Professional Documents

Culture Documents

Pricing Strategies

Pricing Strategies

Uploaded by

vinniieeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pricing Strategies

Pricing Strategies

Uploaded by

vinniieeCopyright:

Available Formats

How does a seller set price?

1) Cost center approach in pricing

2) Demand oriented approach in pricing

3) A combination of cost center and demand oriented approaches.

1) Cost center approach in pricing:

What costs are incurred when you manufacture a product?

Sunk costs –

A cost that has been incurred and cannot be reversed. Also referred to as "stranded cost."

Investopedia explains Sunk Cost

A worn-out piece of equipment bought several years ago is a sunk cost because the cost of

buying it cannot be reversed.

Direct costs

Indirect costs

Non-variable costs

Variable costs

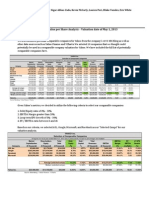

Variable costs Non-variable costs

Direct costs Raw materials Direct workers’ or supervisors’

salaries

Direct maintenance costs

Indirect Costs for production Common staff salaries

Costs for marketing Common rent

Electricity

Managerial compensation

Common stationery expense

(i) Full costing à In monopolistic scenario (all direct, indirect costs) not sunk costs.

(ii) Marginal costing à In highly competitive scenario, a vendor has to bag an order to ensure its

survival and keep the installed machines at least partially occupied.

- Covers at least direct variable costs (set the floor or rock bottom of price)

(iii) Mark-up pricing à Adding a fixed % to the unit cost

- Popular in retail trades (low to high margin) depending on the competitive scenario

PDF created with pdfFactory Pro trial version www.pdffactory.com

2) Demand-oriented approach in pricing:

Look at the intensity of demand unlike cost-oriented approach (std mark-up over costs).

- A high price is charged when the demand is intense and low price is charged when the demand

is weak (even though production unit costs may be the same in both cases)

(i) Price discrimination

Price setting is different for different products based on –

- Customer,

- Product version,

- Place (theatre seats, economy or business class air fares)

- Time (peak season or off-season hotel rates for corporate).

(ii) Market penetration pricing à use marginal pricing strategy.

Gain quick entry and capture a large market volume.

For vendor, the larger the production value and volume (long production runs) the lesser will be the

costs of production (fixed costs) per unit due to low lead times.

- Especially for low-value standard industrial products and services.

3) A combination of cost center and demand oriented approaches.

(i) Target pricing

Pricing method whereby the selling price of a product is calculated to produce a particular rate of

return on investment for a specific volume of production. The target pricing method is used most

often by public utilities, like electric and gas companies, and companies whose capital

investment is high, like automobile manufacturers

(ii) RCA – Relative contribution approach

Different products from same vendor may be in different stages of product life cycle (PLC).

- Introductory stageà market entry stage à infancy à Low load-bearing or low sharing of

overheads.

If you have sophisticated and complex industrial products and services, new prospects and even

existing customers may take a long time to be convinced about buying and using product /

services as they are not aware of the benefits.

Free experiments, trial runs, pilot-scale operations. High pricing may scare away prospective

buyers.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Over time, the vendors’ marketers have to present all the facts before the buying firm’s DMU

and convince and negotiate for better pricing deal.

- Growth stage à money-making stage à youth à high revenue and high load bearing capacity

- Maturity à stage of established product à middle age à relatively lower capacity to bear load

- Decline à clearing the old stocks is important à old age à very low capacity to bear

overheads.

Buyer-specific and product-specific pricing-

1) Sealed bid pricing / reverse bidding mechanism

Purchasers in each plant set the highest possible bidding price, beyond which offers will not be

accepted.

Each vendor is encouraged to offer its own price below the set figure.

The lower the bid offer, the greater the possibility of getting the contract, without compromising on

product quality considerations.

2) Two-step bidding process (sometimes buyers go for quality or lowest bids)

1st a technical bid and next a commercial bid.

DSP – Durgapur Steel Plant – prefer to have technical bidding by vendors, who have to comply with the

desired technical specifications, spare parts availability, delivery schedules, after sales service.

After these are complied with, their technical wing will agree to allow a few chosen vendors to go for

the next phase of commercial bidding, where as a thumb rule, the lowest bid (L1) with the most

acceptable financial terms will be considered, prior to awarding contracts.

Not true at all times.

Nalco Chemicals – MNC – makes and distributes specialty water treatment chemicals (WTC) to a large

number of cooling tower users. These are application specific specialized (fabricated) WTC products.

PRODUCT – specialty water treatment chemicals (WTC)

SELLER – Nalco Chemicals (India) MNC.

BUYER – Cooling tower users (all over India). They need application-specific specialized (fabricated)

WTC products.

PDF created with pdfFactory Pro trial version www.pdffactory.com

These WTCs ensure water purity at the inlet point and also cool the outgoing purified water for

continuous recycling.

The greater the purity and cooling efficiency of the cooling water used in cooling towers, the greater will

be its effect on, say, the quality and quantity of steel production in DSP’s steel melting shop (SMS).

DSP is highly traditional and conservative government organization.

- Usually awarded L1 – lowest bidder contracts

- After trials and tests, Nalco’s management and Betz India Pvt Ltd (another MNC) proved to

DSP’s management that use of superior quality WTC ensured much better quality and quantity

of steel production in their steel melting shops (SMS), as compared to the use of much lower-

quality WTC made and supplied by other vendors (mostly local) whose investment in applied

R&D à negligible or non-existent.

- Free experimentations jointly organized by Nalco and DSP’s technical personnel at steel plant at

Durgapur, DSP officials agreed to officially award a large part of WTC’s yearly rqmt to both Nalco

and Betz – primarily for critical cooling applications.

- Over a 3 year period, a part of contractual offer was awarded at a 30% higher price, as

compared to that awarded to local WTC supplier whose chemicals were of inferior quality.

- Hence, for this fabricated industrial product, better product quality, backed by superior service,

ensured a price level higher than L1.

3) Hiring / Leasing

Fabricated industrial products and capital equipment (like cyrotanks) can also be hired or leased out for

a long period.

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- Market and Financial Feasibility Study For Great Wolf Resorts in Collier County - Feb. 23, 2021Document31 pagesMarket and Financial Feasibility Study For Great Wolf Resorts in Collier County - Feb. 23, 2021Omar Rodriguez OrtizNo ratings yet

- Arun Ice CreamDocument51 pagesArun Ice CreamAbdur Rahman71% (7)

- Accelerator Labs: Applicant GuidebookDocument13 pagesAccelerator Labs: Applicant GuidebookPtb4doc0% (1)

- Catalogue of Investment Opportunities, July 2015Document158 pagesCatalogue of Investment Opportunities, July 2015Ante MaricNo ratings yet

- SBI Life InsuranceDocument73 pagesSBI Life Insuranceiloveyoujaan50% (6)

- 01-JUN-2019 - 30-JUN-2019 (1) - UnlockedDocument3 pages01-JUN-2019 - 30-JUN-2019 (1) - UnlockedSwethasri KNo ratings yet

- Swot AnalysisDocument4 pagesSwot AnalysisJhoanna Marie Algabre BejarinNo ratings yet

- Val PacketDocument157 pagesVal PacketKumar PrashantNo ratings yet

- 6W2X - Business Model Canvas With ExplanationsDocument2 pages6W2X - Business Model Canvas With ExplanationstorqtechNo ratings yet

- Auditing CA Final Investigation and Due DiligenceDocument26 pagesAuditing CA Final Investigation and Due Diligencevarunmonga90No ratings yet

- Pestle Analysis - Alesh and GroupDocument18 pagesPestle Analysis - Alesh and GroupJay KapoorNo ratings yet

- MUG Business Models UplDocument23 pagesMUG Business Models UplChristoph MagistraNo ratings yet

- Investor Guide BookDocument169 pagesInvestor Guide BooktonyvinayakNo ratings yet

- CH - 4 - Time Value of MoneyDocument49 pagesCH - 4 - Time Value of Moneyak sNo ratings yet

- Days-Sales-Outstanding-TemplateDocument3 pagesDays-Sales-Outstanding-TemplateKaren Anne Pineda IngenteNo ratings yet

- Actuaries 4Document69 pagesActuaries 4MuradNo ratings yet

- Evaluation of Investment Project Using IRR and NPVDocument6 pagesEvaluation of Investment Project Using IRR and NPVchew97No ratings yet

- Capital+budgeting UnsolvedDocument4 pagesCapital+budgeting UnsolvedutamiNo ratings yet

- Risk and Return Fundamentals: Portfolio-A Collection, or Group, of AssetsDocument104 pagesRisk and Return Fundamentals: Portfolio-A Collection, or Group, of AssetsSagorNo ratings yet

- Feasibility Study of ProjectDocument15 pagesFeasibility Study of ProjectMauliddha RachmiNo ratings yet

- Create Application: Equity Template BuilderDocument1 pageCreate Application: Equity Template Builderattikouris100% (1)

- Investment Behaviour PDFDocument44 pagesInvestment Behaviour PDFSajoy P.B.100% (1)

- Valuing Private Companies:: Factors and Approaches To ConsiderDocument35 pagesValuing Private Companies:: Factors and Approaches To ConsiderAvinash DasNo ratings yet

- Sensitivity AnalysisDocument13 pagesSensitivity Analysisrastogi paragNo ratings yet

- L8 Raising CapitalDocument26 pagesL8 Raising CapitalKranthi ManthriNo ratings yet

- Aicpa Accounting GlossaryDocument24 pagesAicpa Accounting GlossaryRafael AlemanNo ratings yet

- Pricing Strategy and ManagementDocument15 pagesPricing Strategy and Managementadibhai06No ratings yet

- Facing FailureDocument2 pagesFacing FailureThomas JohnsonNo ratings yet

- The Time Value of MoneyDocument66 pagesThe Time Value of MoneyrachealllNo ratings yet

- Yahoo! Inc. Valuation ProjectDocument8 pagesYahoo! Inc. Valuation ProjectNigar_AbbasNo ratings yet

- The Accounting Cycle: Capturing Economic Events: Mcgraw-Hill/IrwinDocument45 pagesThe Accounting Cycle: Capturing Economic Events: Mcgraw-Hill/IrwinSobia NasreenNo ratings yet

- Discounted Cash Flow ApplicationsDocument27 pagesDiscounted Cash Flow ApplicationsAvinash DasNo ratings yet

- Benfords Law CAATSDocument28 pagesBenfords Law CAATSHetNo ratings yet

- ARNDTECH Solutions Inc ARNDTECH Solutions IncDocument17 pagesARNDTECH Solutions Inc ARNDTECH Solutions IncAmer AliNo ratings yet

- Patpat: Zhang Jiaqi Hu Lin Liu ZhiDocument9 pagesPatpat: Zhang Jiaqi Hu Lin Liu ZhiCharlotte ZhangNo ratings yet

- Application StartupDocument3 pagesApplication StartupSayak MitraNo ratings yet

- Sensitivity Analysis TableDocument3 pagesSensitivity Analysis TableBurhanNo ratings yet

- Pre-Money Valuation: Multiple ApproachDocument16 pagesPre-Money Valuation: Multiple ApproachDavid ChikhladzeNo ratings yet

- Valuation of Early Stage StartupsDocument2 pagesValuation of Early Stage StartupsPaulo Timothy AguilaNo ratings yet

- Company Profile: Kalikasthan, Dillibazar, Kathmandu, Nepal Tel: +977 - 1 - 4442435, 4424743 EmailDocument13 pagesCompany Profile: Kalikasthan, Dillibazar, Kathmandu, Nepal Tel: +977 - 1 - 4442435, 4424743 EmailSaahil GoyalNo ratings yet

- Chapter 13 ValuationDocument23 pagesChapter 13 ValuationIndah Dwi RetnoNo ratings yet

- Valuing Startup VenturesDocument4 pagesValuing Startup VenturesJonhmark AniñonNo ratings yet

- Test 3 Project Finance Case Question Yogesh GandhiDocument14 pagesTest 3 Project Finance Case Question Yogesh GandhiYogi GandhiNo ratings yet

- The Challenges of Integrating Peace Journalism Into Conventional Journalism Practice - A Case Study of The LRA Peace ProcessDocument136 pagesThe Challenges of Integrating Peace Journalism Into Conventional Journalism Practice - A Case Study of The LRA Peace ProcessBirungi KamaraNo ratings yet

- IBDRoadmap PDFDocument7 pagesIBDRoadmap PDFPavitraNo ratings yet

- Capital Budgeting ExamplesDocument16 pagesCapital Budgeting ExamplesMuhammad azeemNo ratings yet

- FCFEDocument7 pagesFCFEbang bebetNo ratings yet

- Methods of Stock ValuationDocument3 pagesMethods of Stock ValuationQuartz KrystalNo ratings yet

- Bio Care Sanitary PadDocument8 pagesBio Care Sanitary PadWie Pin Siddhi100% (1)

- Chapter 16.1 Due Diligence, Investigation and Forensic AuditDocument13 pagesChapter 16.1 Due Diligence, Investigation and Forensic AuditJagrit Oberoi0% (1)

- Lee Chee How 21wbd08408 IndvassignmentDocument19 pagesLee Chee How 21wbd08408 Indvassignmentho cheeNo ratings yet

- FMDocument99 pagesFMvinit1117No ratings yet

- FCFE ValuationDocument27 pagesFCFE ValuationTaleya FatimaNo ratings yet

- Game TheoryDocument186 pagesGame TheoryJulthep NandakwangNo ratings yet

- Analysis of Financial StatementsDocument33 pagesAnalysis of Financial StatementsKushal Lapasia100% (1)

- CVP Analysis - 2018Document23 pagesCVP Analysis - 2018Ali KhanNo ratings yet

- RC Equity Research Report Essentials CFA InstituteDocument3 pagesRC Equity Research Report Essentials CFA InstitutetheakjNo ratings yet

- Sensitivity AnalysisDocument6 pagesSensitivity AnalysisLovedale JoyanaNo ratings yet

- Discounted Cash Flow (DCF) ModellingDocument43 pagesDiscounted Cash Flow (DCF) Modellingjasonccheng25No ratings yet

- Valuation of Company - Part 1: Mahesh Savanth Chartered AccountantDocument16 pagesValuation of Company - Part 1: Mahesh Savanth Chartered AccountantvikasajainNo ratings yet

- Goal SseekDocument5 pagesGoal SseekFilip NikolovskiNo ratings yet

- SMA - Chapter Seven - Cost-Volume-Profit AnalysisDocument35 pagesSMA - Chapter Seven - Cost-Volume-Profit Analysisngandu0% (1)

- Overhead ControlDocument6 pagesOverhead ControlbelladoNo ratings yet

- Pari SBI Life Project ReportDocument100 pagesPari SBI Life Project Reportvinniiee86% (21)

- Six Sigma PPT 3Document16 pagesSix Sigma PPT 3pinku_thakkarNo ratings yet

- SBI Life - ICICI PruDocument47 pagesSBI Life - ICICI PruAbhinandan KumarNo ratings yet

- InsuranceDocument39 pagesInsuranceshaik_723959No ratings yet

- Insurance TermsDocument71 pagesInsurance TermstohpatyNo ratings yet

- Glossary of Re Insurance TermsDocument18 pagesGlossary of Re Insurance TermsShweta08091983No ratings yet

- Subodh Final Project ReportDocument94 pagesSubodh Final Project Reportsubbu1234100% (18)

- Industrial Marketing - HawaldarDocument165 pagesIndustrial Marketing - Hawaldarraheel911100% (2)

- Bread Fast CerealsDocument122 pagesBread Fast Cerealsravi235No ratings yet

- Retail Shrink - CanadaDocument11 pagesRetail Shrink - CanadadustinNo ratings yet

- CIR Orange Juice Study Low SPDocument42 pagesCIR Orange Juice Study Low SPnunoNo ratings yet

- Chapter 1Document26 pagesChapter 1Huy TranNo ratings yet

- Consignment Process SDDocument28 pagesConsignment Process SDSalih SahinNo ratings yet

- Chemstar ProductCatalogDocument54 pagesChemstar ProductCatalogjayfeilenNo ratings yet

- Jimmyjane US Account Order FormDocument2 pagesJimmyjane US Account Order FormAudrey NobleNo ratings yet

- Marketing MixDocument11 pagesMarketing Mixapi-384867086% (7)

- Test Paper PrinciplesDocument7 pagesTest Paper PrinciplesRina DinNo ratings yet

- C K RanganathanDocument21 pagesC K RanganathanMichaelsaj Michael0% (1)

- Flip KartDocument2 pagesFlip KartGitanjali RajputNo ratings yet

- Case Samples McKinseyDocument12 pagesCase Samples McKinseyvav_ag100% (3)

- Integrated Online Marketing CommunicationDocument16 pagesIntegrated Online Marketing CommunicationGrant Marco Mariano100% (1)

- Case Study On MTR's Strategic Competitive AdvantageDocument15 pagesCase Study On MTR's Strategic Competitive AdvantageRanjan Shetty67% (6)

- Ss6 Rationalized Daily Patrol Plan Sept 20, 2023Document40 pagesSs6 Rationalized Daily Patrol Plan Sept 20, 2023Substationsix MalaboncpsNo ratings yet

- Uber Report PDFDocument11 pagesUber Report PDFHbbekn jjdbhhNo ratings yet

- Dmart and The Retail IndustryDocument29 pagesDmart and The Retail IndustryVansh JainNo ratings yet

- ORS Retailing CHP 1Document13 pagesORS Retailing CHP 1Sharina DailamyNo ratings yet

- Last Mile 5category LayoutsDocument24 pagesLast Mile 5category LayoutsManoj NakraNo ratings yet

- Chapter 1Document13 pagesChapter 1Tamoor TariqNo ratings yet

- Study - Id89350 - Buy Now Pay Later BNPL PDFDocument40 pagesStudy - Id89350 - Buy Now Pay Later BNPL PDFXinwei LinNo ratings yet

- Retail Quiz AnswersDocument7 pagesRetail Quiz Answerskilty1No ratings yet

- Dole Food Company - Inc. Form 10-KDocument139 pagesDole Food Company - Inc. Form 10-Kipsa scientia potestas estNo ratings yet

- Customer SatisfactionDocument54 pagesCustomer SatisfactionParamjit Sharma90% (10)

- Januari - Rek AgusDocument2 pagesJanuari - Rek AgusEdi SetyawanNo ratings yet

- Cubicle Curtain Track Shop Drawing For ReferenceDocument22 pagesCubicle Curtain Track Shop Drawing For ReferenceManuel CardielNo ratings yet

- sTARBUCK Case AppliactionDocument10 pagessTARBUCK Case Appliactionsanya-nisar-2818100% (1)