Professional Documents

Culture Documents

2899-Testing Lathe Accuracy

2899-Testing Lathe Accuracy

Uploaded by

NhatQuangNguyenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2899-Testing Lathe Accuracy

2899-Testing Lathe Accuracy

Uploaded by

NhatQuangNguyenCopyright:

Available Formats

TESTING

a driving plate with its plunger bearing

on the fixed centre. Then the machine

spindle is turned, when a steady

reading shows perfect alignment, using

LATHE ACCURACY

a small mirror to see the instrument

upside down and from behind.

Where there are variations in read-

ings, as is virtually always the case, it

can be seen in which direction (vertically

T

HB most important test of a A simple but important test, A, is or sideways) they occur, and the tail-

lathe lies, no doubt, in the the meeting of headstock and tail- stock adjusted to correct sideways

accuracy of the work and stock centres. When’ the fixed centre error.

the manner in which it is produced has noticeably dropped, wear of the A live centre test for running truth,

underside of the tailstock and possibly B, can be made of the one normally

-a skilled operator being able to of the bed itself is indicated. The in the spindle and of others of the

overcome considerable basic in- effect on between-centre turning may same taper with the indicator mounted

accuracy. Even if the work is of be small or non-existent, but care on the slide-rest. This can sometimes

a relatively simple character, ample will be necessary when using centre reveal that the centres themselves

scope for error exists-provided drills or boring cutters from the have not been ground true; and in use

there is sufficient variation to test tailstock-a degree of “lift ” then it may be advisable to keep them to J

all aspects of alignment. being necessary for the tools to centre. one position-spindle or tailstock-

This is to say, a lathe may be The same effect also obtains when marking for fitting in a certain

accurate for one type of work but not supporting chucked work from the manner.

for another, and experience of it tailstock. This test should be made GENERAL ALIGNMENT

can indicate where to expect errors, with the barrel both close in and well A test for general alignment of

though the reason why may not extended. A sideways error of the headstock and tailstock for between-

always be immediately apparent. How- same kind can often be corrected by centre turning can be made employing

ever, there are various simple tests adjusting the tailstock. a mandrel, C. Any suitable piece of

which are largely a substitute for A more severe test of the same sort, rod can be used, carefully centred,

“ work experience ” and which can B, can be made with an indicator, reduced in its length, and with the

be useful for discovering errors, for which can be a dial type or one of the ends turned the same size.

truing the machine (if possible), or on small inexpensive varieties. The A tool mounted on the slide-rest

occasion for setting up. indicator is mounted in a chuck or on can be brought close to one diameter,

leaving a small gap, t

checked on the other

piece of white paper on the bed

providing a light background against

which to see the gaps. Finally, the

tool may be set to touch the diameters

lightly when traversing the saddle.

This aids reasonable setting of a

lathe before work begins, and as an

alternative to a tool an indicator

FIXED CENTRE / can be used.

A faceplate may be checked with a

rule, D, and when mounted on the

spindle and rotated is tested for face

wobble. If chuck work is machined

true, a test can be made on the face-

plate of cross-slide alignment-in two

stages, E and F, using a tool or an

indicator.

Testing along the near side along

line X-Xl, no error may be shown if

the faceplate was machined on the

lathe, for alignment corresponds to

the cross-slide. Testing on the far

side, however, on line X2-X3, any

error is doubled and can be easily

seen.

Topslide setting can be tested as

G, an indicator on a mandrel and a ,

rounded rod on the slide-rest. With

the slide out of alignment, movement

is along such as X4-X5, and checking

with saddle traverse, variations are

shown, whereas with a true setting

readings will be all the same. rzl

13 DECEMBER 1956 831 MODEL ENGINBBR

You might also like

- EN - 840D-810D - Complete Service - v74 PDFDocument380 pagesEN - 840D-810D - Complete Service - v74 PDFNhatQuangNguyen100% (3)

- Dittel WB-AE Overview ENDocument28 pagesDittel WB-AE Overview ENNhatQuangNguyenNo ratings yet

- Hal2100 ManualDocument3 pagesHal2100 Manualapi-2641806078% (9)

- Chapter 01 RA41211EN30GLA0 RL30 OverviewDocument18 pagesChapter 01 RA41211EN30GLA0 RL30 OverviewMudassir HussainNo ratings yet

- 2899-Testing Lathe AccuracyDocument1 page2899-Testing Lathe AccuracySujit MishraNo ratings yet

- Plate 1a Instruments Maceste 2Document9 pagesPlate 1a Instruments Maceste 2Butch Cj MacasayaNo ratings yet

- ANSI AGMA 2004 B89 Gear Materials and Heat Treatment ManualDocument1 pageANSI AGMA 2004 B89 Gear Materials and Heat Treatment ManualLuis TestaNo ratings yet

- Using Adjustable Snap Gages: Section M 1Document14 pagesUsing Adjustable Snap Gages: Section M 1Bhaskar KrishnacharNo ratings yet

- Concrete Construction Article PDF - Automatic Versus Conventional LevelsDocument2 pagesConcrete Construction Article PDF - Automatic Versus Conventional LevelsvladatanNo ratings yet

- Laboratory Activity 6 Elevation Determination and LevelingDocument4 pagesLaboratory Activity 6 Elevation Determination and LevelingMr LawlietNo ratings yet

- 2 Adjustment of InstrumentsDocument9 pages2 Adjustment of InstrumentsTeknologi Pertambangan Fakultas TeknikNo ratings yet

- 11 229 145768005420 24Document5 pages11 229 145768005420 24Yash JagtapNo ratings yet

- Reverse Dial Indicator Alignment ProcedureDocument6 pagesReverse Dial Indicator Alignment Proceduremuhdfadzlee100% (5)

- Levelling ReportDocument18 pagesLevelling Reportazeelanzaini3No ratings yet

- 2017-GASP-CS-Quick-Start INGLESDocument2 pages2017-GASP-CS-Quick-Start INGLESAlex Danny Zapata CalleNo ratings yet

- News November 03Document4 pagesNews November 03Hilal AchrafNo ratings yet

- QuickstartguidewebDocument2 pagesQuickstartguidewebapi-452427194No ratings yet

- 22 Tacheometric SurveyingDocument28 pages22 Tacheometric SurveyingEma50% (2)

- Traverse SurveyingDocument10 pagesTraverse SurveyingEmaNo ratings yet

- Optical Tooling Applications, PART 2 - The Ontario Land Surveyor, Summer 1983Document5 pagesOptical Tooling Applications, PART 2 - The Ontario Land Surveyor, Summer 1983evanmichaelsheriffNo ratings yet

- Laser GASP Quick-Start (English)Document2 pagesLaser GASP Quick-Start (English)Patrick Lao0% (1)

- Type CMR, Instalacion.Document4 pagesType CMR, Instalacion.Mario MarquezNo ratings yet

- Workholding PlayingDocument1 pageWorkholding PlayingMiguel Angel GarcíaNo ratings yet

- Iterative AlignmentDocument1 pageIterative AlignmentIgor MemonNo ratings yet

- Disto A6 User ManualDocument16 pagesDisto A6 User Manualmidenistis3No ratings yet

- Ophthalmic TelebinocularDocument5 pagesOphthalmic Telebinocularbryan HdzNo ratings yet

- Measurement of Vertical Distances g6Document53 pagesMeasurement of Vertical Distances g6HA HA HANo ratings yet

- CNC Milling: 2, Setting The DatumDocument14 pagesCNC Milling: 2, Setting The DatumGundhi AsmoroNo ratings yet

- PDF 326 Cribsheetxlsx CompressDocument117 pagesPDF 326 Cribsheetxlsx Compresstsc madanpurNo ratings yet

- Stress Coefficients For Large Horizontal PipesDocument4 pagesStress Coefficients For Large Horizontal PipestoniobadilloNo ratings yet

- ML BearingsDocument5 pagesML BearingsedgarafonsecaNo ratings yet

- Levelling Procedure: Spirit Level Tube LevelDocument5 pagesLevelling Procedure: Spirit Level Tube LevelMonika KshetriNo ratings yet

- Differentiate Between Line Standard and End Standard of Measurement 1Document19 pagesDifferentiate Between Line Standard and End Standard of Measurement 1ghghgNo ratings yet

- CSURV1110 Lecture Notes Lesson 9 - 12Document2 pagesCSURV1110 Lecture Notes Lesson 9 - 12Gian lester SiandoNo ratings yet

- Anexo 4 Astm D 4695Document6 pagesAnexo 4 Astm D 4695Ricardo DávilaNo ratings yet

- Find & Fic Jdsu PDFDocument1 pageFind & Fic Jdsu PDFoscarNo ratings yet

- PDF Manual290Document9 pagesPDF Manual290torbenNo ratings yet

- Estate Land Survey: LevellingDocument45 pagesEstate Land Survey: LevellingLiyana AmaniNo ratings yet

- Downloaded From Manuals Search EngineDocument2 pagesDownloaded From Manuals Search EngineJuan Pablo GarciaNo ratings yet

- Machine Stops-Trips and Locking Devices 1913 PDFDocument52 pagesMachine Stops-Trips and Locking Devices 1913 PDFjohn silverNo ratings yet

- Tech Note 6: Measuring The Effects of Pipe Strain On Shaft AlignmentDocument4 pagesTech Note 6: Measuring The Effects of Pipe Strain On Shaft AlignmentDiego AlejandroNo ratings yet

- CNC Milling: 1, Setting The ViceDocument9 pagesCNC Milling: 1, Setting The ViceGundhi AsmoroNo ratings yet

- Disco A6 Telemetru.Document16 pagesDisco A6 Telemetru.Lovinf FlorinNo ratings yet

- Yamaha - TDM 900i - Scottoiler ESystem (The Electronic Scottoiler) - English29!8!2011Document1 pageYamaha - TDM 900i - Scottoiler ESystem (The Electronic Scottoiler) - English29!8!2011Ivan ZafirovskiNo ratings yet

- Levelling: Surveying For Engineers Report 1Document15 pagesLevelling: Surveying For Engineers Report 1kakaNo ratings yet

- Db-Ih Um enDocument6 pagesDb-Ih Um enHV ACNo ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- 4.0 Instrument: 4.1 Instrument of Vertical Control (Levelling) Equipment FunctionDocument4 pages4.0 Instrument: 4.1 Instrument of Vertical Control (Levelling) Equipment FunctionAimanNo ratings yet

- Printing Roller Alignment Using Jig Transits - Electro-Optical Metrology - Spectrum MetrologyDocument1 pagePrinting Roller Alignment Using Jig Transits - Electro-Optical Metrology - Spectrum MetrologySivananthaa MurtheeNo ratings yet

- A Spherometer of Precision: Home Search Collections Journals About Contact Us My IopscienceDocument10 pagesA Spherometer of Precision: Home Search Collections Journals About Contact Us My IopscienceAyu MardianaNo ratings yet

- Precise LevellingDocument7 pagesPrecise LevellingvickythreefortyNo ratings yet

- Scottoiler: Kawasaki ZZR 600: Scottoiler Esystem (The Electronic Scottoiler) Installation GuideDocument1 pageScottoiler: Kawasaki ZZR 600: Scottoiler Esystem (The Electronic Scottoiler) Installation GuidejitmarineNo ratings yet

- 160-170precision Machining TechnologyDocument11 pages160-170precision Machining TechnologyCarlos Junior Alexander Ruiz SánchezNo ratings yet

- Dial GaugeDocument8 pagesDial GaugePRABHJOT SINGH100% (1)

- 2A FS TemplateDocument11 pages2A FS TemplateArnel GattocNo ratings yet

- Paut and Change in Canada Paul HollowayDocument7 pagesPaut and Change in Canada Paul HollowayRAF04No ratings yet

- Running A Regal 1946 2of2Document34 pagesRunning A Regal 1946 2of2Julien LemayNo ratings yet

- Adobe Scan 09 Jan 2023Document6 pagesAdobe Scan 09 Jan 2023Parv KhandelwalNo ratings yet

- Levelling and SurveyingDocument7 pagesLevelling and Surveyinghazmee100% (5)

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

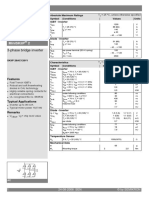

- SEMIKRON DataSheet SKiiP 26AC126V1 25230100Document4 pagesSEMIKRON DataSheet SKiiP 26AC126V1 25230100NhatQuangNguyenNo ratings yet

- 3tf5022-0db4 Siemens Manual DatasheetDocument74 pages3tf5022-0db4 Siemens Manual DatasheetNhatQuangNguyenNo ratings yet

- Ipaq hx2000Document168 pagesIpaq hx2000NhatQuangNguyenNo ratings yet

- BA 1PH813 1PH816 0115 en en-USDocument158 pagesBA 1PH813 1PH816 0115 en en-USNhatQuangNguyenNo ratings yet

- Priminer CatalogDocument24 pagesPriminer CatalogNhatQuangNguyenNo ratings yet

- 6RA80 Fault Diagnostics enDocument78 pages6RA80 Fault Diagnostics enRavindra Angal100% (2)

- 3UG45131BR20 Datasheet enDocument6 pages3UG45131BR20 Datasheet enNhatQuangNguyenNo ratings yet

- Motion Control NC82 Complete English 2022 01Document260 pagesMotion Control NC82 Complete English 2022 01NhatQuangNguyenNo ratings yet

- User's Manual Conversational Programming: NC-Software 286 040-xxDocument205 pagesUser's Manual Conversational Programming: NC-Software 286 040-xxNhatQuangNguyenNo ratings yet

- FBTSL 0108 enDocument183 pagesFBTSL 0108 enNhatQuangNguyenNo ratings yet

- Product Data Sheet 6FX2001-2GB00: Date: 08/06/2014 Subject To ModificationsDocument3 pagesProduct Data Sheet 6FX2001-2GB00: Date: 08/06/2014 Subject To ModificationsNhatQuangNguyenNo ratings yet

- Sinumerik 802D: Automation and DrivesDocument21 pagesSinumerik 802D: Automation and DrivesNhatQuangNguyenNo ratings yet

- EN - 840Dsl CE Conformity 0408 - 2019-03Document26 pagesEN - 840Dsl CE Conformity 0408 - 2019-03NhatQuangNguyen0% (1)

- Voice Activated Automatic Self Folding Dining TableDocument5 pagesVoice Activated Automatic Self Folding Dining TablePrince AugustineNo ratings yet

- Lesson 2 - Principle of ECONDocument26 pagesLesson 2 - Principle of ECONqy8rwv586mNo ratings yet

- ManualDocument40 pagesManualSoundar PandianNo ratings yet

- WBA Service ManualDocument67 pagesWBA Service ManualsolensiNo ratings yet

- 2d - DMM User ManualDocument31 pages2d - DMM User ManualIvan TsuiNo ratings yet

- Assignment # 2Document1 pageAssignment # 2Mod454No ratings yet

- Layers of Atmosphere WorksheetDocument4 pagesLayers of Atmosphere WorksheetLedam Emolotrab AdaipmilNo ratings yet

- Hukum Hooke ExperimentDocument11 pagesHukum Hooke ExperimentCitra MarsidiNo ratings yet

- 2015 Firearms, Bullets, and Wound Ballistics An Imaging PrimerDocument11 pages2015 Firearms, Bullets, and Wound Ballistics An Imaging PrimerMaria Alejandra AtencioNo ratings yet

- Homework Practice and Problem-Solving Practice Workbook (PDFDrive) PDFDocument244 pagesHomework Practice and Problem-Solving Practice Workbook (PDFDrive) PDFLejandra MNo ratings yet

- Theory of Dilute Solution: Colligative PropertiesDocument33 pagesTheory of Dilute Solution: Colligative PropertiesRONTU SARKERNo ratings yet

- GSM Mobile Based Speed Control of DC MotorDocument9 pagesGSM Mobile Based Speed Control of DC MotorRoshan Singh100% (1)

- Sogevac SV40 B / SV65 B / SV100 B / SV120 B ATEX Cat 2: Single-Stage, Oil Sealed Rotary Vane PumpDocument74 pagesSogevac SV40 B / SV65 B / SV100 B / SV120 B ATEX Cat 2: Single-Stage, Oil Sealed Rotary Vane PumpAgus RiyanaNo ratings yet

- FCUBS-FD08!01!01-Data Model Getting StartedDocument21 pagesFCUBS-FD08!01!01-Data Model Getting StartedcuonglunNo ratings yet

- Brought To You by - Boston University Library Mugar Memorial Library Authenticated Download Date - 11/6/16 9:56 AMDocument14 pagesBrought To You by - Boston University Library Mugar Memorial Library Authenticated Download Date - 11/6/16 9:56 AMWalid MohamedNo ratings yet

- Amity School of Engineering & Technology: B.Tech (ECE), Semester 2 JAVA Programming Mr. G.L SainiDocument14 pagesAmity School of Engineering & Technology: B.Tech (ECE), Semester 2 JAVA Programming Mr. G.L Sainiglsaini86No ratings yet

- BL200 ManualDocument199 pagesBL200 ManualAshraful ShohagNo ratings yet

- Lab1 SSN IntroductionDocument18 pagesLab1 SSN Introductionzys WdNo ratings yet

- IS221 Lab3 PDFDocument8 pagesIS221 Lab3 PDFLagilava PauloNo ratings yet

- Off-The-Road Tires: Ultra-Heavy-Duty Mining PerformanceDocument2 pagesOff-The-Road Tires: Ultra-Heavy-Duty Mining PerformanceJAVIER BERMUDEZNo ratings yet

- A Recommended Practice Design, Manufacture and Installation of Glass Reinforced Concrete (GRC)Document92 pagesA Recommended Practice Design, Manufacture and Installation of Glass Reinforced Concrete (GRC)cbler100% (2)

- Tiktoksellercenter Batchupload 20240130 TemplateDocument23 pagesTiktoksellercenter Batchupload 20240130 TemplateHakim AzisonNo ratings yet

- CFT30 IntroDocument35 pagesCFT30 Intromanos4tech100% (1)

- Strut-and-Tie Models Using MulDocument16 pagesStrut-and-Tie Models Using MulwambuigraduationphotosNo ratings yet

- Chap03 (1) With Answers PDFDocument76 pagesChap03 (1) With Answers PDFNihalAbou-GhalyNo ratings yet

- COA of Raw MaterialDocument10 pagesCOA of Raw MaterialShafaq ALINo ratings yet

- Manual Servomex Xendos 1800Document20 pagesManual Servomex Xendos 1800Josh MoralesNo ratings yet

- Aleksey - Baldygin - 201501 - PHD - Oil Recovery in Porous Media Using Emulsion FloodingDocument362 pagesAleksey - Baldygin - 201501 - PHD - Oil Recovery in Porous Media Using Emulsion FloodingGerardo San Luis PotosiNo ratings yet

- SKMJ - Static ElectricityDocument18 pagesSKMJ - Static Electricitykhumaira.jamariNo ratings yet