Professional Documents

Culture Documents

Emergency Relief Vent: For Low Pressure Storage Tanks

Emergency Relief Vent: For Low Pressure Storage Tanks

Uploaded by

Nithin GOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emergency Relief Vent: For Low Pressure Storage Tanks

Emergency Relief Vent: For Low Pressure Storage Tanks

Uploaded by

Nithin GCopyright:

Available Formats

elmactechnologies.

com Emergency Relief Vent TECHNICAL DATA

Emergency Relief Vent

For Low Pressure Storage Tanks Protecting People, Property and our Planet.

The Elmac Technologies® non-sparking Emergency

Relief Vents (ERV's) provide emergency venting

capacity in the event of fire. They can also permit access

to low pressure storage tanks for inspection and

maintenance. They are used extensively on bulk storage

tanks and digesters.

Materials and Options

Principle of Operation

Model Emergency Relief Vent

Emergency Relief Vents are fitted to storage tanks to allow

emergency flow due to the excessive venting requirement Sizes (DN) 10”, 12”, 16”, 18”, 20” & 24”

from a fire burning around a storage tank. This eliminates a

API650 (20” & 24”)

costly tank rupture, providing emergency venting from Process Connection ANSI 150#

abnormal internal pressure beyond the capability of the Special (on request)

pressure relief vent. In the event of a fire, the vent will open at Aluminium

a pre-determined pressure, thus creating a large venting area. Carbon Steel

Materials

Stainless Steel

A PTFE insert is provided to achieve leak tight sealing Special (on request)

between the vent and seat under normal operating

Diaphragm and Insert PTFE

conditions. An alternative model is available, fitted with an

Lead Plate (Standard)

additional spring-loaded vacuum valve that will open under Weight

Stainless Plate

negative pressure to protect the tank from any damage that

may occur under vacuum conditions. Pressure Settings 3”wc (7.5mbar) – 48”wc (120mbar)

Vacuum Settings 3.46”wc (9mbar) – 10”wc (25mbar)

Features and Benefits

• Hinged vent can be manually lifted allowing access to the • Wide range of pressure settings to provide maximum

tank for cleaning and inspection tank protection whilst ensuring minimum product vapour

• Range of sizes and materials to suit diverse applications • Low cost maintenance

elmactechnologies.com Emergency Relief Vent TECHNICAL DATA

Regulatory Requirements

In the United Kingdom, the Health & Safety Executive

Guidance Note, “The Storage of Flammable Liquids in

Tanks” (HSG176) covers the storage of liquids with a flash

point of 60°C or below. These regulations include:

• Petroleum spirit • Aviation fuels

• Kerosene • Most solvents

Since gas oil, medium and heavy fuel oils with higher

flashpoint are excluded from this requirement, the European

tank standard BS EN 14015:2004 states (10.6.2) that

emergency pressure relief shall be provided unless the

purchaser specifically excludes the same in Annex A.

Fire Engulfment

HSG176 requires emergency relief venting to be provided on

storage tanks containing liquids with a flash point below 60°C

to cope with possible fire engulfment. The aim is to relieve

the internal pressure of the tank from rapid product vapour

build- up and avoid rupture of the shell or base, so that the

liquid retaining integrity is preserved.

The pressure build-up will be quite slow, therefore the cover

should not open violently and cause any damage to the tank.

Relief Vents Emitted vapours may well be ignited by the fire, but should

The amount of emergency relief venting to be provided ‘flame-off’ externally until brought under control by fire

should be calculated as per BS EN 14015:2004 Annex L or fighting operations. Emergency Relief Vents will not normally

API 2000. Emergency relief venting can be provided by a afford protection against internal tank vapour explosions

weak shell to roof joint (frangible roof) which is designed to from static discharges etc, due to the fact that the pressure

fail before the shell to base joint. Design constraints mean build- up will be very rapid and exceed the capacity of the

that most tanks less than 15 metres in diameter cannot be device. In this instance, the cover will snap open violently and

considered as having frangible roofs. In such cases, tanks may well cause damage to the tank, it is however likely that

must be provided with emergency relief venting manways on there will be more significant damage elsewhere on the fabric

the roof, designed to open the hinged cover before the tank of the tank from the internal explosion.

maximum design pressure is exceeded. For existing tanks,

Emergency Relief Vents can often be fitted to the existing Elmac Expertise

roof manway to enable tank access.

Elmac Technologies® has been manufacturing protection

equipment since 1948 and brings enhanced levels of flame and

Operation explosion protection to a diverse range of applications.

The Operational Tank Venting System or Pressure/Vacuum

Elmac offers considerable technical leadership and, using test

Relief Valves handle normal tank venting due to product

facilities along with Computational Fluid Dynamics (CFD)

import/export and ambient temperature variations. In the

capabilities, employs research teams renowned for developing

event of fire engulfment, as the vapour pressure in the tank

solutions for the most challenging of industrial applications.

increases to a point where normal venting equipment capacity

is exceeded, the hinged cover will lift, relieving the pressure

and protecting the tank from rupture.

Customer Support

Tel: +44 (0) 1352 717 555

Email: sales@elmactech.com

Fax: +44 (0) 1352 717 642

Coast Road, Greenfield, Flintshire, CH8 9DP United Kingdom Protecting People, Property and our Planet.

All specifications are correct at time of print, are for guidance purposes only and subject to change without prior notice.

You might also like

- Oisd STD 164Document35 pagesOisd STD 164maheshdabli33% (3)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 450.27 - NFPA 70 (2017) National Electrical Code® HandbookDocument1 page450.27 - NFPA 70 (2017) National Electrical Code® HandbookvthiyagainNo ratings yet

- Storage Tank SystemsDocument35 pagesStorage Tank Systemskvramanan_1No ratings yet

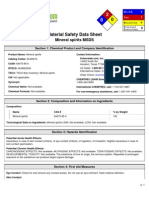

- Mineral Spirits - MsdsDocument5 pagesMineral Spirits - MsdsKen StewartNo ratings yet

- Pre-Fire PlanningDocument9 pagesPre-Fire PlanningAnJanet BioNo ratings yet

- Manway Pressure Relief 121-2sheetDocument2 pagesManway Pressure Relief 121-2sheetnicolasgonzNo ratings yet

- 800 Fire and Safety DesignDocument31 pages800 Fire and Safety Designjhon smith100% (1)

- 800 - Fire and Safety DesignDocument32 pages800 - Fire and Safety DesignShinji46No ratings yet

- Pressure/Vacuum Relief Valve Protego VD/TS: Atmospheric Deflagration-ProofDocument4 pagesPressure/Vacuum Relief Valve Protego VD/TS: Atmospheric Deflagration-ProofwillNo ratings yet

- Shand&Jurs Safety Equipment in Methanol SystemsDocument7 pagesShand&Jurs Safety Equipment in Methanol Systemswferry27No ratings yet

- Fixed or Semi-Fixed Fire Protection Systems For Storage TanksDocument10 pagesFixed or Semi-Fixed Fire Protection Systems For Storage TanksJaneth MeraNo ratings yet

- WilliamsFire-Storage Tank Fire ProtectionDocument29 pagesWilliamsFire-Storage Tank Fire ProtectionSherif Abdel Hamid Fakhry100% (4)

- TFP250 08 2018 Traducido PDFDocument4 pagesTFP250 08 2018 Traducido PDFCarlitos Way Golden BrainNo ratings yet

- Pressure/Vacuum Relief Valve: Atmospheric Defl Agration-ProofDocument4 pagesPressure/Vacuum Relief Valve: Atmospheric Defl Agration-ProofOscar Araujo PolaniaNo ratings yet

- Tanques PVSVDocument13 pagesTanques PVSVwfjerrNo ratings yet

- Zwick Tri Con Application ESD PDFDocument2 pagesZwick Tri Con Application ESD PDFJorge DomínguezNo ratings yet

- Pilot Operated Tank Blanketing Valve, 2": ProtectoDocument8 pagesPilot Operated Tank Blanketing Valve, 2": ProtectoTimNo ratings yet

- Pilot Operated Tank Blanketing Valve: ProtectoDocument8 pagesPilot Operated Tank Blanketing Valve: ProtectoHector Flores MarcosNo ratings yet

- Vents & Fire Protection System For Storage TanksDocument24 pagesVents & Fire Protection System For Storage TanksMohammad Rawoof100% (2)

- Tank ComponentsDocument4 pagesTank ComponentssafwanNo ratings yet

- Pressure VesselsDocument19 pagesPressure VesselsNikhil Deshpande100% (1)

- GROTH Product Selection GuideDocument12 pagesGROTH Product Selection GuideJeniferth GaitanNo ratings yet

- Brochure Válvulas MaxonDocument8 pagesBrochure Válvulas MaxonIngeniero Proyectos 1No ratings yet

- Your Selection of Valve Technology, Matters.: Isolation ValvesDocument28 pagesYour Selection of Valve Technology, Matters.: Isolation Valvesmohamed badranNo ratings yet

- Emergency For Internal Pressure - MorovichDocument34 pagesEmergency For Internal Pressure - MorovichrodrigoperezsimoneNo ratings yet

- Storagetech™ Catalog - rv04Document24 pagesStoragetech™ Catalog - rv04WEPNo ratings yet

- FUELCAPS - EPA (Filtro de Combustible)Document4 pagesFUELCAPS - EPA (Filtro de Combustible)SUPERVISOR PROYECTOS BCI & RCI (EDUARDO VILLANUEVA)No ratings yet

- Determining Acceptability of Vents and Fire-Protection Systems For Storage Tanks PDFDocument29 pagesDetermining Acceptability of Vents and Fire-Protection Systems For Storage Tanks PDFAnonymous S9qBDVkyNo ratings yet

- Studor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)Document1 pageStudor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)sijilNo ratings yet

- 2-Aa Storage Tank - Basic Training Rev 2Document52 pages2-Aa Storage Tank - Basic Training Rev 2mohamedbadawyNo ratings yet

- Specialty Vents & Valves 30 MinDocument15 pagesSpecialty Vents & Valves 30 MinAnonymous Wd2KONNo ratings yet

- Mov Eng1Document16 pagesMov Eng1hacene omarNo ratings yet

- Ultrasonic Pipeline InspectionDocument31 pagesUltrasonic Pipeline InspectionCepi Sindang KamulanNo ratings yet

- Air Handling Units DB HeinanDocument8 pagesAir Handling Units DB HeinanlsaishankarNo ratings yet

- Oil Storage: Types of Storage TanksDocument14 pagesOil Storage: Types of Storage Tankscarlos neiraNo ratings yet

- Cámara de Espuma - Instalación y Mantenimiento PDFDocument5 pagesCámara de Espuma - Instalación y Mantenimiento PDFvivicastedoNo ratings yet

- Opito EEHA Presentation Ex Haz Area Section 4Document143 pagesOpito EEHA Presentation Ex Haz Area Section 4imanNo ratings yet

- Storage Tanks: Fixed or Semi-Fixed SystemsDocument9 pagesStorage Tanks: Fixed or Semi-Fixed SystemsCarlos SalazarNo ratings yet

- Issue 5 Inspectors NewsletterDocument2 pagesIssue 5 Inspectors NewsletterDeepakNo ratings yet

- 329 Cryogenic-Valves July-2019 ReducedDocument8 pages329 Cryogenic-Valves July-2019 ReducedLudi D. LunarNo ratings yet

- Breather Valves2Document12 pagesBreather Valves2prashant_dc_in100% (1)

- Fire Fighting Water Tanks: Balmor Al Tank SDocument32 pagesFire Fighting Water Tanks: Balmor Al Tank SAditya SinghNo ratings yet

- Catalog KSPCDocument20 pagesCatalog KSPCThomas WilliamNo ratings yet

- Sky / Startup Vents: Modulating Control ValvesDocument8 pagesSky / Startup Vents: Modulating Control ValvesGaneshNo ratings yet

- Banlaw ReFuelling AUS Series Tank Vent PDSDocument6 pagesBanlaw ReFuelling AUS Series Tank Vent PDSRudy SaputraNo ratings yet

- Water Tanks For Fire ProtectionDocument4 pagesWater Tanks For Fire Protectionwfjerr100% (1)

- Valvula Sobrepresión - IN2065-08-01 - MPREC - ENDocument4 pagesValvula Sobrepresión - IN2065-08-01 - MPREC - ENSiul VegaNo ratings yet

- Sti R912Document4 pagesSti R912Mauricio AdameNo ratings yet

- Brochure Siex-Co2 Highpressure Eng Web PDFDocument16 pagesBrochure Siex-Co2 Highpressure Eng Web PDFAhmed SalamaNo ratings yet

- Overpressure and Vacuum Protection Challenges For Low Pressure and AtmosphericDocument14 pagesOverpressure and Vacuum Protection Challenges For Low Pressure and AtmosphericHsein WangNo ratings yet

- Win General CatalogDocument14 pagesWin General CatalogSandi AslanNo ratings yet

- NDD010-MCS Type BDocument5 pagesNDD010-MCS Type BShariq KhanNo ratings yet

- Hanfih 0516Document3 pagesHanfih 0516Javier JiménezNo ratings yet

- V1-080-05 EN WebDocument36 pagesV1-080-05 EN Web3238NDNo ratings yet

- FM010Document4 pagesFM010olinser bacelisNo ratings yet

- CCCHART 2012 July PDFDocument29 pagesCCCHART 2012 July PDFNelson J Chaparro MNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Table HAwN6XR0ckCMdZHZMUVAWQacCDocument150 pagesTable HAwN6XR0ckCMdZHZMUVAWQacCNithin GNo ratings yet

- Prometric Pro User GuideDocument24 pagesPrometric Pro User GuideNithin GNo ratings yet

- Abj 89 103778 Ba 6070 00035 0000 01Document22 pagesAbj 89 103778 Ba 6070 00035 0000 01Nithin GNo ratings yet

- 09 - Bank Account Form - PDF File (1)Document1 page09 - Bank Account Form - PDF File (1)Nithin GNo ratings yet

- Pivot MasterDocument2 pagesPivot MasterNithin GNo ratings yet

- Kerala Panchayat Raj (Burial and Burning Grounds) Rules, 1998Document7 pagesKerala Panchayat Raj (Burial and Burning Grounds) Rules, 1998Nithin GNo ratings yet

- Tuv Rheinland Reference Case Advanced NDT Refinery enDocument2 pagesTuv Rheinland Reference Case Advanced NDT Refinery enNithin GNo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- What Is Meridium APMDocument257 pagesWhat Is Meridium APMNithin G100% (1)

- DPR 08 08 2021 Piping BisatDocument683 pagesDPR 08 08 2021 Piping BisatNithin GNo ratings yet

- Testing DetialsDocument7 pagesTesting DetialsNithin GNo ratings yet

- Dry Procedure After Hydrotest/ Pigging / Steaming of Piping and EquipmentDocument1 pageDry Procedure After Hydrotest/ Pigging / Steaming of Piping and EquipmentNithin GNo ratings yet

- UntitledDocument5 pagesUntitledNithin GNo ratings yet

- Isi Insp 5 4 A6 DNV Inspection CVDocument4 pagesIsi Insp 5 4 A6 DNV Inspection CVNithin GNo ratings yet

- SSFD - DSS Piping Action Tracker - 100522 (PQR)Document14 pagesSSFD - DSS Piping Action Tracker - 100522 (PQR)Nithin GNo ratings yet

- Isi Insp 5 4 A6 DNV Inspection CVDocument3 pagesIsi Insp 5 4 A6 DNV Inspection CVNithin GNo ratings yet

- 02 ChanthavilaDocument3 pages02 ChanthavilaNithin GNo ratings yet

- Fire TechDocument282 pagesFire TechDaphney Claire PinedaNo ratings yet

- Methanol MSDS PDFDocument10 pagesMethanol MSDS PDFPutriErvinaNo ratings yet

- ASTM D 36 - 06 Standard Test Method For Softening Point of Bitumen (Ring-and-Ball Apparatus)Document4 pagesASTM D 36 - 06 Standard Test Method For Softening Point of Bitumen (Ring-and-Ball Apparatus)Mohammed EldakhakhnyNo ratings yet

- 117DP - Health, Safety & Environment in Petroleum Industry PDFDocument8 pages117DP - Health, Safety & Environment in Petroleum Industry PDFvenkiscribd444No ratings yet

- Foe Sample QuistionSDocument21 pagesFoe Sample QuistionSYuGenNo ratings yet

- Supramor 4 Black: Color Contrast Magnetic InkDocument2 pagesSupramor 4 Black: Color Contrast Magnetic InkMichaelNo ratings yet

- FMDS0729Document106 pagesFMDS0729Chotiwan RattanasatienNo ratings yet

- Synozol Ultra Black DR (ENG)Document7 pagesSynozol Ultra Black DR (ENG)Jomar OroscoNo ratings yet

- Guidance For Hazard Determination For Compliance With The OSHA Hazard Communication StandardDocument29 pagesGuidance For Hazard Determination For Compliance With The OSHA Hazard Communication Standardbatorn@mac.comNo ratings yet

- NFPA DiamondDocument17 pagesNFPA DiamondEurek Mago LumaguiNo ratings yet

- Chemical Reactor Inherent Safety Index A PDFDocument9 pagesChemical Reactor Inherent Safety Index A PDFAnilNo ratings yet

- GM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophyDocument42 pagesGM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophySuper 7100% (1)

- Msds Methanol BDHDocument10 pagesMsds Methanol BDHRohith KommuNo ratings yet

- Safety Interview Questions and Answers ImportantDocument30 pagesSafety Interview Questions and Answers ImportantRandom Stuff100% (1)

- Safety Data Sheet: Product Name: MOBIL DTE 10 EXCEL 22Document11 pagesSafety Data Sheet: Product Name: MOBIL DTE 10 EXCEL 22Anibal RiosNo ratings yet

- Grease Altis em 2 Msds TCDocument5 pagesGrease Altis em 2 Msds TCLex WallesaNo ratings yet

- Material Safety Data Sheet 2,2,4-Trimethylpentane MSDSDocument6 pagesMaterial Safety Data Sheet 2,2,4-Trimethylpentane MSDSBilly T HoNo ratings yet

- 200005A - P1 - Flash Point ApparatusDocument11 pages200005A - P1 - Flash Point Apparatusaruthlugnesha2001No ratings yet

- M 82-75 (2004) Cutback Asphalt (MC Type)Document2 pagesM 82-75 (2004) Cutback Asphalt (MC Type)WalticoZegarraHerrera100% (1)

- OISD Tank Farm Rules The Piping Engineering WorldDocument1 pageOISD Tank Farm Rules The Piping Engineering Worldrenger20150303100% (1)

- Revised API2000 Vs New ISO StandardDocument21 pagesRevised API2000 Vs New ISO StandardPriyanathan ThayalanNo ratings yet

- Oisd STD 110Document78 pagesOisd STD 110Swaraj PandaNo ratings yet

- Fire Safety ManualDocument27 pagesFire Safety Manualdh6802100% (1)

- Emergencies and SpillsDocument5 pagesEmergencies and SpillsClement KipyegonNo ratings yet

- NMP-Material Safety Data SheetDocument10 pagesNMP-Material Safety Data SheetdchyNo ratings yet

- BGQYNDocument3 pagesBGQYNdalton2003No ratings yet

- Pengenalpastian Produk & SyarikatDocument11 pagesPengenalpastian Produk & SyarikatMohd Shareen Ezzry Mohd SomNo ratings yet