Professional Documents

Culture Documents

MTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670

MTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670

Uploaded by

jamal molanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670

MTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670

Uploaded by

jamal molanaCopyright:

Available Formats

Industrial

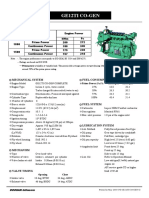

Diesel Engine 12V 2000 Cx6

for C&I and Mining Applications

Dimensions and Masses

Engine Dimensions (LxWxH) mm (in) Mass, dry kg (lbs)

12V 2028 x 1278 x 1461 (79.8 x 50.3 x 57.5) 2950 (6503)

All dimensions are approximate, for complete information refer to the installation drawing.

Engine Model

Bore/stroke mm (in) 135/156 (5.3/6.2)

Cylinder configuration 90° V

Displacement/cylinder l (cu in) 2.23 (136)

Displacement, total l (cu in) 26.8 (1633)

Fuel specification Diesel fuel in accordance with DIN EN 590,

ASTM D 975, BS 2869, US DF # 1-Off Highway and

US DF # 2-Off Highway

Engine Type Rated Power ICFN Peak Torque Optimization

Model kW bhp rpm Nm lb-ft rpm

Application Medium duty operation (5B)

12V 2000 C66 783 1050 2100 4636 3419 1100 38

12V 2000 C66R* 783 1050 1800 4636 3419 1100 38

Optimization: 38 EPA Nonroad T4i Comp (40CFR1039)

* also available for 2A application

Power. Passion. Partnership.

Subject to change. | 3235061 | Edition 01/17 | EPC 2017-03.

Application Power definition

5B Continuous operation w/variable load Load factor: < 60 %, Operating hours: unrestricted, Overload: Fuel stop (ICFN)

Power output within 5% tolerance at standard conditions. Power definition according to ISO 3046 (ratings also correspond to SAE J 1995 and SAE J 1349 standard conditions).

Consult your MTU distributor/dealer for the rating that will apply to your specific application.

Standard Equipment

Starting System Electrical starter 24 VDC

Fuel System Electronically controlled common-rail injection system, dual engine mounted fuel filters

Lube Oil System Forced feed lubricating system with piston cooling, lube oil circulating pump, multi stage oil filter, lube oil heat

exchanger, 15° oil pan

Combustion Air System Two-stage turbocharging, intercooling and charge air cooling, cooled exhaust gas recirculation, turbocharger air

intake from free end

Coolant System SCCC HT (JW) and LT (CAC) separate coolant circuits with coolant pumps and thermostats

Flywheel/Housing SAE 0 flywheel housing, suitable for wet and dry drive solutions

Engine Mounting 3-point or 4-point mounting

Electronics and Instrumentation Latest ADEC engine control and management system

Optional Equipment

Starting System Redundant starting systems electric (dual); air

Fuel system Doublewalled high pressure piping

Oil System Remote mounted oil filters 22°/30° oilpans

Combustion Air System Air shut-off Flaps, turbocharger air intake from driving end

Coolant System Coolant heater, front crank PTO for fan drive (various ratios), connections for accessory heat exchanger

(part flow/full flow)

Flywheel/Housing Flexplate, flywheel housing with aux. PTO`s

Accessory Drives Battery charging alternator, 28VDC, aux. PTO’s for hydr. pump drives and compressors

Reference conditions:

> Intake-air temperature: 25°C (77°F) > Ambient air pressure: 1000 mbar > Altitude above sea level: 100 m (328 ft)

Subject to change without notice. Customization possible. Engines illustrated in this document may feature options not fitted as standard to standard engine.

MTU Friedrichshafen GmbH I MTU Asia Pte Ltd I MTU America Inc.

Part of the Rolls-Royce Group

www.mtu-online.com

You might also like

- PC228 PDFDocument928 pagesPC228 PDFJoão Guilherme Andretto Balloni100% (6)

- Cat DG Set (500-600 Kva) Parts Manual-3412taDocument254 pagesCat DG Set (500-600 Kva) Parts Manual-3412tasblnt2008100% (2)

- Hatz Diesel - Diagnostic Trouble Codes SPN/FMI C81 - V6XX - 05653402Document28 pagesHatz Diesel - Diagnostic Trouble Codes SPN/FMI C81 - V6XX - 05653402MARINE DIESELNo ratings yet

- MTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetDocument2 pagesMTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNo ratings yet

- Vpower / Mtu Series 1500RPM / 50HZ / 400V Vpower / Mtu Series 1500RPM / 50HZ / 400VDocument2 pagesVpower / Mtu Series 1500RPM / 50HZ / 400V Vpower / Mtu Series 1500RPM / 50HZ / 400Vchock channel 19No ratings yet

- V222Document2 pagesV222foxNo ratings yet

- D550 GBDocument4 pagesD550 GBSmeloNo ratings yet

- Significant Ships 2008 PDFDocument104 pagesSignificant Ships 2008 PDF陈浩宇No ratings yet

- MTU Datasheet s4000px3 Constant SpeedDocument2 pagesMTU Datasheet s4000px3 Constant SpeedKrish100% (1)

- MTU 12 16V4000M71 SpecsificationDocument2 pagesMTU 12 16V4000M71 Specsificationzaki100% (1)

- Diesel Engines 16V 4000 M61R/M61: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M61R/M61: For Vessels With Unrestricted Continuous Operation (1A)avinash_1229100% (1)

- Spec Sheet MTU 16V4000 DS2250 FC PDFDocument6 pagesSpec Sheet MTU 16V4000 DS2250 FC PDFMarison SaragihNo ratings yet

- OE Spec MTU12V1600DS660 3B 50Hz 2 14Document5 pagesOE Spec MTU12V1600DS660 3B 50Hz 2 14dinukaeeNo ratings yet

- Technical Data: BCMU 700S-60 BCMU 650P-60Document3 pagesTechnical Data: BCMU 700S-60 BCMU 650P-60Jun AballeNo ratings yet

- V222ti PDFDocument2 pagesV222ti PDFcmendezNo ratings yet

- Dse8610 Data Sheet UsDocument2 pagesDse8610 Data Sheet UsAlfonso TorresNo ratings yet

- RENK AED eDocument8 pagesRENK AED eZehraNo ratings yet

- MTU Gendrive Spec 12V16V18V2000Gx5 3D 3E W2ADocument3 pagesMTU Gendrive Spec 12V16V18V2000Gx5 3D 3E W2Atinhotrading .jinchaoNo ratings yet

- TNK60DG Taneko Gas Generator (TNK JKT)Document2 pagesTNK60DG Taneko Gas Generator (TNK JKT)hareudangNo ratings yet

- 8N 8466Document3 pages8N 8466Rachid KerdidiNo ratings yet

- DE12TISDocument2 pagesDE12TISRowan CorneliusNo ratings yet

- P158LEDocument4 pagesP158LEjackacak100% (1)

- Renk Curved Tooth Couplings Basic Construction Series enDocument52 pagesRenk Curved Tooth Couplings Basic Construction Series enhumayun121No ratings yet

- DET+ & DET-1600/1620 Detonation Sensing Monitors: Detects Detonation and Avoids Consequential Engine DamageDocument2 pagesDET+ & DET-1600/1620 Detonation Sensing Monitors: Detects Detonation and Avoids Consequential Engine DamageSaasiNo ratings yet

- PIM130B1 - Honeywell AGT1500 Archived 03 2009 PDFDocument10 pagesPIM130B1 - Honeywell AGT1500 Archived 03 2009 PDF13421301508No ratings yet

- Ge08ti Co Gen-GDocument2 pagesGe08ti Co Gen-GGuillermo OchoaNo ratings yet

- MTU 1 ST YEAR SYLLABUSDocument80 pagesMTU 1 ST YEAR SYLLABUSaditya7195488No ratings yet

- Diesel Engines 16V 4000 M53M63 1ADocument2 pagesDiesel Engines 16V 4000 M53M63 1AMario100% (1)

- For Vessels With Unrestricted Continuous Operation (1A) : Diesel Engines 8V/12V/16V 4000 M60Document2 pagesFor Vessels With Unrestricted Continuous Operation (1A) : Diesel Engines 8V/12V/16V 4000 M60Abdul Khaliq100% (1)

- MTU20V4000DS2800 2500kW DCCP PDFDocument4 pagesMTU20V4000DS2800 2500kW DCCP PDFNestor AlbarranNo ratings yet

- 05 DPI May 17 ScribdDocument47 pages05 DPI May 17 Scribdratninp9368No ratings yet

- Spec Sheet Mtu 16v4000 Ds2250 FCDocument6 pagesSpec Sheet Mtu 16v4000 Ds2250 FCMarison Saragih100% (1)

- Operating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXDocument183 pagesOperating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXforuzzNo ratings yet

- Class VT 642 Diesel Multiple Unit DESIRO: For German RailDocument4 pagesClass VT 642 Diesel Multiple Unit DESIRO: For German RailAlexandra Idmt100% (1)

- Data, Facts and Products: Innovative Power TransmissionDocument16 pagesData, Facts and Products: Innovative Power TransmissionHeri SetyantoNo ratings yet

- Renk High Torque Planetary Gears PBLZDocument12 pagesRenk High Torque Planetary Gears PBLZhumayun121No ratings yet

- Engine DetailsDocument2 pagesEngine DetailsNeil GudiwallaNo ratings yet

- Transmission For Tracked VehiclesDocument2 pagesTransmission For Tracked Vehiclesmuhammet fidanNo ratings yet

- Renk Single Marine Gears UnitsDocument2 pagesRenk Single Marine Gears Unitsharith faiz100% (1)

- Force MTU Spec Sheet 500 KVA 415V 50 HZ PrimeDocument2 pagesForce MTU Spec Sheet 500 KVA 415V 50 HZ PrimeMohamed KamalNo ratings yet

- MTU-integrated Bi-Fuel Engine Technology To Reduce Fuel CostsDocument2 pagesMTU-integrated Bi-Fuel Engine Technology To Reduce Fuel CostsQaiser IqbalNo ratings yet

- Aoe 12V4000L62 Ratings and Emissions 1: Technical Description TB 46204 F 50Document7 pagesAoe 12V4000L62 Ratings and Emissions 1: Technical Description TB 46204 F 50mgewaliNo ratings yet

- Series 4000: Engines For Industrial and Mining ApplicationsDocument2 pagesSeries 4000: Engines For Industrial and Mining Applicationswaleed yehia100% (1)

- Marine Tfseries DatasheetDocument2 pagesMarine Tfseries DatasheetAnno Fikri ArditoNo ratings yet

- 21M Search and Rescue Vessel: Dimensional Data Standard FeaturesDocument1 page21M Search and Rescue Vessel: Dimensional Data Standard FeaturesNico BossiNo ratings yet

- Curved Tooth Couplings Disengageable at StandstillDocument8 pagesCurved Tooth Couplings Disengageable at Standstillmartensita24No ratings yet

- DP158LD CDocument4 pagesDP158LD Cmoises100% (1)

- ENGINE DATA SHEET 350 KW 8V1600G70SDocument13 pagesENGINE DATA SHEET 350 KW 8V1600G70SAngel RiosNo ratings yet

- Diesel Generating Set BF-DW750: Standby Power 50Hz Prime Power 50HzDocument5 pagesDiesel Generating Set BF-DW750: Standby Power 50Hz Prime Power 50HzheriNo ratings yet

- Technical Data&Configuration List of Mucking Loader-LWLX (C) - 120Document3 pagesTechnical Data&Configuration List of Mucking Loader-LWLX (C) - 120nickdash09No ratings yet

- Renk Service enDocument12 pagesRenk Service enhumayun121No ratings yet

- 16V4000G83 3D en ConsumptionDocument9 pages16V4000G83 3D en ConsumptionmsahbkNo ratings yet

- Renk Bearings RangeDocument2 pagesRenk Bearings Rangehumayun121No ratings yet

- Catalog Specifications Caterpillar 7495 Electric Rope Shovel Rope CrowdDocument3 pagesCatalog Specifications Caterpillar 7495 Electric Rope Shovel Rope Crowdahmed zhranNo ratings yet

- XE2000E技术规格书Document21 pagesXE2000E技术规格书abangNo ratings yet

- MTU Brochure GendriveDocument11 pagesMTU Brochure GendrivevicNo ratings yet

- Global AE Training - Cooling System - 28apr21Document61 pagesGlobal AE Training - Cooling System - 28apr21thainarimeNo ratings yet

- Ge12ti Co Gen-GDocument2 pagesGe12ti Co Gen-GTilok DasNo ratings yet

- HighDocument20 pagesHighRizki Fajar NovantoNo ratings yet

- Diesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Jorge Bellido100% (1)

- DSE7510 Data Sheet PDFDocument2 pagesDSE7510 Data Sheet PDFKrishna Pardeshi100% (1)

- Siemens Sge 2mwDocument2 pagesSiemens Sge 2mwmohsen_cumminsNo ratings yet

- MTU 20V4000 DS2800: Diesel Generator SetDocument4 pagesMTU 20V4000 DS2800: Diesel Generator SetMinaSaeedNo ratings yet

- Series 2000: Stationary Industrial Engines For The Oil & Gas IndustryDocument2 pagesSeries 2000: Stationary Industrial Engines For The Oil & Gas IndustryLeonardo ViilalobosNo ratings yet

- 185-250 JD Air CompressorDocument2 pages185-250 JD Air CompressorEdmore MukotsanjeraNo ratings yet

- 16v4000r43 PDFDocument163 pages16v4000r43 PDFAvir YadavNo ratings yet

- Perkins CatalogDocument4 pagesPerkins CatalogTri RandiNo ratings yet

- 40m Specs Sheet - T5 PDFDocument4 pages40m Specs Sheet - T5 PDFMohamedNo ratings yet

- Test Bank For Automotive Technology A Systems Approach 6th EditionDocument10 pagesTest Bank For Automotive Technology A Systems Approach 6th EditionDerekWrightspzm100% (39)

- Marine Survey Practice - Surveyor Guide Notes For Oil Tankers Survey PDFDocument4 pagesMarine Survey Practice - Surveyor Guide Notes For Oil Tankers Survey PDFJuanjo MarengoNo ratings yet

- RLB (Rider Levette Bucknall) : P.5CQ-21072 - JGVDocument5 pagesRLB (Rider Levette Bucknall) : P.5CQ-21072 - JGVVinz Alyssa Mae OñoNo ratings yet

- PM B25D MK7 ADT Rev+ADocument724 pagesPM B25D MK7 ADT Rev+ABiswajit DasNo ratings yet

- Engineering Chemistry PDFDocument293 pagesEngineering Chemistry PDFAnonymous tdtTl8KypNo ratings yet

- Ranarex GravitometerDocument2 pagesRanarex GravitometerNguyen Vi HungNo ratings yet

- Volkswagen Service Training Vwcom 20l Tsi Turbo24803Document5 pagesVolkswagen Service Training Vwcom 20l Tsi Turbo24803james100% (49)

- Training Report: Share Your ThoughtsDocument1 pageTraining Report: Share Your Thoughtsadeel jamilNo ratings yet

- Why The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncDocument11 pagesWhy The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncAnoj pahathkumburaNo ratings yet

- ABS - Part 4 - e PDFDocument700 pagesABS - Part 4 - e PDFMuhammad Fauzan Mauliawan100% (1)

- PTS 916 Operating ManualDocument5 pagesPTS 916 Operating ManualtskumarNo ratings yet

- GlobalAviator 201406Document100 pagesGlobalAviator 201406Kristi MosesNo ratings yet

- Global Downstream Outlook To 2035Document16 pagesGlobal Downstream Outlook To 2035psnshreemaxNo ratings yet

- Effbe KatalogDocument12 pagesEffbe KatalogNataša AćimovićNo ratings yet

- Lec 4Document7 pagesLec 4اسامه عمر عثمانNo ratings yet

- Hino Catalogue InteractiveDocument103 pagesHino Catalogue InteractiveAbubakar MansoorNo ratings yet

- Diesel: K D 3 8 8 K D 4 8 8Document22 pagesDiesel: K D 3 8 8 K D 4 8 8Muhamad Ilham Fatchu RezaNo ratings yet

- Wittig PDFDocument38 pagesWittig PDFProf YoupaNo ratings yet

- DMTP 5100Document41 pagesDMTP 5100Henry GelvisNo ratings yet

- Nachi HydraulicDocument2 pagesNachi HydraulicDian PramadiNo ratings yet

- A001072 01eDocument97 pagesA001072 01eNutthakarn WisatsiriNo ratings yet