Professional Documents

Culture Documents

Exploitation of Industrial Waste Ghee Residue in Laccases Production PDF

Exploitation of Industrial Waste Ghee Residue in Laccases Production PDF

Uploaded by

Sun INsurance AgencyCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Overhaul s51 s53 s54Document29 pagesOverhaul s51 s53 s54YadiNo ratings yet

- TEST QUESTIONS IN SCIENCE 9 MELC-BASED (Analysis, Application and Evaluation)Document26 pagesTEST QUESTIONS IN SCIENCE 9 MELC-BASED (Analysis, Application and Evaluation)mayette100% (1)

- Exporters Directory October 2019Document85 pagesExporters Directory October 2019Sun INsurance Agency0% (1)

- Buttermilk and Ghee Residue - PDFDocument13 pagesButtermilk and Ghee Residue - PDFSun INsurance AgencyNo ratings yet

- Hort 351 Lecture 3Document21 pagesHort 351 Lecture 3Sun INsurance AgencyNo ratings yet

- Horticultural Zones of IndiaDocument21 pagesHorticultural Zones of IndiaSun INsurance AgencyNo ratings yet

- Revision MCQ - KinematicsDocument2 pagesRevision MCQ - Kinematicsgaya8404No ratings yet

- Voorbeeldtentamen Wiskunde B 1 - ENDocument9 pagesVoorbeeldtentamen Wiskunde B 1 - ENRishika GoswamiNo ratings yet

- Accomplishment Report Week 2Document7 pagesAccomplishment Report Week 2steph curryNo ratings yet

- Sources of Stem CellsDocument13 pagesSources of Stem CellsAnshi AroraNo ratings yet

- Nama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071Document11 pagesNama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071shalsaNo ratings yet

- Pre-Flight Inspection R22Document73 pagesPre-Flight Inspection R22Ann LechatNo ratings yet

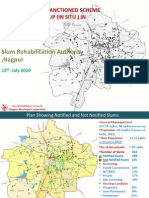

- Presentation - Slum Department 21st Sept 2010Document42 pagesPresentation - Slum Department 21st Sept 2010Nupur Bhadra100% (1)

- Dpcode Vol 3Document30 pagesDpcode Vol 3Murali VNo ratings yet

- 1SDA066549R1 A2b 250 TMF 160 1600 3p F FDocument3 pages1SDA066549R1 A2b 250 TMF 160 1600 3p F FkjushnNo ratings yet

- Baaladhi Deepthanadhi Lajitadhi SayanadhiDocument4 pagesBaaladhi Deepthanadhi Lajitadhi SayanadhiPeter NovakNo ratings yet

- Red Box Hack 2Document22 pagesRed Box Hack 2jgregors8683No ratings yet

- GRAVITY - by Hobie Thompson and Sarah HavernDocument2 pagesGRAVITY - by Hobie Thompson and Sarah HavernJohn OsborneNo ratings yet

- Hearing Is BelievingDocument1 pageHearing Is BelievingAntonioPalloneNo ratings yet

- ST Cecilia CLASSICAL GUITAR Syllabus: Performance ExaminationDocument16 pagesST Cecilia CLASSICAL GUITAR Syllabus: Performance ExaminationRRodas BulejeNo ratings yet

- B02. Junior Engineer MechanicalDocument115 pagesB02. Junior Engineer MechanicalRafay MohiuddinNo ratings yet

- LCA QuestionsDocument2 pagesLCA QuestionsJason HomNo ratings yet

- Cobas C 311 Analyzer: Operator's Manual Software Version 01-04Document590 pagesCobas C 311 Analyzer: Operator's Manual Software Version 01-04khoangsachNo ratings yet

- Eaton Lambert SyndromeDocument8 pagesEaton Lambert Syndromeutami ridaNo ratings yet

- Blood Sucking Flies1Document21 pagesBlood Sucking Flies1Softlens GriyaNo ratings yet

- Nega Bizuye To New Cobble RoadDocument36 pagesNega Bizuye To New Cobble RoadAsmerom MosinehNo ratings yet

- LogicDocument32 pagesLogicBharat Pal SinghNo ratings yet

- ENF204 Microbiology and Parasitology Credits: In-Class Hours: Lab/Clinical: LevelDocument5 pagesENF204 Microbiology and Parasitology Credits: In-Class Hours: Lab/Clinical: LevelamieNo ratings yet

- 6 - Newton's Laws of Motion-Exercises Module-1Document17 pages6 - Newton's Laws of Motion-Exercises Module-1Raju SinghNo ratings yet

- Otoacoustic Emissions From MedscapeDocument5 pagesOtoacoustic Emissions From MedscapeMin-Joo Esther ParkNo ratings yet

- Rain Water Calculation (300mmh)Document6 pagesRain Water Calculation (300mmh)MechanicalLatestNo ratings yet

- Estimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Document41 pagesEstimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Anonymous 7yN43wjl100% (1)

- Oro-Antral CommunicationDocument65 pagesOro-Antral CommunicationNadila RNo ratings yet

- Cisco. (2016)Document5 pagesCisco. (2016)Alga GermanottaNo ratings yet

Exploitation of Industrial Waste Ghee Residue in Laccases Production PDF

Exploitation of Industrial Waste Ghee Residue in Laccases Production PDF

Uploaded by

Sun INsurance AgencyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exploitation of Industrial Waste Ghee Residue in Laccases Production PDF

Exploitation of Industrial Waste Ghee Residue in Laccases Production PDF

Uploaded by

Sun INsurance AgencyCopyright:

Available Formats

Received: 30th July-2012 Revised: 06th August -2012 Accepted: 09tht August -2012

Research article

EXPLOITATION OF INDUSTRIAL WASTE GHEE RESIDUE IN LACCASES PRODUCTION BY

Pycnoporus cinnabarinus strain SYBC-L14

Rasheeda Khanam*1, Dr. R.Gyana Prasuna2 and Sabika Akbar1

1

Department of Microbiology, A.Q.J degree & P.G. College, Visakhapatnam,

2

Department of Microbiology, GITAM Institute of science, GITAM University, Visakhapatnam

*Corresponding author: E-mail ID: rskhanam@gmail.com

ABSTRACT: The objective of this research work was on the production of laccases by agricultural and industrial

waste management using a Basidiomycetes fungus, Pycnoporus cinnabarinus. Agricultural/industrial wastes such as

sawdust, Rice bran and wheat bran can bring down the cost of laccases production. The best laccases production

medium was analyzed by incorporating the agricultural/industrial wastes in the production medium. The best laccase

production was obtained in the medium with wheat bran followed by Rice bran and sawdust. With the aim of

enhancement of laccases production, ghee residue (1%W/V), a byproduct of milk industry was added to the above

media. For comparison, media with peptone (1% W/V) were used. The use of ghee residue in the formulation of the

laccases production media has been found to be beneficial. The production of laccases in presence of peptone and ghee

residue was 1.6 times and 4.16 times more respectively than in the medium with only glucose (15.77 U/ml/min).

Similarly an increase by 1.2 folds and 1.3 folds in laccase production was obtained in the medium containing wheat

bran with peptone and ghee residue respectively when compared to the control i.e. medium containing only wheat bran

(126.99 U/ml/min). 88% increase in laccases production in the medium with agricultural (Wheat bran) and industrial

(Ghee residue) wastes when compared to the basal medium containing glucose. The optimum temperature was found

to be 80oC and pH 5.0 for the laccases activity. The ghee residue and peptone seem to be acting as inducers in laccases

production.

Key words: Laccases, Ghee residue, wheat bran, Rice bran, Saw dust, Pycnoporus cinnabarinus.

INTRODUCTION

The increase in the use of enzymes in diverse industrial fields has made it necessary to look for the cheap and

economic sources for them. Many of such these enzymes are widely distributed in nature; laccases being one of them.

Laccases (benzenediol: oxygen oxidoreductases, E.C 1.10.3.2) are multi-copper enzymes belonging to the group of

blue oxidases. They are defined as oxidoreductases in Enzyme Commission (EC), which oxidizes diphenol and allied

substances and use molecular oxygen as an electron acceptor [13]. Laccases are the oldest and most studied enzymatic

systems for various industrial applications such as textile dye bleaching [9], pulp bleaching and bioremediation. In

order to improve the color and quality of the Kraft pulp chlorine-based bleaching is adopted followed by discharging of

waste waters containing chlorinated aromatics into water bodies [3]. This cytotoxic and cytomutagenic effects on

various living organisms ultimately harming human beings too. A similar process is also observed in textile industries

using harmful cytotoxic coloring dyes as the effluents are released in water bodies [11]. Fungal laccases have wide

applications [6]. They can help us reduce the above, being an environment friendly to overcome the toxicity of the

currently used chemicals. However industrial production of laccases by conventional media is costly. Fungi are capable

of using a wide variety of organic wastes as a source of carbon and nitrogen [4]. In this work we have screened three

organic wastes namely wheat bran, rice bran and saw dust as a source of carbon for laccase production by the test

fungus. Phenolics obtained from plants or other sources have been used as inducer in production of various enzymes,

[12]. Laccases would be able to oxidize phenolic substrates.

International Journal of Plant, Animal and Environmental Sciences Page: 1

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

With this view we have used ghee residue as an inducer for laccase production. Ghee residue, a by-product of the dairy

industry, was found to contain crude protein content of 25.8% which was found to be suitable for the fungus to produce

laccases. The phenolic compounds, defined as the hydroxy derivatives of benzene and its condensed aromatic systems

were found to be present in the byproduct of milk industry in the manufacturing of ghee i.e. ghee residue. They were

screened by performing the test for phenolic compounds [2].

In order to prove the efficiency of Ghee residue, Peptone, a product of incomplete fermentative hydrolysis of protein

containing peptides, diketopiperazines and amino acids, was used as an another possible inducer.

MATERIALS AND METHODS

Test Organism

The laccases producing fungus was obtained from Kakatiya University, Warangal, Andhra Pradesh. It was named as

KR for convenience. The above organism was sent for identification to Xcelris laboratories, Ahmadabad, Gujarat.

The fungal culture was maintained in pure form by inoculating it in malt extract medium containing the following

composition (g/L), 15g Malt extract powder, 1g Dipotassium hydrogen ortho phosphate, 1g Ammonium chloride, 15

ml Citric acid (1N), 20g Agar.

Screening for Laccases Producing Fungi

Screening for laccase producing organisms was done on the screening medium plates containing following

composition (g/l):

3.0 peptone, 10.0 glucose, 0.6 KH2PO4, 0.001 ZnSO4, 0.4 K2HPO4 0.0005 FeSO4, 0.05 MnSO4, 0.5MgSO4, 20.0

agar (pH-6) supplemented with 0.02% Guaiacol [14]. Positive cultures were visualized by reddish brown coloring

zones in the screening plates since laccase catalyzes the oxidative polymerization of Guaiacol to form reddish brown

coloring zones in the medium.

Characterization of Pycnoporus cinnabarinus

Pycnoporus cinnabarinus is a wood-rotting fungus that forms a reddish-orange fruit body with spore-releasing pores

on its undersurface. It is a white rot fungus. It breaks down both cellulose and lignin in the cell walls of its host’s

wood. It is also one of the three species belonging to the genus Pycnoporus, first formalized by P. Karst in 1881. It

grows in a semi-circular (half a circle) or amorphous-elongated shape, attaching to tree or log exteriors, growing

hyphae of varying degrees of branching and wall thickness within a single fruit body and forming pileus that ranges in

color from a reddish-apricot color to a deep red-orange. P. cinnabarinus lives as a detritivore on hard wood trees,

degrading cellulose, hemicellulose, and lignin found in cell wood walls [8].

P. cinnabarinus occurs across the entire northern hemisphere in the North Temperate Zone, extending from Central

American & and North African latitudes to mid-Canada and northern Russia, and so can therefore withstand freezing

temperatures. However, its growth rate is shown to decline significantly at temperatures above 30oC and it is not found

in tropical zones. The fruit body releases spores in the autumn and spring and can survive over the winter. P.

cinnabarinus, however, is usually found on the dead hard-wood of deciduous trees and rarely on the dead wood of

conifers [10].

Studies on Growth Conditions of Fungal Growth

The fungus was inoculated in malt extract medium and was incubated at room temperature. The growth measurement

of the fungus was done by the dry weight estimation at 2 days of time intervals. The fungus was filtered using filter

paper and was dried in hot air oven at 800 C till standard weight was obtained.

International Journal of Plant, Animal and Environmental Sciences Page: 2

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

Optimum pH

A similar procedure was followed to estimate the optimum pH for the fungal growth. The malt extract media was

prepared with different pH ranging from pH 3.0-9.0 by using acetate buffer, phosphate buffer, Tris HCl buffer and was

incubated at room temperature for the period of time where the maximum growth was observed.

Optimum temperature

To estimate the optimum temperature for fungal growth, the malt extract medium was prepared with the optimum pH

by using acetate buffer and was incubated for the period of time where the maximum growth was observed at

temperatures ranging from 00C to 600C.

Fermentation by Submerged Fermentation Technique

In submerged fermentation (SmF) microorganisms were grown in a continuous liquid phase using Pycnoporus

cinnabarinus strain SYBC-L14. The efficiency of the laccase producing organisms can only be exploited with the aid

of media designed with optimum concentrations of every component which influences the production. Research

conducted in this regard mainly aimed at picking up proper carbon sources, nitrogen sources and inducers.

Standardization of Medium Composition for Laccases Production

Laccases production in liquid culture was investigated using glucose, sawdust, rice bran and wheat bran as the sole

carbon sources.

Composition of the Basal medium (in g/l):

Carbon source-10g, aspargine-1.00g, Yeast extract-0.5g, K2HPO4-0.5g, MgSO4.7H2O-1.00g, FeSO4.7H2O-0.001g

[15].

Carbon Source

Laccase production time was standardized using composite medium containing glucose and Guaiacol. Standard time

for production of laccase was found to be on the 15th day. A set of production media with the appropriate carbon

source was inoculated with the Pycnoporus cinnabarinus strain SYBC-L14. The inoculated medium was incubated for

15 days at 27-300 C in an orbital shaking incubator at 120 rpm. After incubation the fungal culture was filtered using a

muslin cloth. The best carbon source for the respective fungal cultures was noted down by using the filtrate as a crude

enzyme source and identifying enzyme activity using Guaiacol as a substrate. This investigation was continued with

the use of inducers (peptone or ghee residue) in combination with alternative carbon sources like glucose, sawdust and

wheat bran in order to increase the production of enzyme.

Nitrogen Source

In addition to yeast extract, peptone/Ghee residue (1.0% w/v) was added in the production medium as an inducer. The

production medium with alternative carbon source (Glucose, sawdust and wheat bran, Rice bran) each with inducer

either peptone or Ghee residue was inoculated with P. cinnabarinus strain and was incubated for 15 days in orbital

shaking incubator at 120 rpm at 27-300C (Fig.1)

After incubation the fungal culture was filtered using a muslin cloth. The best carbon source with the best inducer was

noted down by using the filtrate as a crude enzyme source and identifying enzyme activity using Guaiacol as a

substrate.

Assay of Laccases

Using Guaiacol, Laccase activity in the sample was determined spectrophotometrically by monitoring the rate of

product (dark brown color) formation.

The reaction mixture consists of 1.0 ml 0.2% Guaiacol prepared, 3.0 ml of acetate buffer (pH 5.0) and 1.0 ml of

enzyme (to be tested) [1].

The kinetic reaction was spectrophotometrically recorded at 465 nm [3] for 3 Minutes with 1 min of time interval at

30°C, as an increase in absorbance. The blank contained all the assay constituents except the active enzyme, buffer or

heat inactivated enzyme was used in its place.

International Journal of Plant, Animal and Environmental Sciences Page: 3

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

Fig1: Incubation of P. cinnabarinus in the production media at 120rpm for 15 days

Effect of pH and Temperature on Enzyme Activity

The pH optima of laccases are highly dependable on the substrate. When using Guaiacol as substrate the pH optima are

more acidic and are found in the range 3.0-5.0. For the study of effect of pH and temperature on enzyme activity, the

media showing better production of laccases for P. cinnabarinus was selected, the fungal mycelium was filtered after

15 days of incubation and the filtrate was used as the crude enzyme source .It is incubated in the range of pH 3.0-9.0 at

27-300C and enzyme activity was determined spectrophotometrically. The better pH for the enzyme activity was used

for incubating the crude enzyme sample at the temperatures ranging from 00 C- 900C to determine the enzyme activity

spectrophotometrically. Therefore the better pH and temperature can be applied to find the highest enzyme activity.

Effect of Substrate Concentration on Enzyme Activity

The crude enzyme (1ml) obtained from the cheap and best media was incubated with the increasing concentrations

(0.1%-0.5%) of the substrate (Guaiacol) at the optimum temperature in optimum pH buffer (sodium acetate buffer) and

its activity was noted spectrophotometrically at 465nm.

Calculation of Enzyme Activity (U/ml)

The enzyme activity was calculated by using the formula,

A=Increase in Absorbance at 465 nm

T= Time of observation

Vt = Final vol. of reaction mixture= 5.00

Vs = Sample volume= 1.00

E Guaiacol = extinction coefficient of the product= 27.75

Statistical Analysis

The data presented in results were interpreted statistically using Minitab 16.

RESULTS AND DISCUSSION

This paper summarizes the important reports on the cheap and best production medium for the production of

industrially most important laccases by submerged fermentation method and optimization of pH and temperature for its

activity.

International Journal of Plant, Animal and Environmental Sciences Page: 4

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

As per the reports sent by xcelris laboratory, Ahmadabad, the fungus KR was reported as P. cinnabarinus strain

SYBC-L14 (GenBank Accession Number: HQ891298.1). When the test organism was inoculated in the screening

media for laccases production using Guaiacol as a substrate it shows positive report by the formation of dark reddish

brown zones around the fungal culture (Fig.2).

Fig2: Positive report for the screening test of P.cinnabarinus (KR)

The fungus P. cinnabarinus shows the maximum growth in 14 days of incubation at room temperature in malt extract

medium (pH6.8) Fig.3.

O ptimization of time interv al for maximum gr ow th of P .cinnabar inus

0.5

0.4

Dry wt. in gms

0.3

0.2

0.1

0.0

2 da y s 4 da y s 6 day s 8 da y s 10 da y s 12 da y s 14 day s 16 day s 18 day s 20 day s

Fig.3: Optimization of time interval for the fungal growth

When the organism was inoculated and incubated in the malt extract medium of different pH ranging form 3.0-9.0 at

room temperature for 14 days, the maximum growth was observed in the medium with pH3.0. (Fig.4).

Among the formulated laccases production media using agro waste (wheat bran, rice bran), industrial waste (sawdust)

as a carbon source, higher laccase production was obtained in the medium with wheat bran followed by sawdust,

glucose and rice bran (Table 1.). Further addition of peptone or ghee residue as an inducer lead to higher production of

laccases. 140.78U/ml in the medium with Wheat bran and ghee residue/WBG followed by wheat bran with peptone

/WBP (113.45U/ml) and Sawdust with ghee residue/SDG (90.35U/ml) (Fig.6). Lowest production of laccases was

found in the medium with only Rice bran (0.94U/ml). 88% increase in laccases production in the medium with

agricultural (Wheat bran) and industrial (Ghee residue) wastes when compared to the basal medium containing

glucose.

International Journal of Plant, Animal and Environmental Sciences Page: 5

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

Effect of pH on growth of P. cinnabarinus

0.6

0.5

0.4

Dry wt. in gms

0.3

0.2

0.1

0.0

pH 3.0 pH 4.0 pH 5.0 pH 6.0 pH 7.0 pH 8.0 pH 9.0

Fig.4: pH optimization for the fungal growth

Similarly, the maximum growth was observed at temperature 300C when the fungus was inoculated and incubated in

the malt extract medium (pH3.0) at different temperatures ranging from 0-600C for14 days (Fig.5).

Effe ct of te mpe rature on growth of P.cinnabarinus

0.7

0.6

0.5

Dry wt. in gms

0.4

0.3

0.2

0.1

0.0

0`C 10`C 20`C 30`C 40`C 50`C 60`C

Temperature

Fig.5: temperature optimization for the fungal growth

The carbon source in the medium plays an important role in ligninolytic enzyme production. Lignolytic systems are

activated during the secondary metabolic phase of fungi and are triggered by nitrogen depletion. The effect of different

type of nitrogen source was analyzed, which influences the laccase production significantly. Further the optimum

temperature and pH for enzyme activity produced in the cheap and best media i.e., wheat bran with ghee residue

(WBG) was found to be 800C (Fig.7) and 5.0 (Fig.8) respectively. Since laccases oxidize phenolic compounds (Pcs),

they may also induce its production. Phenolic compounds are a diverse group of chemicals (over 8000 currently

known; L. Bravo, 1998), produced as secondary metabolites by most plants, as natural deterrents to grazing animals.

Pcs get incorporated into milk and milk products. Pcs are found in considerable amounts in ruminant milk (mg/Kg) [5]

Thus, it was found that pcs are present in the ghee residue [2].

International Journal of Plant, Animal and Environmental Sciences Page: 6

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

Table 1: Optimization of carbon source for laccases production

Carbon source Nitrogen source Fungal mass (gm) Production of

laccases(U/ml)

Glucose Yeast extract 0.18 ± 0.04 15.77±0.12

Sawdust Yeast extract 0.79± 0.01 118.24±0.16

Wheat bran Yeast extract 0.41 ± 0.10 126.99±0.11

Rice bran Yeast extract 0.80± 0.05 0.94±0.08

Each value is the average of three replicates and ± indicates standard deviation

Effe ct of diffe re nt me dia on e nzyme production

140

120

100

U/ml/min

80

60

40

20

0

G GP GG SD S DP S DG WB WBP WBG RB RBP RBG

Media

Fig.6: Optimization of media for laccases production

GHEE RESIDUE

Ghee residue is obtained as a by-product of ghee manufacturing industry and is produced in large quantity (about

91000 tones per annum) in India. During its manufacture the solids not fat (SNF) present in cream or butter appears as

small particles known as ghee-residue. It has been obtained after molten ghee has been either strained out with muslin

cloth or separated by continuous centrifugal clarifiers. The yield of ghee-residue varies with the method of preparation

of ghee. This is due to the variation in the non-fatty serum constituents of the different raw materials used for the

preparation of ghee. The average yield of ghee-residue is Maximum in direct creamery (DC) method (12%) followed

by about 3.7%yield in creamery butter (CB) and desi butter (DB) method. Keeping quality of all types of Ghee residue

clarified at 120°C is 3months. Its shelf life can further be increased to more than 4months by pressing it in cake form.

Physical attributes: Ghee residue is moist brownish sediment. On average, particle diameter of ghee residue is about

115 µ and density is 1.14 g/cm3 [vedyadhara.ignou.ac.in/wiki/images/ BPVI-16-Block_4-Unit-14.pd. Unit 14

Buttermilk and Ghee Residue].Soluble nitrogen content of ghee-residue prepared from cream or creamery butter

decreases with heating time. This decrease is due to the denaturation of the proteins. Main sugars in ghee-residue

prepared at 120oC are lactose, galactose and glucose. As the period of heating is increased, the lactose content of ghee-

residue decreases with a corresponding increase in galactose and glucose content. Ghee-residue is a rich source of

natural antioxidants and its antioxidant properties are due to its constituents affected by various technological

parameters. The overall antioxidant properties are due to both lipid and non-lipid constituents

[vedyadhara.ignou.ac.in/wiki/images/ BPVI-16-Block_4-Unit-14.pd.. Unit 14 Buttermilk and Ghee Residue].

Since laccases oxidize phenolic compounds (Pcs), they may also induce its production. Phenolic compounds are a

diverse group of chemicals (over 8000 currently known) [7], produced as secondary metabolites by most plants, as

natural deterrents to grazing animals.

International Journal of Plant, Animal and Environmental Sciences Page: 7

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

Pcs get incorporated into milk and milk products. Pcs are found in considerable amounts in ruminant milk (mg/Kg) and

it was also found to be present in Gee residue [5]. Ghee residue, by virtue of its chemical composition, nutritional

quality, physical characteristics, bulk of production and long shelf life permitting its collection and centralized

handling has great potential and is more amenable to exploit its utilization. Ghee residue can be utilized in a number of

products like chocolate burfi, samosa filling, chapatis etc. However, most dairy plants in India have not been utilizing

ghee residue profitably except for fat extraction. Most of the ghee residue goes to waste

[vedyadhara.ignou.ac.in/wiki/images/BPVI-16-Block_4-Unit-14.pd.Unit14 Buttermilk and Ghee Residue].

In order to utilize whole ghee residue commercially it can be used as an important component in the production

medium for laccases production to put it in the market.

Effect of temperature on enzyme activity in WBG (Coll et al.medium) by P.cinnabarinus

120

100

80

U/ml/min

60

40

20

0`C 10`C 20`C 30`C 40`C 50`C 60`C 70`C 80`C 90`C

Temperature

Fig.7: Optimization of temperature for enzyme activity

Effect pH on enzyme activity in WBG (Coll et al, medium) by P.cinnabarinus

90

80

70

60

U/ml/min

50

40

30

20

10

pH 3.0 pH 4.0 pH 5.0 pH 6.0 pH 7.0 pH 8.0 pH 9.0

Fig.8: Optimization of pH for enzyme activity

International Journal of Plant, Animal and Environmental Sciences Page: 8

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

Effect of s ubs trate concentration on enzyme activity

130

120

110

100

90

U/ml/min

80

70

60

50

40

0.1% 0.2% 0.3% 0.4% 0.5%

S ubstrate Concentration

Fig.9: Optimization of substrate concentration for enzyme activity

As the concentration of the substrate (Guaiacol) increases, the units of enzyme activity also increases (Fig.9).

Because of the versatility of potential substrates, laccases are highly interesting as novel biocatalysts in various

industrial processes. One of the limitations to the large-scale application of the enzyme is the lack of capacity to

produce large volumes of highly active enzyme. Thus, efforts have been made in order to achieve cheap

overproduction of laccase by using the fungus P. cinnabarinus. To obtain more robust, active and less expensive

enzymes, this organism is under the process of strain improvement capable of producing high concentrations and then

optimization of conditions for laccase production.

ACKNOWLEDGEMENT

The authors are thankful to Prof M.A.Singara charya, Department of Microbiology, Kakatiya University for providing

the fungal cultures and a moral support during the tenure of the work

REFERENCES

[1] Airong Li, Yue Zhu, Liang Xu, Wenqing Zhu and Tian 2008. Comparative study on the determination of assay

for laccase of Trametes sp. AJBR 2 (8) 181-183.

[2] A. I. Vogel, A. R. Tatchell, B. S.Furnis, A. J. Hannaford and P. W. G. Smith 2007. Text book of practical

organic chemistry, 5th edition, Prentice Hall Publisher: pg.976.

[3] Arzu (Taspinar) unal, Nazif kolankaya 2001. Dechlorination of Bleached Kraft Pulp by Laccase Enzyme

Produced from Some White-Rot Fungi. Turk J Biol. (25) 67-72.

[4] C. Susana Rodrı´guez and S. Ma. Angeles 2005. Coconut flesh: a novel raw material for laccase production by

Trametes hirsuta under solid-state conditions. Application to Lissamine Green B decolorization. J Food SCI

(71) 2 208-213.

[5] JE O’ Connella, P. F. Foxa 2001. Significance and application of phenolic compounds in the production and

quality of milk and dairy products: a review. INT DAIRY J. (11)103- 120.

International Journal of Plant, Animal and Environmental Sciences Page: 9

Available online at www.ijpaes.com

Rasheeda Khanam and R.Gyana Prasuna Copyrights@2012 IJPAES ISSN 2231-4490

[6] K.Tukayi, S. N.Gibson, M. G.George and B.Stephanie 2010. Potential applications of laccases-mediated

coupling and grafting reactions: A review. Enzyme Microb. 195-208.

[7] L.Bravo 1998. Polyphenols: chemistry, dietary sources, metabolism, and nutritional significance. Lead Review

Article; NUTR REV 56(11), 317-33.

[8] M. Kuo 2010. Pycnoporus cinnabarinus. Retrieved from the MushroomExpert.Com

Web site: http://www.mushroomexpert.com/pycnoporus_cinnabarinus.html

[9] O. V. Morozova, G. P. Shumakovich, M. A. Gorbacheva, S. V. Shleev, and A. I. Yaropolov 2007. “Blue”

Laccases. Biokhimiya (72) 10 1396-1412.

[10] P.Karst 2010. Public Description of Pycnoporus cinnabarinus (Jacq.). Mushroom Observer.

[11] P.Sathiya moorthi, S.Periyar selvam, A.Sasikalaveni, K.Murugesan and P.T.Kalaichelvan 2007. Decolorization

of textile dyes and their effluents using white rot fungi. Afr J Biotechnol 6 (4) 424-429.

[12] R..Paranthaman, R..Vidyalakshmi, J.Indhumathi, and K.Singaravadivel 2009. Biosynthesis of Tannase and

Simultaneous Determination of Phenolic Compounds in Aspergillus niger Fermented Paddy Straw by HPLC.

GJBB 4 (2): 93-97.

[13] S. S. Desai and C. Nityanand 2011. Microbial laccases and their applications: A review. Asian J. Biotechnol. 3:

98-124.

[14] V. Buddolla, M.Subhosh Chandra, H.Pallavi and B.Rajasekhar Reddy 2008. Screening and assessment of

laccase producing fungi isolated from different environmental samples. Afr J Biotechnol. 7 (8) 1129- 1133.

[15] V. K. Vaidyanathan, D. K.Selvaraj, P.Premkumar and S.Subramanian 2011. Screening and induction of laccase

activity in fungal species and its application in dye decolorization. AFR J MICROBIOL RES. 5(11) 1261-

1267.

International Journal of Plant, Animal and Environmental Sciences Page: 10

Available online at www.ijpaes.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Overhaul s51 s53 s54Document29 pagesOverhaul s51 s53 s54YadiNo ratings yet

- TEST QUESTIONS IN SCIENCE 9 MELC-BASED (Analysis, Application and Evaluation)Document26 pagesTEST QUESTIONS IN SCIENCE 9 MELC-BASED (Analysis, Application and Evaluation)mayette100% (1)

- Exporters Directory October 2019Document85 pagesExporters Directory October 2019Sun INsurance Agency0% (1)

- Buttermilk and Ghee Residue - PDFDocument13 pagesButtermilk and Ghee Residue - PDFSun INsurance AgencyNo ratings yet

- Hort 351 Lecture 3Document21 pagesHort 351 Lecture 3Sun INsurance AgencyNo ratings yet

- Horticultural Zones of IndiaDocument21 pagesHorticultural Zones of IndiaSun INsurance AgencyNo ratings yet

- Revision MCQ - KinematicsDocument2 pagesRevision MCQ - Kinematicsgaya8404No ratings yet

- Voorbeeldtentamen Wiskunde B 1 - ENDocument9 pagesVoorbeeldtentamen Wiskunde B 1 - ENRishika GoswamiNo ratings yet

- Accomplishment Report Week 2Document7 pagesAccomplishment Report Week 2steph curryNo ratings yet

- Sources of Stem CellsDocument13 pagesSources of Stem CellsAnshi AroraNo ratings yet

- Nama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071Document11 pagesNama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071shalsaNo ratings yet

- Pre-Flight Inspection R22Document73 pagesPre-Flight Inspection R22Ann LechatNo ratings yet

- Presentation - Slum Department 21st Sept 2010Document42 pagesPresentation - Slum Department 21st Sept 2010Nupur Bhadra100% (1)

- Dpcode Vol 3Document30 pagesDpcode Vol 3Murali VNo ratings yet

- 1SDA066549R1 A2b 250 TMF 160 1600 3p F FDocument3 pages1SDA066549R1 A2b 250 TMF 160 1600 3p F FkjushnNo ratings yet

- Baaladhi Deepthanadhi Lajitadhi SayanadhiDocument4 pagesBaaladhi Deepthanadhi Lajitadhi SayanadhiPeter NovakNo ratings yet

- Red Box Hack 2Document22 pagesRed Box Hack 2jgregors8683No ratings yet

- GRAVITY - by Hobie Thompson and Sarah HavernDocument2 pagesGRAVITY - by Hobie Thompson and Sarah HavernJohn OsborneNo ratings yet

- Hearing Is BelievingDocument1 pageHearing Is BelievingAntonioPalloneNo ratings yet

- ST Cecilia CLASSICAL GUITAR Syllabus: Performance ExaminationDocument16 pagesST Cecilia CLASSICAL GUITAR Syllabus: Performance ExaminationRRodas BulejeNo ratings yet

- B02. Junior Engineer MechanicalDocument115 pagesB02. Junior Engineer MechanicalRafay MohiuddinNo ratings yet

- LCA QuestionsDocument2 pagesLCA QuestionsJason HomNo ratings yet

- Cobas C 311 Analyzer: Operator's Manual Software Version 01-04Document590 pagesCobas C 311 Analyzer: Operator's Manual Software Version 01-04khoangsachNo ratings yet

- Eaton Lambert SyndromeDocument8 pagesEaton Lambert Syndromeutami ridaNo ratings yet

- Blood Sucking Flies1Document21 pagesBlood Sucking Flies1Softlens GriyaNo ratings yet

- Nega Bizuye To New Cobble RoadDocument36 pagesNega Bizuye To New Cobble RoadAsmerom MosinehNo ratings yet

- LogicDocument32 pagesLogicBharat Pal SinghNo ratings yet

- ENF204 Microbiology and Parasitology Credits: In-Class Hours: Lab/Clinical: LevelDocument5 pagesENF204 Microbiology and Parasitology Credits: In-Class Hours: Lab/Clinical: LevelamieNo ratings yet

- 6 - Newton's Laws of Motion-Exercises Module-1Document17 pages6 - Newton's Laws of Motion-Exercises Module-1Raju SinghNo ratings yet

- Otoacoustic Emissions From MedscapeDocument5 pagesOtoacoustic Emissions From MedscapeMin-Joo Esther ParkNo ratings yet

- Rain Water Calculation (300mmh)Document6 pagesRain Water Calculation (300mmh)MechanicalLatestNo ratings yet

- Estimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Document41 pagesEstimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Anonymous 7yN43wjl100% (1)

- Oro-Antral CommunicationDocument65 pagesOro-Antral CommunicationNadila RNo ratings yet

- Cisco. (2016)Document5 pagesCisco. (2016)Alga GermanottaNo ratings yet