Professional Documents

Culture Documents

Risk Assessment Example

Risk Assessment Example

Uploaded by

Gabriel MazzoccaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment Example

Risk Assessment Example

Uploaded by

Gabriel MazzoccaCopyright:

Available Formats

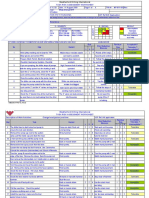

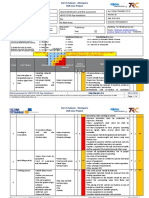

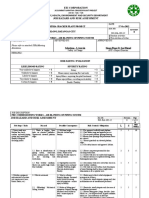

Machine Safety Specialists 04/13/2009 Page 1

Equipment: Minster AB-123-CD Assessment Team Members:

Manufacturer Model / Generation / Tooling Design Contact Person

Location: Module # 1 #33 #12345 Starting Date: 5/1/2009

Line # Machine #

Type of Equipment: Press ABC-123 Plant: Plant B

Instruction: Please follow Safe Guarding Seminar Risk Assessment Flow Chart and Risk Estimation Matrix!

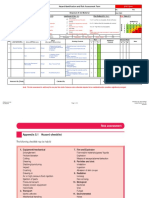

Use the ANSI B11.TR3-2000 Hazard Table to Assist in Identification of Hazards and Promote Consistency!

1–8 Represents Low Level, 9–14 Represents Medium Level, 15–20 Represents High Level

Hazard Identification Risk Level Estimate Method of Reduction Follow-Up

Identified Hazard Type (From Frequency Probability Severity Number Est. Accident Tolerable By By Safe- By Method of Addressing Risk Frequency of Probability of Severity of Number of Final Risk Tolerable?

Annex A #

#

Hazard Hazard Table Annex A) of Exposure of Injury of Injury of People Risk Review Yes/ No Design guarding Admin. Exposure Injury 1,2,4,6 Injury People Level

rd

Reduction or Current Method in

za

1,2,4 1,2,4,6 Exposed Level Yes/No

1,3,6,10 Controls 1,2,4 1,3,6,10 Exposed

Place Making it Tolerable!

Ha

Guarding Concerns

1 E-stops not redundant or 14.0 Failure of Control 2 2 6 1 10 y No X X Add redundancy and safety 2 2 6 1 10 No

properly monitored Circuit monitoring relay

2 Guard switches not in 14.0 Failure of Control 2 4 6 1 12 No X X Change guard switches & add safety 1 1 1 1 3 Yes

conformance Circuit monitoring relay

3 D.C. capacitive buss of 14.0 Failure of Control 2 2 6 1 10 No X Make M1 contactor a safety type and 1 1 1 1 3 Yes

AC drive not isolated Circuit move between drive & motor

from motor

4 Inch function on guards 14.0 Failure of Control 2 2 6 1 10 No X X X Change guard switches and add 1 2 1 1 4 Yes

open not appropriate Circuit safety monitoring relay. Add two-

hand control monitoring relay.

5 CR2, CR3, MCR not in 14.0 Failure of Control 2 2 6 1 10 No X Change to safety relays with 1 2 2 1 5 Yes

conformance Circuit appropriate monitoring

6 No flywheel motion 1.d Mechanical Hazard- 2 2 6 2 16 No X X Add stopped motion detector and 1 2 1 2 5 Yes

detection mass and velocity indicator

(kinetic energy of

elements in controlled

of uncontrolled motion)

7 Software not adequate 3 3 3 1 9 No X Modify software to accommodate 0 Yes

for above items 1-6 above modifications. Items 1-6

8 Main motor drive belts 1.3 Cutting Severing 1 2 3 1 6 Yes X The backside of this guard is open. 0 Yes

1.4 hazard, Entanglement This unit sits approx. 15 ft. above the

hazard ground. No access on top of press

while running

9 Flywheel 1.d Mechanical Hazard- 1 2 6 1 9 No X Flywheel is "counter sunk" in press 0 Yes

mass and velocity housing & covered with fiberglass

(kinetic energy of guard.

elements in controlled

of uncontrolled motion)

12 Main jackshaft 1.3 Cutting Severing 1 1 3 1 5 Yes X Drive belt is totally surrounded by a 0 Yes

1.4 hazard, Entanglement guard

hazard

34 0 0 Yes

35 0 0 Yes

Operational Concerns 0 0 Yes

0 Yes

0 Yes

0 0 Yes

Maintenance Concerns 0 0 Yes

0 0 Yes

0 0 Yes

Page 1 of 7 Form Revision: 4/13/2009

You might also like

- TQ Quantum ComputingDocument15 pagesTQ Quantum ComputingCasemiro Santos75% (12)

- Hazard Identification and Risk Assessment Form: Project ProcessDocument4 pagesHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNo ratings yet

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- Risk Assessment Guidance: Hazard Severity Likelihood of OccurrenceDocument10 pagesRisk Assessment Guidance: Hazard Severity Likelihood of OccurrenceSaleem AkhtarNo ratings yet

- A Review On Translucent Zirconia: KeywordsDocument13 pagesA Review On Translucent Zirconia: Keywordspaulo_mendes_6No ratings yet

- GEN-038 Balance Turbine Unit - All TypesDocument3 pagesGEN-038 Balance Turbine Unit - All Typesacanbasri1980No ratings yet

- Total Risk Management Kingdom DrillingDocument15 pagesTotal Risk Management Kingdom Drillingbengam100% (3)

- Risk Assessment - House and BuildingDocument1 pageRisk Assessment - House and Buildingnayanahari0% (1)

- GEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment CheckDocument3 pagesGEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment Checkacanbasri1980No ratings yet

- MP-001 Change Head and Liner of Mud PumpDocument3 pagesMP-001 Change Head and Liner of Mud PumpkhurramNo ratings yet

- MP-005 Change Relief Valve On Mud Pump.Document2 pagesMP-005 Change Relief Valve On Mud Pump.khurramNo ratings yet

- Dell 3400 LCD FmeaDocument13 pagesDell 3400 LCD Fmeaarif.fahmiNo ratings yet

- True-Rms Multimeters: Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176Document26 pagesTrue-Rms Multimeters: Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176João AlmeidaNo ratings yet

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 pagesDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaNo ratings yet

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- Working at Elevated Areas (Scaffolding)Document4 pagesWorking at Elevated Areas (Scaffolding)Ali Al-GhamghamNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- RISK ASSESSMENT (Included With Work Method Statement)Document10 pagesRISK ASSESSMENT (Included With Work Method Statement)MonicaNo ratings yet

- Hazard Identification and Risk Assessment Form: Project ProcessDocument4 pagesHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNo ratings yet

- 1 - R.A. - 003 - CompactionDocument2 pages1 - R.A. - 003 - CompactionmahmoudabidaliNo ratings yet

- Procedure For Tyre & Wheel SurveyDocument2 pagesProcedure For Tyre & Wheel SurveyNishan RachpallNo ratings yet

- GEN-021 Fact FindingDocument3 pagesGEN-021 Fact Findingacanbasri1980No ratings yet

- Control Reliability - Why It Is So Important in ManufacturingDocument36 pagesControl Reliability - Why It Is So Important in ManufacturingJUAN CARLOS ARMAS CHAVEZNo ratings yet

- Lifting - CraneDocument9 pagesLifting - CraneR Sahadeo ReddyNo ratings yet

- Ignitec FMEA TemplateDocument5 pagesIgnitec FMEA TemplatesamiazamNo ratings yet

- Method Statement & Risk AssDocument8 pagesMethod Statement & Risk AssUsman QayyumNo ratings yet

- JHA Lifting-Moving Heavy ObjectsDocument6 pagesJHA Lifting-Moving Heavy ObjectsamizanNo ratings yet

- 4.1 Risk Assessment - Electrical-Testing & CommissioningDocument5 pages4.1 Risk Assessment - Electrical-Testing & Commissioningzaigham naqvi0% (2)

- 67) DE54 ODME OperationDocument3 pages67) DE54 ODME Operationlatish salianNo ratings yet

- Risk Assessment NewDocument21 pagesRisk Assessment NewTomNo ratings yet

- 073 - R.A - Tank CleaningDocument3 pages073 - R.A - Tank Cleaningbappy s.hNo ratings yet

- RA-PROD-014-GALLAF-General Preheating FlaringDocument11 pagesRA-PROD-014-GALLAF-General Preheating FlaringidrisNo ratings yet

- Magnetically Coded Non-Contact Switch (MC1) : Product InformationDocument2 pagesMagnetically Coded Non-Contact Switch (MC1) : Product InformationGilbertNo ratings yet

- X1 Boost User ManualDocument22 pagesX1 Boost User ManualCharlez ManaloNo ratings yet

- Risk Asses 65 Piping Fabricated and Assembly H03Document13 pagesRisk Asses 65 Piping Fabricated and Assembly H03Khalid IrfanNo ratings yet

- RA-PROD-012-GALLAF - General PReheating and Flaring NewDocument12 pagesRA-PROD-012-GALLAF - General PReheating and Flaring NewidrisNo ratings yet

- Jgs-Ra-102-12 Pre-Commissioning Works - Air Blowing of Piping SystemsDocument6 pagesJgs-Ra-102-12 Pre-Commissioning Works - Air Blowing of Piping Systemsarnel sungkip100% (2)

- Disposal of Old Material HIRADocument3 pagesDisposal of Old Material HIRAAli Al-GhamghamNo ratings yet

- Job Risk Assessment Form: Vessel: M/V Gemini 2Document1 pageJob Risk Assessment Form: Vessel: M/V Gemini 2Danilo OralNo ratings yet

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Risk Assessment - Hand ToolsDocument2 pagesRisk Assessment - Hand ToolsRoy Chandra Sekar JeyapaulNo ratings yet

- FMEA FormatDocument3 pagesFMEA Formatcrazy_hornetNo ratings yet

- 8-8 Nail-Risk Management Report PDFDocument12 pages8-8 Nail-Risk Management Report PDFDiana Rodriguez ParodiNo ratings yet

- Analisis de RiesgosDocument11 pagesAnalisis de Riesgosalejandro MalacaraNo ratings yet

- M - 614.00754.00 X1 Mini G3.1 ManualDocument25 pagesM - 614.00754.00 X1 Mini G3.1 ManualThinh LeNo ratings yet

- SWMS42 Working On Water MainsDocument6 pagesSWMS42 Working On Water MainsShahrin OmarNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. Ahmad100% (1)

- 20161104-NW SHEF RA Boxing of Swordfish WingsDocument4 pages20161104-NW SHEF RA Boxing of Swordfish Wingsmark.wilsonNo ratings yet

- Job Hazard AssessmentDocument2 pagesJob Hazard AssessmentAli JawadNo ratings yet

- 11kV Switchgerar PD MeasurementDocument3 pages11kV Switchgerar PD MeasurementMohammadAsif ThakorNo ratings yet

- Risk Assessment Power Tong InstallationDocument5 pagesRisk Assessment Power Tong InstallationSaqib Aftab (HSE Engineer)No ratings yet

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- Final Risk Assessment For R1114 ProjectDocument45 pagesFinal Risk Assessment For R1114 Projectvinothsekar6662No ratings yet

- 16 Risk Assessment ManagementDocument5 pages16 Risk Assessment ManagementBasit HaswareNo ratings yet

- X96A-programming Control ValveDocument24 pagesX96A-programming Control ValveChandan KumarNo ratings yet

- Engineering Principles - PEO 19 2023Document54 pagesEngineering Principles - PEO 19 2023Christopher RedfernNo ratings yet

- FMEADocument9 pagesFMEARashmita SahooNo ratings yet

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Fundamentals SRMDocument20 pagesFundamentals SRMGabriel MazzoccaNo ratings yet

- SMS Fundamentals: Federal Aviation AdministrationDocument16 pagesSMS Fundamentals: Federal Aviation AdministrationGabriel MazzoccaNo ratings yet

- Considering Aviation Safety System Performance Indicators: 1/ Internal Audits/compliance Monitoring: All Non-CompliancesDocument7 pagesConsidering Aviation Safety System Performance Indicators: 1/ Internal Audits/compliance Monitoring: All Non-CompliancesGabriel MazzoccaNo ratings yet

- Fundamentals: Safety Management System (SMS)Document26 pagesFundamentals: Safety Management System (SMS)Gabriel MazzoccaNo ratings yet

- Additional Mousetrap Investigation NotesDocument69 pagesAdditional Mousetrap Investigation NotesPradeep WalaweNo ratings yet

- 3Document4 pages3Anonymous oUoJ4A8xNo ratings yet

- Exam Questions Modelling With Exponential Functions - MsDocument13 pagesExam Questions Modelling With Exponential Functions - MsfajrbilaNo ratings yet

- Omi - Da - MshvidobaDocument40 pagesOmi - Da - MshvidobaFlokiNo ratings yet

- hpd8 CC NewDocument2 pageshpd8 CC Newc membrenoNo ratings yet

- Current Electricity: TopicDocument31 pagesCurrent Electricity: Topicashok pradhanNo ratings yet

- Notes! Theory of FlightDocument5 pagesNotes! Theory of FlightCris TrinidadNo ratings yet

- Naest 2023 - Prelims Expt - 1Document3 pagesNaest 2023 - Prelims Expt - 1rakshit9951No ratings yet

- Bearing Capacity From SPTDocument10 pagesBearing Capacity From SPTمهندس محب للعلمNo ratings yet

- November 2021 (v3) QP - Paper 4 CAIE Physics IGCSEDocument20 pagesNovember 2021 (v3) QP - Paper 4 CAIE Physics IGCSElikhithfantasticNo ratings yet

- Def Stan 61-12 Part 18Document43 pagesDef Stan 61-12 Part 18Deepto BanerjeeNo ratings yet

- Compass Course Corrections 20.10.20Document51 pagesCompass Course Corrections 20.10.20freyanerisebrownNo ratings yet

- Structural Control of Ore DepositsDocument22 pagesStructural Control of Ore DepositsajreateguicNo ratings yet

- Exercise Set 1.8Document5 pagesExercise Set 1.8Alena MansikaNo ratings yet

- Bathurst Et Al v43 n12 2006 The Influence of Facing Stiffness On The Performance of Thwo Geosynthetic Reinforced Osil Retaining WallsDocument13 pagesBathurst Et Al v43 n12 2006 The Influence of Facing Stiffness On The Performance of Thwo Geosynthetic Reinforced Osil Retaining WallsHUGINo ratings yet

- Chemical Process Principles (CLB10904) : Chapter 2 Material Balance: (PART 1)Document46 pagesChemical Process Principles (CLB10904) : Chapter 2 Material Balance: (PART 1)FATMIENo ratings yet

- Exercise 1: Reactors: 1.1 Reactor SelectionDocument4 pagesExercise 1: Reactors: 1.1 Reactor SelectionAnh Đỗ HoàngNo ratings yet

- Navier-Stokes Equation (An Overview and The Simplification) : July 2020Document10 pagesNavier-Stokes Equation (An Overview and The Simplification) : July 2020JuniorNo ratings yet

- Portable Refractometer RA 130Document2 pagesPortable Refractometer RA 130tefovNo ratings yet

- Zimbabwe School Examinations Council Physics 6032/1: Electronic Calculator And/or Mathematical TablesDocument16 pagesZimbabwe School Examinations Council Physics 6032/1: Electronic Calculator And/or Mathematical TablesKuzivakwasheNo ratings yet

- Experimentno.6 Uniformly Accelerated Motion - Free Fall I. ObjectivesDocument6 pagesExperimentno.6 Uniformly Accelerated Motion - Free Fall I. ObjectivesStephanie AzucenaNo ratings yet

- Mini Project of Batch#5#Document71 pagesMini Project of Batch#5#fathimunnisashaik403No ratings yet

- Syllabus AMIDocument2 pagesSyllabus AMIMathavaraja JeyaramanNo ratings yet

- HOMEWORK Algebra 3 Feb 212023Document6 pagesHOMEWORK Algebra 3 Feb 212023Sharmaine FajutaganaNo ratings yet

- Final LabDocument24 pagesFinal LabNathasha MncubeNo ratings yet

- GB Rca Car 2023 001Document2 pagesGB Rca Car 2023 001cameron toolseeNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- Physics Practical HandbookDocument20 pagesPhysics Practical HandbookMOHAMED SHAMIR BIN TAJUDEENNo ratings yet