Professional Documents

Culture Documents

PBDB Full Es Metric A4

PBDB Full Es Metric A4

Uploaded by

Victor Pablo Cantaro MelgarejoCopyright:

Available Formats

You might also like

- Cosmetology Portfolio: Jaimie R. FortinDocument34 pagesCosmetology Portfolio: Jaimie R. FortinJaimie FantasticNo ratings yet

- Management c1Document173 pagesManagement c1Winnie Pualon CejudoNo ratings yet

- Lecture 2 Fractures Description & ClassificationDocument35 pagesLecture 2 Fractures Description & Classificationmukhtar abddiNo ratings yet

- Project SideshowDocument4 pagesProject SideshowMetro English CanadaNo ratings yet

- Breville BCI600 Ice Cream Maker User Manual PDFDocument40 pagesBreville BCI600 Ice Cream Maker User Manual PDFTon TonNo ratings yet

- Modelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument1 pageModelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AJonathanDavidDeLosSantosAdornoNo ratings yet

- PPDB en Us A4Document1 pagePPDB en Us A4Felipe DiazNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- DRBCLBN Full Es Us A4Document2 pagesDRBCLBN Full Es Us A4Erasmo LimaNo ratings yet

- PPDBLAN Es Metric LetterDocument1 pagePPDBLAN Es Metric Lettersebastian.vegaNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNo ratings yet

- PRDBOEN Full en Us LetterDocument3 pagesPRDBOEN Full en Us LetterPartagon PowNo ratings yet

- PBFB en Us A4Document1 pagePBFB en Us A4operacion hydratekNo ratings yet

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- Relife Valve Rpeclnn - Pilot OperatedDocument2 pagesRelife Valve Rpeclnn - Pilot OperatedHassan KhattabNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4Document1 pageModel Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4mhasansharifiNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- PRDC Sun ValveDocument3 pagesPRDC Sun ValvekhairulanuarjunNo ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2AleosignareNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- RPECOAN Full Es Metric LetterDocument2 pagesRPECOAN Full Es Metric Letteralfredo lopez regaladoNo ratings yet

- Valvula Reguladora Continental PBFB-LAVDocument1 pageValvula Reguladora Continental PBFB-LAVsalesparts.norvateNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- Relife Valve Low Flow Rbac - T10aDocument1 pageRelife Valve Low Flow Rbac - T10aHassan KhattabNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- Modelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Document1 pageModelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Erasmo LimaNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- RDBALAN Full en Metric A4Document2 pagesRDBALAN Full en Metric A4David AltarribaNo ratings yet

- RSBC Full en Us A4Document2 pagesRSBC Full en Us A4Mykola TitovNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- RPEI en Us A4Document1 pageRPEI en Us A4Rafael GoulartNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- RPCCLAN Full en Us LetterDocument2 pagesRPCCLAN Full en Us Lettera safaieNo ratings yet

- RDBALAN Full Es Metric A4Document2 pagesRDBALAN Full Es Metric A4Willam Hugo Luna PonteNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalNo ratings yet

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveDocument1 pageModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriNo ratings yet

- RDJA Full en Us A4Document3 pagesRDJA Full en Us A4GERALD SIMONNo ratings yet

- RDDALAN Es Metric LetterDocument1 pageRDDALAN Es Metric Lettersebastian.vegaNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- CBGGLJN Es Metric LetterDocument1 pageCBGGLJN Es Metric LetterjesusNo ratings yet

- CCCALBN en Us LetterDocument1 pageCCCALBN en Us Letterisaiahsamsonm_948069No ratings yet

- CBGG Es Metric LetterDocument2 pagesCBGG Es Metric LetterjesusNo ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- Sun Hydraulics RDDA-LCNDocument3 pagesSun Hydraulics RDDA-LCNJustinNo ratings yet

- Powered ExoskeletonDocument22 pagesPowered ExoskeletonSarfaras Ali K100% (1)

- Hypertension FamcoDocument42 pagesHypertension FamcoMusleh Al MusalhiNo ratings yet

- ADV Word GivenDocument13 pagesADV Word Givengloria500100% (1)

- Soal Pat Semester 2 Bing 7Document5 pagesSoal Pat Semester 2 Bing 7SAIFULNo ratings yet

- Project Report On Garment BusinessDocument2 pagesProject Report On Garment BusinessAnupNo ratings yet

- Cube Test Letter - SignedDocument2 pagesCube Test Letter - Signedsamarsandip1No ratings yet

- 17 - Guide To Asbestos For IndustryDocument73 pages17 - Guide To Asbestos For Industryraul_bsuNo ratings yet

- Amy Rowley, by Her Parents and Natural Guardians, Clifford and Nancy Rowley, and Clifford and Nancy Rowley, in Their Own Right v. The Board of Education of the Hendrick Hudson Central School District, Westchester County, and the Commissioner of Education of the State of New York, 632 F.2d 945, 2d Cir. (1980)Document17 pagesAmy Rowley, by Her Parents and Natural Guardians, Clifford and Nancy Rowley, and Clifford and Nancy Rowley, in Their Own Right v. The Board of Education of the Hendrick Hudson Central School District, Westchester County, and the Commissioner of Education of the State of New York, 632 F.2d 945, 2d Cir. (1980)Scribd Government DocsNo ratings yet

- Arizona Communicable Disease FlipchartDocument98 pagesArizona Communicable Disease Flipchartapi-510866696No ratings yet

- Survey Questionnaire PresentationDocument14 pagesSurvey Questionnaire PresentationFaith PaladoNo ratings yet

- Exercises For Lab Report 0 202133Document3 pagesExercises For Lab Report 0 202133Luis Giovanni Ortiz Rodríguez IINo ratings yet

- MTT10 Dummy MG PDFDocument20 pagesMTT10 Dummy MG PDFnewspubincNo ratings yet

- Part I. Assessment On Emotional Quotient (Modified: Daniel Goleman EQ Test, 1995)Document4 pagesPart I. Assessment On Emotional Quotient (Modified: Daniel Goleman EQ Test, 1995)Jennalyn AdatoNo ratings yet

- Smart MaterialDocument3 pagesSmart MaterialyokaNo ratings yet

- Synthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDocument29 pagesSynthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDl Divakar LNo ratings yet

- ZER O: One Point LessonsDocument14 pagesZER O: One Point LessonsZulema GaramendiNo ratings yet

- Shani Taub: Certified Dietary Consultant 732-300-8541, 732-364-7392Document1 pageShani Taub: Certified Dietary Consultant 732-300-8541, 732-364-7392henny bandaNo ratings yet

- Lab 2. Lowry MethodDocument3 pagesLab 2. Lowry MethodDũng Nguyễn ViệtNo ratings yet

- Penerapan Sistem Haccp Jurusan Gizi Poltekkes Kemenkes MalangDocument3 pagesPenerapan Sistem Haccp Jurusan Gizi Poltekkes Kemenkes MalangGita Martha VIndiartiNo ratings yet

- Kadar Protein Terlarut Dalam Albumin Ikan Gabus (Channa Striata Dan Channa Micropeltes) Asal BogorDocument9 pagesKadar Protein Terlarut Dalam Albumin Ikan Gabus (Channa Striata Dan Channa Micropeltes) Asal BogorAnkaranaRenvaNo ratings yet

- Volcanic EruptionDocument2 pagesVolcanic EruptionAhmad NursidikNo ratings yet

- Amcel KP20Document1 pageAmcel KP20Marcos KuriharaNo ratings yet

- Quote Vendor File ExcelDocument254 pagesQuote Vendor File ExcelsefiplanNo ratings yet

- 0628-334-01 - D LLHS Operator ManualDocument48 pages0628-334-01 - D LLHS Operator Manualtecvision.assistenciaNo ratings yet

- Get To Know The Newly Redesigned Texas DL and ID Cards: Adult & Under 21 Identification CardDocument2 pagesGet To Know The Newly Redesigned Texas DL and ID Cards: Adult & Under 21 Identification Carddominique marshallNo ratings yet

PBDB Full Es Metric A4

PBDB Full Es Metric A4

Uploaded by

Victor Pablo Cantaro MelgarejoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PBDB Full Es Metric A4

PBDB Full Es Metric A4

Uploaded by

Victor Pablo Cantaro MelgarejoCopyright:

Available Formats

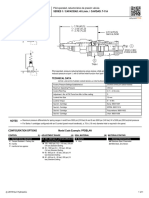

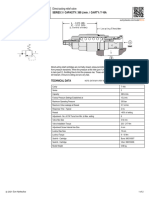

MODELO Pilot-operated, reductor de presión válvula

PBDB SERIES 1 / CAPACIDAD: 40 L/min. / CAVIDAD: T-11A

sunhydraulics.com/model/PBDB

Pilot-operated, pressure reducing valves reduce a high primary pressure at the inlet (port 2) to a constant reduced

pressure at port 1, allowing circuits with multiple pressure requirements to be operated using a single pump.

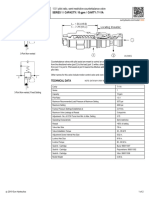

TECHNICAL DATA

NOTAR: LOS DATOS PUEDEN VARIAR SEGÚN LA CONFIGURACIÓN . CONSULTE LA SECCIÓN DE CONFIGURATION

cavidad T-11A

Series 1

Capacity 40 L/min.

Factory Pressure Settings Established at blocked control port (dead headed)

Maximum Operating Pressure 350 bar

Control Pilot Flow 0,11 - 0,16 L/min.

Adjustment - No. of CW Turns from Min. to Max. setting 5

Valve Hex Size 22,2 mm

Valve Installation Torque 41 - 47 Nm

Adjustment Screw Internal Hex Size 4 mm

Locknut Hex Size 15 mm

Locknut Torque 9 - 10 Nm

Seal kit - Cartridge Buna: 990011007

Seal kit - Cartridge EPDM: 990011014

Seal kit - Cartridge Polyurethane: 990011002

Seal kit - Cartridge Viton: 990011006

Model Weight 0.16 kg.

NOTES Maximum pressure differentials for spring ranges: A and B are 3000 psi (210 bar) N and Q are 2000 psi (140 bar) W is 5000 psi (350 bar)inlet pressure

For Series 1 cartridges configured with an O control (panel mount handknob), a .75 in. (19 mm) diameter hole is required in the panel.

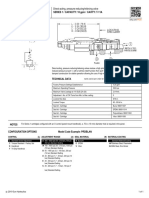

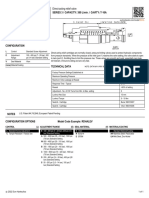

CONFIGURATION OPTIONS Model Code Example: PBDBLAN

CONTROL (L) ADJUSTMENT RANGE (A) SEAL MATERIAL (N) MATERIAL/COATING

L Standard Screw Adjustment A 100 - 3000 psi (7 - 210 bar), 200 psi (14 N Buna-N Standard Material/Coating

C Tamper Resistant - Factory Set bar) Standard Setting V Viton /AP Stainless Steel, Passivated

K manilla W 150 - 4500 psi (10,5 - 315 bar), 200 psi /LH Mild Steel, Zinc-Nickel

W Hex Wrench Adjustment (14 bar) Standard Setting

Y manilla de tres agarres B 50 - 1500 psi (3,5 - 105 bar), 200 psi

(14 bar) Standard Setting

N 60 - 800 psi (4 - 55 bar), 200 psi (14

bar) Standard Setting

Q 60 - 400 psi (4 - 28 bar), 200 psi (14

bar) Standard Setting

c 2019 Sun Hydraulics

1 of 2

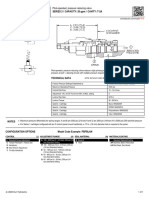

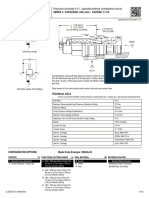

TECHNICAL FEATURES

All three-port pressure reducing and reducing/relieving cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size). When

considering mounting configurations, it is sometimes recommended that a full capacity return line (port 3) be used with reducing/relieving cartridges.

Full reverse flow from reduced pressure (port 1) to inlet (port 2) may cause the main spool to close. If reverse free flow is required in the circuit, consider adding a

separate check valve to the circuit.

If pilot flow consumption is critical, consider using direct acting reducing/relieving valves.

Main stage orifice is protected by a 150 micron stainless steel screen.

Recommended maximum inlet pressure is determined by the adjustment range. Ranges D, E, N, and Q are tested with a 2000 psi (140 bar) maximum differential

between inlet and reduced pressure. Ranges A, B, and H are tested with a 3000 psi (210 bar) maximum differential between inlet and reduced pressure. Ranges C

and W are tested with 5000 psi (350 bar) of inlet pressure.

Pilot operated valves exhibit exceptionally flat pressure/flow characteristics, are very stable and have low hysteresis.

Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 5000 psi (350 bar).

Pilot operated reducing, reducing/relieving valves by nature are not fast acting valves. For superior dynamic response, consider direct acting valves.

W and Y controls (where applicable) can be specified with or without a special setting. When no special setting is specified, the valve is adjustable throughout its full

range using the W or Y control. When a special setting is specified, this setting represents the maximum setting of the valve.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP for external stainless steel

components, or /LH for external zinc-nickel plated components. See the CONFIGURATION section for all options. For further details, please see the Materials of

Construction page located under TECH RESOURCES.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

PERFORMANCE CURVES

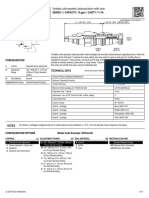

RELATED MODELS

PBDB8 Pilot-operated, reductor de presión módulo principal con cavidad de control T-8A integral

c 2019 Sun Hydraulics

2 of 2

You might also like

- Cosmetology Portfolio: Jaimie R. FortinDocument34 pagesCosmetology Portfolio: Jaimie R. FortinJaimie FantasticNo ratings yet

- Management c1Document173 pagesManagement c1Winnie Pualon CejudoNo ratings yet

- Lecture 2 Fractures Description & ClassificationDocument35 pagesLecture 2 Fractures Description & Classificationmukhtar abddiNo ratings yet

- Project SideshowDocument4 pagesProject SideshowMetro English CanadaNo ratings yet

- Breville BCI600 Ice Cream Maker User Manual PDFDocument40 pagesBreville BCI600 Ice Cream Maker User Manual PDFTon TonNo ratings yet

- Modelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument1 pageModelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AJonathanDavidDeLosSantosAdornoNo ratings yet

- PPDB en Us A4Document1 pagePPDB en Us A4Felipe DiazNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- DRBCLBN Full Es Us A4Document2 pagesDRBCLBN Full Es Us A4Erasmo LimaNo ratings yet

- PPDBLAN Es Metric LetterDocument1 pagePPDBLAN Es Metric Lettersebastian.vegaNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNo ratings yet

- PRDBOEN Full en Us LetterDocument3 pagesPRDBOEN Full en Us LetterPartagon PowNo ratings yet

- PBFB en Us A4Document1 pagePBFB en Us A4operacion hydratekNo ratings yet

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- Relife Valve Rpeclnn - Pilot OperatedDocument2 pagesRelife Valve Rpeclnn - Pilot OperatedHassan KhattabNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4Document1 pageModel Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4mhasansharifiNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- PRDC Sun ValveDocument3 pagesPRDC Sun ValvekhairulanuarjunNo ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2AleosignareNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- RPECOAN Full Es Metric LetterDocument2 pagesRPECOAN Full Es Metric Letteralfredo lopez regaladoNo ratings yet

- Valvula Reguladora Continental PBFB-LAVDocument1 pageValvula Reguladora Continental PBFB-LAVsalesparts.norvateNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- Relife Valve Low Flow Rbac - T10aDocument1 pageRelife Valve Low Flow Rbac - T10aHassan KhattabNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- Modelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Document1 pageModelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Erasmo LimaNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- RDBALAN Full en Metric A4Document2 pagesRDBALAN Full en Metric A4David AltarribaNo ratings yet

- RSBC Full en Us A4Document2 pagesRSBC Full en Us A4Mykola TitovNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- RPEI en Us A4Document1 pageRPEI en Us A4Rafael GoulartNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- RPCCLAN Full en Us LetterDocument2 pagesRPCCLAN Full en Us Lettera safaieNo ratings yet

- RDBALAN Full Es Metric A4Document2 pagesRDBALAN Full Es Metric A4Willam Hugo Luna PonteNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalNo ratings yet

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveDocument1 pageModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriNo ratings yet

- RDJA Full en Us A4Document3 pagesRDJA Full en Us A4GERALD SIMONNo ratings yet

- RDDALAN Es Metric LetterDocument1 pageRDDALAN Es Metric Lettersebastian.vegaNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- CBGGLJN Es Metric LetterDocument1 pageCBGGLJN Es Metric LetterjesusNo ratings yet

- CCCALBN en Us LetterDocument1 pageCCCALBN en Us Letterisaiahsamsonm_948069No ratings yet

- CBGG Es Metric LetterDocument2 pagesCBGG Es Metric LetterjesusNo ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- Sun Hydraulics RDDA-LCNDocument3 pagesSun Hydraulics RDDA-LCNJustinNo ratings yet

- Powered ExoskeletonDocument22 pagesPowered ExoskeletonSarfaras Ali K100% (1)

- Hypertension FamcoDocument42 pagesHypertension FamcoMusleh Al MusalhiNo ratings yet

- ADV Word GivenDocument13 pagesADV Word Givengloria500100% (1)

- Soal Pat Semester 2 Bing 7Document5 pagesSoal Pat Semester 2 Bing 7SAIFULNo ratings yet

- Project Report On Garment BusinessDocument2 pagesProject Report On Garment BusinessAnupNo ratings yet

- Cube Test Letter - SignedDocument2 pagesCube Test Letter - Signedsamarsandip1No ratings yet

- 17 - Guide To Asbestos For IndustryDocument73 pages17 - Guide To Asbestos For Industryraul_bsuNo ratings yet

- Amy Rowley, by Her Parents and Natural Guardians, Clifford and Nancy Rowley, and Clifford and Nancy Rowley, in Their Own Right v. The Board of Education of the Hendrick Hudson Central School District, Westchester County, and the Commissioner of Education of the State of New York, 632 F.2d 945, 2d Cir. (1980)Document17 pagesAmy Rowley, by Her Parents and Natural Guardians, Clifford and Nancy Rowley, and Clifford and Nancy Rowley, in Their Own Right v. The Board of Education of the Hendrick Hudson Central School District, Westchester County, and the Commissioner of Education of the State of New York, 632 F.2d 945, 2d Cir. (1980)Scribd Government DocsNo ratings yet

- Arizona Communicable Disease FlipchartDocument98 pagesArizona Communicable Disease Flipchartapi-510866696No ratings yet

- Survey Questionnaire PresentationDocument14 pagesSurvey Questionnaire PresentationFaith PaladoNo ratings yet

- Exercises For Lab Report 0 202133Document3 pagesExercises For Lab Report 0 202133Luis Giovanni Ortiz Rodríguez IINo ratings yet

- MTT10 Dummy MG PDFDocument20 pagesMTT10 Dummy MG PDFnewspubincNo ratings yet

- Part I. Assessment On Emotional Quotient (Modified: Daniel Goleman EQ Test, 1995)Document4 pagesPart I. Assessment On Emotional Quotient (Modified: Daniel Goleman EQ Test, 1995)Jennalyn AdatoNo ratings yet

- Smart MaterialDocument3 pagesSmart MaterialyokaNo ratings yet

- Synthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDocument29 pagesSynthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDl Divakar LNo ratings yet

- ZER O: One Point LessonsDocument14 pagesZER O: One Point LessonsZulema GaramendiNo ratings yet

- Shani Taub: Certified Dietary Consultant 732-300-8541, 732-364-7392Document1 pageShani Taub: Certified Dietary Consultant 732-300-8541, 732-364-7392henny bandaNo ratings yet

- Lab 2. Lowry MethodDocument3 pagesLab 2. Lowry MethodDũng Nguyễn ViệtNo ratings yet

- Penerapan Sistem Haccp Jurusan Gizi Poltekkes Kemenkes MalangDocument3 pagesPenerapan Sistem Haccp Jurusan Gizi Poltekkes Kemenkes MalangGita Martha VIndiartiNo ratings yet

- Kadar Protein Terlarut Dalam Albumin Ikan Gabus (Channa Striata Dan Channa Micropeltes) Asal BogorDocument9 pagesKadar Protein Terlarut Dalam Albumin Ikan Gabus (Channa Striata Dan Channa Micropeltes) Asal BogorAnkaranaRenvaNo ratings yet

- Volcanic EruptionDocument2 pagesVolcanic EruptionAhmad NursidikNo ratings yet

- Amcel KP20Document1 pageAmcel KP20Marcos KuriharaNo ratings yet

- Quote Vendor File ExcelDocument254 pagesQuote Vendor File ExcelsefiplanNo ratings yet

- 0628-334-01 - D LLHS Operator ManualDocument48 pages0628-334-01 - D LLHS Operator Manualtecvision.assistenciaNo ratings yet

- Get To Know The Newly Redesigned Texas DL and ID Cards: Adult & Under 21 Identification CardDocument2 pagesGet To Know The Newly Redesigned Texas DL and ID Cards: Adult & Under 21 Identification Carddominique marshallNo ratings yet