Professional Documents

Culture Documents

PrEN 13474 2 99 Glass in BLDG Design For Uniformly Dist Loads

PrEN 13474 2 99 Glass in BLDG Design For Uniformly Dist Loads

Uploaded by

hisamberg0 ratings0% found this document useful (0 votes)

5 views54 pagesOriginal Title

PrEN 13474 2 99 Glass in Bldg Design for Uniformly Dist Loads

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

5 views54 pagesPrEN 13474 2 99 Glass in BLDG Design For Uniformly Dist Loads

PrEN 13474 2 99 Glass in BLDG Design For Uniformly Dist Loads

Uploaded by

hisambergCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 54

@

a

DRAFT

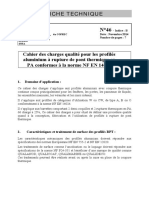

EUROPEAN STANDARD prEN 13474-2

NORME EUROPEENNE

EUROPAISCHE NORM February 2000

tos

English version

Glass in building - Design of glass panes - Part 2: Design for

uniformly distributed loads

Verre dens la construction = Conception des vtrages = Glas im Bauwosen - Bomessung von Glasschelbon - Te 2:

Partie 2: Calcul des chatges unifornémentrepartis ‘Bemessung fr gleichnaig vorolte Bolastungen

“This drat Euopean Standard is submited to CEN members for enquiry. has been drawn up by the Technical Committee CEN/TC 123.

It this draft becomes a European Standard, CEN members are bound to comply with he CEN/CENELEG intemal Regulations which

ipoate the condtions for ging thls European Standard te satus ofa national standard without any alteration,

“This draft European Standard was established by CEN In tee oficial versions (English, French, German). version in any other language

‘race by vensloton under the responsibly of a CEN member Int is own language and nated to the Cental Secretariat has the samme

‘slatus as the oficial versions.

CEN members are the natonal standards bodes of Ausiia, Belgium, Czech Repubéc, Denmark, Fidand, France, Germany, Greece,

foeland, eland aly, Luxembourg, Nethotands, Norway, Portugal, Spain, Sweden, Switzortand and Unted Kingdom,

\Waming : This document is nota European Standard. tis dstibuted for review and comments. It is subjoct to change without notice and

shall net be refered to as a Europoan Standard.

EUROPEAN COMMIFTEE FOR STANDARDIZATION

COMITE EUROPEEN DE NORMALISATION

EUROPAISCHES KOMITEE FOR NORMUNG

Central Secretarlat:rue de Stassart, 868-1050 Brussels

©2000 CEN Al rights of explottation in any form and by any means reserved Rt, No. prEN 13474-2:2000 E

‘worldwide for CEN national Members.

00/103131DC

Page 2

PEN 13474-2:2000

Contents

Foreword

Introduction

1 Scope

2 Normative references

3. Definitions

4° Symbols

5 Design principles

6 Design of monolithic glass panes

7 Design of laminated glass panes

8 Design of insulating glass units

Annex A (normative) Glass edge support

Annex B (normative) Rectangular glass panes

Annex C (normative) Triangular and circular glass panes

Annex D (informative) Glass panes with other shape formats

Annex E (informative) Calculation procedure for stress

Annex F (normative) Effective thickness and shear transfer coefficient for laminated

glass

Annex G (normative) Procedure for calculating stresses and deflections of fnsulating

8lass units which are not fully supported along all edges.

Annex H (informative) Calculation examples

00103131Dc

Page 3

prEN 13474-2:2000

Foreword

This draft European Standard has been prepared by the Technical Committee CEN/TC 129

“Glass in Building’, the secretariat of which is held by IBN.

CEN/TC 129/WG 8 ‘Mechanical Strength’ prepared the draft ‘Glass in building - Design of

glass panes - Part 2: Design for uniformly distributed loads’.

CEN/TC 129 has decided to submit Part 2 of this draft European Standard to CEN enquiry.

00/103131DC

Page 4

PrEN 13474-2:2000

Introduction

‘The basis of design for glass is given in prEN 13474 — 1

On the basis of the theoretical design model, a practicable design method is given in this Part

of this Standard with the assumption of fixed values for most of the parameters. This is

effective for glass panes which are loaded perpendicularly to the orientation of the plane of

the glass pane by uniform loading such as self-weight, wind, snow and climatic actions and

therefore are defined as static plates.

1 Scope

‘This European standard specifies a method to calculate the thickness of flat glass panes

required to resist uniformly distributed actions (e.g. self-weight, wind and snow loads) acting

normal to the glass pane.

Particular solutions are given for

rectangular glass panes which are simply supported on four, three or two opposite edges;

© right-angled triangular and isosceles triangular glass panes which are simply supported on

three edges; and

«circular glass panes which are simply supported at the edge.

For other triangular and for trapezoidal glass panes approximate equations are provided,

Effects acting in the plane of the glass pane (e.g. the pane is used as a structural element) are

not covered by this part of the standard.

2 Normative references

‘This European Standard incorporates by dated or undated reference, provisions from other

publications. These normative references are cited at the appropriate places in the text and

the publications are listed hereafter. For dated references, subsequent amendments to be

revisions of any of these publications apply to this European Standard only when incorporated

in it by amendment or revision. For undated references, the latest edition of the publication

referred to applies.

ENS72. Glass in building - Basic glass products

prEN 1279 Glass in building - Insulating glass units

EN 1748-1 Glass in building - Borosilicate glass

EN 1748-2 Glass in building - Glass ceramics

prEN 1863 Glass in building - Heat-strengthened glass

prEN 12150 Glass in building - Thermally toughened safety glass

prEN 12337 Glass in building - Chemical strengthened glass

BN 12543-2 Glass in building - Laminated safety glass

BN 12543-3 Glass in building - Laminated glass

00103131DC

Page 5

prEN 13474-2:2000

BIEN oo Glass in building - Thermally toughened borosilicate safety glass

pIEN ..... Glass in building - Heat strengthened borosilicate glass

DIBN Glass in building - Heat soaked thermally toughened safety glass

ENV 1991- Basis of design and actions on structures - Basis of design

ENV 1991-2-1Basis of design and actions on structures - Densities, self-weight, imposed

loads"

ENV 1991-2-3Basis of design and actions on structures - Snow loads

ENV 1991-2-4Basis of design and actions on structures - Wind actions

prEN 1288-1 Determination of bending strength of glass - Introduction to testing

glass

prEN 1288-2 Determination of bending strength of glass - Coaxial double ring test on

flat specimens with large test surface areas

prEN 1288-3 Determination of bending strength of glass - Test with specimens

supported at two points (four point bending)

prEN 1288-4 Determination of bending strength of glass - Coaxial double ring test on

flat specimens with small test surface areas

3 Definitions

Flat glass pane: A pane which has not been given a specific curvature during manufacture.

Curved glass pane: A pane which has been given a specific curvature during manufacture.

Slightly curved glass pane: A curved glass pane whose crown height is not greater than

1/100 of the length of the curved side (see figure 1).

1/100

peo ee

L

Figure 1. Limit of slightly curved glass

Simply supported edge: An edge of a glass pane which has been given continuous support,

which is free to rotate and free to move in plane, but which is held down at the comers.

Vertical glazing: Glazed installations which are vertical, or within 15° cither side of vertical

(ie. have a slope 2 75°).

00/403181DC

Page 6

PEN 13474-2:2000

Effective thickness: The thickness used in calculations for laminated glass, which, when

used in stress or deflection formulae appropriate for monolithic glass, results in a sufficiently

accurate value to describe the deflection of the laminated glass or the stress in the individual

plies of glass in the laminated glass.

4 Symbols

Area of the uniformly stressed glass pane with the dimensions a and b

A dimension of a glass pane

Characteristic length of an insulating glass unit

A dimension of a glass pane

Volume coefficient of an insulating glass unit

Relative stiffiness of the outer pane of a double glazed insulating glass unit

Relative stiffness of the inner pane of a double glazed insulating glass unit

Young's modulus

Note. For soda-timesilicate glast, E= 7010! Ninn?

Insulating unit factor

Poisson number

Note. For sodactime-siticate glass, = 0,23

ea Allowable stress

Fa Design load

Gxj Permanent action

7%) Partial factor for permanent actions

LF Shear transfer coefficient for laminated glass

h Thickness of the glass

4, Thickness of the outer glass pane in a double glazed insulating glass unit

tz Thickness of the inner glass pane in a double glazed insulating glass unit

4 Thickness of glass ply number i in laminated glass

fy Thickness of glass ply number j in laminated glass

fete _ Bffective thickness of laminated glass for calculation of stress

‘rete Effective thickness of laminated glass for calculation of deflection

sy hay kay ks

‘Constants used in the equations ee

ky Size factor (see also prEN 13474-1)

L —_Acdimension of a glass pane

A Aspect ratio Bla or alb

Poo _ Isochore pressure due to climatic effects

Pu Isochore pressure due to altitude effects

p* Normalised load

Qxs Variable action

5 Cavity width of an insulating glass unit

Gare Calculated stress

Effective stress (comparison stress)

ofa Normalised effective stress

ox Resistant tensile bending stress for a given fracture probability

t Action duration

w Deflection of the pane

&

EO MHESeeges

00103131Dc.

Page 7

prEN 13474-2:2000

Wmax Maximum deflection of the pane

wa Allowable deflection

w* Normalised deflection

V Volume change due to deflection of a pane (in an insulating glass unit)

5 Design principles

5.1 General

This clause covers the principles of the design procedure which are common to all glass

types. Clauses 6, 7 and 8 give specific information which is relevant to the design of

monolithic glass panes, laminated glass panes and insulating glass units respectively.

‘The following items are fundamental to the design process:

shape of the pane;

edge support of the pane;

design loads;

calculated stress and / or deflection of the pane;

determination of the allowable stress and deflection;

comparison of the calculated and allowable stresses and deflections.

5.2 Shape of glass panes

‘This method is applicable to flat glass panes. However, for the loading conditions under

consideration, a slightly curved glass pane can be considered as a flat glass pane.

Rectangular panes, circular panes, right angled triangular panes and isosceles triangular panes

can be dealt with accurately. Other shapes are dealt with by approximation in this Part of this

Standard.

5.3 Edge support of the glass pane

‘The support conditions for the glass edges are important for the calculation of the stress and

the deflection of glass panes. The solutions given in this Part of this Standard are based on

the glass panes having simply supported edges (see 3.4). Conventional glazing in a frame by

means of gaskets or sealing with clastic materials is assumed to produce simply supported

edges.

Note. A linear butt joint (see figure 2) between the edges of glass panes does not effectively support

either pane. The part of the edge sealed by such a joint should be considered as unsupported and the

pane designed accordingly.

ead ae

Figure 2. Linear butt joint between two glass panes

00/1031340C

Page 8

prEN 13474-2:2000

‘An edge where the support is not completely continuous, but is supported for at least 90% of

the length of the edge and at the comers ofthat edge, may also be designed as if its simply

supported.

A simply supported edge assumes a sufficient stiffness of the supporting element (frame or

Blazing ar) in relation to the rigidity of the gluss panes. A means of obtaining «

Tecommended minimum stiffness for a supporting element, considered over the length 1. of

the glass pane, is to allow a deflection of 1/200 or less, when the glass is exposed to self-

weight, wind and snow loads not exceeding 2 kN/m? in total. However, for special

applications (e.g. aquaria bases or floors) or when the design load exceeds 2 kN/m*, the

stiffness may need to be increased. Annex A describes a method of calculating the necessary

stiffness of the supporting element. The stiffness of the supporting element shall be

determined without taking account ofthe stiffness ofthe glass pane or insulating glass unit.

5.4 Design loads

The design value of the actions (the design load), Fa, shall be calculated in accordance with

prEN 13474-1 (Part 1 of this Standard).

Note, Equations 9.13 and 9.14 for ultimate limit state and 9.19 and 9.20 for serviceability limit state

from EWY 1991-1 shall be used to determine Fz Its intended that Part 1 will be changed to reflece

this.

The calculation formula are given in table 1.

Table 1. Calculation formulae for actions

___One variable action 2 or more variable actions

Ultimate limit state Yr6Gy +150, L7G, +1359 0,

i 7 7

Serviceability limit

Rae teuie DG, + Qu ¥G, +0950,

Z A i

5.5 Calculated stress and / or deflection of the glass pane

5.5.1 General

The tensile sttess in the glass and the deflection of the glass shall be calculated using the

appropriate design load, F, from 5.4.

The method used for the calculation shall be an engineering formula or method appropriate to

the load distribution, the shape of the glass pane and the support conditions (see also

prEN 13474-1),

00103131DC.

ee

Page 9

prEN 13474-2:2000

5.5.2 Rectangular glass panes

‘The method of calculation for rectangular glass panes depends on the support conditions as

follows:

© Four-edge support

In the case of a four-edge supported pane, the effective stress can be calculated according to

linear plate theory, provided the deflection under the design load is lower than the thickness

of the glass pane. If the maximum deflection exceeds the thickness of the glass pane, linear

plate theory overestimates the stresses and deflections. In this case it is recommended that the

effective stress and deflection be calculated using bending theory for large deflections,

Methods are given in Annex B.1.

© Three-edge support

In the case of a three-edge supported pane, the effective stress and maximum deflection can

bbe calculated from linear plate theory. Methods are given in Annex B.2.

© Two-edge support

In the case of a two-edge supported pane, the effective stress and maximum deflection can be

calculated from linear plate theory. Methods are given in Annex B.3.

5.5.3 Triangular and circular glass panes

For linear plate theory, the equations for the stresses and deflections of right-angle triangular

panes and isosceles triangular panes, simply supported on all three edges, are given in

annex C.

For other triangular panes, supported on all three edges, the stresses and deflections can be

estimated by assessing an equivalent circular pane, The method for obtaining the equivalence

is given in Annex C, together with the equations for the stresses and deflections of simply

supported circular panes

5.5.4 Other shapes

For some shapes there are no readily available equations which will allow the calculation of

the stresses and deflections. However, stresses and deflections can be estimated by

approximating the shapes to ones for which calculations are available.

Methods are given in Annex D for the following shapes:

‘+ uapezoidal panes

‘© rectangular panes with one raked edge

* rectangular panes with one arched edge

00/103131DC

5.6 Allowable stresses and deflections

‘The allowable stress and the allowable deflection shall be determined in accordance with

Part | of this standard,

For panes up to 4.0 m” area, the values given in table 2 can be used for the allowable stress,

Note. The allowable stress values in table 2 have been calculated using a ky value of 1.057.

Table 2 Allowable stresses

Gian prea ‘nitrmiy dissuaded duration ot

Gis | aces hor darstan took ‘eda dara ads Permanent ade

ore Wind lou Snov loads, Climatic ads _| Selcweight toads. Alu fonds

Giusare Tint [Servecabiny | Uline ht | Serviceablay ] Climate lant [Sereecboig

fae Tuga te ste lim ie ate Hit sate

rat glass and | annealed 17.0) 307 85 183 a Hs

set gos teal 279 ana iva 320 ny 282

swenpthened

‘hermaly we 807 wi a3 390 eis

toaphenet

‘hemically | 627 1007 aa wy 320 aS

suenptbened

Gramcied gow | heat 178 307 aS isa oa Ths

sweeagtened

‘tel Toi 307 26 we Ta Ws

Panermed | annealed ma Be 67. Te} 30 ae

Test 167) 286 100 168 Ba Tae

seenhened

thenally 83 461 DT Ma 200 wa

toughcoed

‘hemicaly [48,3 Te a7 eas 400 as

tengthenet

Wood | raneraed wind] “9.6 170) a8 BS 36 6a

ile

Tolshed weed] 73.3 Re oF Tk 30 cr

ass

5.7 Comparison of the calculated and allowable stresses and deflections

The calculated siress for the most onerous load condition shall not exceed the allowable

stress:

Geate SS ya

w

Note. Since the allowable stress depends on the duration of the applied loads, the highest

load in numerical terms is not necessarily the most onerous load condition. In order to assess

which is the most onerous condition, the order of calculations given in Annex E is

recommended,

00103131Dc

Page 1

prEN 13474-2:2000

If there is a requirement for limitation of the glass deflection, the maximum deflection

calculated for the most onerous load condition shall not exceed the allowable deflection:

Wax S Wy Q)

6 Design of monolithic glass panes

61 General

‘This clause shall be used to design monolithic glass panes which comply with the following

European Standards:

EN 572-2 Gass in building - Basic glass products — Float glass

EN 572-3 Glass in building - Basic glass products — Polished wired glass

EN572-4 Glass in building - Basic glass products ~ Drawn sheet glass

EN572-5 Glass in building - Basic glass products — Patterned glass

EN572-6 Glass in building - Basic glass products — Patterned wired glass

prBN 1279 Glass in building - Insulating glass units

prBN 1748-1 Glass in building - Borosilicate glass

prEN 1748-2 Glass in building - Glass ceramics

prEN 1863, Glass in building - Heat-strengthened glass

prEN 12150 Glass in building - Thermally toughened safety glass

prEN 12337 Glass in building - Chemical strengthened glass

6.2 Design loads

‘The design loads shall be calculated according to 5.4.

6.3 Calculated stresses and deflections

‘The stresses and deflections shall be calculated according to 5.5.

6.4 Allowable stresses and deflections

The allowable stresses and deflections shall be calculated according to 5.6.

6.5 Comparison of calculated and allowable stresses and deflections

‘The comparison shall be made according to 5.7.

00/1031310C

Page 12

PrEN 13474-2:2000

7 Design of laminated glass panes

7.1 General

This clause shall be used to design laminated glass panes and laminated safety glass panes

which comply with the following European Standards:

prBN 12543-2 Gass in building - Laminated safety glass

prBN 12543-3 Glass in building - Laminated glass

7.2 Effective thickness and shear transfer coefficient

For the design of laminated glass and laminated safety glass, the transfer of shear forces by

different types of interlayer depends on:

~ the duration of the load

- the temperature

‘The effective thickness of a laminated glass pane, for calculation of the stress and the

deflection, and the value for the shear transfer coefficient, are given in Annex F.

7.3 Design loads

The design loads shall be calculated according to 5.4.

7.4 — Calculated stresses and deflections

The stresses and deflections shall be calculated according to 5.5, substituting the appropriate

value of effective thickness of the laminated glass, from annex F, into the formulae for

‘monolithic glass panes given in annexes B, Cand D.

7.5 Allowable stresses and deflections

The allowable stresses and deflections shall be calculated according to 5.6.

7.6 Comparison of calculated and allowable stresses and deflections

‘The comparison shall be made according to 5.7.

00103131

Page 13,

prEN 13474-2:2000

8 Design of insulating glass units

8.1 General

‘This clause shall be used to design insulating glass units which comply with the following

European Standards:

prBN 1279 Glass in building - Insulating glass units

prEN 1279-1 Generalities and dimensional tolerances

prEN 1279-2 Long term test method and requirements on moisture vapour

penetration

prEN 1279-3 Initial type testing on gas filled insulating glass units: gas concentration

and gas leakage rate

prEN 1279-4 Methods of test for the physical attributes of edge seals,

prEN 1279-5 Evaluation of conformity

prEN 1279-6 Factory production control

& Insulating glass units shall be designed to resist the extemal action (e.g. self-weight, snow and

wind) acting normal to the glass. The intemal actions resulting from temperature,

meteorological air pressure and geographical air pressure shall also be considered.

‘The calculation shall be carried out separately for both external and internal actions.

8.2 Shape of insulating glass unit

‘Whilst a flat insulating glass unit can alter its shape due to the actions, it is still designed as a

flat pane.

8.3 Additional calculation parameters for insulating glass units

8.3.1. Stiffness of panes

ee In the case of double glazing, the partition of the extemal loads is determined by the relative

ee stiffness of the panes.

Stiffness of pane I (the outer pane) is:

he

+h

GB)

Stiffness of pane 2 (the inner pane)

4)

00/103131DC

Page 14

PEN 13474-2:2000

8.3.2 Insulating unit factor

Additionally the partition of external loads and the

the insulating unit factor

* of internal loads is determined by

(5)

Where a is a dimension of the unit, as described in Annex B.1 for fectangular panes, or

Annex C for circular panes and various triangular panes, and a* is the characteristic Tength of

the unit:

0,25

shph}

* = 28,9)

a 8, (erie ©

Where ks is obtained from Annex B.1 for rectangular panes, or Annex C for cireular panes

and various rectangular panes.

8.4 Design loads on insulating glass units

8.4.1 External actions

The ultimate limit state design loads shall be determined in accordance with the following

fauations, which are modified from the equations of table 1 to take into account the

interaction of the panes of an insulating glass unit.

For one variable action, Oxi, on the outer pane (pane 1)

‘The design load on pane 1 is:

F,,=(6,+06, [Sre6u #1504 )+0-B)5 D796 0

‘The design load on pane 2 is:

Fy. =( -$)6, L7G +150,, |+(¢5, + 6, WDrGGauj (8)

i 7

00103131DC.

Page 15

prEN 13474-2:2000

} (9)

‘The design load on pane 2 is:

122 #5 Dr aGus 65,48] Bran #150.)

For one variable action, Qx2, on the inner pane (pane 2)

‘The design load on pane 1 is:

Fu = (6, + 88) E 7G Gy +1 #8 ZraGen +150,

For more than one variable action:

‘The design load on pane 1

Fy =(6,+95, {Zre6 +1350,

“(-0(Zro% +1350, (a)

‘The design load on pane 2 is:

Fea (-05{ Erin +1950}

+(96, +8 ( Era +1350, } (a2)

i

8.4.2 Internal actions

The serviceability limit state design loads shall be determined in accordance with the

following equations, which are modified from the equations of table 1 to take into account the

interaction of the panes of an insulating glass unit.

00/103131DC

Page 16

prEN 13474-2.2000

‘The design load on pane | is:

seen :

Fy, =(6, +02) L0G vy + 0,90,

7

+1-9)8) L7G Gry +0902 |[tO(Pyo tO9Peo) ay

j

‘The design load on pane 2 is:

Fa = (1-0), S746, +090,

+(6, +8{ Eau 0,90. |£O(Ping $0,929) aw

i

The isochore pressures, pro for altitude and peo for climate, shall be obtained from

prEN 13474-1.

8.5 — Calculated stresses and deflections

8.5.1 External actions

‘The stresses and deflections shall be calculated according to 5.5.

8.5.2 Internal actions

The serviceability limit state stresses and deflections shall be calculated according to 5.5, &

except when the insulating glass unit is not supported on all edges. The procedure for these“

cases, e.g. three-edge supported or two-edge supported insulating glass units, is given in

Annex G.

2

8.6 Allowable stresses and deflections

The allowable stresses and deflections shall be calculated according to 5.6.

8.7 Comparison of calculated and allowable stresses and deflections

‘The comparison shall be made according to 5.7.

001031310C

ce

&

oes

8.8 Small insulating glass units

Page

prBN 13474-22000

Insulating glass units supported on all edges, for which the conditions in table 3 are valid,

may be used in vertical glazing for a height of installation up to 20 m above ground level,

assuming normal production and installation conditions, without any further calculation.

Table 3: Deemed-to-satisfy conditions for insulating glass units

Property Resinicuion

Glass type Float glass or thermally toughened safety

{elas a

s Lom H =

Surface area of the pane_

Thickness of each pane

Difference in the thickness

Cavity width

amm

s4mm

16mm

External action

‘Altitude difference between production and site

Wind loads only, $ 0,8 KN/m™

500m

00/103131DC

Page 18

PrEN 13474.2:2000

Annex A (normative)

Glass edge support

For special applications and for loads exceeding 2,0 kN/nv, the continuous edge support, as

an important parameter for the calculation of stress and deflection, can only be assumed

subject to the following condition:

Eyl, 2 QUIK (AD

where:

2 Young's modulus of the material of the supporting element

‘Moment of inertia of the supporting construction

Coefficient according to the supported number of panes

Fora pane on one side of the supporting member only

For a pane on both sides of the profile

Length of the supported edge of the glass pane

Stiffness of the glass pane according to equation A2

RODD DSS

IF the supporting member does not have sufficient stiffness, the influence of the deformation

Of the edge support shall be taken into account for the calculation of the stresses of the glass

pane,

00103131Dc.

Pay

prEN 13474-

Annex B (normative)

Rectangular glass panes

B.1__ Four-edge supported glass panes

Of the dimensions a and b of the pane, a shall be taken as the shorter dimension. The aspect

ratio is given by 2=alb.

For practical determination of the stress, the deflection and the change in volume (for the

cavity of insulating glass units), formulae are given as follows:

Maximum tensile stress BI)

Effective stress 82)

W, k af

Deflection hag = hy (B3)

- hE

4

a’ F,

Volume V =k,—-*ab (Ba)

WE

In case of four-edge supported panes, the dimensionless coefficients ky, ka, ka, and ks depend

on the aspect ratio, A, and the normalised load. The values of the coefficients are given in

tables B.1 10 B.4.

a‘ F,

WE

‘The coefficients in tables B.1 to B.4 are valid for a Poisson number in the range 0,20 to 0,24.

Normalised load pe (Bs)

00/103131DC

Page 20

PrEN 13474-2:2000

‘Table B.1; Coefficient for calculation of the maximum stress

LOO F300 P00 FS yy

[0.188 TOS | ates

[0208 | 0703 | ike

0.210 | tive

Azul | SHEE 0

Lo | 0272 | a2 | 26s oss |

09 | 0428 [6320 | vid

OS P0383 | oats [aies |

joe? “ones 21

0 029

0.590 [03 0.268

0.665 | 0.683 0.292

0,722 | 0714 |

0.349 | 0.337 | 0,423

0747 | 0.746 [0.561 | |

[0.750 | 0.750_| . 0,748 | 0.746 | 0739

0,750_| 0,750 | 0.750 ; 0,750 [-0,750

‘Table B.2: Coefficient , for calculation of the effective stress

10 [20 1oo_| 200 |" 300 [300

0,246 | 0.235 0,164 | 0,146 0437 | 0126

0,279 | 0.259 0174 | 0,156 | 0,147 {| 0135

[0.323 | 0,292 0.216 | 0,186 | 0,168 [0,159 | 0.147

0,398 E 0.330 0.237 | 6. | 0.183 | 0.173

0,463 0432_| 0, 0,267 | 0,220 [0,201 OA9L

0,527 0.495 [0 0.312 | 0,241 | 0,222 | 0.212

0,588 | 0581 0512,

0.639 | 0,637, 0,602 |

0,678 | 0.677 [0.676 | 0.672

0,383 | 0.281 | 0,247 [0.236

0,500 |” 0,384" [0,278 [0.265

0,644 | 0.577 [0,463 | 0.390

— 0.1 [0,699] 0,699 | 0.699 | 0,699 | 0.699] 0.698 | 0,697 |0,692 | 0,683

0 | 0,699 T 0,699 | 0,699 |” 0,699 [0,699 | 0,698 | 0,698 | 0,698 | 0.608

Table B.3: Coefficient k, for calculation of the maximum deflection eS

3 4 50, 100 _] 200

0.046 | 0,032 | 0.024_| 0,017

0.036 | 0,027 [0.019 | 0. L.

{0,051 |G.041-10,030_| 0.021 [oars [on

0,059 [0,048 [0.035 | 0.920 [0.016

0.071 [0,057 [0 2: 0 0,019)

0.086 | 0.070 |"'0.051_|0,036 {0.030 | 0.023

{0.083

0 T0,099- |

0.

0.126 | 0.105 | 0.08%" [0.065 | 0,046 | 0.03% | 0,030_

_[atao ] oO 0.138 [0, 0,088 | 0.064 | 0.053] 0.041

0147 | 0.145 [0.140 [0.126 | 0.101 i

0.148 | 0, “0. GNA | Otas | 047 | Oa [0.143 [0.136

Olas 014s | 0.148 0,148 | 0,148 | 0,148 | 0,148 | 0,148 | 0,148 |

00/103131DC

Page 21

prEN 13474.2:2000

‘Table B.4: Coefficient ks for calculation of the volume change

UIs.

sf it

| 10.) oo [odie | curs i [Bios

| end | aga | 6.023 | 0.032 0,007 | 0,006

! I 029") aa2s | 0.026

Vo. 35 | 0.035 |

boos O42 | OAH? |

0.049

0,061

0074

0,031

0.042,

062,

0.050

0,058 | 0

(066

0,020

0.08

[0.086 _ 0,086 [0.085 | 0.084 | 0.081 | 0.077 [tes

Be [0.095 | 0,095 | 0,095 | 0,095 | 0,095’ [0,095 | 0,095 [0.095

ee

B.2_—_Three-edge supported panes

a

© } +

Figure B1: Three-edge supported rectangular panes

For practical determination of the stress and the deflection, formulae are given as follows:

2

a

Maximum tensile stress nx = 2 Fy, (B6)

Effective stress (BT)

00/103131DC

Page 22

prEN 13474-2:2000

Deflection w, (B8)

__| 0.165

0.167

Note. This table is approximate. The correct values will be available after enquiry.

B3 — Two-edge supported panes

For two opposite edges supported, the length a is the free span, as shown in figure B.2

Figure B.2: Rectangular panes supported on two opposite edges

For practical determination of the stress and the deflection, formulae are given as follows:

2

a

Maximum tensile stress = 0,75—~ F,

9)

00/103131DC

prEN 13474-2:2000

2

o,= 0,699, F, 10)

i

Effective stress

Deflection Warne (Bn)

‘The equations B9 to BLL are valid for a Poisson number in the range 0,20 to 0,24.

00/103131DC

Page 24

prEN 13474-2:2000

Annex C (normative)

ngular and circular glass panes

C1 Isosceles triangular panes

‘The triangle is described by dimensions a and b as shown

given by A = bla.

Figure C.1: Isosceles triangular pane

For practical determination of the maximum stress, the deflection and the change in volume

(for ue cavity of insulating glass units), formulae are given as Follows:

2

a

Maximum tensile stress Gon =k,

4

a F,

Deflection Wann = ky

WE

4

a F,

Volume V =k,——ab

WE

in figure C.1, The aspect ratio is

(cn

(C2)

(3)

00/1031310¢

Page 25

prEN 13474-2:2000

The dimensionless coefficients 1. ks, and ks depend on the aspect ratio, 4. The values of the

coefficients for linear deflection theory are given in table C.1

‘The coefficients in table C.1 are valid for a Poisson number in the range 0,20 to 0,24, They

can be interpreted linearly.

Table C.1: Coefficients for isosceles triangular panes

[n.o186 = ~ 0.000003 7

Fo.0200 0.0002, 0,000.10 ae

[nos (0.0001 {,000026

10 © o.0007

0.0483 9.0010

[04 0.0014

LoisostHite 00624

[0.60

[0.70 0.0869

0.80 __ | 0.0966,

O87 10.

0,90 — {0.1170 — {0.0071

1,00 0.1320 __| 0.0086

1.50 __f 0.2010 0.0169

2.00) 0.2550 __ [0.0249

2.50 0.3000 0.0318

3,00 0,3350 0.0391

C2 Right-angled triangular panes

‘The triangle is described by dimensions a and b, where a is the shortest side, as shown in

figure C.2. The aspect ratio is given by 2 = bla.

Figure C.2: Right-angled triangular pane

00/103131DC

Page 26

prEN 13474-2:2000

For practical determination of the maximum stress, the deflection and the change in volume

(for the cavity of insulating glass units), formulae are given as follows:

Maximum tensile stress (cay

Deflection (cs)

Volume (C6)

‘The dimensionless coefficients ky, ka, and ks depend on the aspect ratio, 2. The values of the

coefficients for linear deflection theory are given in table C.2.

The coefficients in table C.2 are valid for a Poisson number in the range 0,20 to 0,24. ‘They

can be interpreted linearly.

Table C.2: Coefficients for right-angled triangular panes

ke ky

0.00:

[0.0107 3

0.0143 0.0035

0.0175 0,0049 4

0.0197 0,0059

0,0208 0.0064

0.0242 is

0.0315

0.0383

10,0440

0.0491

0,0583

Looo 0,0645

C3 Other triangular panes

Other triangular glass panes than those treated in C.1 and C.2, and with all three angles being

at Teast 30°, can be assessed by substituting an equivalent circlular pane.

The triangle is described by dimensions and L, where b is the shortest side, as shown in

figure C3.

00/103131DC.

Pa

Z

Page 27

prEN (3474-2:2000

1

Figure C.3: Equivalent circular pane

For a uniformly distributed load, the diameter, a, shall be determined as follows:

a=0,70L

C4 Circular panes

For practical determination of the maximum stress, the deflection and the change in volume

(for the cavity of insulating glass units), formulae are given as follows:

2

Maximum tensile stress On = 0,303 ie F, cm

4

Deflection | Woes = oar s)

a’ F,

Volume V =0,0298 e ie 9

‘The equations C9 to C11 are valid for a Poisson number in the range 0,20 to 0,24.

00/103131DC

Page 2

PEN 13474-22000

Annex D (informative)

Glass panes with other shape formats

D.1_— Trapezoidal glass panes

For trapezoidal glass panes supported on all edges, the trapezium can be wansformed into a

rectangular pane (see Annex B.1 for calculation formulae) as shown in figure D.1

are(L-a)

Figure D1: Transformation of a trapezoidal pane into an equivalent rectangular pane

‘The coefficient & is given in table D.1.

Table D.1: Dimensionless coefficients, E

&

ue

(aya é

0,50 0,64

i 0,75 is 0,55

1,0 eee eee 0,49

1,16 gece (ee 046

15 mi 0.43 i

2.0, 048

00/103131DC.

Page 29

prEN 13474-2:2000

€ D.2__ Rectangular glass panes with one raked edge

Por raked glass panes supported on all edges, the shape can be transformed into @ rectangular

pane (see Annex B.1 for calculation formulae) as shown in figure D.2

Figure D.2: Raked glass pane

D.3__ Rectangular glass panes with one arched edge

For arched glass panes supported on all edges, the shape can be transformed into a rectangular

pane (see Annex B.1 for calculation formulae) as shown in figure D.3.

&

0,85410,152 a

Figure D3: Arched glass pane

00/1031310C

Page 30

PrEN 13474-2:2000

Dal Irregular four sided panes with two opposite edges parallel

For glass panes supported on all edges, the shape can be transformed into @ Fectangular pane

(see Annex B.1 for calculation formulae) as shown in figure D.4

ce

Figure D4: Irregular glass pane with two parallel sides

00/103131Dc

&

ae

Se

Page 31

prEN 13474-2:2000

Annex E (informative)

Calculation procedure for stress

‘The calculation should proceed in the following order. If, at any stage, the calculated stress

exceeds the allowable stress, the calculation should be restarted using a different glass type

and/or thickness.

E.1 Permanent loads except altitude

If there are any permanent loads (except any altitude internal load on an insulating glass unit):

Determine the calculated stress for any self-weight load combined with any other permanent

loads (excluding any altitude internal load on an insulating glass unit). Compare this with the

ultimate limit state allowable stress for permanent loads.

E.2 Altitude loads

If there are any altitude loads:

Determine the calculated stress for the altitude loads combined with any self-weight loads and

any other permanent loads. Compare this with the serviceability limit state allowable stress

for permanent loads.

£3 Snow loads

If there are any snow loads or other medium duration loads (except any climatic internal load

on an insulating glass unit):

Determine the calculated stress for the combination of any snow loads and other medium

duration loads, together with any self-weight loads and other permanent loads (excluding any

internal loads on an insulating glass unit). Compare this with the ultimate limit state

allowable stress for medium duration loads.

E.4 Climatic loads

If there are any climatic loads:

Determine thé calculated stress for the combination of any climatic loads, snow loads and

other medium duration loads, together with any self-weight loads, altitude loads and other

permanent loads. Compare this with the serviceability limit state allowable stress for medium

duration loads.

00/103131DC

Page 32

prEN 13474-2:2000

E.5. Wind loads or other short duration loads

If there are any wind loads and other short duration loads:

(H Determine the calculated stress for the combination of all Loads (excluding any internal

loads on an insulating glass unit). Compare this with the ultimate limit state allowable stress

for short duration loads.

(ii) For an insulating glass unit, determine the calculated stress for the combination of any

internal loads with all other loads. Compare this with the serviceability limit state allowable

stress for short duration loads.

00/103131DC

&

Page 33

prBN 13474-2:2000

Annex F (normative)

Effective thickness and shear transfer coefficient for laminated glass

F.1 Shear transfer coefficient,

“The relative effectiveness of the interlayer in its ability to transfer shear forces is described for

laminated glass by a shear transfer coefficient according to table F.1

‘Table F.1 Shear transfer coefficients for the interlayers of laminated glass and

laminated safety glass

Type of glass ~__ Shear transfer coefficient for

Short duration actions, e.g. wind Other actions

Laminated glass 0 i 0

Laminated safety glass 1 Ee 0

F2 Effective thickness

If the shear stress transfer coefficient is 1, then, then the effective thicknesses for calculating

both the stress and deflection is:

Negig = begin = DA eb

If the shear stress transfer coefficient is 0, then, then the effective thicknesses for calculating

deflection is:

(F2)

(3)

Note. The stress calculation normally needs only o be performed for the thickest pane, unless there

are different types of glass in the laminate.

00/1031310C

Page 34

PrEN 13474-2:2000

Annex G (normative)

Procedure for calculating stresses and deflections of insulating glass units which are not

fully supported along all edges.

While the effets of external actions on insulating glass units depends on the physical support

given by the supporting members or frame, the intemal actions are reacted from one pare to

the other through the hermetic seal, independently from the type of supporting member. As a

result the effects of internal actions shall be calculated assuming all edges of the glass panes

are fully supported.

In order to calculate the combined effects of external and internal actions on insulating glass

units which are not supported on all edges it is necessary to reconsider the equations 13 and

14 from 8.4.2.

‘The following procedure is shown for equation 13. The treatment of equation 14 is similar,

‘The design load shall be separated into two parts:

F,

£648, [ E764 +090,

i

+(-6)5| Dr Gnu, +0.90,. cn

i

Fass = $B +09 Peo) «@

‘The design load from equation G1 shall then be used in the formula appropriate for the

Support condition and shape of the insulating glass unit, to obtain that part of the effects of the

actions (i. stress or deflection) due to the extemal actions. For example, for calculating the

stress, ott, for a three-edge supported rectangular insulating glass unit, the formulae from

‘Annex B.2 shall be used.

The design load from equation G2 shall then be used in the formula appropriate for full edge

Support condition and shape of the insulating glass unit, to obtain that part of the effects of the

actions (i.c. stress or deflection) due to the internal actions. For example, for calculating the

Stress, Gia, for a three-edge supported rectangular insulating glass unit, the formulae for a

four-edge supported rectangular pane from Annex B.1 shall be used,

‘The two results shall then be added to obtain the total of the effects of the actions. For

example, for calculating the stre

Feale = Ceatexe + Feet

00/1031310C

Page 35

prEN 13474-2:2000

Annex H (informative)

Calculation examples

H.1 Single glazing

Vertical pane of single glazed 15 mm float glass, 1400 mm wide x 2000 mm high, supported

only at the top and bottom, subjected to a wind load of 0,9 kN/m?

A=1,4x2,0= 2,8 m?

From prEN 13474-1:

k, = AM 32,89 = 1,042

Fox

Yuka

Yq, =0,72X a —— x 1,0 = 17,3 Nimm?

ak

Fora = Ron 1,8x1,042

From table 1:

For ultimate limit state:

F,= L6G +1,50,, =1,35x0+1,5 0,9 = 1,35 kNim?

i

= 1350 Nim?

For serviceability limit state:

Fy =D Gy + Qy, =0+0,9 = 0,9 enim?

ij

= 900 N/m?

From equation B10:

; :

oy = 0,699, F, = 0,699x 22, 1350 =16,8 Winn? (4172

h 15,0

From equation B11:

a‘ F, 2,0 x 2000? 900

= 0148-4 = 0,148 x = x ——. = 9,0 mm

BE “700007 "

00/103131DC.

Page 38

PEN 13474-2:2000

H.2 Insulating glass unit

Vertical insulating glass unit 4 mm toughened float glass / 12 mm cavity /}6 mm float glass,

1301mm wide x 989 mm high, supported on all four edges, subjected to a wind load of

1,51 kKN/m?, glazed at an altitude of less than 400 m.

Aspect ratio = 989/1301 = 0,76

From table B.2: ko = 0,362

From table B.3: y= 0,074

From table B.4: ks = 0,031

From equation 6:

shins)?" 12x4°x6? \"*

+= 28,9 Site = 28,9) &

‘ (+k, (4 4+6°)x0,031 ©

= 340 mm

From equation 5:

¢

From table 2:

For the 4 mm toughened glass:

For wind load (ultimate limit state): Fa = 49,6 Nimes?

For wind load (serviceability limit state): f',., = 80,7 Nimm? :

a = 65,3 Ninn?

For climate load (serviceability limit state) f,

00/103131Dc

Page 37

prEN 13474-2:2000

For altitude load (serviceability limit state) ff, = 61,5 imme

For the 6 mm float glass:

For wind load (ultimate limit state): Sf ga = 17,0 Nim?

For wind load (serviceability limit statey: — f',. = 30,7 N/mm?

For climate load (serviceability limit state) Fyia =15,3 Némm*

For altitude load (serviceability limit state) f, ay = 11,5 Nimm?

‘The procedure from Annex E is followed.

E.1 Not necessary (no permanent loads other than internal loads).

E.2 From prEN 13474-1, table 1:

pit = +3,6 KN/m? or ~3,6 N/m’.

For the 4 mm toughened glass:

From equation 13:

=(6, + 46,{ Dre +090,

+(1-9)6, (Zro6u +090. | APu +0 Peo)

Fyyq = (0,229 +0,0138x 0,771)x(0)

+ (1-0,0138)x0,229 x (0)-0,0138 x (-3,6+0,9x0)

F,,, = 0,050 nim? = 50 Nim?

From equation B7:

ot = hy r= =0,362x 298 x50 = 1,1 Nm? {<61,5]

00/403131DC

Page 38

PrEN 13474-2:2000

From equation BS

Similarly, for the 6 mm float glass:

From equation 14:

Fy.) = 0,050 kim? = 50 Nim?

From equation B7:

0,989?

Oy = ne R «np, =0,. 362% x x50 =0,5 Nimm? (<11,5]

From equation B8:

2 2

ve =k 5% 20074 0,989 ae 50 =0,2 mm

h 6 70000

E.3 Not necessary (no medium duration loads other than internal loads).

E4 From prEN 13474-1, table 1

Pug = +12,0 kN/m? or -15,0 KN/m’,

For the 4 mm toughened glass:

From equation 13:

Fax = (6, +85, DraGiy +090,

: 7

+(1 #8 (Sra +092, } Pn, +0,9 Peo)

i

F,,,, = (0,229 +.0,0138 x 0,771)x (0)

+(1-0,0138)x 0,229 x (0)--0,0138x (-3,6 +0,9 x-15,0)

F,,, = 0,236 kvm? = 236 Nim?

00/103131Dc

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Certificado JmeterDocument1 pageCertificado JmeterhisambergNo ratings yet

- Passive Cooking Timing GuideDocument4 pagesPassive Cooking Timing GuidehisambergNo ratings yet

- Etkt 1667445814102Document2 pagesEtkt 1667445814102hisambergNo ratings yet

- Villa Kfardebian - Aluminum Profiles Verification For WL50E - WL65E - WS65 - WS160 - Calculation Note - Rev 00Document34 pagesVilla Kfardebian - Aluminum Profiles Verification For WL50E - WL65E - WS65 - WS160 - Calculation Note - Rev 00hisambergNo ratings yet

- Date Currency Bid Ask Mid: Exchange Rates Against LBPDocument1 pageDate Currency Bid Ask Mid: Exchange Rates Against LBPhisambergNo ratings yet

- Certificado JmeterDocument1 pageCertificado JmeterhisambergNo ratings yet

- Windsor Project - ACP ReinforcementDocument44 pagesWindsor Project - ACP ReinforcementhisambergNo ratings yet

- Technical - Data - XQ5P1530 For TechnoFly110Document1 pageTechnical - Data - XQ5P1530 For TechnoFly110hisambergNo ratings yet

- Windsor Project - ACP ReinforcementDocument44 pagesWindsor Project - ACP ReinforcementhisambergNo ratings yet

- Fiche Technique 46 Cahier Charges Qualite Profiles RPT 243Document7 pagesFiche Technique 46 Cahier Charges Qualite Profiles RPT 243hisambergNo ratings yet

- V-Tower - Design Parameters-Calculation Note-Rev 00Document24 pagesV-Tower - Design Parameters-Calculation Note-Rev 00hisambergNo ratings yet

- KWIK KH Steel Screw AnchorDocument5 pagesKWIK KH Steel Screw AnchorhisambergNo ratings yet

- Wictec 50Sg Structural Glazing Curtain Wall: Technical PerformanceDocument1 pageWictec 50Sg Structural Glazing Curtain Wall: Technical PerformancehisambergNo ratings yet