaining ring

Spacer ring

Gasket

Bonnet

Backseat

Disc

Seat

Body

Guide

SEE MORE DESIGN DETAILS :

> Disc (Spherical, parabolic)

> Pressure seal bonnet gasket

> Packing for fugitive emissions

> Live loading device

TM

14 / 44

VALC O

+ Catalogue Valco A4 V7.indd 14 18/09/12 09:44

DESIGN AND DISC DETAIL

DESIGN :

Non rotative rising stem, parabolic disc as standard.

ADVANTAGES :

Robust, swivelling disc with parabolic form for more precise flow control.

Direction of flow over the disc, sealing ensured regardless of the temperature variations.

GUIDED DISC DETAIL :

> For severe service conditions.

> Disc guided within the body,

reduces disc vibrations.

> Equalizing device by hole thru the disc.

> The guiding can be stellited as an option.

ALTERNATIVE, STOP PISTON CHECK VALVE :

> The disc can be stopped in closed position.

> Closure facilitated by preloaded spring.

> Disc guided within the body and by the stem.

> The guiding can be stellited as an option.

15 / 44

+ Catalogue Valco A4 V7.indd 15 18/09/12 09:44

GLOBE VALVE SIZE 6" and higher

Yoke

Guide

Segment

Stem retaining ring

Packing Spacer ring

Gasket Backseat

Bonnet Disc

Seat

Body

Guide

SEE MORE DESIGN DETAILS :

> Disc (Spherical, parabolic)

> Pressure seal bonnet gasket

> Yoke and Bleeder screw

> Packing

TM

16 / 44

VALC O

+ Catalogue Valco A4 V7.indd 16 18/09/12 09:44

INTERNAL BYPASS DEVICE

DESIGN :

Non rotative rising stem, parabolic disc with equalizing device by means of an internal

by-pass.

ADVANTAGES :

Low opening torque achieved by internal by-pass device, lower actuator sizing.

OPERATING :

The internal bypass is opened with the internal rising of the stem.

The contact between the seat and the disc is ensured by the pressure.

Continued rising of the stem, will open the valve.

The inlet pressure decreases rapidly at the opening of the bypass, so the opening

operation is easier.

BYPASS DETAILS :

> Bypass size > 1".

> The disc is still in contact with the seat.

RATING FLOW :

> Whatever the adjusted position,

the disc is still in contact with the

stem head.

17 / 44

+ Catalogue Valco A4 V7.indd 17 18/09/12 09:44

GLOBE VALVES DIMENSIONS

VALVES CLASS 600# :

Only per request, the PSB design

is not recommended for this

pressure level.

VALVES CLASS 900 #

Size Gearbox

Inch mm Ø ID G H J K L Jm H gb L gb Weight CV

2" 50 50 369 350 508 547 578 72 50

2"1/2 65 66 305 400 564 612 647 547 80 50

3" 80 66 305 400 564 612 647 547 80 85

4" 100 90 356 500 600 644 696 574 105 160

5" 125 90 432 500 600 644 696 574 110 160

6" 150 133 610 768 831 632 400 888 385 350

8" 200 172 737 734 804 634 400 1052 410 595

10" 250 242 838 960 1072 820 560 1288 733 920

12" 300 280 965 1109 1226 965 630 1517 1205 1470

14" 350 280 1092 1109 1226 965 710 1517 1263 2426

16" 400 280 1092 1109 1226 965 710 1517 1263 2426

VALVES CLASS 1500 #

Size Gearbox

Inch mm Ø ID G H J K L Jm H gb L gb Weight CV

2" 50 50 369 350 508 547 578 72 50

2"1/2 65 66 305 400 564 612 647 547 80 50

3" 80 66 305 400 564 612 647 547 80 85

4" 100 90 406 500 600 644 696 574 115 160

5" 125 90 483 500 600 644 696 574 120 160

6" 150 133 705 726 790 632 560 1000 450 350

8" 200 162 832 896 978 790 630 1239 714 515

10" 250 202 864 1045 1146 890 630 1442 943 805

12" 300

14" 350

16" 400

VALVES CLASS 2500 #

Size Gearbox

Inch mm Ø ID G H J K L Jm H gb L gb Weight CV

2" 50 46 279 500 623 667 700 597 105 50

2"1/2 65 46 330 500 623 667 700 597 110 50

3" 80 50 369 690 722 610 300 830 138 50

4" 100 66 457 712 755 631 400 887 167 85

5" 125 83 533 673 723 579 500 873 245 139

6" 150 100 610 743 799 649 630 905 535 195

8" 200 133 762 800 879 672 710 1121 719 350

10" 250 168 914 1048 1148 895 710 1350 1245 555

12" 300 198 1041 1305 1465 1145 710 1665 1820 770

14" 350

16" 400

18" 450 314 1397 1430 1589 1250 710 1700 3720 1940

TM

18 / 44

VALC O

+ Catalogue Valco A4 V7.indd 18 18/09/12 09:44

EXAMPLES OF SPECIAL

GLOBE VALVES

POWER APPLICATION :

Valves size : 4’’ Class 2500 # ‘’ SKY VALVE ‘’

Service : Steam 576°C / 152 b

Used to adjust steam pressure on boiler MARINE APPLICATION :

Body guide and disc with stellite overlay Valves size : 16’’ Class 900 #,

CMI Project : MARMARA , TURKEY 1998 Hydraulique actuator

19 / 44

+ Catalogue Valco A4 V7.indd 19 18/09/12 09:44

GLOBE VALVES AND PISTON STOP CHECK VALVES

‘’Y’’ PATTERN

Example of Y globe valve : 14’’ Cl 2500 # for Power application.

Guided disc with internal bypass, seat and disc with stellite gr6 overlay.

TM

20 / 44

VALC O

+ Catalogue Valco A4 V7.indd 20 18/09/12 09:44

GLOBE VALVES AND PISTON STOP CHECK VALVES

‘’ Y ‘’ PATTERN

Examples of ‘’Y’’ stop check valves : Size : 3’’ Cl 1500#

Size : 18’ Cl 1500#

Size : 14’’ Cl 2500#

21 / 44

+ Catalogue Valco A4 V7.indd 21 18/09/12 09:44

SWING CHECK VALVE

Bleeder screw

Segment

retaining ring

Spacer ring

Gasket

Bonnet

Hinge

Disc nut

Disc

Seat

Body

Hinge pin

Hinge

Packing Hinge plug

Plug

SEE MORE DESIGN DETAILS :

> Bonnet sealing

> Hinge pin sealing

> Bleeder screw

TM

22 / 44

VALC O

+ Catalogue Valco A4 V7.indd 22 18/09/12 09:44

DESIGN AND DETAILS

DESIGN :

Inclined seat, full port opening , bleeder screw, pressure seal hinge plug, secure disc nut.

ADVANTAGES :

Full opening possible, less pressure drop.

Pressure seal bonnet and plug pressure seal for greater safety.

Seat and disc with stellite overlay thickness of more than 2,5 mm.

Bonnet with bleeder screw to bleed the valve.

SECURE DISC NUT

HINGE PLUG DETAIL

23 / 44

+ Catalogue Valco A4 V7.indd 23 18/09/12 09:44

NON-SLAM TILTING DISC CHECK VALVE

Bleeder screw

Segment

retaining ring

Spacer ring

Gasket

Bonnet

Body

SEE MORE DESIGN DETAILS :

> Bonnet sealing

> Bleeder screw

TM

24 / 44

VALC O

+ Catalogue Valco A4 V7.indd 24 18/09/12 09:44

DESIGN AND DETAILS

DESIGN :

Disc balanced, non slam tilting disc.

Inclined seat, full opening, bleeder screw.

Pipe horizontal or vertical.

ADVANTAGES :

Full opening possible.

Pressure seal bonnet, for greater safety.

Seat and disc stellite overlay thickness more than 2,5 mm.

Bonnet with bleeder screw to bleed the valve.

DISC PIN ASSEMBLY DETAIL

Seat

Disc

Disc pin

Spring

25 / 44

+ Catalogue Valco A4 V7.indd 25 18/09/12 09:44

CHECK VALVES DIMENSIONS

SWING CHECK VALVES VALVES CLASS 600 #

Only per request, the PSB design

is not recommended for this

pressure class.

VALVES CLASS 900 #

Size

Inch mm Ø ID G H Weight CV

2" 50 48 368,3 218 45 90

2"1/2 65 65 305 248 50 182

3" 80 73 305 248 55 275

4" 100 89 355,6 280 65 850

6" 150 132 508 377 185 1620

8" 200 166 660,4 396 275 2560

10" 250 222 787,4 464 390 4500

12" 300 263 914,4 548 620 6400

14" 350 280 991 570 715 7250

16" 400 334 1092 675 1115 9850

18" 450 374 1219 750 1350 13000

20" 500 445 1320,8 796 2350 14000

24" 600 480 1346 820 3200 21400

VALVES CLASS 1500 #

Size

Inch mm Ø ID G H Weight CV

2" 50 48 368,3 218 45 90

2"1/2 65 65 305 248 50 182

3" 80 73 305 248 55 275

NON-SLAM CHECK VALVES 4" 100 98 406,4 292 75 850

6" 150 132 558,5 377 245 1620

8" 200 166 711 396 325 2560

10" 250 197 863,5 512 415 3500

12" 300 263 990,6 548 705 6100

14" 350 298 1067 565 845 8050

16" 400 298 1193,8 565 1450 7800

18" 450 334 1537 675 1925 10200

20" 500 374 1664 710 2700 12150

24" 600 450 1549 835 4050 17600

VALVES CLASS 2500 #

Size

Inch mm Ø ID G H Weight CV

2" 50 48 450,8 250 65 90

2"1/2 65 48 450,8 250 75 110

3" 80 57 368,3 230 85 135

4" 100 73 457 268 285 275

6" 150 98 609,5 320 375 850

8" 200 146 762 471 550 1980

10" 250 184 914 488 1250 3100

12" 300 220 1041,4 601 1250 4200

14" 350 242 1117,6 607 1800 5200

16" 400 248 1244,6 637 1900 5700

18" 450 280 1397 707 2750 6900

20" 500 310 1422 710 3800 8460

24" 600 374 1549 750 4200 12200

TM

VALC O

26 / 44

+ Catalogue Valco A4 V7.indd 26 18/09/12 09:44

EXAMPLES OF SPECIAL

CHECK VALVES

POWER APPLICATION :

Swing check valve, size : 14'' Cl 1500#

with assisted closing device by linear

actuator.

CMI project : North Bangkok power

station 2008.

PIPELINE APPLICATION :

Swing check valve, size : 48'' Cl 900#

with damper and manual opening device.

DAELIM project : Pipeline, Malaysia 1996

27 / 44

+ Catalogue Valco A4 V7.indd 27 18/09/12 09:45

DESIGN FOR VALVES DESIGN FOR VALVES

SIZE UP TO 4" SIZE > 4"

Yoke

Screw

Bonnet

retaining

flange

Bonnet

Segment

retaining ring

Gasket

BONNET SEALING DESIGN

DESIGN :

Expansed graphite gasket with two stainless steel 316L backup rings.

Ring with compression limiter, therefore gasket joint keeps its elasticity.

The sealing is ensured whatever the temperature conditions.

Segment split and heel for easy assembly/disassembly.

Nut

Bonnet

retaining

Flange

Spacer ring

Gasket

Bonnet

TM

28 / 44

VALC O

+ Catalogue Valco A4 V7.indd 28 18/09/12 09:45

BLEEDER

DESIGN

SCREW

AND

DETAIL

DETAILS

SIZES > 4’’

DESIGN :

A bleeder screw has been fitted near the stuffing box or segment for valves with NPS > 4’’.

It enables bleeding the air out of the valves to perform tests during manufacture or on site.

This is a straight forward system consisting of only one bleeder srew.

Bleeding require just a simple loosening and retightening after bleeding

(tightening torque 60 Nm).

BLEEDER SCREW DETAIL

BLEEDER SCREW DETAIL

29 / 44

+ Catalogue Valco A4 V7.indd 29 18/09/12 09:45

STUFFING BOX SEALING DESIGN

Our design can meet your most severe

sealing requirements.

- Fugitive emissions class A - B

- Certified : ISO EN 15848 1 - 2

- Shell (Mesc SPE 77/300-312)

OPTIONAL DESIGN - Gas, H2S, Oxygen

- SANTOTHERM service

Live loading design :

- Compensate the packing wear

- Sealing maintened for longer life

- Less maintenance

Gland follower :

- Reduced clearances

- Better Centering and guiding

- Low friction, AISI 316L 160 HB maxi

Standard packing graphite :

- 2 Braided graphite, top and bottom

- ± 5 packing rings, pure expanded graphite

Optional , special design for :

- Severe service conditions

Backup ring :

- Stem guide, reduced clearances

- Low friction, AISI 316L 160 HB maxi

Bonnet backseating :

- Standard one-piece CR13

- Optional : Stellite gr6 overlay, or ring

AISI 316L + Stellite gr6 overlay

Stem backseating :

- Standard : one-piece, stem material

- Optional : Stellite gr6 overlay

TM

VALC O

30 / 44

+ Catalogue Valco A4 V7.indd 30 18/09/12 09:45

CERTIFICATE

LIVE LOADING DETAIL

MESURING DEVICES

Testing benches :

Nitrogen an Helium 0 to 690 bars

Mass spectrometer Adixen ASM 142

(sniffing sensibility : 1.10-7 mbar.1s-1)

TESTS

Valve tested up to 400°C

Fugitive emissions class A

TAT SHELL 2009

31 / 44

+ Catalogue Valco A4 V7.indd 31 18/09/12 09:45

PARALLEL SLIDE GATE VALVE : STEM / COLLAR /

DISC ASSEMBLY

> Screw the stem into the collar, then lock the stem with the two pins and secure by spot weld.

> Place the collar on the first disc, then the two clamps, followed by the spring.

> Place the second disc, then clamp the assembly.

Stem

Pins

Collar

Clamps

Disc

Collar

Clamp

Disc

TM

32 / 44

VALC O

+ Catalogue Valco A4 V7.indd 32 18/09/12 09:45

EQUALIZATION DEVICES

PRESENTATIONS :

For steam service, under certain conditions, during the heating of the installation.

The condensate trapped between the valve seats, is converted into steam.

This steam must be evacuated to ensure good functioning of the valve.

The following devices can achieve this :

Wedge with hole drilled, body with balancing pipe, body with single balancing bypass,

body with double bypass, pressure relief valve.

DESIGN WITH HOLE, FLOW IN ONE DIRECTION ONLY :

Simple and low cost design to balance the pressure between body cavity and HP side.

A hole Ø 3 to 5 is drilled on one part of the wedge.

An arrow is welded on the body to indicate the flow direction.

A marking indicating the "HP SIDE" can be stamped on the flange.

The wedge must be placed at the correct position.

DESIGN WITH BALANCING PIPE, FLOW IN ONE DIRECTION ONLY :

Better indication of the HP side.

No mistakes possible during gate assembly, even in rotational position.

An arrow is welded on the body to indicate the flow direction.

DESIGN WITH WEDGE HOLE DESIGN WITH BALANCING PIPE

TM

3 / 44

VALC O

+ Catalogue Valco A4 V7.indd 34 18/09/12 09:45

EQUALIZATION DEVICES

DESIGN WITH BALANCING BYPASS, FLOW IN ONLY ONE DIRECTION :

With a by-pass you can choose when you want to balance pressure.

An arrow is welded on the body to indicate the flow direction.

A marking indicating "HP SIDE " can be stamped on the flange.

At the purchase order stage, specify the by-pass position for the right or left side,

and indicate required insulation thickness.

3 / 44

+ Catalogue Valco A4 V7.indd 35 18/09/12 09:45

EQUALIZATION DEVICES

DESIGN WITH TWO BYPASS, BIDIRECTIONAL FLOW :

With two bypass valves you can choose which side you need to balance pressure.

You can also use the bypass to balance pressure upstream, downstream, or to reheat

the installation.

At the purchase order stage, specify the bypass position for the right or left side and indicate

required insulation thickness.

The bypass can be installed on the upper valve body as an option.

VALVE WITH TWO

BYPASS VALVES

TM

VALC O

3 / 44

+ Catalogue Valco A4 V7.indd 36 18/09/12 09:45

EQUALIZATION DEVICES

INSULATED VALVE AND BYPASS :

Bypass on upper body valve.

Valve Yoke

Two bypass valves

Insulation box

DESIGN WITH PRESSURE RELIEF VALVE, BIDIRECTIONAL FLOW :

With a pressure relief valve the valve is secure without operator intervention.

The relief valve is set to working condition with a safety factor.

At the purchase order stage, specify the relief valve position, and indicate required

insulation thickness.

RELIEF VALVE DETAIL

3 / 44

+ Catalogue Valco A4 V7.indd 37 18/09/12 09:45

LOCKING DEVICES

BY CHAIN OR CANE AND PADLOCK : BY MULTITURN LOCK :

Simple and economical devices : The Multi turn Lock is suitable for all

> Suitable for all handwheel or gearbox- handwheel or gearbox-operated valves.

operated valves. The principe of mechanical key is the transfer

> Locking device by chain and padlock. of keys. Each lock is executed with two keys,

> Locking device by cane and padlock. one for the locked open position and one for

the closed position. When the valve is open,

the open key is released and can be removed

ready to operate the next lock in the sequence

which will share the same lock code.

Valve with handwheel Valve with handwheel

Cane

Chain KEY

PADLOCK

Valve with gearbox Valve with gearbox KEY

PADLOCK

TM

VALC O

3 / 44

+ Catalogue Valco A4 V7.indd 38 18/09/12 09:45

SWITCHING DEVICES

WE CAN ADAPT ALL KINDS OF TWO POSSIBILITIES :

LIMIT SWITCHES :

Simple and economical devices :

> At the yoke position for handwheel valves.

Mechanical switch > On the stem cover for gear box valves.

EEx Mechanical switch Valve with handwheel

Box with proximity switches

Valve with gearbox

EEx Proximity switch

Junction box

3 / 44

+ Catalogue Valco A4 V7.indd 39 18/09/12 09:45

WE CAN ALSO SUPPLY BOLTED BONNET DESIGN FOR

OIL GAS INDUSTRIES

POWER COGENERATION PLANTS

WEDGE AND PARALLEL SLIDE GATE VALVES :

Design API 600 / ASME B16-34 / EN 12516 ...

Flanged or Butt Welded

Size range 2’’ up to 4 ‘’, request

Pressure rating Class 900 - 1500 - 2500#

Temperature range up to 575 °C

Materials ASTM / EN ...

GLOBE VALVES :

Design BS 1873 / ASME B16-34 / EN 12516 ...

Flanged or Butt Welded

Size range 2’’ up to 16‘’, according to your request

Pressure rating Class 900 - 1500 - 2500#

Temperature range up to 575 °C

Materials ASTM / EN ...

CHECK VALVES :

Design API 6D / ASME B16-34 / EN 12516 ...

Flanged or Butt Welded

Size range 2’’ up to 4 ’’, request

Pressure rating Class 900 - 1500 - 2500#

Temperature range up to 575 °C

Materials ASTM / EN ...

TM

/ 44

VALC O

+ Catalogue Valco A4 V7.indd 40 18/09/12 09:45

4 / 44

+ Catalogue Valco A4 V7.indd 41 18/09/12 09:45

TEST CAPABILITIES

TEST BENCHES AT AMBIENT

TEMPERATURE

Water tests

Air tests

Helium tests

Nitrogen tests

Pressure test prod (pneumatic)

AT CRYOGENIC

TEMPERATURE

Down to -196°C

NDE FACILITIES Dye penetrant

Ultrasonic testing

Magnetic particle examination

Positive material identification

Thickness measurements

Hardness

a s special magnetic

particle e aminations via our

partner service provider

CUSTOMER’S CERTIFICATION

EDF

COGEMA

ALSTOM

AREVA COMURHEX

...

TM

4 / 44

VALC O

+ Catalogue Valco A4 V7.indd 42 18/09/12 09:45

N E

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

............................................................................................................

TM

4 / 44

VALC O

+ Catalogue Valco A4 V7.indd 42 18/09/12 09:45

QUALITY CERTIFICATION

ISO 9001 – 200

CE MARKING

FIRE SAFE DESIGN

BS6755 PART 2

DNV

M

KOREAN REGISTER

LLOYD’S REGISTER

BUREAU VERITAS

TÜV

CONSTRUCTION STANDARDS

API 600 - ISO 10434, EN 12516,

ASME B16.34, B31.1, B31.3

B16.5, B16.10, B16.25

ASME Section VIII, Section IX

ASTM, EN as per client’s request

MSS SP25, SP55, SP61, SP82

CST EDF, MESC SHELL…

43 / 44

+ Catalogue Valco A4 V7.indd 43 18/09/12 09:45

10-31-2949 / Certifié PEFC / Ce produit est issu de forêts gérées durablement et de sources contrôlées. / pefc-france.org

TM

www.valcogroup.fr Dedication to delivery

VALC O

Valco Group based in Ruffec & Chambéry France, includes 4 brand names (Guichon, Malbranque, SNRI & Valco Valves Services), dedicated to service, innovation and delivery.

Valco Group Sales offices in Australia & Malaysia + sales office factory in South Africa.

Valco Group France produces valves and related products as well as after sales services for applications world-wide in Marine, Oil & Gas Down-Stream, Energy & Industry

fields.

Valco Group produces valves and related products as well as after sales and servicing for applications world-wide in Oil & Gas Down-Stream, Marine/LNG, Power Energy,

Petrochemical, Nuclear, Chemical and Polymers.

Valco Group France's product range contains well-known and established valves brands mainly manufactured on-site as well as providing complementary part & spares. Our

long experience has demonstrated our capability to integrate in our valve line the combination of high pressure with very low or high temperatures. We also provide valves

which cover Sour Service as well as many types of special applications where quality product requirement matters.

+ Catalogue Valco A4 V7.indd 44 18/09/12 09:45

You might also like

- Pokémon Unbound Mission List+ v2.1.0Document8 pagesPokémon Unbound Mission List+ v2.1.0Kokot100% (3)

- Wouter Witzel Corporate Brochure NewDocument11 pagesWouter Witzel Corporate Brochure NewMohamed RjebNo ratings yet

- Isolation & Control Butterfly ValvesDocument62 pagesIsolation & Control Butterfly Valvesmanmohansingh1999No ratings yet

- Brochure - Valco - Presentatation For Export - EnglishDocument2 pagesBrochure - Valco - Presentatation For Export - EnglishMeet JaniNo ratings yet

- VST Valves Presentation General AADocument46 pagesVST Valves Presentation General AAJaydeep PanchalNo ratings yet

- Kanon Green Binder Rev 2Document202 pagesKanon Green Binder Rev 2AZLAN ABDULLAINo ratings yet

- Dovewell Oilfield Services LTDDocument28 pagesDovewell Oilfield Services LTDlibyashuaaNo ratings yet

- Thermosolar Catalogue PDFDocument28 pagesThermosolar Catalogue PDFbagastcNo ratings yet

- VBO - Triple Offset Butterfly ValveDocument14 pagesVBO - Triple Offset Butterfly ValveFabio Peres de LimaNo ratings yet

- Pentair Valves & Control OverviewDocument32 pagesPentair Valves & Control OverviewArief PrabowoNo ratings yet

- Gas Division: ArfluDocument56 pagesGas Division: ArfluDammnNo ratings yet

- Pressure Seal Bonnet Design: Dedication To DeliveryDocument44 pagesPressure Seal Bonnet Design: Dedication To DeliveryMeet JaniNo ratings yet

- Severe Service SolutionsDocument22 pagesSevere Service SolutionsAnonymous HGZfO4IQNo ratings yet

- CVA Gate Globe Check Strainers CatalogDocument95 pagesCVA Gate Globe Check Strainers CatalogRiss0No ratings yet

- VGE - Company ProfileDocument24 pagesVGE - Company Profile85126439No ratings yet

- Catalog: Trunnion Mounted Ball ValveDocument84 pagesCatalog: Trunnion Mounted Ball ValveGerardo Taborda NuñezNo ratings yet

- Online Pressure Safety Valve TestingDocument2 pagesOnline Pressure Safety Valve TestingKauffman LOKONo ratings yet

- Valvula Bola 1500 PsiDocument8 pagesValvula Bola 1500 PsibetojulioNo ratings yet

- Severe Service Valve SolutionsDocument22 pagesSevere Service Valve SolutionsHector Flores Marcos100% (1)

- ValvTechnologies 01 - Zero Leakage Valve Solution PDFDocument20 pagesValvTechnologies 01 - Zero Leakage Valve Solution PDFNanangdp48No ratings yet

- 04 HIT VALVE Control Ball Valves Product CatalogueDocument20 pages04 HIT VALVE Control Ball Valves Product CatalogueRAVINDR.KNo ratings yet

- Complete Solution For Industrial Valves: Neway ValveDocument24 pagesComplete Solution For Industrial Valves: Neway ValveLuis Felipe Cortes PachecoNo ratings yet

- Check Valves WeightDocument16 pagesCheck Valves WeightИлья БересневNo ratings yet

- CheckValve Walworth - DualPlate Setpoint PDFDocument40 pagesCheckValve Walworth - DualPlate Setpoint PDFfernandez2011No ratings yet

- Test Pump WindlassDocument40 pagesTest Pump WindlassMd.farman Ali AhmedNo ratings yet

- Catalogue 2018 D.PDocument18 pagesCatalogue 2018 D.PPhongsak SihanatNo ratings yet

- B-Fire Products BrochureDocument12 pagesB-Fire Products Brochurejeronimo113No ratings yet

- Complete Catalog API Din Uniflow Data Sheet en Ds20Document222 pagesComplete Catalog API Din Uniflow Data Sheet en Ds20Tuesou MachereNo ratings yet

- ControlDocument26 pagesControlritesh sharmaNo ratings yet

- 12 585 Rov Latches Brochure v3 Web 1 PDFDocument8 pages12 585 Rov Latches Brochure v3 Web 1 PDFIZayvenkoNo ratings yet

- Catalog: Expanding GateDocument32 pagesCatalog: Expanding GateAndersson Benito HerreraNo ratings yet

- Heeco Transformer BrouchersDocument4 pagesHeeco Transformer BrouchersFahadNo ratings yet

- Ball Valve Weight EstDocument31 pagesBall Valve Weight EstLincoln ChauNo ratings yet

- Brochure TrunnionDocument52 pagesBrochure TrunnionZts MksNo ratings yet

- EB174 ERIKS Flow ControlDocument12 pagesEB174 ERIKS Flow ControlKunming WangNo ratings yet

- 04-Fire Fighting Valves and Hydrants SVMCDocument14 pages04-Fire Fighting Valves and Hydrants SVMCIgor NhamanoNo ratings yet

- AVK Philipppines Price List 2022-2023Document52 pagesAVK Philipppines Price List 2022-2023Mark Philip BaliwisNo ratings yet

- EN Company Profile EmailDocument16 pagesEN Company Profile EmailSonakshi HuddaNo ratings yet

- Capelec 2024 Catalog CompressedDocument56 pagesCapelec 2024 Catalog CompressedDuarteSilvaNo ratings yet

- Subsea Valves BRDocument14 pagesSubsea Valves BRFrancesco AntoniniNo ratings yet

- Torex Ilv SeriesDocument52 pagesTorex Ilv SeriesElton Da Silva FariasNo ratings yet

- Weir Ball ValveDocument20 pagesWeir Ball ValveAmr ZayanNo ratings yet

- WH Scott - Crane Services BrochureDocument2 pagesWH Scott - Crane Services Brochurejithinjose86No ratings yet

- 2024 Company ProfileDocument15 pages2024 Company ProfileSomen SarkarNo ratings yet

- Catalog: Industrial Bronze ValvesDocument60 pagesCatalog: Industrial Bronze ValvesFederico MoranNo ratings yet

- TFTUK 201909 X Stream Brochure PWDocument12 pagesTFTUK 201909 X Stream Brochure PWArturNo ratings yet

- AVK NL Industrie EngDocument32 pagesAVK NL Industrie EngADRIAN SUŁAWANo ratings yet

- Catalog Ach OldDocument25 pagesCatalog Ach Oldprakash1010No ratings yet

- On Site Engineering - CompressedDocument12 pagesOn Site Engineering - CompressedanthonythiaNo ratings yet

- Zero-Leakage Valve Solutions: Product & Capabilities OverviewDocument20 pagesZero-Leakage Valve Solutions: Product & Capabilities OverviewAndry HermawanNo ratings yet

- Control Valv3Document12 pagesControl Valv3Михаил ПолковниковNo ratings yet

- Walworth Cast Steel Catalog 2012 1Document100 pagesWalworth Cast Steel Catalog 2012 1Andersson Benito HerreraNo ratings yet

- Válvulas de Seguridad y Alivio de AceroDocument80 pagesVálvulas de Seguridad y Alivio de Aceromarco lezcanoNo ratings yet

- Corporate Presentation At3wDocument19 pagesCorporate Presentation At3wReinaldo Sciliano juniorNo ratings yet

- Descarga 1170758086Document20 pagesDescarga 1170758086Federico AraujoNo ratings yet

- Twin Plate Check Valves: General CatalogueDocument32 pagesTwin Plate Check Valves: General CatalogueeajNo ratings yet

- Catalogue enDocument155 pagesCatalogue enworkingNo ratings yet

- Wavin: Inspection ChambersDocument62 pagesWavin: Inspection ChambersXAVIER RUBIONo ratings yet

- Tech Product CatalogDocument52 pagesTech Product CatalogJelan FanarNo ratings yet

- Catalog: Safety and Relief BronzeDocument32 pagesCatalog: Safety and Relief BronzeAndersson Benito HerreraNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Kpop Songs LyricsDocument15 pagesKpop Songs LyricsAsh Alizer TesaniNo ratings yet

- Maur MeyerDocument488 pagesMaur MeyerItachi KunNo ratings yet

- Data Siswa Kelas Xii 2018Document84 pagesData Siswa Kelas Xii 2018Kang Mas HurieyNo ratings yet

- Gererac Guardián 7.5 KWDocument52 pagesGererac Guardián 7.5 KWOPERACIONES TORRESANo ratings yet

- Victorian Compromise and Literary Movements PDFDocument2 pagesVictorian Compromise and Literary Movements PDFChuii MuiiNo ratings yet

- Solubility of Benzoic Acid in Organic SolventsDocument2 pagesSolubility of Benzoic Acid in Organic Solventssrshah67% (6)

- Lhamo Lomagyonma PracticeDocument4 pagesLhamo Lomagyonma Practicemozollis22No ratings yet

- Weighted Least Squares Kinetic Upwind Method Using Eigen Vector BasisDocument55 pagesWeighted Least Squares Kinetic Upwind Method Using Eigen Vector BasiskonarkaroraNo ratings yet

- BEP 359 - Virtual Teams 1: Video Conference MeetingsDocument12 pagesBEP 359 - Virtual Teams 1: Video Conference MeetingsPatrickNo ratings yet

- FRERES DORIENTConstantinople 1054 or 1090Document15 pagesFRERES DORIENTConstantinople 1054 or 1090Er Might100% (5)

- List of Accessories, Materials and Equipments - PictorialDocument12 pagesList of Accessories, Materials and Equipments - PictorialnasiseidrscribdNo ratings yet

- 1Document14 pages1netsa_marNo ratings yet

- HMP Openser Sip AnDocument9 pagesHMP Openser Sip Anchingo9252No ratings yet

- The Philippine Marketing Environment: Bruto, Ivy Marijoyce Magtibay, Sarah Jane Guno, RhizaDocument26 pagesThe Philippine Marketing Environment: Bruto, Ivy Marijoyce Magtibay, Sarah Jane Guno, Rhizakenghie tv showNo ratings yet

- Characterization and Modeling of Oriented Strand CompositesDocument208 pagesCharacterization and Modeling of Oriented Strand CompositesBeatriz SilvaNo ratings yet

- Wellness Campus Song LyricsDocument2 pagesWellness Campus Song LyricsIshmael NarioNo ratings yet

- C955 Pre-Assessment - MindEdge Alignment Table - Sheet1Document3 pagesC955 Pre-Assessment - MindEdge Alignment Table - Sheet1Robert Allen Rippey0% (1)

- RUSLEDocument16 pagesRUSLEVivek KasarNo ratings yet

- Conversion Optimization FrameworkDocument34 pagesConversion Optimization FrameworkKavya GopakumarNo ratings yet

- Case StudyDocument5 pagesCase StudyRushabh AjmeraNo ratings yet

- Memorandum To Governor - Assam Mojuri Srameek UnionDocument4 pagesMemorandum To Governor - Assam Mojuri Srameek UnionArup BaisyaNo ratings yet

- Service Marketing: BY, Bhavithra AsokanDocument20 pagesService Marketing: BY, Bhavithra AsokanDomnic SavioNo ratings yet

- Rough Main Project KansaiDocument91 pagesRough Main Project KansaisuganyaambaNo ratings yet

- GE OEC 9800 Operator Manual and SupplementDocument160 pagesGE OEC 9800 Operator Manual and SupplementC CraigNo ratings yet

- Eni MP Grease 2 - 1720 - 5.0 - ENDocument16 pagesEni MP Grease 2 - 1720 - 5.0 - ENMuhammad Abdul RehmanNo ratings yet

- HY USMLE Review Part IVDocument31 pagesHY USMLE Review Part IVDr.2020100% (1)

- Mecha v. INS, 4th Cir. (2000)Document4 pagesMecha v. INS, 4th Cir. (2000)Scribd Government DocsNo ratings yet

- CV - Banjubi Boruah - FMS - NIFT - Shillong PDFDocument2 pagesCV - Banjubi Boruah - FMS - NIFT - Shillong PDFruchi mishraNo ratings yet

- End Term Question Paper Linux For Devices 2021Document2 pagesEnd Term Question Paper Linux For Devices 2021KeshavNo ratings yet